Академический Документы

Профессиональный Документы

Культура Документы

Ammonia Oxidation Over Conventional Combustion Catalysts Lara S. Escandón, Salvador Ordóñez, Fernando V. Díez and Herminio Sastre

Загружено:

Hien NguyenИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Ammonia Oxidation Over Conventional Combustion Catalysts Lara S. Escandón, Salvador Ordóñez, Fernando V. Díez and Herminio Sastre

Загружено:

Hien NguyenАвторское право:

Доступные форматы

Jointly published by Akadmiai Kiad, Budapest and Kluwer Academic Publishers, Dordrecht

React.Kinet.Catal.Lett. 1 Vol. 76, No. 1, 61-68 (2002)

RKCL3972 AMMONIA OXIDATION OVER CONVENTIONAL COMBUSTION CATALYSTS Lara S. Escandn, Salvador Ordez*, Fernando V. Dez and Herminio Sastre

Department of Chemical and Environmental Engineering, University of Oviedo, Avda. Julin Clavera s/n; 33071-Oviedo, Spain Received September 18, 2001 In revised form December 20, 2001 Accepted January 14, 2002 Abstract The combustion of ammonia in air over different conventional oxidation catalysts has been studied in the present work. The final oxidation product is NO, although N2O is also formed at intermediate temperatures. The environmentally desirable product, N2, is only appreciably yielded over iron oxides catalysts. Keywords: Ammonia oxidation, supported noble metal catalysts, metal oxides

INTRODUCTION In addition to the fuel saving, one of the most important advantages of catalytic incineration, if it is compared with thermal incineration, is the no formation of nitrogen oxides from nitrogen and oxygen (so-called thermal NOx), because of the low reaction temperatures needed. This aspect has led to a wide use of catalytic incineration in the abatement of VOCs in industrial emissions (aromatics, alcohols, etc.). In the last years concern about methane emissions has increased because it is a powerful greenhouse gas. Catalytic incineration was shown to be an efficient technique even for the abatement of methane, although it is the less reactive hydrocarbon. However, in the main anthropogenic emissions of methane, such as emissions from coke ovens, wastewater treatment plants, sanitary landfills, farms or composting facilities, this compound is accompanied by variable amounts of ammonia. In these emissions, ammonia could be oxidized, producing nitrogen oxides.

0133-1736/2002/US$ 12.00. Akadmiai Kiad, Budapest. All rights reserved.

62

ESCANDN et al.: AMMONIA OXIDATION

The oxidation of ammonia focused on the minimization of nitrogen oxides was studied by Li and Armor and Ilchenko et al. [1, 2]. The main conclusion of Ilchenko, who studied the oxidation of ammonia over supported Pd, Pt, Fe and W catalysts, Co3O4, MnO2 and V2O5, is that V2O5 is the most selective catalyst for the ammonia oxidation to N2 [1]. However, this catalyst has two important drawbacks: it provides low NH3 conversions and it is not active for the abatement of VOCs. Li and Armor [2] compared the activity of ZSM-5- and Al2O-supported noble metal catalysts with V2O5/TiO2 and Co2O3/ZSM-5. They achieve much higher N2 selectivities (especially with Pd-ZSM-5), working with wet streams, low concentration of oxygen (5 %) and low temperatures, however these operation conditions are not applicable to VOCs abatement (especially methane containing emissions). Good selectivities to N2 at higher temperatures (325C) were found by Curtin et al. [3], using alumina-supported copper oxide catalysts, whereas Wllner et al. report that titania enhances the performance of copper and manganese oxides for these reactions [4]. The aim of this work is to study the oxidation of ammonia over conventional catalysts used for VOCs abatement, such as alumina-supported catalysts and metal oxide catalysts. EXPERIMENTAL The oxidation of ammonia was studied over two different kinds of catalysts. Five different noble metal catalysts supported on alumina (Pd, Pt, Ru, Rh and PdPt) and three metal oxide-based catalysts: a commercial Cr-Cu-Ti catalyst, a bulk perovskitic catalysts (La0.9Ce0.1CoO3, synthesized by the sol-gel method at the Catholic University of Louvaine, Belgium [5]) and a home-made catalyst based on red mud (that has shown high activity for oxidation reactions [6]) were tested. Composition and suppliers of all the catalysts are given in Table 1. Experiments were carried out at atmospheric pressure, in a U-shaped quartz reactor placed in electric furnace controlled by a PID. Feed gas consisted of a mixture of 0.02 % NH3 and 20 % oxygen balanced in argon. Catalyst (50 mg), was placed over a plug of quartz wool and a thermocouple was placed inside the catalyst bed. Before starting each run, catalysts were pretreated with 10 mL/min of pure He at 420C, in order to eliminate the possible compounds adsorbed over catalyst surface. After this pre-treatment, the reactor was cooled to 75C, the reactive mixture (10 mL/min) was introduced and the reaction was carried out. In all the experiments, the samples were heated from 75C to 950C with a ramping temperature rate of 10C/min. Previously a negligible influence of this parameter in the range 1-10C/min has been observed. This aspect, as well as the similar results obtained when catalyst loads were changed keeping

