Академический Документы

Профессиональный Документы

Культура Документы

Ganchos de Liberacion Rapida

Загружено:

Julieth Bolivar ValenciaИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Ganchos de Liberacion Rapida

Загружено:

Julieth Bolivar ValenciaАвторское право:

Доступные форматы

TRIMECA TRINELCA SAS SISTEMA INTEGRADO DE GESTIPN HSEQ REQUISICIN DE COMPRAS Y/O SERVICIOS

Pgina 1 de 4

Cdigo: GA-P01-F01

Versin: 01

MOORING FITTINGS SPECIFICATIONS.

PART 1 GENERAL

DESCRIPTION OF WORK The Work includes furnishing of all necessary material, labor, and equipment for providing and installing

mooring fittings as indicated on the Drawings and this Section.

SUBMITTALS

Submit the following in accordance with Administrative Requirements. A. Shop drawings showing details of assemblies, connection hardware, and installation B. Mill certification reports and material specifications C. Paint system specifications

REFERENCES

TRIMECA TRINELCA SAS SISTEMA INTEGRADO DE GESTIPN HSEQ REQUISICIN DE COMPRAS Y/O SERVICIOS

Pgina 2 de 4

Cdigo: GA-P01-F01

Versin: 01

QUALITY ASSURANCE

A. Qualification of Fabricators The fabricators shall be experienced in the fabrication and working of all materials shown on the Drawings and specified in the Section. B. Qualification of Workmen The Contractor shall provide at least one person is thoroughly familiar with this type of installation and who shall direct all Work personnel under this Section.

PRODUCT HANDLING

A. Protection Use all means necessary to protect materials before, during, and after installation and to protect the installed Work and materials of other trades. B. Replacements In the event of damage, the Contractor shall make all repairs and replacements necessary at no additional cost to the Owner.

TRIMECA TRINELCA SAS SISTEMA INTEGRADO DE GESTIPN HSEQ REQUISICIN DE COMPRAS Y/O SERVICIOS

Pgina 3 de 4

Cdigo: GA-P01-F01

Versin: 01

PART 2 PRODUCTS

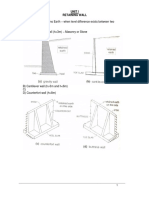

QUICK RELEASE MOORING HOOKS

Provide two- and three-hook arrays as indicated on the reference design drawings. Final procurement specifications shall be prepared by the Contractor and approved by the Owners representative per the following basic requirements. QRH shall be designed and manufactured for marine use, and shall be adapted from a standard catalog item in regular production. Body shall be cast steel conforming to ASTM A 27, Grade 70-40, Class 1. Hooks shall be machined smooth and shall have impact and wear protection for the deck due to hook release and rotations. Base shall be fabricated from steel conforming to ASTM A 36. Additional requirements shall be as follows: 1. Minimum safe working load for each hook shall be 100 tons. Mounting base shall be designed to withstand the combined loads from multiple hooks. 2. QRH units shall be ABS certified for the require load and exposure conditions 3. QRH units shall be certified for hazardous conditions 4. Hooks shall be able to rotate + 90 degrees while under full load 5. Hooks shall be fully functional at vertical line angles up to 60 degrees, with rope guards to prevent accidental detaching of slack lines 6. Maximum manual release lever force shall be 20 kg when at full load. 7. Hooks shall be fully suspended from the base and be counterbalanced to allow reset by a single person 8. Hooks shall be provided with remote electronic load monitoring and remote release, with a sensor in each hook which activates an indicator light in the control panel when the hook is in the open position 9. Quick release hookds (QRH) shall be provided with integrated capstans with motors enclosed within the QRH base. Capstan shall conform to the following requirements: Starting line pull: 2500 lbs (1134 kg), +/- 10% .Minimum running pull/speed: 1,000 lb at 50 ft/min (453 kg at 15.2m/min) 2. Operate with a vertical axis of rotation, with the drum located within 2 to 3.5 feet (0.6 to 1.1 m) above the deck area where the operator stands. 3. Shall be mounted to the base so as to be in line with each hook as a mooring line is heaved in.

TRIMECA TRINELCA SAS SISTEMA INTEGRADO DE GESTIPN HSEQ REQUISICIN DE COMPRAS Y/O SERVICIOS

Pgina 4 de 4

Cdigo: GA-P01-F01

Versin: 01

Chafing guards shall be provided when needed to prevent line contact with the capstan housing. Each capstan shall be fully reversible and controlled by a two pedal foot switch. Foot pedal unit shall have a flexible connection to the base so that the switch can be positioned any distance up to 4 feet (1.2 m) from the capstan head.

