Академический Документы

Профессиональный Документы

Культура Документы

T RN Highway Products

Загружено:

Simon CooperИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

T RN Highway Products

Загружено:

Simon CooperАвторское право:

Доступные форматы

TRINITY

HIGHWAY PRODUCTS

BUILDING TOMORROWS HIGHWAY SAFETY SOLUTIONS TODAY

Revised January 2008

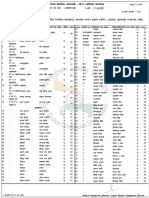

TABLE OF CONTENTS

2 6

Crash Cushions Truck Mounted Attenuators End Terminals

10 12 14 8

Posts Cable Barriers Offset Blocks

15 20

Guardrail Sales Contacts

INNOVATION

As an industry leader in the guardrail and end treatment business, Trinity Highway Products makes certain that several important steps in manufacturing outstanding highway products are taken.

DEVELOPMENT Utilizing a diverse group of outside investors and transportation research institutions and the latest available technology, Trinity Highway Products is able to offer exciting new products, to include energy absorbing devices that are accepted for use worldwide. ACCEPTANCE By working closely with each states Department of Transportation and toll road authority, Trinity Highway Products sales and marketing teams are available to aid in the product approval and specication process. Once approved, specied and let, we begin the manufacturing process in one of our several highway safety manufacturing facilities. EVALUATION Trinity Highway Products uses several independent test facilities to conduct the crash tests for product approval required by the Federal Highway Administration. Each product must meet the requirements of NCHRP-350. Test results are then presented to the Federal Highway Administration for review and acceptance to use on the National Highway System.

Highway safety concerns are increasing around the world. Every year, more countries make a commitment to improve conditions for their driving public.

TRINITY

HIGHWAY PRODUCTS

Trinity Highway Products, LLC, headquartered in Dallas, Texas, is a leading manufacturer of highway guardrail, highway guardrail end treatments, temporary and permanent crash cushions, truck-mounted attenuators and cable barrier systems. Offering a full line of standard and proprietary products, Trinity Highway Products is a recognized innovator of highway safety products. Trinity Highway Products manufactures products that have been tested, approved, and accepted as meeting established federal and state safety guidelines. In fact, all products offered by Trinity Highway Products have been accepted and approved by the Federal Highway Administration as being National Cooperative Highway Research Program Report 350 (NCHRP Report 350) compliant. With all federally funded highway projects, state departments of transportation are required to specify guardrail end treatments, crash cushions and barriers that meet state and federal requirements. Trinity Highway Products innovations that satisfy such requirements include the ET-Plus Guardrail End Treatment, Trinity Attenuating Crash Cushion Family (TRACC Family), Heart Energy Absorbing Reusable Terminal (HEART) and Cable Safety System (CASS).

1-800-527-6050 www.highwayguardrail.com

CRASH CUSHIONS

USAGE

HIGHWAY WORKZONE TEMPORARY PERMANENT UNIDIRECTIONAL TRAFFIC BI-DIRECTIONAL TRAFFIC BRIDGES/TUNNELS MUNICIPAL/CITY

CRASH CUSHIONS

The Trinity Attenuating Crash Cushions (TRACC) meet NCHRP Report 350. Systems are offered at both Test Level 2 and Level 3.

TRACC FAMILY The Trinity Attenuating Crash Cushions Family (TRACC Family) feature a complete line of re-directive, non-gating crash cushions that are available in a variety of lengths for a variety of highway speeds. The 14 - 3 (4.3 m) SHORTRACC, the 21 - 3 (6.5 m) TRACC, the 26 (7.9 m) FASTRACC and the variable width/length WIDETRACC come fully assembled for fast and cost-effective installation. TRACCs are re-directive, Trinity Highway Products manufactures the TRACC Family with galvanized, all-steel construction that reduce concern of product deterioration from the suns ultra-violet rays and extends service life with minimal maintenance by end users. Interchangeable components facilitate swift and inexpensive repairs for state and federal departments of transportation.

non-gating, bi-directional, energy absorbing crash cushions that can be found on highway systems around the country.