ESCANDN et al.: AMMONIA OXIDATION

63

64

ESCANDN et al.: AMMONIA OXIDATION

constant the space time, lead to think that mass transfer or thermal effects are not important in these experiments. The effluent from the reactor was analyzed by a Gaslab 300 quadrupole mass spectrometer, which used a capillary inlet system for sampling and computer acquisition of multiple mass peaks. Calibration of the spectrometer was carried out using standard gaseous mixtures of the analysed compounds (NH3, N2, N2O, NO and NO2).

RESULTS AND DISCUSSION Two typical curves are shown in Figs 1 (supported palladium catalyst) and 2 (red mud-based catalyst).

1

470 313

0,8

Signal (a.u.)

0,6

NO N2O N2

0,4

0,2

0 0 200 400 600 800 1000

Temperature (oC )

Fig. 1. Products released in temperature-programmed ammonia oxidation over Pd/Al2O3 catalyst

ESCANDN et al.: AMMONIA OXIDATION

65

The parameter T50 (i.e. temperature needed to get 50% of ammonia conversion) was used to characterize the activity of the different catalysts. Its values for all the catalysts tested are listed in Table 1. In the case of noble metal catalysts, it is observed that rhodium (T50=125C) is the most active catalyst, followed by ruthenium (T50=213C), platinum and palladium (275 and 287C, respectively), and being the bimetallic Pd-Pt catalyst the less active catalyst (T50=390C). Concerning to the metal oxide catalysts, the differences in the reactivity are lower, T50 varying around 210C for the perovskites, 275C for the commercial catalyst and 287C for the red mud based catalyst.

1

470 313

0,8

Signal (a.u.)

0,6

NO N2O N2

0,4

0,2

0 0 200 400 600 800 1000

Temperature (oC )

Fig. 2. Products released in temperature-programmed ammonia oxidation over red mud based catalyst

However, the most important issue in the comparison of the catalysts is the selectivity for the different reaction products. The final product is NO in all the cases, being the only oxidation product at temperatures higher than 500C600C, depending on the catalyst. At lower temperatures, intermediate oxidation products, such as N2 or N2O, are formed. In the case of palladium catalyst NO2 is also released at intermediate temperatures. The temperature of the maximum

66

ESCANDN et al.: AMMONIA OXIDATION

of release of N2O, N2 and NO2 and the values of the selectivity and ammonia conversion at this temperature are summarized in Table 1. It is observed that in the case of noble metal catalysts, N2O is the main oxidation product at lower temperatures, only the formation of N2 being observed in the case of palladium catalyst and to a very low extent. It is also important to remark that the maxima for N2O formation are in a very narrow window (260 - 305C). These results indicate that N2O is probably formed by direct oxidation of NH3. At this point, Busca et al. [7] suggest four different mechanisms for N2O formation: direct oxidation of ammonia, reaction of ammonia and NO, decomposition of NO and disproportionation of NO. The reactions involved will be the following: 2 NH3 4 NH3 2 NO 3 NO + 2 O2 2 N2O + 3 H2O + 6 H2O + 1/2 O2 + NO2 (1) (2) (3) (4)

