Академический Документы

Профессиональный Документы

Культура Документы

Homart Pharmaceuticals Case Study

Загружено:

Lehsah LoИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Homart Pharmaceuticals Case Study

Загружено:

Lehsah LoАвторское право:

Доступные форматы

Homart Pharmaceuticals

Homart Pharmaceuticals Established in Australia in 1992, Homart specialises in manufacturing and marketing high quality Australian health supplements. Some of the health supplements Homart offers ranges from fish oil capsules and vitamins, to unique products such as colostrum tablets, marine collagen capsules, eucalyptus propolis toothpaste, and emu oil products. Homart also does contract manufacturing for a diverse customer base, helping clients with research & development, licensing, exporting and distribution. Homart operates a successful business from two properties in Silverwater combining offices, warehouse and manufacturing facilities.

Sustainability Drivers

Jeffrey Yei, Operations Manager for Homart Pharmaceuticals saw the Energy Efficiency for Small Business program as a great initiative to learn more about his businesses energy consumption and explore any opportunities to enhance efficiencies. Keeping stock below 30 degrees Celsius presented an ongoing challenge in the warehouses, and before the program had been achieved during the summer months with air conditioning.

Assessing Energy Usage

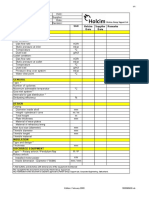

Figure 1: Energy profile for Homart

The energy profile of Homarts two properties is combined above. The other equipment contribution can be solely attributed to the manufacturing facility of one of the two properties.

Action Plan Recommendations

The assessment uncovered a wide range of energy savings actions. Both facilities shared many of the same recommendations with the exception of the ceiling insulation and heat extraction unit for the packaging heat tunnel.

Description

Estimated Cost $1,170 $180 $2,300 $726 $600 $4,250 $10,020 $2,220 $1,600 $23,066

Potential Savings pa $278.08 $75.03 $460.05 $191.64 $97.89 $523.13 $1,046.25 $353.06 $221.25 $3,246

Implementing the Recommendations

Homart are in the process of implementing a broad range of recommendations, having already installed the roof ventilators and heat reflective paint. The program rebate will provide up to 50% of the investment (up to $10.000) for both properties.

Split lighting circuits & install multiple sw itches Install digital timer for extractor fans in kitchen/toilet Install infra-red sensors in low traf fic office areas & toilets Replace 50W w ith 35W IRC halogen dow nlight Install automatic timers on Hot Water Systems Install Roof Ventillators in w arehouses Apply Heat Reflective Paint Install Batt Insulation - Ceiling Comercial air/heat extractor unit on packaging heat tunnel

Results & Achievements

As a result of the implemented actions to date and those left on the list, it is estimated that Homart will save around $3240 and over 17 tonnes of CO2-e per year. The total investment after rebate will pay for itself in energy savings over approximately 4.2 years. The changes already implemented have significantly reduced air conditioning loads and enabled stock to be kept within the desired temperature range. Homart had planned to install more aid conditioning to meet the growing storage loads, but the heat reflective paint as an alternative provided a cost effective insulation solution, which despite costing more upfront, operationally over time will cost less than more air conditioning said Jeffrey Yei. The programs rebate was able to provide that extra incentive to pay more upfront for a better long-term solution.

Figure 2: New vent above office

Вам также может понравиться

- Shellmax SMDL Manual PDFДокумент210 страницShellmax SMDL Manual PDFRandy Fajardo100% (4)

- Supermarket Commercial Refrigeration Total Solution Rev06Документ136 страницSupermarket Commercial Refrigeration Total Solution Rev06Huy HuỳnhОценок пока нет

- Crompton Blue Chip Case Study.Документ11 страницCrompton Blue Chip Case Study.KinjalBhadreshwara0% (2)

- Module III - Concepts and Principles of Distribution LossДокумент28 страницModule III - Concepts and Principles of Distribution LossKunik SwaroopОценок пока нет

- Hotel Energy SolutionsДокумент14 страницHotel Energy SolutionsOmar S. Hamdan100% (1)

- Leak Prevention Repair GuidelinesДокумент20 страницLeak Prevention Repair Guidelinesshank100Оценок пока нет

- AQUATETHYS AnglaisseulДокумент14 страницAQUATETHYS AnglaisseulAlexОценок пока нет

