Академический Документы

Профессиональный Документы

Культура Документы

Saep 1102

Загружено:

Francis ReyesИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Saep 1102

Загружено:

Francis ReyesАвторское право:

Доступные форматы

Engineering Procedure

SAEP-1102 Welding Test Supplement S02 for SMAW, Carbon and Low Alloy Steel Pipe, Downhill Document Responsibility: Inspection Department 29 October, 2003

Saudi Aramco DeskTop Standards

Table of Contents

1 2 3

Scope............................................................. 2 Applicable Documents................................... 2 Instructions.................................................... 2

Previous Issue: 30 April, 2000 Next Planned Update: 1 November, 2008 Revised paragraphs are indicated in the right margin Primary contact: Supervisor, ID/OID/IEU on 874-6604

Page 1 of 6

Document Responsibility: Inspection Department Issue Date: 29 October, 2003 Next Planned Update: 1 November, 2008

SAEP-1102 Welding Test Supplement S02 for SMAW, Carbon and Low Alloy Steel Pipe, Downhill

Scope This welder performance qualification Test Supplement shall govern the testing of welders with the Shielded Metal Arc Welding (SMAW) process, welding progression vertical down, for welding carbon and low alloy steel pipe.

Applicable Documents The requirements contained in the following document apply to the extent specified in this procedure. 2.1 Saudi Aramco Reference(s) Saudi Aramco Engineering Procedure SAEP-321 2.2 Performance Qualification Testing and Certification of Saudi Aramco Welders

Industry Code(s) and Standard(s) American Society of Mechanical Engineers ASME SEC IX Qualification Standard for Welding and Brazing Procedures, Welders, Brazers, and Welding and Brazing Operators

Instructions Conduct the Performance qualification testing of welders following the requirements of SAEP-321 as supplemented by the subsequent instructions. 3.1 Applications Piping Pipelines Pressure Vessels Tanks Structural Dissimilar Metals * Not applicable Yes * Not applicable Yes * Yes * No

See restrictions in paragraph 3.9

Page 2 of 6

Document Responsibility: Inspection Department Issue Date: 29 October, 2003 Next Planned Update: 1 November, 2008

SAEP-1102 Welding Test Supplement S02 for SMAW, Carbon and Low Alloy Steel Pipe, Downhill

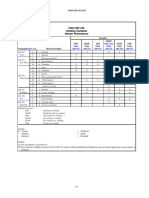

3.7

Testing and Inspection Requirements Time Limit of Test Radiography Visual Inspection Four (4) hours maximum 100% (ASME QW-191) See paragraph 6.1.3 of SAEP-321

3.8

Qualification Limits Material Form Joint Type Base Material Process Filler Metal: Root/Fill/Cap Base Metal Thickness Diameter Range Positions Vertical Progression EXX10/11 (A5.1, A5.5) Unlimited 2.5" NPS and greater All Downhill Plate or pipe Groove welds with and without backing (see restrictions in 3.9), and fillet welds Carbon steel (P1) SMAW

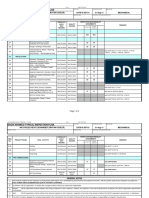

3.9

Restrictions (A) Pipelines Welding is restricted to: (1) (2) (B) Circumferential full penetration butt joints, and Fillet welds (" max) between nonpressure parts (structural attachments) and pressure parts.

Tanks and Structural Welding is restricted to: (1) Full penetration welds from three-sixteenths inch ( 316 ") to threeeighths inch ( 3 8 ") thick welded from both sides (second side arc gouged or ground to sound metal), and

Page 3 of 6

Document Responsibility: Inspection Department Issue Date: 29 October, 2003 Next Planned Update: 1 November, 2008

SAEP-1102 Welding Test Supplement S02 for SMAW, Carbon and Low Alloy Steel Pipe, Downhill

(2)

Fillet welds (" maximum size) between structural members, and nonpressure parts (structural attachments) to pressure parts.

29 October, 2003

Revision Summary Minor revision to convert the text statements into a form layout (ASME SEC IX format). Revised the "Next Planned Update".

