Академический Документы

Профессиональный Документы

Культура Документы

Blowdown Rate Cal 200902110704281301523368 - Blowdowncalculationforboiler

Загружено:

OA AooИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Blowdown Rate Cal 200902110704281301523368 - Blowdowncalculationforboiler

Загружено:

OA AooАвторское право:

Доступные форматы

BLOWDOWN CALCULATION FOR BOILER

This term is the most important term in boiler operation and monitoring. The parameters of the blow down are to be maintained for particular boiler. This is due to the fact that water inside the boiler gets continuously evaporated due to steam generation. Concentration of dissolve solid, inside the drum increases and reach beyond the limit, so carryover of solids along with steam can occur. To prevent boiler tube chocking and overheating of the boiler tubes the blow down is necessary. The blow down is the water removed from boiler to maintain the solids level in the boiler drum. This can be calculated as follows: E = Evaporation or steam generation rate. S = Amount of solids (ppm) B = Blow down (m3 / hr) C = Maximum permissible concentration of solid inside the boiler drum B = E x S (m3 / hr.) CS %B= S CS

This formula has been equally applied to control individual constituents in boiler. Blow down means, lost heat. This is because any water, which is getting drained from the boiler drum, will be at the saturation temperature of steam and this has been heated starting from water of ambient temperature. Hence any reduction in this quantity of water would mean corresponding saving of fuel which can be qualified.

The chart attached showing volume of boiler Water Blow Liter/minute at various pressure and valve size in most common use: 1 kg / cm2 = 14.2 PSIG

Garware-Wai Case Study: Boiler capacity Steam Pressure Blowdown valve diameter Holdup volume Feed water TDS Existing Boiler water TDS As per formula: Blowdown = 300 x 100 6000 300 = 5.263 = 2.5 TPH = 9.5 kg/cm2 = 1 inch = 5 m3 = 300 ppm (max.) = 6000 ppm

For 2.5 TPH capacity boiler = 2.5 x 5.263 100 = 0.131 = 131 litres / hrs = 3157 litres / day Now as per chart 9.5 kg/cm2 At 9.50 kg/cm2 by having 1 inch blowdown valve diameter, we can remove 480 lit / minute.

To remove 3157 liter/day, we need =

3157 480

= 6.58 minutes of total blow down. Our current blow down confirms the above calculation. Based on above calculation, one can easily calculate the blow down needed to maintain the TDS at any level. For above case, to maintain TDS at 3500 The water to be removed from the system is 5625 lit/day & the total required blow down time is 11.71 minutes.

B.O. Valve

1" Pipe Kg

1.5" Pipe Litre / Kg

2" Pipe Litre / Kg

2.5" Pipe Litre / Minute Kg Coal

3" Pipe Litre / Minute Kg Coal

Press. Temp. Litre / Kg/cm2 7.04 8.80 C

Minute Coal Minute Coal Minute Coal

167.22 435.84 14.98 1089.60 37.68 1852.32 64.47 2655.90 92.16

4767.00 165.71

178.33 463.08 16.80 1198.56 43.58 2015.76 73.55 2941.92 107.60 5039.40 184.32

10.56 185.56 503.94 19.07 1307.52 49.94 2233.68 85.35 3214.32 123.03 5448.00 208.39 12.32 191.67 544.80 21.34 1416.48 55.84 2451.60 97.16 3541.20 140.29 5856.60 231.99 14.08 197.78 599.28 24.52 1525.44 62.65 2669.52 109.41 3813.60 156.18 6265.20 256.96 15.85 202.78 653.76 27.69 1634.40 69.01 2860.20 120.31 4086.00 172.07 6673.80 281.03 17.61 207.78 708.24 29.96 1743.36 75.36 3105.36 134.38 4358.40 188.41 7082.40 306.45 21.13 216.11 789.96 35.41 1906.80 85.81 3386.84 152.09 4712.52 212.02 7845.12 353.21 24.65 223.89 817.20 39.50 2070.24 97.16 3650.16 171.16 5066.64 237.44 8607.84 404.51 28.17 231.11 926.16 44.95 2233.68 108.05 3940.72 191.13 5420.76 262.87 9397.80 455.82 31.69 237.22 1007.88 49.94 2397.12 119.40 4194.96 208.84 5774.88 287.84 10187.76 507.57