- Hydrogen Gas Detectors FAQДокумент4 страницыHydrogen Gas Detectors FAQAdrienne87aОценок пока нет

- Hydraulic FluidДокумент4 страницыHydraulic FluidBaskar KannaiahОценок пока нет

- Oil and Gas Companies.Документ7 страницOil and Gas Companies.Sindhuja SundaresanОценок пока нет

- PTSDCM0001 40000Документ85 страницPTSDCM0001 40000Mahesh VeerОценок пока нет

- Quotation-11KV 630A 25KA Outdoor VCB Panel-Megawin MakeДокумент3 страницыQuotation-11KV 630A 25KA Outdoor VCB Panel-Megawin MakeSharafat Ali100% (1)

- Carrier chiller-30XAДокумент12 страницCarrier chiller-30XAamitbslpawar100% (1)

- Application and Product Guide - SupermarketДокумент4 страницыApplication and Product Guide - SupermarketezmereldaОценок пока нет

- Cyclone SeparatorДокумент1 страницаCyclone SeparatordadОценок пока нет

- Energy Efficiency CompendiumДокумент118 страницEnergy Efficiency CompendiumSmita NayakОценок пока нет

- Energy Efficiency 4 PillarsДокумент5 страницEnergy Efficiency 4 PillarsVenkatesh Kumar RamanujamОценок пока нет

- Chapter No.5 Reactor DesignДокумент8 страницChapter No.5 Reactor DesignmichsantosОценок пока нет

- Carrier Catalogue 2014 RLC I LCCДокумент52 страницыCarrier Catalogue 2014 RLC I LCCEuro-klima BitolaОценок пока нет

- 2012EU ACC ViewerДокумент44 страницы2012EU ACC ViewerDana LoreОценок пока нет

- 2012 EU LG Commercial Air ConditionersДокумент63 страницы2012 EU LG Commercial Air ConditionersDana LoreОценок пока нет

- Leed Application Guide: Melink Corporation, 5140 River Valley Road, Milford, OH 45150Документ14 страницLeed Application Guide: Melink Corporation, 5140 River Valley Road, Milford, OH 45150M A MunimОценок пока нет

- Environmental Performance and Business Success - The Electrolux ExperienceДокумент5 страницEnvironmental Performance and Business Success - The Electrolux ExperienceRonAhujaОценок пока нет

- 2013 Euro Multi V 0221Документ104 страницы2013 Euro Multi V 0221Dana LoreОценок пока нет

- 2 Wattmeters MethodДокумент13 страниц2 Wattmeters MethodPranav ManavatОценок пока нет

- Solution Dynamics Boiler Efficiency ImprovementДокумент2 страницыSolution Dynamics Boiler Efficiency ImprovementtvsshindeОценок пока нет

- Havells India Limited: Awarded For Best Sustainable PracticesДокумент18 страницHavells India Limited: Awarded For Best Sustainable PracticesJESWIN BENNY 1928517Оценок пока нет

- Intercontinental Hotel Cuts Energy by 40%Документ4 страницыIntercontinental Hotel Cuts Energy by 40%QOBITОценок пока нет

- Anaerobic Digestion-Shanagolden Case Study 2010Документ4 страницыAnaerobic Digestion-Shanagolden Case Study 2010Riski SaputraОценок пока нет

- PriceChopper - Hill Phoenix Rack Saratoga - SNLTX2-ReleaseДокумент5 страницPriceChopper - Hill Phoenix Rack Saratoga - SNLTX2-ReleaseevrimkОценок пока нет

- Thermax LTD.: Solutions Suite - Innovative and Eco-FriendlyДокумент7 страницThermax LTD.: Solutions Suite - Innovative and Eco-FriendlyChandan GaddamanuguОценок пока нет

- Energystar: Building Upgrade ManualДокумент27 страницEnergystar: Building Upgrade Manual88sanОценок пока нет

- Flue & Chimney BrochureДокумент15 страницFlue & Chimney BrochureAirtherm Engineering LtdОценок пока нет

- Thermax Brochure For BoilersДокумент40 страницThermax Brochure For Boilersmanupaul123Оценок пока нет

- SM Global Manual 10-160Документ157 страницSM Global Manual 10-160Radhwan100% (1)

- Airtherm Short BrochureДокумент9 страницAirtherm Short BrochureAIRTHERM ENG LTDОценок пока нет