+ 4 NO + 3 O2 4 N2O N2O N2O

From these reactions, only the first one is likely to occur since at the temperatures, at which the release of N2O starts, the selectivity for NO is near zero over most of the catalysts. In the case of Pd containing catalysts and perovskite, NO2 formation was also observed, the maximum release of this compound being at 366C for Pd, 469C for Pd-Pt and 390C for perovskite. Although it is well known that this compound is a key intermediate in the SCR reactions in presence of oxygen, the formation of this compound is not well reported in the literature. Only Busca et al. [7] report the possibility of the formation of NO2 by disproportionation of NO (4). However, no N2O release is associated to the emission of NO2. Oxidation of NO is not likely to occur since this reaction is considered as equilibrium controlled. By these reasons a direct oxidation of NH3 to NO2 seems to be the most plausible possibility. Regarding the N2 formation, only the Pd catalyst and especially the iron oxide catalyst yield appreciable selectivities for this compound. In the case of Pd is observed that N2 is formed at low temperatures, (maximum at 240C), whereas in the case of iron oxide, the maximum occurs at higher temperatures (470C). These aspects suggest that the formation of N2 follows different reaction pathways in the two cases. In the case of Pd, N2 is formed by direct oxidation of ammonia, so it is observed that the maxima of N2 and N2O release occur at almost the same temperature. So, at low temperatures N2 and N2O are

ESCANDN et al.: AMMONIA OXIDATION

67

formed following a parallel mechanism and N2 is formed according to the reaction: (5) NH3 + 3/2 O2 N2 + 3 H2O However, in the case of red mud-based catalysts, two different pathways are possible, the catalytic decomposition of N2O and a typical SCR reaction between NO (its formation is important at these temperatures) and NH3. The reactions involved are the following: N2O 4 NH3 N2 + O2 + 6 NO 5 N2 + 6 H2O (6) (7)

Direct decomposition of NO is not likely to occur with the catalysts tested because only Cu-loaded strong acid catalysts (Cu-ZSM5) can catalyze this reaction to a significant extent [8]. It is also remarkable that bulk iron oxides have been reported to be slightly active for both N2O decomposition [9] and SCR reaction [10]. The results obtained with the red mud based catalyst are of great practical importance, since they indicate that ammonia is mainly transformed into inner nitrogen at the temperature needed for the oxidation of the most refractory organic compounds (e.g. methane). In the case of the other catalysts, ammonia will be transformed into nitrogen oxides. Concerning the presence of organic compounds, methane (which is commonly released with ammonia) is not a very effective reducing agent, except when the solid can catalyze the oxidative coupling of methane, such as several metal loaded zeolites or rare-earth oxides [11].

Acknowledgements. This research was financed by the Environmental Research Program of the European Union (ENV4-CT97-0599). Commercial catalysts tested were generous gifts from Sd-Chemie, BASF and Engelhard.

REFERENCES

1. 2. 3. 4. 5. 6. N.I. Ilchenko: Russ. Chem. Rev., 45, 119 (1976). Y. Li, J.N. Armor: Appl. Catal. B, 13, 131 (1997). T. Curtin, F.O. Regan, C. Deconinck, N. Knttle, B.K. Hodnett: Catal. Today, 55, 189 (2000). A. Wollner, F. Lange, H. Schmelz, H. Knzinger: Appl. Catal. A, 94, 181 (1993). J.R. Paredes, S. Ordez, F.V. Dez, H. Sastre: Proc. 6th World Congress on Oxidation Catalysis, 153 (2001). R. Auer, L. Warnier, F.C. Thyrion: Stud. Surf. Sci. Catal., 133, 599 (2001).

68

ESCANDN et al.: AMMONIA OXIDATION

7. 8. 9. 10. 11.

G. Busca, L. Lietti, G. Ramis, F. Berti: Appl. Catal. B, 18, 1 (1998). Y. Li, W.K. Hall: J. Catal., 129, 202 (1991). W.M. Kalback, C.M. Sliepcevic: Ind. Eng. Chem. Fundam., 17, 165 (1978). A. Kato, S. Matsuda, F. Nakajima, Y. Watanabe: J. Phys. Chem., 85, 1710 (1981). C. Shi, A.B. Walkers, M.A. Vannice: Appl. Catal. B, 14, 175 (1997).

