Академический Документы

Профессиональный Документы

Культура Документы

Bedini Monopole 3 Group Experiment

Загружено:

nadirma66Исходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Bedini Monopole 3 Group Experiment

Загружено:

nadirma66Авторское право:

Доступные форматы

Bedini Monopole 3 Group Experiment 1 Overview

Bedini Monopole 3 group members can meet the groups learning goals by building and testing a John Bedini Monopole Mechanical Oscillator according to the circuit shown here. A new plastic BMX bicycle wheel mounted in a study wood support structure is recommended; however: you may use your own design. What happens to the charging battery? What does the meter indicate going into the battery? What do we get out of the battery on a repeated basis?

Do as many presentations as you wish to help in this project.

2 Step by Step Instructions

2.1 Safety First

Flying magnets are dangerous. Wrap fiberglass filament tape around the circumference of your wheel to restrain the magnets. This safety measure is in addition to regular gluing of the magnets. Lead-acid batteries contain a diluted sulfuric acid electrolyte, which is a highly corrosive and poisonous. When working with batteries, wear safety goggles, protective clothing and have plenty of ventilation, remove your jewelry, and exercise caution. Wash you hands after contact with batteries. Neutralize spilled acid with baking soda.

2.2 Assemble and Test Basic Unit

After you have obtained your parts from either the kit or sources indicated in the parts list, construct the basic unit. Connect the batteries and verify the unit runs. See the message area for Troubleshooting information.

Copyright BM3 Group

Page 1 of 5

Version 0.03 3

Bedini Monopole 3 Group Experiment

2.3 Tuning

Tune for the highest wheel speed for supply battery current. This is reported in Magnets per Minute per milliamp of supply battery current (mpmA).

2.4 Measure Output Current to Battery

The best way is to use an analog current meter in series with the charge battery. If you use a digital current meter, average the readings. Do not leave the current meter permanently connected as it reduces charge rate.

2.5 COP Testing

Batteries do not charge or discharge exactly as people expect. Repeated load testing helps you understand the complexities of batteries. The best way to measure how much energy a battery has is to measure how much work it can do via a load test.

Copyright BM3 Group

Page 2 of 5

Version 0.03 3

Bedini Monopole 3 Group Experiment

The Batterys Coefficient Of Performance (COP) is calculated from these load tests. Tabulate data for each charging/discharge test as shown in the example below.

Table 1 : Discharge Results Intial 1 2 3 4 5 6 12.25 12.31 12.24 12.30 12.26 12.29 Final 12.92 12.89 12.94 13.00 12.93 12.97 Charge Charge Amps 0.036 0.036 0.036 0.036 0.036 0.036 Time Battery Load Battery COP 0.994 0.899 0.916 1.360 1.195 1.517 Input to System Volts Amps Joules 13.22 0.160 88,077 13.22 0.160 97,342 13.22 0.160 95,565 13.22 0.160 83,254 13.22 0.160 95,184 13.22 0.160 92,011

Run Voltage Voltage

Joules Start End Hours Watts Mins Joules 18,865 19 50 07 24 11.57 15.63 20 18,756 20,875 18 35 07 22 12.78 15.63 20 18,756 20,477 18 00 06 33 12.55 15.63 20 18,756 17,925 22 45 09 41 10.93 15.63 26 24,383 20,404 12 20 00 50 12.50 15.63 26 24,383 19,779 08 30 20 35 12.08 15.63 32 30,010

Run Initial Voltage Final Voltage Charge Amps Charge Joules Start Time End Time Hours Battery Load Watts Battery Load Minutes Battery Load Joules Battery COP Input to System Volts Input to System Amps Input to System Joules

The number of the charge/discharge cycle The voltage of battery at beginning of charging The voltage of the battery at end of charging The measured charge rate in amperes from section 2.4 The energy put into the battery in joules Time battery charging started Time battery charging ended Duration of charge (End Time Start Time) Value in watts of discharge rate Duration of battery discharge in minutes Energy obtained from battery discharge in joules Ratio of Battery Load Joules and Charge joules Average voltage of input to SSG Average input current to SSG in amperes Energy input to system in joules

Three of the above values are calculated from the collected data. Charge Joules is the result of average Initial Voltage and Final Voltage x Charge Amps x Hours x 3600. Hours is End Time - Start Time in hours. Battery Load Joules is Discharge Rate x Hours x 3600.