- Thesis On Heat PumpДокумент6 страницThesis On Heat PumpBestCustomPaperWritingServiceCanada100% (2)

- An Introduction To Environmental AccountingДокумент1 страницаAn Introduction To Environmental Accountingnaim_texОценок пока нет

- cgpp2004 26 SummaryДокумент4 страницыcgpp2004 26 Summaryapi-286562658Оценок пока нет

- Profire Investor's PowerPoint 9.12.12Документ21 страницаProfire Investor's PowerPoint 9.12.12ProfireEnergyОценок пока нет

- Air ConditionerДокумент10 страницAir ConditionerMohitraheja007Оценок пока нет

- TextoДокумент2 страницыTextomoninieberОценок пока нет

- Heat Book PDFДокумент104 страницыHeat Book PDFjitender20Оценок пока нет

- Tuesday - Ways To Reduce Your Carbon FootprintДокумент3 страницыTuesday - Ways To Reduce Your Carbon FootprintKai Sin LingОценок пока нет

- Regulatory Information: Please Read This Manual Carefully Before Operating Your Set and Retain It For Future ReferenceДокумент22 страницыRegulatory Information: Please Read This Manual Carefully Before Operating Your Set and Retain It For Future Referenceqwerty69sОценок пока нет

- Refrigeration Research PaperДокумент5 страницRefrigeration Research Paperc9rvz6mm100% (1)

- Applied Systems Catalogue - ECPEN15 400 Tcm478 351834Документ167 страницApplied Systems Catalogue - ECPEN15 400 Tcm478 351834stefan_c_petreОценок пока нет

- Stepping Into A Green World - Glayx, Italia - Francesco Del Medico - Success StoryДокумент12 страницStepping Into A Green World - Glayx, Italia - Francesco Del Medico - Success StoryCentro de Innovación UC Anacleto AngeliniОценок пока нет

- Bulletin 16 - Conversion of Triple Effect Evaporator With Five Effect EvaporatorДокумент2 страницыBulletin 16 - Conversion of Triple Effect Evaporator With Five Effect EvaporatorSivaram KrishnamoorthyОценок пока нет

- SM DH Series ManualДокумент154 страницыSM DH Series Manualkikyangello90Оценок пока нет

- IES Calorifier Catalogue 2019Документ16 страницIES Calorifier Catalogue 2019Karim Galal IsmailОценок пока нет

- Energy Leads To More WME ArticleДокумент1 страницаEnergy Leads To More WME Articlefetts5853Оценок пока нет

- Consultants ServicesДокумент2 страницыConsultants ServicesFarzad RezaeiОценок пока нет

- Exhaust Fan CatalogДокумент32 страницыExhaust Fan Catalogcumpio425428Оценок пока нет

- Columna Energy OptimaДокумент11 страницColumna Energy OptimaLope ColumnaОценок пока нет

- Energy Star: The Energy Star Service Mark Is Placed On Energy-Efficient ProductsДокумент6 страницEnergy Star: The Energy Star Service Mark Is Placed On Energy-Efficient ProductsYeager GaryОценок пока нет

- Alist2Документ56 страницAlist2jigar00775Оценок пока нет

- Airtherm Brochure 2012Документ40 страницAirtherm Brochure 2012AIRTHERM ENG LTDОценок пока нет

- ProductCatalogue2011 UKEPCEN11-500 LRДокумент264 страницыProductCatalogue2011 UKEPCEN11-500 LRDana LoreОценок пока нет

- Ctv007 Office Based CompaniesДокумент23 страницыCtv007 Office Based CompaniesCatalin StrugariuОценок пока нет

- Safety and Health Tips For Cooling Tower Inspections.20140409.172028Документ2 страницыSafety and Health Tips For Cooling Tower Inspections.20140409.172028betty37salmonОценок пока нет

- High Speed/ Low Effluent Process For Ethanol: DOE Inventions & Innovations Program-Final ReportДокумент87 страницHigh Speed/ Low Effluent Process For Ethanol: DOE Inventions & Innovations Program-Final ReportCamila RosiniОценок пока нет

- Direct Cold Plasma: The Innovative Answer To Odour Control in The Food and Feed IndustryДокумент4 страницыDirect Cold Plasma: The Innovative Answer To Odour Control in The Food and Feed IndustryInternational Aquafeed magazineОценок пока нет

