Академический Документы

Профессиональный Документы

Культура Документы

Boiler operation checklist

Загружено:

Japheth AresoИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Boiler operation checklist

Загружено:

Japheth AresoАвторское право:

Доступные форматы

Vickers Hoskins (M) Sdn. Bhd. ( 37739-A) ADDRESS: Lot 6074, Jln. Hj.

Abdul Manan, 42200 Kapar Selangor, Malaysia Tel: ++(603) 33927385 Fax: ++(603) 33927389 www.vickershoskins.com

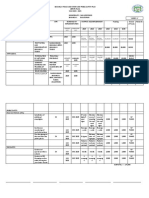

BOILER OPERATION

CHECKS & STEPS REQUIRED BEFORE, DURING & AFTER OPERATION OF BOILER

1. Check water level in the boiler. Normally half full in the steam drum. 2. Ensure all valves are in good working condition. All valves must be tightly closed except the feedwater valve and blow down stop valve. 3. Ensure that air compressor is in good working condition and the compressor head is filled with oil. 4. Open the air vent valve. If there is superheater both the air vent valve and drain valve must be opened (more care must be taken for the superheater to prevent the tubes from been punctured or distorted). Always check the drain bypass pipe orifice, if blocked clean immediately. 5. Ensure the ID fan and FD fan dampers and fuel door can be opened and closed manually. Open the dampers before starting any burning to allow the gases to flow. 6. Inspect the fire grate, brickwork and air nozzles in the furnace ensuring they are in good condition. Ensure the air lock is not blocked. 7. During burning, the temperature in the furnace must rise slowly and gradually to prevent any cracks in the brickwork. 8. When the steam pressure is at 3 bar, close the air vent valve. 9. Open and close the side headers drain valves two (2) to three (3) times to flush out the dirt and residue. 10. Ensure the instrument and control panel is switched off before switching on the ID fan to prevent burnt out of electronic instruments. The voltage will drop while the ID fan is switch on. 11. Ensure the ID fan damper is fully closed before starting the fan motor. FD fan damper shall also be fully closed before starting fan motor. 12. During manual operation of the ID and FD fans, ensure the furnace draft reading is between 0-50mm Hg. 13. When boiler pressure is at ten (10) bar. a. Manually check gauge glass for leaks and the water level. i. Close steam and water valves and open drain valve. ii. With drain valve opened, open the water valve and listen for water draining out, then close the water valve. iii. With drain valve opened, open the steam valve and listen for steam discharge, then close the steam valve. iv. Now close the drain valve and open both steam and water valves. You will see the correct water level in the gauge glass. b. Check Mobrey control to ensure extra low alarm is working properly. i. Close steam and water valves and open drain valve. ii. When the water in the chamber drained off, the float will sink to the bottom. iii. Now the extra low alarm will sound. Process Value (PV) of Chino should be about 21%. iv. Dirt in the chamber will also be drained off. v. Close the drain valve and then open slowly the water valve. The float will rise up. vi. Now open the steam valve, the Mobrey will show normal water level. vii. While testing extra low water level, all equipments must be switched off except the fuel feeder fan in order to ensure the extra low alarm works.

Vickers Hoskins (M) Sdn. Bhd. ( 37739-A) ADDRESS: Lot 6074, Jln. Hj. Abdul Manan, 42200 Kapar Selangor, Malaysia Tel: ++(603) 33927385 Fax: ++(603) 33927389 www.vickershoskins.com

c.

Open and close the blowdown valve quickly several times continuously for 10 to 15 seconds. If the Total Dissolved Solid (TDS) level is higher than normal, blowdown more frequently.

