Академический Документы

Профессиональный Документы

Культура Документы

Weld Imperfection Examination Standard

Загружено:

Mohd Akmal ShafieИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Weld Imperfection Examination Standard

Загружено:

Mohd Akmal ShafieАвторское право:

Доступные форматы

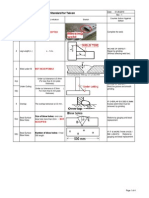

WELD IMPERFECTIONS EXAMINATION

TEST CODE/PAGE BS EN 25817 : 1992 Arc-welded joints in steel DEFECT Crack Porosity and gas pores DEFECT CRITERIA all types of cracks except micro cracks (h.l 1mm) including Crater crack. a) Max. dimension of the sum of crack area b) Max. dimension of a single pore: i) butt welds ii) fillet welds c) Max. dimension for a single pore a) Max. dimension of the sum of porosity area . b) Max. dimension of a single pore : i) butt welds ii) fillet welds c) Max. dimension for a cluster porosity. a) Long imperfections for both butt and fillet welds b) Short imperfections for : i) butt welds ii) fillet welds c) Max. dimension for wormholes a) Long imperfections for both butt and fillet welds b) Short imperfections for i) butt welds ii) fillet welds c) Max. dimension for solid inclusions All dimension of Copper inclusions. All dimension of lack of fusion or incomplete fusion. STRINGENT Not Permitted 1% d 0.3s 0.3a 3mm 4% d 0.3s 0.3a 2mm Not permitted h 0.4 s 0.4a 3mm or NLTT Not permitted h 0.3 s 0.3a 2mm or NLTT Not Permitted Not Permitted

Table 1: Guidance on quality levels for imperfections

Cluster porosity

Page 5 & Page 6 Wormholes

Solid inclusion ( other than copper)

Copper inclusions Lack of fusion

TEST CODE/PAGE

DEFECT Lack of penetration All dimension of lack of penetration or incomplete penetration.

DEFECT CRITERIA

STRINGENT Not Permitted

Page 7, Page 8 & Page 9

Bad fit-up (fillet)

An excessive or insufficient gap between the parts to be joined. *Gaps exceeding the limit may in certain cases be compensated by increase the throat. Smooth transition is required

h 0.5mm + 0.1a max. 2mm

Undercut

h 0.5mm

Excess weld metal

Smooth transition is required

h 1mm + 0.1b max 5mm

Excessive convexity

All dimension of Excessive convexity.

h 1mm + 0.1b max 3mm

Fillet throat (big)

Fillet weld having a throat thickness greater than the nominal value. *Throat thickness greater than the nominal one may not be a reasonfor rejection.

h 1mm + 0.15a max. 3mm

TEST CODE/PAGE

DEFECT Fillet throat (small)

Page 10 & Page 11

DEFECT CRITERIA Fillet weld having a throat thickness smaller than the nominal value. *If the depth of penetration complies with the nominal value, it is not considered as imperfections.

STRINGENT Not permitted

Excessive penetration

All dimension of Excessive penetration.

h 1mm + 0.3b max. 3mm

Local protrusion

All dimension of Local protrusion.

Occasional local excess permitted Long defect not permitted

Incompletely filled groove

Smooth transition required.

Linear misalignment Sagging

The limit relate to deviations from the correct position is when the centrelines coincide. Smooth transition required.

h 1t max. 3mm h 0.05t max. 0.5mm

Excessive asymmetry fillet weld

It is assumed that an asymmetric fillet weld has not been expressly prescribed.

h 1.5mm + 0.15a

Root concavity / Shrinkage groove

Smooth transition required.

h 0.5mm

TEST CODE/PAGE

DEFECT Overlap Poor Restart

DEFECT CRITERIA All dimension of Overlap. All dimension of Poor Restart. All dimension of Spatter

STRINGENT Not permitted Not permitted Depends on applications 0.15s or 0.15a, max. 10mm

Page 11 & Page 12 Spatter

Multiple Imperfections in any cross-section

For thickness s 10mm or a 10mm or less, special consideration may be necessary.

Stray flash or arc strike

All dimension of Stray flash or Arc strike. *acceptance may be influenced by post treatment. acceptance depends on type of BM, with reference to crack sensitivity.