Copyright BM3 Group

Page 3 of 5

Version 0.03 3

Bedini Monopole 3 Group Experiment

2.6 Selecting a Lead-Acid Battery for Testing

The size and condition of the battery you use will affect the times required for charging and discharging cycles. For the SSG to be most effective, the battery must be conditioned by about 20 to 30 charge/discharge cycles. Old batteries go through a desulfating process at first which is slow, thus a brand new battery is recommended. For quicker results, select a 3 to 7 amp hour (Ah) battery. For a battery rated in cranking amperes divide by 20 to get the approximate amp hour rating. Lead-Acid batteries come in Sealed (SLA), Valve Regulated (VR), deep cycle, flooded and many other constructions. We recommend flooded construction as it gives better results.

2.7 The Charging Process

The charging process is usually stopped after a predetermined voltage is reached or a fixed amount of time. See section 2.9 for determining terminal voltage and/or time duration to use.

2.8 The Discharge Process

Rest the battery a minimum of one hour before discharging. The charging process can continue up to 24 hours after removing it from the SSG. Batteries are rated for a 20-hour discharge. The amperage that will discharge the battery from full (about 12.8 volts) to empty (about 12.2 volts) in 20 hours is called the C20 rate. Discharge rates higher than C20 reduce the life of a battery. Discharging is done with a resistor of adequate power rating. It is stopped after a predetermined low voltage limit is reached. Use 12.2 volts or a value determined by criteria in section 2.9. Discharge times are tabulated in a spreadsheet similar to Table 1.

2.9 Selecting Charge/Discharge Criteria

Depth of Discharge (DOD) is the percentage of the battery capacity removed. For maximum battery life DOD values should be a minimum of 10% and a maximum of 50%. 10% DOD of a 10 amp hour (Ah) battery removed at the C20 rate requires 2 hours. 50% DOD requires 10 hours. The discharge resistor value is calculated by 12.2 volts divided by discharge current. For a 10Ah battery discharged at the C20 rate (0.5 A) use a 24.4 ohm resistor. The minimum power rating of this resistor is 12.2 volts x discharge current (0.5 A) or 6.1 watts. A State of Charge (SOC) table for your particular battery is required to determine what terminal voltage to use. Many variables such as temperature and battery construction affect the open

Copyright BM3 Group

Page 4 of 5

Version 0.03 3

Bedini Monopole 3 Group Experiment

circuit voltage measured with a digital voltmeter. Typical values for a flooded cell battery at 80 degrees F (26.7 C) are: 100% - 12.65v, 75% - 12.45v, 50% - 12.24v, 25% - 12.06v and 0% 11.89. These open circuit (i.e. nothing connected to the battery) values are not terminal voltages used for discharge limits. Do a trial discharge to some value such as 12.5 volts. Disconnect the discharge resistor. Measure the open circuit voltage of the battery after a few minutes. Use this voltage and a SOC table for your battery to determine how much battery capacity you have left. Choosing modest battery size and lower DOD values makes the testing more pleasant.

Copyright BM3 Group

Page 5 of 5

Version 0.03 3

Вам также может понравиться

- Stanley Meyer Big Bobbin Builders Guide 2019 v1: Very Rare Guide for How to Assemble Water Fueled injector tri-filar bobbinОт EverandStanley Meyer Big Bobbin Builders Guide 2019 v1: Very Rare Guide for How to Assemble Water Fueled injector tri-filar bobbinОценок пока нет

- Andrei Melnichenko InventionsДокумент7 страницAndrei Melnichenko InventionsPopescu George BogdanОценок пока нет