Page 4 of 6

Document Responsibility: Inspection Department Issue Date: 29 October, 2003 Next Planned Update: 1 November, 2008

SAEP-1102 Welding Test Supplement S02 for SMAW, Carbon and Low Alloy Steel Pipe, Downhill

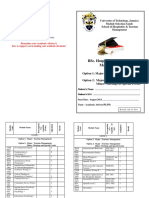

WELDING PROCEDURE SPECIFICATION (WPS)

Procedure Qualification Record (PQR): Scope: For welder qualification only BASE MATERIAL (QW-403) Test coupon type: Material Spec, type or Grade: Diameter of test coupon Thickness of test coupon: Pipe Carbon Steel 8" NPS 0.812" Time: Other: None Welding Process:

WPS S02 Rev. 0 Page 1 of 2 SMAW, manual None

Prior Qualification Requirement:

POST WELD HEAT TREATMENT (QW-407) Temperature: None

To Material spec. type or grade: Carbon Steel Tack Welds: Four (4) made by the welder and incorporated into the root pass FILLER METALS (QW-404) Weld Metal Analysis Number: Filler Metal F No.: AWS specification: AWS Classification: 1 Shielding Backing Trailing TECHNIQUE String or weave: Oscillation: Multiple or Single pass per side: Single or multiple electrode: Other: Multiple Single Stringer or Weave Gas NONE E6010 - F3 & E7018 - F4 E6010 & E7018 - SFA 5.1 E6010 & E7018 GAS (QW-408) Composite Flow (CFH)

POSITION (QW-405) Position of Groove: Weld Progression: Preheat Temperature: Interpass temperature: Other: 6G Downhill 50C 315C

PREHEAT (QW 406)

Joint Design: Single Vee

A = 30 +/- 2.5 B = 1.6 +/- 0.8mm C = 1.6 +/- 0.8mm

Page 5 of 6

Document Responsibility: Inspection Department Issue Date: 29 October, 2003 Next Planned Update: 1 November, 2008

SAEP-1102 Welding Test Supplement S02 for SMAW, Carbon and Low Alloy Steel Pipe, Downhill

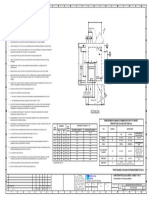

WELDING PROCEDURE SPECIFICATION (WPS)

FILLER METAL Dia. Class (mm) E6010/E7010 3.2/4.0 E6010/E7010 3.2/4.0 E6010/E7010 3.2/4.0 E6010/E7010 3.2/4.0 CURRENT Polarity DCEP DCEP DCEP DCEP Amps. 80-140 70-100 90-160 90-160

WPS S02 Rev. 0 Page 2 of 2 TRAVELSPEED (cm/min) 3.8-8.9 3.8-10.2 3.8-14 5.0-15.2

WELD LAYER Root Hot Fill Cap

PROCESS SMAW SMAW SMAW SMAW

VOLTAGE 19-25 19-25 22-28 22-28

Page 6 of 6

Вам также может понравиться

- Training For Humans Guide: FAQ's How Many Sets/reps Should I Do Per Exercise?Документ28 страницTraining For Humans Guide: FAQ's How Many Sets/reps Should I Do Per Exercise?Paulo Pires100% (1)

- Satip F 001 04Документ4 страницыSatip F 001 04Anonymous 4e7GNjzGWОценок пока нет

- SMG 07-005 Application of Saudi Aramco Building Code To Contractors 2021-11-25Документ38 страницSMG 07-005 Application of Saudi Aramco Building Code To Contractors 2021-11-25baseet gazaliОценок пока нет

- Lecture2 GranulopoiesisДокумент9 страницLecture2 GranulopoiesisAfifa Prima GittaОценок пока нет

- Iso 14692 4 2017Документ15 страницIso 14692 4 2017Mayara AlvesОценок пока нет

- SAIC-L-2136 Rev 0Документ3 страницыSAIC-L-2136 Rev 0philipyapОценок пока нет

- Iii. Applicable Codes & Standards For Aramco ProjectsДокумент5 страницIii. Applicable Codes & Standards For Aramco ProjectsZain Ali KidwaiОценок пока нет