Prepared by Name Designation Date

: __________________ : Mohd Akmal B. Shafie : Material Engineer : 28th May 2012

Approved by :_________________ Name : Zaidi B. Ali Designation : Operation Manager Date : 28th May 2012

Вам также может понравиться

- CSWIP 3.1 New Book PDFДокумент590 страницCSWIP 3.1 New Book PDFAsim90% (10)

- Bs4872 Visual ApprovalДокумент1 страницаBs4872 Visual Approvalkjmcbain100% (1)

- Surface Tension Transfer (STT) Pipe WeldingДокумент3 страницыSurface Tension Transfer (STT) Pipe WeldingahmedОценок пока нет

- Extracted Pages From Design Guide 21 - Welded Connections - A Primer For EngineersДокумент2 страницыExtracted Pages From Design Guide 21 - Welded Connections - A Primer For EngineersAnonymous 7MdZQn1Оценок пока нет

- Weld Map SampleДокумент2 страницыWeld Map SampleKhushal TripathiОценок пока нет

- Welding Symbols WorksheetДокумент10 страницWelding Symbols WorksheetMel Paras100% (1)

- Visual TestДокумент5 страницVisual TestMohd Hafizan ZahariОценок пока нет

- Multiple Choice Questions On Welding SymbolДокумент10 страницMultiple Choice Questions On Welding SymbolCaspian Datta67% (3)

- A General Review of The Causes and Acceptance of Shape ImperfectionsДокумент7 страницA General Review of The Causes and Acceptance of Shape ImperfectionsMuhammed SulfeekОценок пока нет

- Welding Standard Ver1Документ4 страницыWelding Standard Ver1Sowmen ChakrobortyОценок пока нет

- Quality Level CДокумент17 страницQuality Level CUgonnaОценок пока нет

- A L F I: Cceptance Imit OR MperfectionsДокумент29 страницA L F I: Cceptance Imit OR MperfectionsDavid MacatangayОценок пока нет

- Limits For Imperfections ISO 5817Документ2 страницыLimits For Imperfections ISO 5817tudorteuОценок пока нет

- Acceptance Criteria of Weld Defects As Per Different Codes - The Engineers Edge Institute of NDT CBEДокумент18 страницAcceptance Criteria of Weld Defects As Per Different Codes - The Engineers Edge Institute of NDT CBEEngineersEDGE CoimbatoreОценок пока нет

- Quality Level BДокумент17 страницQuality Level BUgonnaОценок пока нет

- Welding TWIДокумент16 страницWelding TWIEngr Arfan Ali DhamrahoОценок пока нет

- Solution of 5817 Standard PDFДокумент37 страницSolution of 5817 Standard PDFRajesh KumarОценок пока нет

- DefectДокумент2 страницыDefectanon_90890103100% (1)

- 3.3.1-Basics of Weld Joint Design-9th Mar 21Документ60 страниц3.3.1-Basics of Weld Joint Design-9th Mar 21Vivek kmОценок пока нет

- 'TWI CSWIP Macro Practical Inspection (Compatibility Mode)Документ36 страниц'TWI CSWIP Macro Practical Inspection (Compatibility Mode)Veeralekshmanan KumarОценок пока нет

- Visual Testing 1Документ16 страницVisual Testing 1HÉCTOR EDUARDO PONCE HERNÁNDEZОценок пока нет

- WPQR6Документ3 страницыWPQR6Dimitris NikouОценок пока нет

- Specification No: LMB-COI-TRG-001 Rev No. R0 Page ofДокумент16 страницSpecification No: LMB-COI-TRG-001 Rev No. R0 Page ofApoorv MathurОценок пока нет

- A Brief Synopsis ofДокумент54 страницыA Brief Synopsis ofNO ONEОценок пока нет

- TWI CSWIP 3 1 WIS 5 Welding InspectionДокумент11 страницTWI CSWIP 3 1 WIS 5 Welding Inspectionsenthilkumar100% (1)

- Is 7310 RequirementsДокумент4 страницыIs 7310 RequirementsRavichandran Tirupattur SubramaniamОценок пока нет

- Appendix 3 Example Report E9Документ3 страницыAppendix 3 Example Report E9Laith SalmanОценок пока нет

- Acceptance CriteriaДокумент19 страницAcceptance CriteriaAnonymous 5iv0i3cZОценок пока нет

- 1143 EWF IIW Diploma Overview - August 2013Документ2 страницы1143 EWF IIW Diploma Overview - August 2013Sean ฌอนОценок пока нет