- Bedini SG Intermediate HandbookДокумент8 страницBedini SG Intermediate HandbookVlad Adrian0% (1)

- DC Induction HeatingДокумент6 страницDC Induction Heatingnangkarak8201Оценок пока нет

- Application of Flexible AC Transmission System Devices in Wind Energy Conversion SystemsОт EverandApplication of Flexible AC Transmission System Devices in Wind Energy Conversion SystemsОценок пока нет

- Hubbard Amplifying TransformerДокумент8 страницHubbard Amplifying TransformerTomislav JovanovicОценок пока нет

- United States Patent (10) Patent No.: US 9.230,730 B2Документ22 страницыUnited States Patent (10) Patent No.: US 9.230,730 B2Mihai DanielОценок пока нет

- Capacitor Discharges - Magnetohydrodynamics - X-Rays - UltrasonicsОт EverandCapacitor Discharges - Magnetohydrodynamics - X-Rays - UltrasonicsРейтинг: 5 из 5 звезд5/5 (1)

- Konzen Electric Pulse MotorДокумент6 страницKonzen Electric Pulse Motorfreiwild100% (1)

- A Noobs Guide To Ufopolitics Rev.1.3 3-7-12Документ19 страницA Noobs Guide To Ufopolitics Rev.1.3 3-7-12Andrej Juli Borko NesoviОценок пока нет

- Reibot - Easy High Voltage - ReiBotДокумент6 страницReibot - Easy High Voltage - ReiBotGilberto ManhattanОценок пока нет

- Inventions, Researches and Writings of Nikola Tesla: Including Tesla's AutobiographyОт EverandInventions, Researches and Writings of Nikola Tesla: Including Tesla's AutobiographyОценок пока нет

- Evgray Research - Vibrator Circuit by Gary PorterДокумент18 страницEvgray Research - Vibrator Circuit by Gary Porterlittledigger100% (1)

- Water Powered GeneratorsДокумент2 страницыWater Powered GeneratorsixCxlОценок пока нет

- Bedini Motor Open SourceДокумент2 страницыBedini Motor Open Sourceslavkobatich100% (1)

- Anti-Lenz - Anti-LenzДокумент6 страницAnti-Lenz - Anti-LenzTomislav JovanovicОценок пока нет

- The Resonance Energy Device Explained: PrefaceДокумент39 страницThe Resonance Energy Device Explained: PrefaceR. K GuptaОценок пока нет

- The Tesla SwitchДокумент8 страницThe Tesla SwitchJan Groenewald100% (1)

- Make A High Voltage Supply in 5 MinutesДокумент11 страницMake A High Voltage Supply in 5 MinutesfabaummОценок пока нет

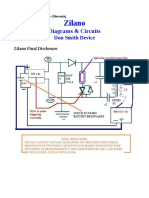

- Zilano Diagrams and Circuits For Study of Zilano Posts1Документ29 страницZilano Diagrams and Circuits For Study of Zilano Posts1Sebastian Gonczarek100% (1)

- As Works (Devays) of (Tarielya) To (Kapanadze) .: Moral AspectДокумент64 страницыAs Works (Devays) of (Tarielya) To (Kapanadze) .: Moral AspectchigoОценок пока нет

- Donald Smith Devices Too Good To Be TrueДокумент16 страницDonald Smith Devices Too Good To Be TrueSilviu CorcanОценок пока нет

- Energy From Static FieldДокумент4 страницыEnergy From Static FieldEnik WahyuniatiОценок пока нет

- A Noobs Guide To UfopoliticsДокумент18 страницA Noobs Guide To UfopoliticsPraveen240679Оценок пока нет

- Lenz LessДокумент8 страницLenz LessGindac Ralea100% (1)

- Adams Motor DetaljerДокумент18 страницAdams Motor DetaljerGeorg LidtveitОценок пока нет

- Andrey Melnichenko 19 AugДокумент3 страницыAndrey Melnichenko 19 AugJaroslav KnopОценок пока нет