- Assessment 1 API 570Документ5 страницAssessment 1 API 570Mohamed ZainОценок пока нет

- Api 1104 VT TestДокумент2 страницыApi 1104 VT TestKali AbdennourОценок пока нет

- 175 022503Документ2 страницы175 022503Abu Anas M.SalaheldinОценок пока нет

- Saep 119Документ11 страницSaep 119Demac SaudОценок пока нет

- Aramco Plumbing Interview QuestionsДокумент6 страницAramco Plumbing Interview QuestionsMohanad Suliman100% (1)

- Table - Qw-416 Welding Variables For Welder PerformanceДокумент1 страницаTable - Qw-416 Welding Variables For Welder PerformanceAnonymous VohpMtUSN100% (1)

- Synthesis, Analysis and Simulation of A Four-Bar Mechanism Using Matlab ProgrammingДокумент12 страницSynthesis, Analysis and Simulation of A Four-Bar Mechanism Using Matlab ProgrammingPedroAugustoОценок пока нет

- Agenda Item: 650-2024: Coating Prior To Hydrostatic TestingДокумент4 страницыAgenda Item: 650-2024: Coating Prior To Hydrostatic Testinggigiphi1Оценок пока нет

- SATR-A-2011 Rev 2 - Re-Instatement Checklist (Form)Документ2 страницыSATR-A-2011 Rev 2 - Re-Instatement Checklist (Form)deepa narayanОценок пока нет

- PQR FormatДокумент2 страницыPQR Formatravi0009880% (5)

- CBT QuestionsДокумент17 страницCBT QuestionsNaseer Ahmed SokhalОценок пока нет

- Saic D 2025Документ10 страницSaic D 2025jerinОценок пока нет

- SAEP-321 Performance Qualification Testing and Certification of Saudi Aramco WeldersДокумент28 страницSAEP-321 Performance Qualification Testing and Certification of Saudi Aramco WeldersSergey KichenkoОценок пока нет

- Impact of Pantawid Pamilyang Pilipino Program On EducationДокумент10 страницImpact of Pantawid Pamilyang Pilipino Program On EducationEllyssa Erika MabayagОценок пока нет

- Assessment 3 API 570Документ12 страницAssessment 3 API 570Mohamed ZainОценок пока нет

- Evolution Army 3 R DadДокумент341 страницаEvolution Army 3 R DadStanisław DisęОценок пока нет

- IMCI Chart BookletДокумент43 страницыIMCI Chart Bookletmysticeyes_17100% (1)

- Office: Printout Sample - ASME WPSДокумент2 страницыOffice: Printout Sample - ASME WPSDanem HalasОценок пока нет

- Certification Type Requirements Location GI#: Saudi Aramco: Company General UseДокумент2 страницыCertification Type Requirements Location GI#: Saudi Aramco: Company General UseMuhammad TariqОценок пока нет

- SAEP-1106 - Welding Test Supplement S06 For GTAW, Aluminum With BackingДокумент5 страницSAEP-1106 - Welding Test Supplement S06 For GTAW, Aluminum With BackingFiras AlbaweiОценок пока нет

- NDT Training Syllabus PDFДокумент8 страницNDT Training Syllabus PDFNkwor AndersonОценок пока нет

- Apcs 117Документ12 страницApcs 117Ilyas AhmedОценок пока нет

- SATIP-T-492-01 Ver 08Документ1 страницаSATIP-T-492-01 Ver 08thezaidОценок пока нет

- Diamatre Teava - PEDДокумент72 страницыDiamatre Teava - PEDAlin TomozeiОценок пока нет

- Satip e 007 01Документ2 страницыSatip e 007 01Anonymous 4e7GNjzGWОценок пока нет

- 12 Samss 008 PDFДокумент4 страницы12 Samss 008 PDFErin JohnsonОценок пока нет

- 01-SAMSS-048 PDF Download - CRA Clad or Lined Steel PipeДокумент4 страницы01-SAMSS-048 PDF Download - CRA Clad or Lined Steel PipeZahidRafiqueОценок пока нет