The TRACC Family of crash cushions includes TRACC, a narrow Test Level 3 cushion; SHORTRACC, a narrow Test Level 2 cushion; FASTRACC, a narrow Test Level 3 crash cushion with additional capacity for head-on impacts up to 70 mph (113 kph). The WIDETRACC is available in varying lengths, widths and test levels (per design speed). It can be congured for any appropriate wide application.

SPECIFICATIONS

TRACC

TRACC WIDETRACC SHORTRACC

21-3 (6.5 m) 24 Wide (610 mm) 3200 Lbs. (1451 kg)

SHORTRACC

14 -3 (4.3 m) 24 Wide (610 mm) 2200 Lbs. (998 kg)

FASTRACC

26 (7.9 m) 24 Wide (610 mm) 4000 Lbs. (1814 kg)

WIDETRACC (*standard wide system)

Features Galvanized all-steel construction for longer life and durability. No cartridges or black boxes. Only visual maintenance required unless impacted. A variety of backup width options with WIDETRACC. Wing Extensions. Multiple speed options. Fewer anchor bolts than other products. NCHRP Report 350 Test Level 2 and Test Level 3 compliant. Back-Up Structure Attachments Concrete barrier Bridge parapet Bridge piers Square blocks W-Beam Thrie-Beam

Installation and Repair Advantages Can be installed on new or existing concrete or asphalt pad. Open design facilitates easy installation, inspection, and repair. Units ship fully assembled.

(can be shipped unassembled upon request)

FASTRACC

21 Long (6.4 m) 58 Wide Standard (1.47 m) 3825 Lbs. (1735 kg)

*Can be customized to protect any width.

CRASH CUSHIONS

In addition to the TRACC Family of crash cushions, Trinity Highway Products offers the ADIEM, CAT-350 and HEART. Each are designed to absorb energy during impact.

ADIEM The Advanced Dynamic Impact Extension Module (ADIEM) is a cost effective energy-absorbing system that utilizes lightweight, crushable concrete modules. Enhanced coatings and optional covers provide additional protection from the elements. Features No site-specic foundation pad needed. Can be placed on existing surfaces such as concrete, asphalt or compacted soil/base material. Composed of three component groups; reinforced concrete base, engineered lightweight concrete modules, and anchor brackets. Redirective capability [Beginning Length of Need at 15 (4.6 m) from nose]. NCHRP Report 350 Test Level compliant. Installation and Repair Advantages Pinned anchorage allows unit to be moved and relocated quickly. All ten lightweight modules are identical in design and composition, requiring no sequence priority when attaching or replacing damaged modules. Impact damage to the product is typically conned to the modules making repair a simple process. Contains no torque-sensitive bolts. No concrete to pour.

CAT-350 HEART

ADIEM USAGE

HIGHWAY WORKZONE TEMPORARY PERMANENT UNIDIRECTIONAL TRAFFIC BI-DIRECTIONAL TRAFFIC BRIDGES/TUNNELS MUNICIPAL/CITY

ADIEM

SPECIFICATIONS

ADIEM

System Length: 30-0 (9.2m) Base System Width: 32 (313mm) at Widest Point System Height: 28 (712mm) at Nose, 48 (1.2m) at Hazard Base Weight: 11,500 lbs. (5216 kilos)

CAT-350

System Length: 31-3 (9.52m) System Width: 24 (610mm) Inside System Width: 30 (762mm) Outside System Height: 27.75 (705mm) Top of Rails Total Number of Posts: 6 Redirective Capability (LON), Begins at Post 4 from Nose

HEART

CAT-350 The Crash Cushion Attenuating Terminal (CAT) is an energy-absorbing attenuator available for use where blunt ends of rigid barriers and xed objects are in the median or on the shoulder. Features CAT can be used as a longitudinal barrier end treatment and as a crash cushion either in the median or on the shoulder. Various post and post/sleeve options are available. Available in weathering steel. NCHRP Report 350 Test Level 3 compliant.