- 22 LNT Ni1 (ER80S-Ni1) 2.4mm 3.1 MTCДокумент1 страница22 LNT Ni1 (ER80S-Ni1) 2.4mm 3.1 MTCnwoforОценок пока нет

- Visual Inspection - AWS & BS PDFДокумент22 страницыVisual Inspection - AWS & BS PDFSelvakpm06Оценок пока нет

- Acceptance Standards RTДокумент1 страницаAcceptance Standards RTRaju TiwaryОценок пока нет

- ISO 5817 Chennai 2011 Pres PDFДокумент17 страницISO 5817 Chennai 2011 Pres PDFcesargamboaОценок пока нет

- TWI CSWIP 3.1 Wis 5 Welding Inspection Practical Visual Inspection of Pipe WeldsДокумент11 страницTWI CSWIP 3.1 Wis 5 Welding Inspection Practical Visual Inspection of Pipe WeldsJohn DareОценок пока нет

- WIS10 M.TestДокумент46 страницWIS10 M.TestUmaibalan100% (1)

- MEI - Aluminium MIG WeldДокумент56 страницMEI - Aluminium MIG WeldSaravana Kumar100% (1)

- WIS 5 EOCA QuestionsДокумент31 страницаWIS 5 EOCA QuestionsAli ClubistОценок пока нет

- Cswip 3.0 ReportingДокумент32 страницыCswip 3.0 ReportingAvijit DebnathОценок пока нет

- Cswip - Section 02-Terms and Definition PDFДокумент19 страницCswip - Section 02-Terms and Definition PDFNsidibe Michael EtimОценок пока нет

- Weld DefectsДокумент23 страницыWeld DefectsSridhar CnОценок пока нет

- VP16 PDFДокумент13 страницVP16 PDFKara WhiteОценок пока нет

- International Welding Inspector (IWI) : M1.1.4. Tungsten Inert Gas WeldingДокумент60 страницInternational Welding Inspector (IWI) : M1.1.4. Tungsten Inert Gas Weldingresky marantinanОценок пока нет

- Cswip Questions and AnswerДокумент4 страницыCswip Questions and Answerenels770% (2)

- Defects AND DiscontinuitiesДокумент39 страницDefects AND DiscontinuitiesThe Engineers EDGE, Coimbatore100% (1)

- API Acceptance CriteriaДокумент1 страницаAPI Acceptance CriteriaravigurajapuОценок пока нет

- Interview QuestionsДокумент13 страницInterview QuestionsWalter RuedaОценок пока нет

- Welding Inspection: Defects/Repairs Course Reference WIS 5Документ54 страницыWelding Inspection: Defects/Repairs Course Reference WIS 5verall_averusОценок пока нет

- Dye Penetrant Inspection - Wikipedia, The Free EncyclopediaДокумент5 страницDye Penetrant Inspection - Wikipedia, The Free Encyclopediaviswamanoj100% (1)

- SAIC-W-2085 Pre-Welding Inspection PDFДокумент4 страницыSAIC-W-2085 Pre-Welding Inspection PDFkarioke mohaОценок пока нет

- MCQS .... CSWIP Questions and AnswersДокумент67 страницMCQS .... CSWIP Questions and AnswersAli Kashif100% (1)

- CSWIP 3.1U RevisionДокумент12 страницCSWIP 3.1U Revisionayman coreОценок пока нет

- Module 4 Weld Geometry and Welding Symbols-1Документ87 страницModule 4 Weld Geometry and Welding Symbols-1Miki Jaksic100% (1)

- Cordon Off - 4 (00000003)Документ1 страницаCordon Off - 4 (00000003)Anonymous PlyxbQ3tОценок пока нет

- RT Acceptance Criteria: API-1104 AWS D1.1Документ1 страницаRT Acceptance Criteria: API-1104 AWS D1.1Shabbir ali100% (1)

- WIS5 - Appendix 2Документ86 страницWIS5 - Appendix 2Reza Fakhrizal100% (1)

- 112 Ewf 652r1 11 Sv00 Ewf Guideline Welding Coordination 1090 October 2011Документ33 страницы112 Ewf 652r1 11 Sv00 Ewf Guideline Welding Coordination 1090 October 2011Carlos Nombela PalaciosОценок пока нет