d. Open and close all side headers drain valves. If the boiler was operated for twenty four (24) hours, open the valve slowly and close when the dirt is discharged. 14. When the boiler pressure reaches fifteen (15) bar, open the main stop valve and ensure all main and turbine drain valves are opened. Once the pressure is at set point, switch the ID fan and FD fan dampers to Auto control. 15. Ensure the electrical pump outlet valve is closed before switching on the pump motor to prevent tripping. When the motor is on, open the outlet valve slowly ensuring that the amp is below the specified amps. Check that the pressure relief pipe orifice is not blocked from time to time. 16. Clean the smoke density sensor every morning. If the smoke reading is higher than normal, clean again. Rightly the reading should be same as the smoke in the chimney. 17. Ensure the fuel in the furnace is evenly spread. Always and each time when opening the firedoor, ensure the FD fan damper is manually closed to prevent back fire. Remove the ash from the ash pit every sixteen (16) operating hours. After the ash has been removed, fill the ash pit with water to the required level. 18. Discharge water in the boiler with the blowdown every hour. Check that the TDS is between 2000 to 2200 ppm. If the TDS value is higher, discharge more frequently to achieve the required value. 19. While opening the Pressure Reducing Valve (PRV) for soot blowing, ensure by opening slowly and intermittently. The pressure shall not exceed 100 psi (Pressure for PRV is 100 psi or 7 bar). Soot blowing should be carried out everyday every six (6) to eight (8) hours. a. Ensure soot blower drain valve is opened and not blocked. b. Ensure the pressure does not exceed 100 psi. c. Ensure the soot blower pipe is not bent. 20. When stopping operation of boiler, ensure water in the boiler is enough. 21. Remove all fuel and ash from the furnace and ash pit. 22. Ensure main steam outlet, PRV, steam pump, feedwater inlet, and blowdown stop valve are closed. 23. After switching off ID fan, open the damper fully to release the air and gases in the furnace. 24. Reduce the boiler pressure as much as possible. Discharge water and dirt from the headers. 25. Before returning home, ensure water in drum is three quarter (3/4) full (level will drop when pressure drop). Turbine Feedwater Pump a. Ensure there is oil in the governor. b. Apply oil to all handle and spring. c. Inspect the trip handle. d. Warm up the turbine everyday. e. Replace turbine oil every three (3) months.

Vickers Hoskins (M) Sdn. Bhd. ( 37739-A) ADDRESS: Lot 6074, Jln. Hj. Abdul Manan, 42200 Kapar Selangor, Malaysia Tel: ++(603) 33927385 Fax: ++(603) 33927389 www.vickershoskins.com

DAILY TASKS. a. Drain air compressor every hour. b. Remove ash in ash pit every sixteen (16) hours. c. Soot blow every six (6) to eight (8) hours. d. Blow down water every hour, if TDS is high blow down more frequently. e. Check power pack oil level and open coolant drain valve when running air compressor. Inspect drain valve regularly. WEEKLY TASKS (MAINTENANCE DAY) a. Clean areas in furnace and ash pit. b. Clear all openings in the furnace. c. Inspect and clean inside of ash hopper. d. Clean ID fan and ash from chimney. e. Dismantle and service ID and FD fan cylinder pistons. f. Apply grease to every valve stem (gear). g. Tidy boiler area. h. Apply grease to turbine and electric feedwater pump. EVERY THREE (3) MONTHLY TASKS. a. Clean boiler tubes area and dust collector. b. Replace air compressor oil. c. Inspect soot blower elements (blow pipes). d. Inspect dust collector cones for puncture. e. Replace water in the pressure gauge pipe. f. Inspect internals of steam drum and re-tighten bolts & nuts. Check that scrubber plates are tight and correct to prevent water carry over. EVERY SIX (6) MONTHLY TASKS. a. Inspect the steam and water drums for dirt and residue.

Вам также может понравиться

- Webinar Boiler: Driving Competencies Dukun BoilerДокумент201 страницаWebinar Boiler: Driving Competencies Dukun BoilerHafizul AminОценок пока нет

- Boiler Start UpДокумент15 страницBoiler Start UpMt. Sasongko100% (1)

- Chapter 3 Technical FeasibilityДокумент88 страницChapter 3 Technical FeasibilityAnissa Munira100% (2)

- Spect Press CB15T & CB4000L For BPK & TS MillДокумент3 страницыSpect Press CB15T & CB4000L For BPK & TS Millrendra100% (1)

- Mengatasi Masalah Silica Sand MeltingДокумент9 страницMengatasi Masalah Silica Sand MeltingTb RamdaniОценок пока нет

- Oil Palm Mill System and ProcessДокумент18 страницOil Palm Mill System and Processsjr141071100% (4)

- Depericarping System: Fiber Cyclone Fan Back Calculation Plant Capacity/LineДокумент3 страницыDepericarping System: Fiber Cyclone Fan Back Calculation Plant Capacity/Lineyusefri100% (1)

- Pom - Workshop Management 20131023Документ77 страницPom - Workshop Management 201310235iregarОценок пока нет

- Penyelenggaraan, Pemeriksaan Dan Pembaikan DandangДокумент12 страницPenyelenggaraan, Pemeriksaan Dan Pembaikan DandangMdnor RahimОценок пока нет