CAT-350 USAGE

HIGHWAY PERMANENT UNIDIRECTIONAL TRAFFIC BI-DIRECTIONAL TRAFFIC BRIDGES/TUNNELS

HEART The HEART is a reusable, restorable and non-gating re-directive crash cushion manufactured by Trinity Highway Products, LLC. The HEART is compliant with the NCHRP Report 350 TL-3. The HEART uses High Molecular Weight/ High Density Polyethylene (HMW/HDPE) side panels and a rounded frontal nose piece, which are connected to steel diaphragms mounted on tubular steel tracks. The HEARTs HMW/HDPE panels and nose reduce lifecycle costs and minimize maintenance. Features Reusable High Molecular/ High Density Polyethylene (HMW/HDPE) Anchor bolts are easily accessible without the removal of side panels or diaphragms. NCHRP Report 350 TL-3 compliant. Back-Up Structure Attachments Concrete barrier Bridge piers Bridge parapet Square blocks Installation and Repair Advantages Units arrive fully assembled. Installs on new or existing concrete pad. Open design facilitates easy installation, inspection, and repair.

26 Long 32 High 25 27 Wide at the diaphragms with a maximum width of 36 between diaphragms 3 and 4. 2700 Lbs

Installation and Repair Advantages No torque requirements on bolts. Requires no concrete pads (can be installed in soil). Foundations and deadmen anchors are not required. Material below ground is typically found undamaged after impact, allowing for simple repair and replacement of damaged parts.

TRUCK MOUNTED ATTENUATORS

USAGE

HIGHWAY WORKZONE TEMPORARY PERMANENT UNIDIRECTIONAL TRAFFIC BI-DIRECTIONAL TRAFFIC BRIDGES/TUNNELS MUNICIPAL/CITY

Trinity Highway Products MPS-350 Truck-Mounted Attenuator offers unique form and function for shadow or support vehicle protection.

INNOVATIVE TRUCK PROTECTION

MPS-350 The MPS-350 (Mobile Protection System 350) is available for use on stationary or moving shadow or support vehicles and is the first truck-mounted attenuator to pass NCHRP Report 350 Test Level 3. It has an open design and all-steel construction of functional components. The MPS-350 design is a new concept that eliminates bulky, crushable cartridges.

MPS-350

SPECIFICATIONS

MPS-350

14 L (4.30 m) in down position 126 H (3.81 m) when raised 69 (1.75 m) without plastic side panels 72 (1.83 m) with plastic side panels 1800 lbs. weight (816 kg)

Features Open design for easy inspection. All-steel construction reduces moisture absorption concern. Electric hoist raises frame to traveling position. Limit switch for automatic shut-off. Adjustable support chains eliminate sagging when unit is in down/horizonal position. Automatic safety latch locks frame in traveling position. Customized lighting packages available. NCHRP Report 350 Test Level 3 compliant, passing both mandatory and optional tests.

Installation and Repair Advantages Swivel jacks at side and rear for easy installation and removal. Open design facilitates easy repair, keeping all parts within view and reach. Operating components are at side and out of the way of the frame.

END TERMINALS

USAGE

HIGHWAY PERMANENT UNIDIRECTIONAL TRAFFIC BI-DIRECTIONAL TRAFFIC BRIDGES/TUNNELS MUNICIPAL/CITY

END TERMINALS

Trinity Highway Products manufactures a wide variety of end terminals.

Trinity Highway Products guardrail terminal product line includes a wide variety of end treatments, including the ET-Plus, Euro-ET, SRT350 family and the WY-BET Box Beam End Treatment. ET-PLUS The ET-Plus is a federally approved, competitively priced, energy-absorbing end treatment. It can be used at the termination of exible barriers on the shoulder of a roadway or in the median. The ET-Plus is a cable-anchored system utilizing standard guardrail components. EURO-ET The EURO-ET offers speciers and installers the latest innovation of the worlds leading guardrail end treatment. The European version of the ET-Plus meets or exceeds EN 1317-4 P4 criteria. It is uniquely congured to meet European highway safety specications. SRT-350 The Slotted Rail Terminal (SRT-350) is a gating, ared end terminal and is available in a 6-Post and 8-Post System. The SRT/ HBA 6-Post System, has 2 steel breakaway posts, 4 wood CRT posts, and is installed in a straight-line are. The straight-line are offers a simple layout on new installations. The 6-Post System also has steel breakaway posts that are typically reusable after NCHRP Report 350 criteria impacts. The SRT 8-Post System has 2 tube sleeves/wood posts, 6 wood CRT posts, and installs on a parabolic are. The parabolic are has a footprint similar to the previously used BCTs and MELTs, making replacement easier. Strategically located slots in the w-beam rail enhance SRT-350 performance. WY-BET The Wyoming Box-beam End Terminal (WY-BET) uses an oversized outer tube that telescopes over the standard box-beam rail element. When impacted, within NCHRP Report 350 criteria, on the trafc face within the length of need, the terminal functions like the box beam guardrail to contain and redirect the impacting vehicle.