- Help For Ti'sДокумент17 страницHelp For Ti'sohbabyohbabyОценок пока нет

- 1 Modern Radiant Energy Circuit PDFДокумент3 страницы1 Modern Radiant Energy Circuit PDFavisenicОценок пока нет

- Switching A Normal' Load. Energizing A Load Begins With A Switching Device in The OpenДокумент5 страницSwitching A Normal' Load. Energizing A Load Begins With A Switching Device in The OpendenramrОценок пока нет

- Lab Notes Transcribed - Floyd SweetДокумент15 страницLab Notes Transcribed - Floyd Sweethyiq0% (1)

- No. 390,721, Patented 00 T. 9, 1888.: Best Avalable Cop N, TeslaДокумент4 страницыNo. 390,721, Patented 00 T. 9, 1888.: Best Avalable Cop N, TeslaAtharva Deshpande100% (1)

- A Compilation/Summary of Devices That Produce Over Unity - Rough ResearchДокумент20 страницA Compilation/Summary of Devices That Produce Over Unity - Rough ResearchCris VillarОценок пока нет

- Experiment 6Документ10 страницExperiment 6Nfa Noorfadzilah MdisaОценок пока нет

- Townsend DischargeДокумент4 страницыTownsend DischargeRonald Malave100% (1)

- BiFilar Coil As CapacitorДокумент3 страницыBiFilar Coil As Capacitordllabarre0% (1)

- Slayer Exciter: by Ivan WilbergДокумент7 страницSlayer Exciter: by Ivan Wilbergapi-408463795Оценок пока нет

- Close Look at Charge Deposition From Pulsed Tesla Coil Hull + FusareДокумент7 страницClose Look at Charge Deposition From Pulsed Tesla Coil Hull + FusaremctyОценок пока нет

- Hendershot MRXДокумент16 страницHendershot MRXvictor munteanОценок пока нет

- Matchett 140801073955 Phpapp01Документ8 страницMatchett 140801073955 Phpapp01MamachelloОценок пока нет

- Radiant EnergyДокумент4 страницыRadiant EnergyGilberto ManhattanОценок пока нет

- Index PDFДокумент31 страницаIndex PDFamanОценок пока нет

- Cold CathodeДокумент4 страницыCold CathodeGilberto ManhattanОценок пока нет

- Homopolar GeneratorДокумент5 страницHomopolar GeneratorYashwanth SrinivasaОценок пока нет

- Electromag and ElectrostaticsДокумент29 страницElectromag and ElectrostaticsChristine MalibiranОценок пока нет

- Tesla Symp06 CorumДокумент7 страницTesla Symp06 CorumNO,NO,NO 2 status QUOОценок пока нет

- Free-Energy:: Nikola Tesla Secrets For EverybodyДокумент67 страницFree-Energy:: Nikola Tesla Secrets For Everybodyto_netiksОценок пока нет

- In A 1929 Article OnДокумент10 страницIn A 1929 Article OnAlexandra Adriana RaduОценок пока нет

- Gray 4595975Документ7 страницGray 4595975MANNAJANELAGUNAОценок пока нет

- Part 3 Zpe PDFДокумент11 страницPart 3 Zpe PDFAnonymous u5128WZ1KОценок пока нет

- Bob BoyceДокумент47 страницBob BoyceDmitryRussuОценок пока нет

- Free Energy GenerationДокумент3 страницыFree Energy Generationjohn peterОценок пока нет

- Cold ElectricityДокумент16 страницCold Electricityi2lovejesusОценок пока нет

- Chapter 13Документ61 страницаChapter 13Stevan FarkasОценок пока нет

- Bedini Monopole 3 Group ExperimentДокумент5 страницBedini Monopole 3 Group Experimentfrankmiller1480% (1)

- Handbook of Timing Belts and Pulleys: Section 1 IntroductionДокумент3 страницыHandbook of Timing Belts and Pulleys: Section 1 IntroductionIzzHyukОценок пока нет