Shall use an explosion proof electrical motor, and motor starter. Be galvanized or base coated with a zinc rich primer. External surfaces shall have a top coat system suitable for use in a severe marine environment. All mounting bolts, nuts, washers and plates shall be galvanized. Complete installation, operation, and maintenance instructions shall be provided with the unit. All mounting bolts, nuts, washers, and plates shall be galvanized. Each unit shall include a bolt template for mounting in a new concrete foundation.

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (120)

- Horizontal Flow Wrapper Machine Case Study enДокумент4 страницыHorizontal Flow Wrapper Machine Case Study enastojadin1873Оценок пока нет

- Course Handout PSIIДокумент4 страницыCourse Handout PSIINishant SaxenaОценок пока нет

- Tender Boq - xls139170140Документ12 страницTender Boq - xls139170140Sheikh Nouman Mohsin RamziОценок пока нет

- Emerald Emerging Markets Case Studies: Article InformationДокумент11 страницEmerald Emerging Markets Case Studies: Article InformationluqmanОценок пока нет

- 9 Consolidation TestДокумент29 страниц9 Consolidation TestBryan Kevin Toding ManginteОценок пока нет

- RF Circuit Design - UC San Diego ExtensionДокумент3 страницыRF Circuit Design - UC San Diego ExtensionAdfgatLjsdcolqwdhjpОценок пока нет

- Crane Control and Automation: Global SolutionsДокумент32 страницыCrane Control and Automation: Global SolutionsstoneminerОценок пока нет

- ISO 9001 CertifiedДокумент7 страницISO 9001 Certifiedselva mechОценок пока нет

- Simplified Guide To Understanding SCCRДокумент6 страницSimplified Guide To Understanding SCCRUthara SyamdevОценок пока нет

- Civil Engineering Reaction 1Документ2 страницыCivil Engineering Reaction 1Angelica Joyce Muñoz100% (4)

- SE - MINI PROJECT-PPT - Template-2Документ13 страницSE - MINI PROJECT-PPT - Template-2Durva YerunkarОценок пока нет

- Risk Assessment Techniques For Software DevelopmentДокумент8 страницRisk Assessment Techniques For Software DevelopmentJayaletchumi MoorthyОценок пока нет

- Software Engineering and Best PracticesДокумент29 страницSoftware Engineering and Best Practicesindieguycbe1Оценок пока нет

- Evaluation of Graduate Students Employability From Employer Perspective: Review of The LiteratureДокумент6 страницEvaluation of Graduate Students Employability From Employer Perspective: Review of The LiteraturerizkiОценок пока нет

- Creo 7.0 Education Product Capability ChartДокумент7 страницCreo 7.0 Education Product Capability CharthemakarunaОценок пока нет

- Multi-Motor Control System Design Based On Can BusДокумент4 страницыMulti-Motor Control System Design Based On Can BusPrakash ArulОценок пока нет

- Drcebm NotesДокумент141 страницаDrcebm NotesvallirajaОценок пока нет

- Railway Over Bridge Training ReportДокумент50 страницRailway Over Bridge Training ReportMitulChopra100% (1)

- Solutions Profile: Using Fuzzy Logic in LogixДокумент2 страницыSolutions Profile: Using Fuzzy Logic in LogixpfalencarОценок пока нет

- Transstellar Journal Publications and Research Consultancy Private LimitedДокумент3 страницыTransstellar Journal Publications and Research Consultancy Private LimitedTJPRC Publications100% (2)

- Research ProposalДокумент2 страницыResearch Proposalapi-301422938Оценок пока нет

- Inspection & Testing Requirements Scope:: Test and Inspection PerДокумент2 страницыInspection & Testing Requirements Scope:: Test and Inspection PerJebranОценок пока нет

- Marley Cooling TowerДокумент16 страницMarley Cooling TowerAdades Safede EfdОценок пока нет

- Small Dam Design Manual - Complete1Документ395 страницSmall Dam Design Manual - Complete1faridullahОценок пока нет

- CH 4Документ7 страницCH 4Irem Dolek0% (1)

- Distress in Rigid and Flexible PavementsДокумент69 страницDistress in Rigid and Flexible Pavementsကိုနေဝင်း100% (4)

- Avi Seminar 1Документ39 страницAvi Seminar 1avinash peddintiОценок пока нет

- Construction Method Statement FOR RCC Boundry Wall With Precast Panel & ColumnДокумент8 страницConstruction Method Statement FOR RCC Boundry Wall With Precast Panel & Columnkhurshidoman123Оценок пока нет

- Final Choice of Subjects 2020Документ6 страницFinal Choice of Subjects 2020Leevan BarrattОценок пока нет

- SDLC - Quick GuideДокумент7 страницSDLC - Quick GuidesvdonthaОценок пока нет