- Boiler Paper For 2nd Class 2017Документ5 страницBoiler Paper For 2nd Class 2017iqbal100% (4)

- Boiler Lightup SOPДокумент3 страницыBoiler Lightup SOPSudipta DasОценок пока нет

- CFBC Boiler Training ManualДокумент4 страницыCFBC Boiler Training ManualGusti Prasetyo Rendy AnggaraОценок пока нет

- Steam Turbine Basic TheoryДокумент34 страницыSteam Turbine Basic TheoryEliyanto E BudiartoОценок пока нет

- ICE Akta1Документ40 страницICE Akta1SeindahNyaОценок пока нет

- Processing Station - Part 1 (Mpob HQ 21711)Документ56 страницProcessing Station - Part 1 (Mpob HQ 21711)Ameen Zenn100% (2)

- 183 - Viva Questions Shared by Candidates of Gujarat BOE 2017Документ4 страницы183 - Viva Questions Shared by Candidates of Gujarat BOE 2017yousufali56100% (1)

- CFBC START UP STEPSДокумент2 страницыCFBC START UP STEPSJAY PARIKHОценок пока нет

- Boiler Start-Up & Shut-DownДокумент42 страницыBoiler Start-Up & Shut-DownBurhan Khan100% (1)

- Spesification Design Loading RampДокумент3 страницыSpesification Design Loading RampFickri Hafriz100% (3)

- MPOB Sterilizer Process ControlДокумент9 страницMPOB Sterilizer Process ControlgerrykhangОценок пока нет

- Palm Oil Effluent Treatment SchemeДокумент11 страницPalm Oil Effluent Treatment SchemebathalapalliОценок пока нет

- Oil PurifierДокумент3 страницыOil PurifierNAITIKОценок пока нет

- Boiler IntroductionДокумент17 страницBoiler IntroductionDavid SilalahiОценок пока нет

- Operation Of Boilers: Key Phases And Water Treatment StepsДокумент50 страницOperation Of Boilers: Key Phases And Water Treatment Stepstsrinivasan5083100% (1)

- AQC-X Boiler Schedule (21.07.2014 Target)Документ15 страницAQC-X Boiler Schedule (21.07.2014 Target)Stephen Bridges100% (1)

- Boiler Tube Repair ProcedureДокумент7 страницBoiler Tube Repair ProcedurejoelandrewpintoОценок пока нет

- h (V) (m) M (T) /η 45 (0.7734) (20) 1800 (298) /0.8Документ9 страницh (V) (m) M (T) /η 45 (0.7734) (20) 1800 (298) /0.8RajashekarBheemaОценок пока нет

- Palm Oil Mill - Clarification StationДокумент1 страницаPalm Oil Mill - Clarification StationkiraikОценок пока нет

- Report LiДокумент68 страницReport Lipitt8780% (5)

- System Automatic Control Level Dan Temperature Dearator: Pt. Multi Ganda ScoteknikДокумент18 страницSystem Automatic Control Level Dan Temperature Dearator: Pt. Multi Ganda ScoteknikichsanОценок пока нет

- EH - Topic 1 Reception - Final Draft 300413Документ5 страницEH - Topic 1 Reception - Final Draft 300413Amin Buhari Md Zain100% (1)

- Boiler Startup ProcedureДокумент5 страницBoiler Startup ProcedureBrijesh Srivastav0% (1)

- PALM KERNEL OIL EXPELLER OPERATION MANUALДокумент10 страницPALM KERNEL OIL EXPELLER OPERATION MANUALIldebrando Montaño MedinaОценок пока нет

- A Diagnostic Study in A Husk Fired Boiler For A Power PlantДокумент44 страницыA Diagnostic Study in A Husk Fired Boiler For A Power Plantparthi20065768Оценок пока нет

- Maintaining Boiler Water Quality (35 charactersДокумент3 страницыMaintaining Boiler Water Quality (35 characterskcp1986Оценок пока нет

- SOP Simulator BoilerДокумент10 страницSOP Simulator BoilerBambang SetiajiОценок пока нет

- 2016 Test Paper-1 SolutionsДокумент11 страниц2016 Test Paper-1 SolutionsHari PrasadОценок пока нет

- Typ. Slow Firing Alkali BoiloutДокумент3 страницыTyp. Slow Firing Alkali Boiloutsantoshkumarmishra2009100% (2)

- Boiler - Tube PluggingДокумент3 страницыBoiler - Tube PluggingSH1961100% (1)