ET-PLUS

ET-PLUS

SPECIFICATIONS

Offset: 0 to 2 (0-610 mm) Length: 25 (7.62 m), 37 6 (11.43 m) or 50 0 (15.24 m) Post Spacing: 6-3 (1905 mm) Length of need: 126 (3.81 m)

SRT-350

ET-PLUS Features Tall and narrow extruder head. Softer ride down for smaller vehicles. Lighter weight head facilitates installation. NCHRP Report 350 Test Level 2 and Test Level 3 compliant. ET-Plus head is sometimes reusable after a NCHRP Report 350 criteria impact.

WY-BET Features The rst tested and approved NCHRP Report 350 end terminal congured for box beam guide railing. May be used in both shoulder and median applications. NCHRP Report 350 Test Level 3 compliant. Installation and Repair Advantages WY-BET head is typically reusable after an impact with NCHRP Report 350 criteria.

Offset: 30 to 40 (915-1220 mm) Length: 37 6 (11.43 m) Length of need: 126 (3.81 m) from the end of the terminal (at the 3rd post) Parabolic or straight are options EURO-ET

WY-BET

SRT-350 6 POST

SRT-350 8 POST

SRT-350 FAMILY Installation and Repair Advantages 30-40 (915 mm-1220 mm) offset results in reduced installation costs. Two steel breakaway posts are typically reusable after an impact within NCHRP Report 350 criteria. Improved angle struts allow for easier installation. Fewer posts and a straight layout provide cost savings in construction, making replacement easier.

WY-BET

Length: 50 0 (15.24 m) Post Spacing: 6 (1.83 m) Shoulder and median options

Features All-steel construction. Easy installation. ET-Plus head is frequently reusable after a design impact. EN 1317-4 P4 compliants. 12 meter pay length.

EURO-ET

POSTS

Trinity Highway Products manufactures a full range of highway posts, from the Steel Yielding Terminal Post to the O-Post and Hinged Break-Away Post. Each model provides distinct advantages for highway use.

HIGH PERFORMANCE, LOW MAINTENANCE

STEEL YIELDING TERMINAL POST (SYTP) The Steel Yielding Terminal Post (SYTP) is an innovative steel post conguration that can be utilized in the ET-Plus family of products. The ET-Plus with SYTP is available in a wide variety of congurations when specifying a 50 0 (15.24m) terminal system. The post is made of standard material with special shop-fabricated holes. Upon an impact within NCHRP Report 350 criteria, the post yields allowing the ET-Plus head to atten the rails and absorb some of the energy of the impacting vehicle. SYTP is NCHRP Report 350 Test Level 3 compliant. Features Yielding action minimizes roadside debris often found with conventional wood post options. Reduction in parts inventory. Galvanized steel reduces issues with wood posts caused by weather. Recycled steel offers environmentally sound options as compared to chemically treated wood posts. NCHRP Report 350 Test Level 3 compliant. Installation and Repair Advantages Can be installed with a standard driving head. Fewer parts simplify buying and stocking for repairs. Product Application All-steel post option available for use in the ET-Plus family of guardrail end treatments.