- Emmanuel S. Ferrer: Educational BackgroundДокумент3 страницыEmmanuel S. Ferrer: Educational BackgroundEmman FerrerОценок пока нет

- Karcher 720 - MX PDFДокумент14 страницKarcher 720 - MX PDFIraklis100% (1)

- Onkyo Repair-Tips (ET)Документ34 страницыOnkyo Repair-Tips (ET)perico1962100% (1)

- aLLEN KEYДокумент9 страницaLLEN KEYpatrik710Оценок пока нет

- Using DS18B20 Temp Sensor On AVRДокумент16 страницUsing DS18B20 Temp Sensor On AVRjoprinzОценок пока нет

- Pages From Kubota Z602 Sme3b SeriesДокумент1 страницаPages From Kubota Z602 Sme3b SeriesrickescherОценок пока нет

- Lesson 7 BrakesДокумент35 страницLesson 7 BrakesAjejejeОценок пока нет

- 1 Esp It Worksheet Book 1 Unit 4Документ2 страницы1 Esp It Worksheet Book 1 Unit 4bartosz kosiorОценок пока нет

- 1966 Ford Mustang Breaker Points and Condenser Removal and InstallationДокумент4 страницы1966 Ford Mustang Breaker Points and Condenser Removal and InstallationOxgardОценок пока нет

- Memory Design: SOC and Board-Based SystemsДокумент48 страницMemory Design: SOC and Board-Based SystemsSathiyaSeelaОценок пока нет

- C-Lift® Chain Pulley BlocksДокумент2 страницыC-Lift® Chain Pulley BlocksVarun ShahОценок пока нет

- Customer Service Department: Komatsu Utility Europe Pag. 1 Di 5 WETT001304Документ5 страницCustomer Service Department: Komatsu Utility Europe Pag. 1 Di 5 WETT001304juanito100% (1)

- TM PDFДокумент183 страницыTM PDFalexОценок пока нет

- World Class Automation Training: PLC Scada Dcs VFD Hmi Control PanelsДокумент20 страницWorld Class Automation Training: PLC Scada Dcs VFD Hmi Control PanelsPronadeep BoraОценок пока нет

- Fire Sprinkler System Testing FormДокумент2 страницыFire Sprinkler System Testing FormDaniel Flores100% (1)

- Juk LH-3128-7 3128Документ48 страницJuk LH-3128-7 3128RHoska100% (1)

- Littelfuse Fuse KLK DatasheetДокумент3 страницыLittelfuse Fuse KLK Datasheetagus2kОценок пока нет

- Regenerative Braking System: Group GuideДокумент14 страницRegenerative Braking System: Group GuidePooja BanОценок пока нет

- DC220 Catalogue 4th EditionДокумент70 страницDC220 Catalogue 4th EditionMuchammatAlvinurОценок пока нет

- bss65, bss65r Zetex L1 PDFДокумент2 страницыbss65, bss65r Zetex L1 PDFuzenhoОценок пока нет

- Bourdon GageДокумент5 страницBourdon GageMark Aldaba ReytiranОценок пока нет

- Shortage 08112023Документ360 страницShortage 08112023ahmadridwanhpОценок пока нет

- Toto Automatic Toilet - Urinal Flush Valve Tet2dns-31 PDF User's Manual Download & PreviewДокумент2 страницыToto Automatic Toilet - Urinal Flush Valve Tet2dns-31 PDF User's Manual Download & Previewken1234Оценок пока нет

- 10.DBR OKTOBER 2023 New Rev0Документ40 страниц10.DBR OKTOBER 2023 New Rev0Muhammad FatahillahОценок пока нет

- Keeway KatalogДокумент22 страницыKeeway KatalogugoranОценок пока нет

- 737-300/400/500 MAINTENANCE TRAINING MANUAL Main Hydraulic Systems - Reservoir Pressurization System - Component LocationsДокумент11 страниц737-300/400/500 MAINTENANCE TRAINING MANUAL Main Hydraulic Systems - Reservoir Pressurization System - Component LocationsBYRON PAUL YANEZ BOMBONОценок пока нет