- Deaerators in Industrial Steam Systems: Additional BenefitsДокумент2 страницыDeaerators in Industrial Steam Systems: Additional BenefitsMochammad RezaОценок пока нет

- At A Glance The Green Seafood Business Programme Project DescriptionДокумент2 страницыAt A Glance The Green Seafood Business Programme Project Descriptionapi-286562658Оценок пока нет

- Carbon Footprint & Its Initiation: Submitted by - Urshila Bhuyan 70/D/2009 PGDBM 4 TrimesterДокумент7 страницCarbon Footprint & Its Initiation: Submitted by - Urshila Bhuyan 70/D/2009 PGDBM 4 TrimesterManas D BorkakotyОценок пока нет

- Making Your Home More Energy Efficient: A Practical Guide to Saving Your Money and Our PlanetОт EverandMaking Your Home More Energy Efficient: A Practical Guide to Saving Your Money and Our PlanetОценок пока нет

- The Future of Oil and Gas Business: Development of Local Content in Mozambique post-COVID-19Документ11 страницThe Future of Oil and Gas Business: Development of Local Content in Mozambique post-COVID-19manuel machavaОценок пока нет

- Annual Report 2011Документ86 страницAnnual Report 2011hortalemosОценок пока нет

- BP090&120 50 HZ TechДокумент24 страницыBP090&120 50 HZ Techmauricio.vidalyork6735Оценок пока нет

- Valvepedia JuneДокумент14 страницValvepedia Juneali100% (1)

- Hook Up Man-Hours and Factors Roel SoelemanДокумент5 страницHook Up Man-Hours and Factors Roel SoelemanRoel SoelemanОценок пока нет

- Wesm FaqsДокумент4 страницыWesm FaqsHermo PatacsilОценок пока нет

- Nordson EFD Pulse Valve Data SheetДокумент5 страницNordson EFD Pulse Valve Data SheetTreborОценок пока нет

- Classic CatalogueДокумент48 страницClassic CataloguelmelendeziОценок пока нет

- Economic Analysis of LNG Distribution For Power PLДокумент9 страницEconomic Analysis of LNG Distribution For Power PLFachrurraziОценок пока нет

- FDP Business PDFДокумент31 страницаFDP Business PDFRANJINI02VОценок пока нет

- GSE EnVision UsersListДокумент2 страницыGSE EnVision UsersListasamad54Оценок пока нет

- 98a2 EDC Toronto Green Industries Directory Edition 1 - 19 Jun 19Документ19 страниц98a2 EDC Toronto Green Industries Directory Edition 1 - 19 Jun 19Danish ShaikhОценок пока нет

- Vortex FlowMeter ProductCatalogue InconeelДокумент6 страницVortex FlowMeter ProductCatalogue InconeelMoloy DasОценок пока нет

- XLPE UGC Withstand TestДокумент6 страницXLPE UGC Withstand TestFuad BurhaniОценок пока нет

- Exporting North American Natural Gas, Closing The Worldwide Price DisparityДокумент35 страницExporting North American Natural Gas, Closing The Worldwide Price DisparityVitaliyKatsenelsonОценок пока нет

- Recognised Standard 01 PDFДокумент15 страницRecognised Standard 01 PDFPraveen KumarОценок пока нет

- Land-Based Salmon Farming Concerns and Responses: ScaleДокумент4 страницыLand-Based Salmon Farming Concerns and Responses: ScaleRobertas KupstasОценок пока нет

- Cleveland Cascades LTD: Providing The Industry Standard For Loading SolutionsДокумент20 страницCleveland Cascades LTD: Providing The Industry Standard For Loading SolutionsHassan SleemОценок пока нет

- Bill of Supply For Electricity: BSES Yamuna Power LimitedДокумент2 страницыBill of Supply For Electricity: BSES Yamuna Power LimitedvoiceofindiapressОценок пока нет

- Potential Sector AJKДокумент28 страницPotential Sector AJKAsad JahangirОценок пока нет

- Filling Valve Manual & Need To Make It Automatic 2. Rubber of Unloading Reel Is Damaged. Rub Mark Appear For ThatДокумент2 страницыFilling Valve Manual & Need To Make It Automatic 2. Rubber of Unloading Reel Is Damaged. Rub Mark Appear For ThatDyeing DyeingОценок пока нет