Вам также может понравиться

- Maintaining Boiler Water Quality (35 charactersДокумент3 страницыMaintaining Boiler Water Quality (35 characterskcp1986Оценок пока нет

- Boiler Design and Operation ParametersДокумент88 страницBoiler Design and Operation ParametersKrishnan Santhanaraj100% (3)

- Unit - 4 Vapour Power Cycles Session 4 NotesДокумент19 страницUnit - 4 Vapour Power Cycles Session 4 NotesFlamboyantAttittudeОценок пока нет

- Properties of Steam Numericals v2Документ32 страницыProperties of Steam Numericals v2Saurabh R Shah100% (4)

- The Indian Boilers Act 1923Документ16 страницThe Indian Boilers Act 1923Anand Swami100% (1)

- Boiler Efficient, Safe & Emergency OperationДокумент51 страницаBoiler Efficient, Safe & Emergency OperationShambhu MehtaОценок пока нет

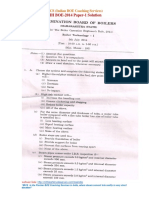

- Indian BOE Coaching Services: Gujarat BOE-2016 Paper-2 (Boiler Engg-2) SolutionДокумент7 страницIndian BOE Coaching Services: Gujarat BOE-2016 Paper-2 (Boiler Engg-2) SolutionAlok DoshiОценок пока нет

- Boiler Bed Height Formula - NirmaДокумент1 страницаBoiler Bed Height Formula - NirmaRaj KumarОценок пока нет

- h (V) (m) M (T) /η 45 (0.7734) (20) 1800 (298) /0.8Документ9 страницh (V) (m) M (T) /η 45 (0.7734) (20) 1800 (298) /0.8RajashekarBheemaОценок пока нет

- Boiler NotesДокумент34 страницыBoiler NotesRakesh Singh BhadoriyaОценок пока нет

- Power Plant Combustion TheoreyДокумент6 страницPower Plant Combustion TheoreySaiVenkat0% (1)

- Boost Boiler Efficiency Through Performance EvaluationДокумент32 страницыBoost Boiler Efficiency Through Performance EvaluationMuthu Kumar100% (1)

- Boiler Technology Exam PapersДокумент9 страницBoiler Technology Exam PaperssaurabhshineОценок пока нет

- MH BOE 2014 Paper 1 SolutionДокумент15 страницMH BOE 2014 Paper 1 SolutionPratima MondalОценок пока нет

- Explosion Occurance in CFBC Boiler and Necessary OperationsДокумент6 страницExplosion Occurance in CFBC Boiler and Necessary OperationsAnudeep ChittluriОценок пока нет

- Failure of Boiler Tubes Due To EROSIONДокумент9 страницFailure of Boiler Tubes Due To EROSIONShiVa20155244Оценок пока нет

- Efficiency of Waste Heat Boiler Calculation and SpecificationДокумент13 страницEfficiency of Waste Heat Boiler Calculation and SpecificationHasan Ahmed100% (1)

- Dryness Fraction PDFДокумент3 страницыDryness Fraction PDFPranay NayanОценок пока нет

- Steam TurbineДокумент77 страницSteam TurbineAmit KhadkaОценок пока нет

- CBD IbdДокумент2 страницыCBD Ibdpremk20100% (5)

- MH BOE 2016 Paper 2 SolutionДокумент9 страницMH BOE 2016 Paper 2 SolutionKamleshОценок пока нет

- Pump Manual - Single Plunger AmbicaДокумент24 страницыPump Manual - Single Plunger AmbicaHimTex /JaswinderОценок пока нет

- Alkali Boil Out Chemical RequirementДокумент1 страницаAlkali Boil Out Chemical RequirementdinuОценок пока нет

- Boiler Protection AND InterlocksДокумент54 страницыBoiler Protection AND InterlocksSarah Frazier100% (1)

- Boiler Blowdown Types and Boiler Blowdown CalculationДокумент3 страницыBoiler Blowdown Types and Boiler Blowdown CalculationMark StrifeОценок пока нет

- Boiler Efficiency CalculationДокумент4 страницыBoiler Efficiency CalculationAhmad RahanОценок пока нет