- Steriliser Type 2Документ17 страницSteriliser Type 2Amin Buhari Md Zain100% (1)

- Boiler Technology Exam PapersДокумент9 страницBoiler Technology Exam PaperssaurabhshineОценок пока нет

- Sterilizer TiltingДокумент23 страницыSterilizer Tiltingofchis50% (2)

- Energy BalanceДокумент6 страницEnergy BalanceAnissa MuniraОценок пока нет

- Efficiency-Boiler & TurbineДокумент21 страницаEfficiency-Boiler & TurbineAnand Swami100% (1)

- Gujarat Boiler Examination Board Boiler Operation Engineer Exam-2017Документ10 страницGujarat Boiler Examination Board Boiler Operation Engineer Exam-2017Alok DoshiОценок пока нет

- Boilers - Thermal EngineeringДокумент45 страницBoilers - Thermal Engineeringommech2020Оценок пока нет

- SYNOPSIS by WambeckДокумент671 страницаSYNOPSIS by WambeckTeong Pei LiangОценок пока нет

- CFBC Boiler Start Up ProcedureДокумент4 страницыCFBC Boiler Start Up ProcedurePrasad Aher100% (1)

- Kernel StationДокумент163 страницыKernel StationArifal100% (1)

- Wom201 - Job Description - Mill EngineerДокумент1 страницаWom201 - Job Description - Mill EngineerJapheth Areso100% (1)

- MPOB GMP Palm Oil MillsДокумент21 страницаMPOB GMP Palm Oil MillsAbu Navaradeeforty88% (8)

- Boe Exam Paper Sep 2013Документ8 страницBoe Exam Paper Sep 2013Sandip WarbheОценок пока нет

- Managing Silica in Boiler WaterДокумент100 страницManaging Silica in Boiler Watermuks1308100% (1)

- Boiler Emergencies - 2017Документ10 страницBoiler Emergencies - 2017RAJKUMAR100% (1)

- BOE PaperДокумент3 страницыBOE PaperAnand Swami100% (2)

- Boiler Blowdown & TDS Control SystemДокумент31 страницаBoiler Blowdown & TDS Control SystemHélder PascoalОценок пока нет

- Calculating Boiler Efficiency by Indirect MethodДокумент15 страницCalculating Boiler Efficiency by Indirect MethodMD SOHEL RANA100% (2)

- Print MeДокумент10 страницPrint MeBryan TanОценок пока нет

- Boiler Q&A FurtherДокумент7 страницBoiler Q&A FurtherRachitОценок пока нет

- Manual Starting and Desludging of PurifierДокумент2 страницыManual Starting and Desludging of PurifierAnupGautam50% (2)

- Wom201 - Job Description - Mill EngineerДокумент1 страницаWom201 - Job Description - Mill EngineerJapheth Areso100% (1)

- Boiler operation checklistДокумент3 страницыBoiler operation checklistJapheth Areso100% (1)

- Daily Fuel Consumption (May, 2012)Документ2 страницыDaily Fuel Consumption (May, 2012)Japheth AresoОценок пока нет

- Caterpillar LogsheetДокумент1 страницаCaterpillar LogsheetJapheth AresoОценок пока нет

- 5S Presentation - (DR - Govin)Документ42 страницы5S Presentation - (DR - Govin)Japheth AresoОценок пока нет

- 00, 10Документ52 страницы00, 10Japheth AresoОценок пока нет

- Guidelines - EMPДокумент14 страницGuidelines - EMPJapheth AresoОценок пока нет

- Power LoadДокумент2 страницыPower LoadJapheth AresoОценок пока нет

- Tolukuma TopoДокумент2 страницыTolukuma TopoJapheth AresoОценок пока нет

- 2022 Intro To Process and Plant Safety NewДокумент163 страницы2022 Intro To Process and Plant Safety Newdavid gabriel100% (2)

- Chemistry Tshirt ProjectДокумент7 страницChemistry Tshirt Projectapi-524483093Оценок пока нет

- Test Procedure (HTC)Документ1 страницаTest Procedure (HTC)raja qammarОценок пока нет

- 016-5032-002-C - SmarTrax - Case IH STX-Steiger-Quadtrac (AccuGuide-Ready) and New Holland TJ-T90X0-T9XXX (IntelliSteer-Ready) - Installation ManualДокумент26 страниц016-5032-002-C - SmarTrax - Case IH STX-Steiger-Quadtrac (AccuGuide-Ready) and New Holland TJ-T90X0-T9XXX (IntelliSteer-Ready) - Installation ManualAndreyОценок пока нет