SPECIFICATIONS

SYTP

W6 x 8.5 lb (W150x13) A-36 steel post @ 60 (1.83m) in length Galvanized per ASTM A-123 with special shop-fabricated yielding holes to be used in any of the 50 0(15.24m) versions of ET-Plus

O-POST

SYTP

HBA POST Trinity Highway Products Hinged Break-Away (HBA) post is a two-piece, reusable steel post manufactured to be used with the ET-Plus and SRT Families of products. Upon impact within NCHRP Report 350 criteria, the HBA Posts 3/8 bolts shear, allowing the post to hinge and fold over at ground level. Features Can be substituted for wood posts. Drivable into most soils. Galvanized steel. NCHRP Report 350 Test Level 3 compliant.

O-POST The O-Post is a single ply post that is robust and corrosion resistant, yet incorporates features that facilitate handling and installation. Features Easy to handle; roll-formed shape provides handle-like grip, with no sharp edges. 25% lighter in weight than a standard W6x8.5 lb (W150x13) steel post. Reinforced bolt hole edge. Specially manufactured for roadway applications. Ribs and rolled edges add section strength and increase driveability. NCHRP Report 350 Test Level 3 compliant. Installation and Repair Advantages Retains its shape when driving through gravel, road base or asphalt. 25% more posts per truck load. Lighter weight posts provide easier handling and installation. Bolt holes for standard routed wood or composite blocks. Installed with standard post drivers.

O-POST

11

12 guage (2.7mm) thickness 60 (1.83m) in length

HBA POST

HBA POST

W6 x 8.5lb (W150x13) Galvanized per ASTM A-123 to be used with ET-Plus and SRT families of products Installation and Repair Advantages Typically, reusable after design impact within NCHRP Report 350 criteria. The post can typically be repaired after design impact within NCHRP Report 350 criteria,by pulling it back to the original upright position and replacing the shear bolts. HBA Post eliminates the need for soil plates and tube sleeves.

10

CABLE BARRIERS

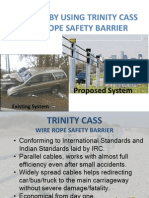

Trinity Highway Products Cable Safety System (CASS) helps end-users address the issue of median crossover accidents on highway systems throughout the world.

CASS TL-3 Features NCHRP Report 350 TL3 compliant. Three-cable, high-tension system. Pre-stretched (recommended) or standard cables. Wave-shaped slot in post results in lower deections. Option of NCHRP Report 350 compliant Cable Terminal or non 350 Cable Anchor. Aesthetically pleasing design. Cables aligned within body of the post.

CASS is congured for use on medians, shoulders and slopes. CASS can also be custom-tailored by end-users for appropriate deections via variable post spacing.

CASS TL-3

SPECIFICATIONS

CASS (C-Shaped Post)

Pre-stretched (recommended) or standard cables: 3/4 (19mm) Post spacing: 66 (2m) to 165 (5m) C-Shaped post: 2x4x8GA (50mm x 100mm x 4mm) NCHRP Report 350 TL-3 and EN-1317 N2 compliant

CASS TL-3 (I-Beam Post)

CASS

INNOVATIVE CABLE SAFETY SYSTEM

CASS CASS assists in re-directing errant vehicles that would otherwise traverse the median of a roadway. The unique post employs a proprietary wave-shaped slot, which works in tandem with strategically positioned cables to increase the systems ability to restrain various types of vehicles that impact the system within the criteria of the NCHRP Report 350. The proprietary shape of the post allows for lower deections during crash tests by minimizing the length of unsupported cables. Additionally, the widened cable spread works to retain different types of vehicles. Features Three-cable (pre-stretched or standard) high-tension system. No sharp edges or hooks in 6:1 slope systems. Wave-shaped slot in post results in lower deections. Option of NCHRP Report 350 Cable Terminal or non-350 Cable Anchor. Aesthetically pleasing design with no interwoven cables. NCHRP Report 350 Test Level 3 and Test Level 4 compliant. Installation and Repair Advantages Posts can be driven or placed into steel sleeves (set in soil, asphalt or concrete). Pre-stretched and tensioned cables require no maintenance by end-users. Cables provided in convenient pre-assembled 1000 lengths (305 meters). No interwoven cables. Minimal maintenance and quick repair after impact by end-users.