- Power Plant Chemistry For BoeДокумент22 страницыPower Plant Chemistry For BoeRamakrishna ChiliveryОценок пока нет

- Steam Plant FundamentalsДокумент228 страницSteam Plant FundamentalsMark Allen San Antonio100% (1)

- Components of Circulating Fluidized Bed BoilersДокумент20 страницComponents of Circulating Fluidized Bed BoilersTyrelle Joseph ManitiОценок пока нет

- IR CFBC Cold Start Up ProcedureДокумент15 страницIR CFBC Cold Start Up ProcedureJose Angie CabreraОценок пока нет

- Boiler Operation Engineers Examination Papers Nov 2016Документ10 страницBoiler Operation Engineers Examination Papers Nov 20169766224189Оценок пока нет

- Why Thermal Power Plant Efficiency is Low & How to Improve ItДокумент1 страницаWhy Thermal Power Plant Efficiency is Low & How to Improve ItNallathambiОценок пока нет

- Requirements of Bed Material, Charcoal & Diesel. Bed MaterialДокумент4 страницыRequirements of Bed Material, Charcoal & Diesel. Bed MaterialpurvgargОценок пока нет

- Boiler Emergencies - 2017Документ10 страницBoiler Emergencies - 2017RAJKUMAR100% (1)

- Boiler IntroductionДокумент17 страницBoiler IntroductionDavid SilalahiОценок пока нет

- Steam TurbinesДокумент45 страницSteam TurbinesHaseeb Bokhari100% (1)

- Bed tube failure analysis reportДокумент65 страницBed tube failure analysis reportparthi20065768Оценок пока нет

- Report on 135 TPH CFBC Boiler Start UpДокумент40 страницReport on 135 TPH CFBC Boiler Start UparvindshuklaОценок пока нет

- Boiler Fuel Firing SystemДокумент44 страницыBoiler Fuel Firing Systemrashm006ranjanОценок пока нет

- Slop Fired Boiler: Development of An EfficientДокумент36 страницSlop Fired Boiler: Development of An EfficientSantosh Kumar JaiswalОценок пока нет

- Simple Ideal Rankine Cycle: State 3 Work OutputДокумент2 страницыSimple Ideal Rankine Cycle: State 3 Work OutputfabyunaaaОценок пока нет

- Best 60 Power Plant Information Booster Points - AskpowerplantДокумент17 страницBest 60 Power Plant Information Booster Points - AskpowerplantRaju MaityОценок пока нет

- Boiler Lightup SOPДокумент3 страницыBoiler Lightup SOPSudipta DasОценок пока нет

- C&I in CFBC-1Документ25 страницC&I in CFBC-1Prudhvi RajОценок пока нет

- Heat and Mass Balance Index: S.N. Topics Page NosДокумент50 страницHeat and Mass Balance Index: S.N. Topics Page NosRavi Satyapal100% (1)

- Successful Commissioning of An AFBC BoilerДокумент72 страницыSuccessful Commissioning of An AFBC Boilerparthi20065768Оценок пока нет

- Top 50 Boiler Information Booster Question Answers - ASKPOWERPLANTДокумент19 страницTop 50 Boiler Information Booster Question Answers - ASKPOWERPLANTRaju MaityОценок пока нет

- Boiler Q AДокумент26 страницBoiler Q AGnanaSekar100% (1)

- Boe MCQДокумент13 страницBoe MCQSyam Prasad100% (1)

- SuperCritical Boiler-1Документ45 страницSuperCritical Boiler-1api-19986783100% (2)

- Training Material for Efficient CFB Boiler OperationsДокумент110 страницTraining Material for Efficient CFB Boiler OperationsgkswaroopОценок пока нет

- Module 5 CombustionДокумент51 страницаModule 5 CombustionermiasОценок пока нет

- Blow Down BoilerДокумент41 страницаBlow Down Boilergiannis2Оценок пока нет

- Block 15 DesuperheatingДокумент42 страницыBlock 15 DesuperheatingBabu Aravind100% (1)

- To Calculate The Boiler Blowdown RateДокумент6 страницTo Calculate The Boiler Blowdown Rateedos izedonmwenОценок пока нет

- Control Boiler Water Quality with Proper BlowdownДокумент3 страницыControl Boiler Water Quality with Proper BlowdownSwaroop Kumar100% (1)