- Project Report On Biodegradable Plates, Glasses, Food Container, Spoon Etc.Документ6 страницProject Report On Biodegradable Plates, Glasses, Food Container, Spoon Etc.EIRI Board of Consultants and Publishers0% (1)

- Archives of Oral Biology 100 (2019) 42-48Документ7 страницArchives of Oral Biology 100 (2019) 42-48pedro cuellar proОценок пока нет

- Bio23 LindenДокумент34 страницыBio23 LindenDjamal ToeОценок пока нет

- EMAAR HOUSING HVAC SYSTEM SPECIFICATIONSДокумент91 страницаEMAAR HOUSING HVAC SYSTEM SPECIFICATIONSBhuvan BajajОценок пока нет

- Urinary System 1. List The Functions of The KidneysДокумент6 страницUrinary System 1. List The Functions of The KidneysheerОценок пока нет

- B-64483EN-2 - 05 - 01 Dual Check Safety - CONNECTION MANUAL - Password - RemovedДокумент270 страницB-64483EN-2 - 05 - 01 Dual Check Safety - CONNECTION MANUAL - Password - Removedretox9000Оценок пока нет

- Science 6-Q1-M6Документ14 страницScience 6-Q1-M6John Philip LegaspiОценок пока нет

- Rorschach y SuicidioДокумент17 страницRorschach y SuicidioLaura SierraОценок пока нет

- Exudate Detection For Diabetic Retinopathy With Circular HoughДокумент7 страницExudate Detection For Diabetic Retinopathy With Circular HoughAshif MahbubОценок пока нет

- Seizure Acute ManagementДокумент29 страницSeizure Acute ManagementFridayana SekaiОценок пока нет

- Assignment of PsychologyДокумент28 страницAssignment of PsychologyMuhammad Hamza AshfaqОценок пока нет

- Assignment On Types of Retail Marketing: Submitted By: MR - Swapnil S. Ghag. Roll No.10 (A)Документ9 страницAssignment On Types of Retail Marketing: Submitted By: MR - Swapnil S. Ghag. Roll No.10 (A)Swapnil Ghag100% (1)

- LLL'DSWD: Administrative Order No. Series 2017Документ18 страницLLL'DSWD: Administrative Order No. Series 2017SGTОценок пока нет

- JP - Health and Wholeness Through The Holy CommunionДокумент62 страницыJP - Health and Wholeness Through The Holy Communionjevontan90% (10)

- Annotated Bibliography Graphic OrganizerДокумент4 страницыAnnotated Bibliography Graphic Organizerapi-348035481Оценок пока нет

- Work, Energy Power RevДокумент31 страницаWork, Energy Power RevRency Micaella CristobalОценок пока нет

- Effects of Limited Face-to-Face Classes on Grade 11 TVL Students and TeachersДокумент45 страницEffects of Limited Face-to-Face Classes on Grade 11 TVL Students and TeachersJoseph Xyrel Malacad100% (1)

- Will BrinkДокумент10 страницWill BrinkJoao TorresОценок пока нет

- Pvpsit Department of Mechanical Engineering PVP19Документ2 страницыPvpsit Department of Mechanical Engineering PVP19Satya NarayanaОценок пока нет

- AC7101.1 Rev G 2Документ37 страницAC7101.1 Rev G 2Namelezz ShadowwОценок пока нет

- Hybridization Review WorksheetДокумент6 страницHybridization Review WorksheetRejed VillanuevaОценок пока нет

- Bhima Devi Poudel Adhikari Year 2 Assignment 1 - 220179000Документ10 страницBhima Devi Poudel Adhikari Year 2 Assignment 1 - 220179000api-525310113Оценок пока нет

- Effects of Sucrose Concentration On Cell Respiration in YeastДокумент7 страницEffects of Sucrose Concentration On Cell Respiration in YeastRachel Utomo83% (23)

- Examiner's report on F6 Taxation (UK) December 2010 paperДокумент3 страницыExaminer's report on F6 Taxation (UK) December 2010 paperyorcpl200Оценок пока нет

- Barangay Peace and Order and Public Safety Plan Bpops Annex AДокумент3 страницыBarangay Peace and Order and Public Safety Plan Bpops Annex AImee CorreaОценок пока нет

- Early Methods of Fire-Lighting and the Invention of MatchesДокумент11 страницEarly Methods of Fire-Lighting and the Invention of MatchesVogware Academy JindОценок пока нет