Вам также может понравиться

- Zhao 2004Документ7 страницZhao 200463011273Оценок пока нет

- Ammonia Oxidation Into Nitrous Oxide Over Mn-Bi-Al Catalyst I Pokrovskaya Et Al Chem Eng J 2003 PDFДокумент8 страницAmmonia Oxidation Into Nitrous Oxide Over Mn-Bi-Al Catalyst I Pokrovskaya Et Al Chem Eng J 2003 PDFjuan davidОценок пока нет

- Research Article Effect of Ce Addition On Adsorption and Oxidation of No Over Mno /al OДокумент8 страницResearch Article Effect of Ce Addition On Adsorption and Oxidation of No Over Mno /al OIka Ria Indriani 2110246987Оценок пока нет

- 056 - 057 - NO To NO2 ConvetertДокумент2 страницы056 - 057 - NO To NO2 ConvetertrakeshkjОценок пока нет

- A Transient Response Study of The Selective Catalytic Oxidation of Ammonia To Nitrogen On Pt-CuO-Al2O3 Olofsson Et Al Chem. Eng. Sci. 2004Документ11 страницA Transient Response Study of The Selective Catalytic Oxidation of Ammonia To Nitrogen On Pt-CuO-Al2O3 Olofsson Et Al Chem. Eng. Sci. 2004juan davidОценок пока нет

- Copper Ion-Exchanged Zeolite Catalysts in Deno Reaction: Hidenori Yahiro, Masakazu IwamotoДокумент19 страницCopper Ion-Exchanged Zeolite Catalysts in Deno Reaction: Hidenori Yahiro, Masakazu IwamotoborgiamatriceОценок пока нет

- 1 s2.0 S0021951799925381 MainДокумент9 страниц1 s2.0 S0021951799925381 Mainbhkim88Оценок пока нет

- The Removal of Carbon Monoxide by Iron Oxide NanoparticlesДокумент12 страницThe Removal of Carbon Monoxide by Iron Oxide NanoparticlesGoutam GiriОценок пока нет

- Aromatics Hydrogenation On Silica-Alumina Supported Palladium-Nickel CatalystsДокумент14 страницAromatics Hydrogenation On Silica-Alumina Supported Palladium-Nickel Catalystsioanaandra5690Оценок пока нет

- Oxidative Dehydrogenation of Propane Over Vanadium Oxide Based Catalysts Effect of Support and Alkali PromoterДокумент9 страницOxidative Dehydrogenation of Propane Over Vanadium Oxide Based Catalysts Effect of Support and Alkali PromoterAbdulhamid AliОценок пока нет

- Temperature-Programmed Studies On Partial Oxidation of CH To Syngas Over A Ni/Al O CatalystДокумент3 страницыTemperature-Programmed Studies On Partial Oxidation of CH To Syngas Over A Ni/Al O CatalystImran KhanОценок пока нет

- Ug Project (Aug-Nov 2020) : Effects of Ceo Morphology On No Reduction by NH - SCRДокумент15 страницUg Project (Aug-Nov 2020) : Effects of Ceo Morphology On No Reduction by NH - SCRBHARAT PANWARОценок пока нет

- Effect of Pressure On The Mechanisms ofДокумент13 страницEffect of Pressure On The Mechanisms ofcuentadericardo2424Оценок пока нет

- A2BO4 Type PerovskiteДокумент11 страницA2BO4 Type PerovskiteMahmoud ȜliОценок пока нет

- Sulfuric Acid ConverterДокумент8 страницSulfuric Acid ConverterchikukotwalОценок пока нет

- La0 6sr0 4co0 2fe0 8o3 Perovskite A Stable Anode Catalyst For Direct Methane Solid Oxide Fuel CellsДокумент17 страницLa0 6sr0 4co0 2fe0 8o3 Perovskite A Stable Anode Catalyst For Direct Methane Solid Oxide Fuel CellsG XeragoОценок пока нет

- Catalytic Application of Niobium CompoundsДокумент13 страницCatalytic Application of Niobium CompoundsGuilherme Esteves100% (1)

- Oxidative Degradation of Mono Ethanol A MineДокумент20 страницOxidative Degradation of Mono Ethanol A MineJuan Antonio JuárezОценок пока нет