- 2008 MechДокумент54 страницы2008 MechKaran BamrahОценок пока нет

- Cswip Div 9 03 General Inspector 4th Edition Jan 2008Документ12 страницCswip Div 9 03 General Inspector 4th Edition Jan 2008obinnaОценок пока нет

- ASP Procedures For Testing Characteristics of Automotive Sheet Steel LubricantsДокумент31 страницаASP Procedures For Testing Characteristics of Automotive Sheet Steel LubricantsSamsudin AhmadОценок пока нет

- Mobile Offshore Drilling Units 2008: Rules For Building and ClassingДокумент14 страницMobile Offshore Drilling Units 2008: Rules For Building and ClassingmfazioliОценок пока нет

- Api 577 QuestionsДокумент2 страницыApi 577 QuestionskorichiОценок пока нет

- Written Schemes of Examinations Example Template - Course DownloadДокумент9 страницWritten Schemes of Examinations Example Template - Course Downloadgamil2Оценок пока нет

- Pipeline SlidesДокумент14 страницPipeline Slidesc丽诗Оценок пока нет

- Materials System SpecificationДокумент11 страницMaterials System SpecificationZubair RaoofОценок пока нет

- Saudi Aramco Inspection ChecklistДокумент4 страницыSaudi Aramco Inspection ChecklistRijwan MohammadОценок пока нет

- Hempel Curing Agent 98021 MsdsДокумент10 страницHempel Curing Agent 98021 MsdsM.FAIZAN ARSHADОценок пока нет

- CRMS ItpДокумент2 страницыCRMS Itparockiyathass100% (1)

- Schedule B - Attachment IVДокумент29 страницSchedule B - Attachment IVAbdul Ahad LoneОценок пока нет

- Saes G 115Документ9 страницSaes G 115junaidОценок пока нет

- Counter Weight DrawingДокумент1 страницаCounter Weight Drawingrajaguru20003Оценок пока нет

- Sa 6717Документ1 страницаSa 6717biplabpal2009Оценок пока нет

- Saad Bin Sharf: API-510, API-570 & API-653 Authorize InspectorДокумент5 страницSaad Bin Sharf: API-510, API-570 & API-653 Authorize InspectorSaad Bin SharfОценок пока нет

- Fosroc Conbextra EP150: Free Flow Epoxy Resin Grout Uses DescriptionДокумент4 страницыFosroc Conbextra EP150: Free Flow Epoxy Resin Grout Uses DescriptionVincent JavateОценок пока нет

- Solutions: Solutions Manual For Welding Principles and Practices 5Th Edition BohnartДокумент7 страницSolutions: Solutions Manual For Welding Principles and Practices 5Th Edition BohnartBassel AlshamiОценок пока нет

- Scaff CV 1Документ7 страницScaff CV 1Teodoro EsquilloОценок пока нет

- Saudi Aramco Inspection ChecklistДокумент8 страницSaudi Aramco Inspection ChecklistAnantha PadmanabhanОценок пока нет

- Dokumen - Tips Cswip TipsДокумент16 страницDokumen - Tips Cswip TipszuhebОценок пока нет

- Saudi Aramco Test Report Temperature Tie-In Welding ReportДокумент2 страницыSaudi Aramco Test Report Temperature Tie-In Welding ReportManoj Kumar100% (2)

- Refractory Inspection: Prepared by Integrity EngineeringДокумент17 страницRefractory Inspection: Prepared by Integrity EngineeringAhmedОценок пока нет

- Astm 890Документ3 страницыAstm 890bsnegi111Оценок пока нет

- 0301e - Guidebook For Inspectors - 2018-3Документ6 страниц0301e - Guidebook For Inspectors - 2018-3FranciscoОценок пока нет

- Saudi Aramco Inspection Checklist: Re-Instatement/Punchlisting of Under Ground Pipeline SAIC-L-2133 25-May-05 PipeДокумент7 страницSaudi Aramco Inspection Checklist: Re-Instatement/Punchlisting of Under Ground Pipeline SAIC-L-2133 25-May-05 PipeAnonymous S9qBDVkyОценок пока нет