- Corrosion and Materials in Hydrocarbon Production: A Compendium of Operational and Engineering AspectsОт EverandCorrosion and Materials in Hydrocarbon Production: A Compendium of Operational and Engineering AspectsОценок пока нет

- Acceptance Criteria of Weld Defects As Per Different CodesДокумент17 страницAcceptance Criteria of Weld Defects As Per Different CodesdhasdjОценок пока нет

- Acceptance Criteria of Weld Defects As Per Different CodesДокумент17 страницAcceptance Criteria of Weld Defects As Per Different CodesShubham ShuklaОценок пока нет

- Job Knowledge 68Документ8 страницJob Knowledge 68Mehmet Soysal100% (1)

- Acceptance Criteria of Weld Defects As Per Different CodesДокумент17 страницAcceptance Criteria of Weld Defects As Per Different CodesShankar Pl GowdaОценок пока нет

- Acceptance Criteria of Weld DefectsДокумент17 страницAcceptance Criteria of Weld DefectsvikasОценок пока нет

- Acceptance Criteria of Weld Defects As Per Different CodesДокумент17 страницAcceptance Criteria of Weld Defects As Per Different CodesDudy Pindayana FirdausОценок пока нет

- PDFДокумент15 страницPDFMatthew HaleОценок пока нет

- How To Read Welding GaugesДокумент8 страницHow To Read Welding Gaugeservikas34Оценок пока нет

- ECДокумент40 страницECJosé CarlosОценок пока нет

- New Microsoft Office Word DocumentДокумент9 страницNew Microsoft Office Word DocumentKhalid PerwezОценок пока нет

- 294 - 327 WELDINGPages From Interpreting Engineering Drawings (PDFDrive)Документ34 страницы294 - 327 WELDINGPages From Interpreting Engineering Drawings (PDFDrive)premchandeОценок пока нет

- HTTP WWW - Welding.com Weld - Symbols - Welding - SymbolsДокумент21 страницаHTTP WWW - Welding.com Weld - Symbols - Welding - Symbolsvmuthu76Оценок пока нет

- Welding DocumentДокумент128 страницWelding DocumentVishal SharmaОценок пока нет

- Weld Profiles - AWS D1.1 D1.1M-2010Документ1 страницаWeld Profiles - AWS D1.1 D1.1M-2010gigiphiОценок пока нет

- Mastering Autodesk Inventor 2016 and Autodesk Inventor LT 2016 Autodesk Official Press 1st Edition Ebook PDFДокумент62 страницыMastering Autodesk Inventor 2016 and Autodesk Inventor LT 2016 Autodesk Official Press 1st Edition Ebook PDFkaryn.corman83698% (48)

- Welding Symbols - The Basics: by Rosemary RegelloДокумент5 страницWelding Symbols - The Basics: by Rosemary RegelloAravind H B Engineering CivilОценок пока нет

- Welded JointsДокумент24 страницыWelded JointsSahil SoniОценок пока нет

- Design of Welded Connections PDFДокумент37 страницDesign of Welded Connections PDFMarat Khodzhaiev100% (1)

- Welding SymbolsДокумент21 страницаWelding Symbolstuna61Оценок пока нет

- Welded Connection - 3Документ18 страницWelded Connection - 3Ravi RawatОценок пока нет

- Steel PR 8Документ48 страницSteel PR 8Fraz AliОценок пока нет

- 3.2 MaterialДокумент306 страниц3.2 MaterialBuddharaju KiranОценок пока нет

- Visual Inspection of Tanks & Pressure VesselsДокумент29 страницVisual Inspection of Tanks & Pressure VesselsShahul Hameed Razik100% (5)

- Fillet Welded JointsДокумент4 страницыFillet Welded Jointsjocelyn beltranОценок пока нет

- Design of Welded Connections - Lincoln ElectricДокумент234 страницыDesign of Welded Connections - Lincoln Electrickyletgerber100% (3)

- WeldingДокумент6 страницWeldingAnonymous kIrNuhОценок пока нет

- SteelДокумент29 страницSteelRaj Bakhtani100% (1)

- Minimum Leak Path For TTJДокумент3 страницыMinimum Leak Path For TTJparikshitpadture100% (2)

- Welding Inspection: Duties/TermsДокумент27 страницWelding Inspection: Duties/Termsadeoye_okunoyeОценок пока нет