- Selective Oxidation of H S To Sulphur From Biogas On V O /ceo CatalystsДокумент6 страницSelective Oxidation of H S To Sulphur From Biogas On V O /ceo CatalystsThảo LêОценок пока нет

- Kelompok 1Документ7 страницKelompok 1Roby SudarmanОценок пока нет

- Effect of Different Potassium Species On The Deactivation of V2O5-WO3/TiO2 SCR Catalyst: Comparison of K2SO4, KCL and K2OДокумент7 страницEffect of Different Potassium Species On The Deactivation of V2O5-WO3/TiO2 SCR Catalyst: Comparison of K2SO4, KCL and K2OLilyОценок пока нет

- Sodium Nitrite Catalyzed Aerobic Oxidative Deoximation Under Mild ConditionsДокумент4 страницыSodium Nitrite Catalyzed Aerobic Oxidative Deoximation Under Mild ConditionsCláudio SerafimОценок пока нет

- Measurement Principle of The Chemiluminescence Method (Eco Physics CLD 822 CM HR)Документ2 страницыMeasurement Principle of The Chemiluminescence Method (Eco Physics CLD 822 CM HR)evin34Оценок пока нет

- Ç GüldürДокумент15 страницÇ GüldürsencanlisОценок пока нет

- PrecursorsДокумент4 страницыPrecursorssimonwadelinОценок пока нет

- Cat and SelectivitiesДокумент5 страницCat and SelectivitiesadamОценок пока нет

- The Selective Oxidation of Toluene To Benzaldehyde Applying A Fuel Cell System in The Gas PhaseДокумент7 страницThe Selective Oxidation of Toluene To Benzaldehyde Applying A Fuel Cell System in The Gas PhaseOana VasileОценок пока нет

- Report PDFДокумент10 страницReport PDFShubham GoelОценок пока нет

- AsdfДокумент12 страницAsdfasdfОценок пока нет

- A.balla Rev - Chim.2015Документ7 страницA.balla Rev - Chim.2015abderrahimnОценок пока нет

- Role of Singlet Oxygen in The Oxidation of Toluene On Vanadium Molybdenum Catalytic SystemsДокумент5 страницRole of Singlet Oxygen in The Oxidation of Toluene On Vanadium Molybdenum Catalytic SystemsFaizahОценок пока нет

- Aldehydes and KetonsДокумент8 страницAldehydes and KetonsnishaninishaОценок пока нет

- MN - (Co Y-O Ce)Документ8 страницMN - (Co Y-O Ce)Karen CruzОценок пока нет

- Carbon Dioxide Reforming of Methane Over NiAl2O3 Treated With Glow Discharge PlasmaДокумент6 страницCarbon Dioxide Reforming of Methane Over NiAl2O3 Treated With Glow Discharge PlasmaViệtDũng TôОценок пока нет

- Carbon Dioxide Reforming of Methane Over NiAl2O3 Treated With Glow Discharge PlasmaДокумент6 страницCarbon Dioxide Reforming of Methane Over NiAl2O3 Treated With Glow Discharge PlasmaViệtDũng TôОценок пока нет

- Catalytic Oxidation of Ammonia I Reaction Kinetic and Mechanism Ilchenko Et Al J. Catal. 1975Документ16 страницCatalytic Oxidation of Ammonia I Reaction Kinetic and Mechanism Ilchenko Et Al J. Catal. 1975juan davidОценок пока нет

- Hydrothermally Stable Metal Oxide Zeolite Composite Catalys - 2023 - Chinese CheДокумент12 страницHydrothermally Stable Metal Oxide Zeolite Composite Catalys - 2023 - Chinese CheDana MateiОценок пока нет

- Paper Catalyst For Automobile Exhaust EmissionДокумент13 страницPaper Catalyst For Automobile Exhaust Emissionngokngek00Оценок пока нет

- Reduction of ManganeseДокумент11 страницReduction of ManganeseChris BothaОценок пока нет

- Preparation and Characterization of Sno Catalysts For Co and CH OxidationДокумент13 страницPreparation and Characterization of Sno Catalysts For Co and CH Oxidationbruno barrosОценок пока нет