- Inspection & Testing Requirements Scope:: Test and Inspection PerДокумент2 страницыInspection & Testing Requirements Scope:: Test and Inspection PerAbu Anas M.SalaheldinОценок пока нет

- SCCDAДокумент4 страницыSCCDAengineerchemical285038Оценок пока нет

- Material Handling Equipment World Summary: Market Values & Financials by CountryОт EverandMaterial Handling Equipment World Summary: Market Values & Financials by CountryОценок пока нет

- Fertilization Guide For CoconutsДокумент2 страницыFertilization Guide For CoconutsTrade goalОценок пока нет

- ReadmeДокумент2 страницыReadmechethan100% (1)

- Unsuccessful MT-SM DeliveryДокумент2 страницыUnsuccessful MT-SM DeliveryPitam MaitiОценок пока нет

- Week 4 - Theoretical Framework - LectureДокумент13 страницWeek 4 - Theoretical Framework - LectureRayan Al-ShibliОценок пока нет

- Determination Rules SAP SDДокумент2 страницыDetermination Rules SAP SDkssumanthОценок пока нет

- Safety Procedures in Using Hand Tools and EquipmentДокумент12 страницSafety Procedures in Using Hand Tools and EquipmentJan IcejimenezОценок пока нет

- Pityriasis VersicolorДокумент10 страницPityriasis Versicolorketty putriОценок пока нет

- LP For EarthquakeДокумент6 страницLP For Earthquakejelena jorgeoОценок пока нет

- BSC HTM - TourismДокумент4 страницыBSC HTM - Tourismjaydaman08Оценок пока нет

- Z-Purlins: Technical DocumentationДокумент11 страницZ-Purlins: Technical Documentationardit bedhiaОценок пока нет

- Kyle Pape - Between Queer Theory and Native Studies, A Potential For CollaborationДокумент16 страницKyle Pape - Between Queer Theory and Native Studies, A Potential For CollaborationRafael Alarcón Vidal100% (1)

- Continue Practice Exam Test Questions Part 1 of The SeriesДокумент7 страницContinue Practice Exam Test Questions Part 1 of The SeriesKenn Earl Bringino VillanuevaОценок пока нет

- (Jones) GoodwinДокумент164 страницы(Jones) Goodwinmount2011Оценок пока нет

- rp10 PDFДокумент77 страницrp10 PDFRobson DiasОценок пока нет

- Global Divides: The North and The South: National University Sports AcademyДокумент32 страницыGlobal Divides: The North and The South: National University Sports AcademyYassi CurtisОценок пока нет

- Notes:: Reinforcement in Manhole Chamber With Depth To Obvert Greater Than 3.5M and Less Than 6.0MДокумент1 страницаNotes:: Reinforcement in Manhole Chamber With Depth To Obvert Greater Than 3.5M and Less Than 6.0Mسجى وليدОценок пока нет

- The Influence of Irish Monks On Merovingian Diocesan Organization-Robbins BittermannДокумент15 страницThe Influence of Irish Monks On Merovingian Diocesan Organization-Robbins BittermanngeorgiescuОценок пока нет

- Comparison Between CompetitorsДокумент2 страницыComparison Between Competitorsritesh singhОценок пока нет

- 22 Khan S.Документ7 страниц22 Khan S.scholarlyreseachjОценок пока нет

- Injections Quiz 2Документ6 страницInjections Quiz 2Allysa MacalinoОценок пока нет

- Lamentation of The Old Pensioner FinalДокумент17 страницLamentation of The Old Pensioner FinalRahulОценок пока нет

- Bolt Grade Markings and Strength ChartДокумент2 страницыBolt Grade Markings and Strength ChartGregory GaschteffОценок пока нет

- Escaner Electromagnético de Faja Transportadora-Steel SPECTДокумент85 страницEscaner Electromagnético de Faja Transportadora-Steel SPECTEdwin Alfredo Eche QuirozОценок пока нет

- Quiz 140322224412 Phpapp02Документ26 страницQuiz 140322224412 Phpapp02Muhammad Mubeen Iqbal PuriОценок пока нет