Pre-stretched (recommended) or standard cables: 3/4 (19mm) Steel Yielding Cable Post (SYCP): S4x7.7# (S100 x 11.5) I-Beam Cable heights: 20.9 (530mm), 25.2 (640mm), 29.5 (750mm) Post spacing: 66 (2m) to 20 (6.1m) NCHRP Report 350 TL3 compliant

CASS TL-4 (I-Beam Post)

CASS TL-4

Pre-stretched (recommended) or standard cables: 3/4 (19mm) Steel Yielding Cable Post (SYCP): S4 x 7.7# (S100 x 11.5) I-Beam Cable heights: 20.9 (530mm), 29.5 (750mm), 38.1 (970mm) Post spacing: 66 (2m) to 20 (6.1m) NCHRP Report 350 TL4 compliant

CASS TL-4 Features NCHRP Report 350 TL 4 compliant. Three-cable, high-tension system. Pre-stretched (recommended) or standard cables. Wave-shaped slot in post results in lower deections. Option of NCHRP Report 350 compliant Cable Terminal or non-350 Cable Anchor. Aesthetically pleasing design. Cables aligned within body of the post.

13

12

OFFSET BLOCKS

GUARDRAIL

The King Block is a composite, polyethylene/ crumb rubber block made fully from recycled materials. It can be substituted for wood or steel blocks on steel posts by end-users.

The King Block is used for W-Beam installations, and the King-Size King Block is used for ThrieBeam installations.

Trinity Highway Products has provided guardrails on our nations highways for over 30 years.

T-31 GUARDRAIL

T-31 GUARDRAIL Trinity Highway Products proprietary T-31 Guardrail is a strong post w-beam system that has been successfully crash-tested and accepted by the Federal Highway Administration (FHWA) to both NCHRP Report 350 TL-3 and the FHWA proposed 350 update criteria. In the 31 system height, the w-beam attaches directly to Steel Yielding Line Posts (SYLP) eliminating the need for offset blocks. Features Strong posts with weakening holes at the ground line. No offset blocks required. Countersunk-Head Bolts and Flange Protectors. Mid-span splices between adjacent posts. NCHRP Report 350 TL3 compliant. Meets the proposed 350 update criteria. Reduced site grading by eliminating spacer block. Single-face or Double-Face (median) application. T-39 GUARDRAIL The T-39 Guardrail is a strong post thrie-beam system that has been successfully crash-tested with the heavier pickup truck detailed by the FHWA proposed NCHRP 350 update criteria, as well as to NCHRP Report 350 TL4. In the 39 system height, the thrie-beam attaches directly to Steel Yielding Line Posts (SYLP) eliminating the need for off- set blocks. Features Strong posts with weakening holes at the ground line. No offset blocks required. T-39 GUARDRAIL Countersunk-Head Bolts and Flange Protectors. Mid-span splices between adjacent posts. NCHRP Report 350 TL4 compliant. Successfully crash tested with the heavier pickup truck of the FHWA proposed 350 update criteria. Reduced site grading by eliminating spacer block. Single-Face or Double-Face (median) application.

KING BLOCK

SPECIFICATIONS

T-31 GUARDRAIL

KING BLOCK

KING-SIZE KING BLOCK

SPECIFICATIONS

KING BLOCK

King block 4W x 14L x 7.5D, 8 lbs. (100mm x 350mm x 190.5mm), 3.6 kg King-Sized King Block 4w x 22L x 7.5D, 12 lbs. (100mm x 560mm x 190.5mm), 5.5 kg

Features Self-hanging ngers. Self-aligning side rails. Light weight only 8 lbs.(3.6 kg) for W-beam, 12 lbs.(5.5 kg) for Thrie-Beam. Bottom tab supports rail during installation. Block is considered a green product, environmentally safe and recyclable. Molded product reduces inconsistencies sometimes seen in wood blockouts NCHRP Report 350 Test Level 3 compliant. Installation and Repair Advantages Self-hanging ngers minimize the need for assistance by end-users during installation. Self-aligning side rails help hold block in place and minimize spinning. Narrower width allows easier access to bolts at splices. Once installed, these blocks maintain original size, vastly reducing the need for tightening guardrail bolts due to shrinkage often found with wood blocks.