- Hydrogen Production by Steam Reforming of Commercially Available LPG in UAEДокумент8 страницHydrogen Production by Steam Reforming of Commercially Available LPG in UAEEng MohammedОценок пока нет

- CO2 Reforming of CH4 Over Nickel and Cobalt CatalystsДокумент6 страницCO2 Reforming of CH4 Over Nickel and Cobalt CatalystsEdwin CaceresОценок пока нет

- Synthesis, Characterization and Catalytic Properties of PtCeO2-Al2O3 and PtLa2O3-Al2O3 Sol-Gel Derived CatalystsДокумент9 страницSynthesis, Characterization and Catalytic Properties of PtCeO2-Al2O3 and PtLa2O3-Al2O3 Sol-Gel Derived CatalystsSangHao NgОценок пока нет

- Acidity and Basicity of Metal Oxide Surfaces 1 II. Determination by Catalytic Decomposition of IsopropanolДокумент9 страницAcidity and Basicity of Metal Oxide Surfaces 1 II. Determination by Catalytic Decomposition of Isopropanolnguyennha1211Оценок пока нет

- Zirconia-Supported Copper Catalysts For NO-CO ReactionsДокумент7 страницZirconia-Supported Copper Catalysts For NO-CO ReactionsLucas MarchiniОценок пока нет

- Thermalmagneticinvestigationofthedecomp CuOxalate-precursorforCuO J Mater Sci v402005Документ7 страницThermalmagneticinvestigationofthedecomp CuOxalate-precursorforCuO J Mater Sci v402005Vítězslav HegerОценок пока нет

- Production of Hydrogen by Steam Reforming of Ethanol Over A Ni/Zno CatalystДокумент6 страницProduction of Hydrogen by Steam Reforming of Ethanol Over A Ni/Zno Catalystpetro121Оценок пока нет

- Novel Highly Active Carbon Supported Ternary Pdnibi Nanoparticles As Anode Catalyst For The Alkaline Direct Ethanol Fuel CellДокумент11 страницNovel Highly Active Carbon Supported Ternary Pdnibi Nanoparticles As Anode Catalyst For The Alkaline Direct Ethanol Fuel CellFabricio CarrilloОценок пока нет

- Autothermal Reforming ProcessДокумент9 страницAutothermal Reforming ProcessOliver Everett EspinoОценок пока нет

- Low Temperature Performance of Selective Catalytic Reduction of NO With NH Under A Concentrated CO AtmosphereДокумент11 страницLow Temperature Performance of Selective Catalytic Reduction of NO With NH Under A Concentrated CO Atmospherenay denОценок пока нет

- 44 NOx ReductionДокумент24 страницы44 NOx ReductionJsueОценок пока нет

- Extraction of Metals NotesДокумент6 страницExtraction of Metals NotesAyush JadiaОценок пока нет

- IR Ni LanthanaДокумент6 страницIR Ni LanthanaNelly RojasОценок пока нет

- Chemical Monitoring and Management: Chemist XДокумент11 страницChemical Monitoring and Management: Chemist XLОценок пока нет

- Jaime de La Sota PDFДокумент6 страницJaime de La Sota PDFbryan10032013Оценок пока нет

- Lec2 Nitric AcidДокумент8 страницLec2 Nitric AcidChaitanya PottiОценок пока нет

- The Mechanism of The Oxidation of Propene To AcroleinДокумент9 страницThe Mechanism of The Oxidation of Propene To AcroleinLeonardo BrunelliОценок пока нет

- Copper OxychlorideДокумент8 страницCopper Oxychlorideikarussg75Оценок пока нет

- Alkane FunctionalizationОт EverandAlkane FunctionalizationArmando J. L. PombeiroОценок пока нет

- Advances in Organometallic Chemistry and Catalysis: The Silver / Gold Jubilee International Conference on Organometallic Chemistry Celebratory BookОт EverandAdvances in Organometallic Chemistry and Catalysis: The Silver / Gold Jubilee International Conference on Organometallic Chemistry Celebratory BookArmando J. L. PombeiroРейтинг: 5 из 5 звезд5/5 (1)