- 2CMC710006K0001 Phase ShifterДокумент2 страницы2CMC710006K0001 Phase ShifterpedroОценок пока нет

- Servo Motor - RushikeshДокумент17 страницServo Motor - RushikeshRushikesh wavare100% (2)

- Operating Instructions: Downloaded From Manuals Search EngineДокумент81 страницаOperating Instructions: Downloaded From Manuals Search Engineeduardo chavezОценок пока нет

- Practical Electrical Wiring: Residential, Farm, Commercial, and IndustrialОт EverandPractical Electrical Wiring: Residential, Farm, Commercial, and IndustrialРейтинг: 3.5 из 5 звезд3.5/5 (3)

- Conquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeОт EverandConquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeРейтинг: 4.5 из 5 звезд4.5/5 (9)

- Digital Filmmaking: The Ultimate Guide to Web Video Production for Beginners and Non-Professionals, Learn Useful Tips and Advice on How You Can Create, Film and Edit Your VideosОт EverandDigital Filmmaking: The Ultimate Guide to Web Video Production for Beginners and Non-Professionals, Learn Useful Tips and Advice on How You Can Create, Film and Edit Your VideosРейтинг: 5 из 5 звезд5/5 (1)

- Analog Design and Simulation Using OrCAD Capture and PSpiceОт EverandAnalog Design and Simulation Using OrCAD Capture and PSpiceОценок пока нет

- INCOSE Systems Engineering Handbook: A Guide for System Life Cycle Processes and ActivitiesОт EverandINCOSE Systems Engineering Handbook: A Guide for System Life Cycle Processes and ActivitiesРейтинг: 5 из 5 звезд5/5 (1)

- Programming the Raspberry Pi, Third Edition: Getting Started with PythonОт EverandProgramming the Raspberry Pi, Third Edition: Getting Started with PythonРейтинг: 5 из 5 звезд5/5 (2)

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionОт EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionРейтинг: 4.5 из 5 звезд4.5/5 (543)

- Hacking Electronics: An Illustrated DIY Guide for Makers and HobbyistsОт EverandHacking Electronics: An Illustrated DIY Guide for Makers and HobbyistsРейтинг: 3.5 из 5 звезд3.5/5 (2)

- Upcycled Technology: Clever Projects You Can Do With Your Discarded Tech (Tech gift)От EverandUpcycled Technology: Clever Projects You Can Do With Your Discarded Tech (Tech gift)Рейтинг: 4.5 из 5 звезд4.5/5 (2)

- The Phone Fix: The Brain-Focused Guide to Building Healthy Digital Habits and Breaking Bad OnesОт EverandThe Phone Fix: The Brain-Focused Guide to Building Healthy Digital Habits and Breaking Bad OnesРейтинг: 5 из 5 звезд5/5 (1)

- Wearable Sensors: Fundamentals, Implementation and ApplicationsОт EverandWearable Sensors: Fundamentals, Implementation and ApplicationsEdward SazonovОценок пока нет

- Practical Electronics for Inventors, Fourth EditionОт EverandPractical Electronics for Inventors, Fourth EditionРейтинг: 4 из 5 звезд4/5 (3)

- ARDUINO CODE: Mastering Arduino Programming for Embedded Systems (2024 Guide)От EverandARDUINO CODE: Mastering Arduino Programming for Embedded Systems (2024 Guide)Оценок пока нет

- Build Your Own Electric Vehicle, Third EditionОт EverandBuild Your Own Electric Vehicle, Third EditionРейтинг: 4.5 из 5 звезд4.5/5 (3)

- Understanding Automotive Electronics: An Engineering PerspectiveОт EverandUnderstanding Automotive Electronics: An Engineering PerspectiveРейтинг: 3.5 из 5 звезд3.5/5 (16)

- Teach Yourself Electricity and Electronics, 6th EditionОт EverandTeach Yourself Electricity and Electronics, 6th EditionРейтинг: 3.5 из 5 звезд3.5/5 (15)