- Che Lab EvaporatorДокумент6 страницChe Lab EvaporatorAyobami AkindeleОценок пока нет

- Process Heating: Boiler OperationДокумент12 страницProcess Heating: Boiler Operationagrocel_bhv5591Оценок пока нет

- Boiler Blowdown and Heat RecoveryДокумент8 страницBoiler Blowdown and Heat RecoveryRury MardianaОценок пока нет

- Boiler:: Heat Exported by Outlet Steam Heat Supplied by The FuelДокумент13 страницBoiler:: Heat Exported by Outlet Steam Heat Supplied by The FuelBrijesh SrivastavОценок пока нет

- Industrial Piping and Equipment Estimating ManualОт EverandIndustrial Piping and Equipment Estimating ManualРейтинг: 5 из 5 звезд5/5 (7)

- Pocket Guide to Flanges, Fittings, and Piping DataОт EverandPocket Guide to Flanges, Fittings, and Piping DataРейтинг: 3.5 из 5 звезд3.5/5 (22)

- Asset Integrity Management for Offshore and Onshore StructuresОт EverandAsset Integrity Management for Offshore and Onshore StructuresОценок пока нет

- Machinery Lubrication Technician (MLT) I and II Certification Exam GuideОт EverandMachinery Lubrication Technician (MLT) I and II Certification Exam GuideРейтинг: 2 из 5 звезд2/5 (1)

- Oil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionОт EverandOil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionРейтинг: 4.5 из 5 звезд4.5/5 (16)

- Machine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesОт EverandMachine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesPatrick BangertРейтинг: 3 из 5 звезд3/5 (2)

- Biostratigraphic and Geological Significance of Planktonic ForaminiferaОт EverandBiostratigraphic and Geological Significance of Planktonic ForaminiferaРейтинг: 4 из 5 звезд4/5 (5)

- Well Control for Completions and InterventionsОт EverandWell Control for Completions and InterventionsРейтинг: 4 из 5 звезд4/5 (10)

- Pipeline Integrity: Management and Risk EvaluationОт EverandPipeline Integrity: Management and Risk EvaluationРейтинг: 4.5 из 5 звезд4.5/5 (6)

- Practical Wellbore Hydraulics and Hole Cleaning: Unlock Faster, more Efficient, and Trouble-Free Drilling OperationsОт EverandPractical Wellbore Hydraulics and Hole Cleaning: Unlock Faster, more Efficient, and Trouble-Free Drilling OperationsРейтинг: 5 из 5 звезд5/5 (1)

- Hydraulic Fracturing in Unconventional Reservoirs: Theories, Operations, and Economic AnalysisОт EverandHydraulic Fracturing in Unconventional Reservoirs: Theories, Operations, and Economic AnalysisОценок пока нет

- Oil & Gas Design Engineering Guide Book: Useful Practices and Equipment & SystemsОт EverandOil & Gas Design Engineering Guide Book: Useful Practices and Equipment & SystemsОценок пока нет

- Practical Reservoir Engineering and CharacterizationОт EverandPractical Reservoir Engineering and CharacterizationРейтинг: 4.5 из 5 звезд4.5/5 (3)

- Internal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesОт EverandInternal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesРейтинг: 4 из 5 звезд4/5 (2)

- Black Gold Stranglehold: The Myth of Scarcity and the Politics of OilОт EverandBlack Gold Stranglehold: The Myth of Scarcity and the Politics of OilОценок пока нет

- Deepwater Drilling: Well Planning, Design, Engineering, Operations, and Technology ApplicationОт EverandDeepwater Drilling: Well Planning, Design, Engineering, Operations, and Technology ApplicationРейтинг: 4.5 из 5 звезд4.5/5 (2)

- Risk Management in the Oil and Gas Industry: Offshore and Onshore Concepts and Case StudiesОт EverandRisk Management in the Oil and Gas Industry: Offshore and Onshore Concepts and Case StudiesОценок пока нет

- Asphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsОт EverandAsphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsОценок пока нет

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryОт EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryОценок пока нет

- Petroleum Rock Mechanics: Drilling Operations and Well DesignОт EverandPetroleum Rock Mechanics: Drilling Operations and Well DesignРейтинг: 5 из 5 звезд5/5 (1)