- TheoryДокумент4 страницыTheoryDarin Rocky SumairОценок пока нет

- Structure-Property Studies in (0.8-X) Moo - 0.2B O - XK O (0 X 0.25) Glasses by Spectral and Magnetic MeasurementsДокумент6 страницStructure-Property Studies in (0.8-X) Moo - 0.2B O - XK O (0 X 0.25) Glasses by Spectral and Magnetic MeasurementsDelovita GintingОценок пока нет

- Manual IiДокумент80 страницManual Iijast1111Оценок пока нет

- Chapter 10 Practice Worksheet: Liquids, Solids, and Phase ChangesДокумент3 страницыChapter 10 Practice Worksheet: Liquids, Solids, and Phase ChangesLuisa TacordaОценок пока нет

- Book ListДокумент491 страницаBook Listphantanthanh0% (1)

- Hindalco Industries Limited, Belgaum: Our VisionДокумент15 страницHindalco Industries Limited, Belgaum: Our VisionMadan Jaiswal0% (1)

- Stock 07 Oktober 2022Документ19 страницStock 07 Oktober 2022Dwi AnggrainiОценок пока нет

- TITRATION-2 EditedДокумент2 страницыTITRATION-2 Edited12-M3 SUDHISHNAA GОценок пока нет

- Soldering Flux PasteДокумент9 страницSoldering Flux PasteMark Evan SalutinОценок пока нет

- TDS CN Blu F28B (01 - 11)Документ1 страницаTDS CN Blu F28B (01 - 11)huynhtrantriОценок пока нет

- AstmДокумент24 страницыAstmmanuel landinОценок пока нет

- OILCO Swivel Joint Catalog No508 PDFДокумент36 страницOILCO Swivel Joint Catalog No508 PDFhamr01Оценок пока нет

- Coating-Failure-Defects 2 PDFДокумент10 страницCoating-Failure-Defects 2 PDFaahil ahmadОценок пока нет

- CompotecLine HosesДокумент2 страницыCompotecLine HosesIchsan RosidinОценок пока нет

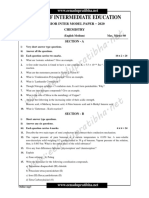

- Board of Intermediate Education: Senior Inter Model Paper ChemistryДокумент2 страницыBoard of Intermediate Education: Senior Inter Model Paper Chemistryrathod adithОценок пока нет

- TOKO 1978 Electric Welding Rod Technical Data SheetДокумент8 страницTOKO 1978 Electric Welding Rod Technical Data SheetYurizki LhzОценок пока нет

- Aral Industrial LubricantsДокумент55 страницAral Industrial LubricantsAnonymous oAbjbl4H100% (1)

- Reinforcekit Beam Fiche TechniqueДокумент24 страницыReinforcekit Beam Fiche TechniqueAmel RADJEFОценок пока нет

- Chem Class XI ch.01Документ7 страницChem Class XI ch.01Navin KumarОценок пока нет

- Glukosa DialabДокумент2 страницыGlukosa DialabDian Ayu UtamiОценок пока нет

- ColaFax CPE-KДокумент4 страницыColaFax CPE-KmndmattОценок пока нет

- Production of Butadiene From Ethyl AlcoholДокумент2 страницыProduction of Butadiene From Ethyl AlcoholSedef ŞıraОценок пока нет

- Chemcad Cc5 ExampleДокумент37 страницChemcad Cc5 ExampleBabulu BalarkanОценок пока нет

- Vaccume DegassingДокумент58 страницVaccume DegassingRakesh Kumar YadavОценок пока нет

- Project FinalДокумент50 страницProject FinalRAVNOOR KaurОценок пока нет

- Httppostedfile Track Eqp 1feb11 23393Документ12 страницHttppostedfile Track Eqp 1feb11 23393dorao80Оценок пока нет

- 927166Документ10 страниц927166Siva SubramaniyanОценок пока нет

- Nafion ConductivityДокумент9 страницNafion ConductivityAli Alipor NajmiОценок пока нет

- Nickel Aluminum Bronze GuideДокумент9 страницNickel Aluminum Bronze GuideAnoir AkkariОценок пока нет

- STD - 537 APIДокумент27 страницSTD - 537 APIAdhi ErlanggaОценок пока нет