Standard w-beam guardrail Steel Yielding Line Posts (SYLP): W6x8.5x60 (W150x12.6x1.83m) W-beam guardrail height: 31 (790mm) Post spacing: 63 (1.9m) 5/8x1 3/4 (16mmx45mm) Countersunk Head Bolts W-beam Flange Protector at each post

T-39 GUARDRAIL

Standard thrie-beam guardrail Steel Yielding Line Posts (SYLP): W6x8.5x60 (W150x13x1.83m) Thrie-beam guardrail height: 39 (990mm) Post spacing: 63 (1.9m) 5/8x1 3/4 (16mmx45mm) Countersunk Head Bolts W-beam Flange Protector at each post

14

15

GUARDRAIL

W-BEAM RAIL

61/4 (159)

W-BEAM & THRIE BEAM RAIL END SECTIONS

12-6 or 25-0* (3810 or 7620)

6 1/4 (159)

6-3 (1905)

6-3 (1905)

3 1/4 (83)

NOMINAL WEIGHT

lbs W-Beam

12 1/4 (311)

kg

8.2 10.0 10.0

lbs Thrie-Beam

950G (12 ga.) 957G (12 ga.) 975G (10 ga.) 29 37 37

kg

13.2 16.8 16.8

5(127)

901G (12 ga.) 907G (12 ga.) 926G (10 ga.)

18 22 22

3 (76) 2 /4 (70)

3

Reflectorized Washer

3

/4 x 2 1/2 (19x 64) Post Bolt Slots

29

/32 x 1 1/8 (23 x 29) Splice Bolt Slots

161/4 (413)

M180 01234567 08 00 A

2 3 4 5

2

6

1 dia. holes (25)

W-BEAM / THRIE BEAM CENTER PUNCHING

901G

907G

926G (10 ga. only)

1. MANUFACTURER

12-6(3810 mm)

SPACING

25-0(7620 mm) O.C. 58G / 258G O.C. 60G / 260G O.C. 61G / 261G

= Trinity Industries

2. AASHTO SPECIFICATIONS 3. MILL HEAT NUMBER 4. GALVANIZED LOT 08 = Week (8th week) 00 = Year (2000) 5. CLASS Class A = 12 gauge Class B = 10 gauge

6. TYPE Type 1 = Zinc Coated 1.8 oz/ft2 (550 g/m2) minimum single spot Type 2 = Zinc Coated 3.6 oz/ft2 (1100 g/m2) minimum single spot Type 3 = Uncoated steel Type 4 = Weathering Steel

8G / 208G 9G / 209G 11G / 211G

12- 6 (3810 mm) 6- 3 (1905 mm) 3- 11/2 (952 mm)

Part numbers shown for 12 guage material; 10 gauge part numbers available upon request.

24 (610) 1 dia. holes (25)

THRIE BEAM RAIL

950G

6 /4 (159)

1

957G

975G (10 ga. only)

12-6 or 25-0* (3810 or 7620)

6 /4 (159)

1

6-3 (1905)

6-3 (1905)

3 1/4 (83)

24 (610)

271/2 (700) 9 (230) 65/16'R (160)

30 (762) 33/8 (86)

20 (508)

End Section (Flared)

End Section (Rounded)

Terminal Connector Parapet

3/4 x 2 1/2 (19x 64) Post Bolt Slots

29

/32 x 1 1/8 (23 x 29) Splice Bolt Slots

(Metric numbers in green)

Components are available in 12 gauge or 10 gauge as required (except where noted). Finish is available either hot dip galvanized or weathering steel.

14 16

17

GUARDRAIL

RADIUS RAIL INFORMATION

Rise (D) (Inches) Radius (R) (Feet) Rise (D) (MM) Radius (R) (M)

W-BEAM POST SYSTEMS

Rail sections specied to be installed on curves having a radius of 5 feet (1.5m) to 150 feet (45.7m) can be curved in our fabricating facilities prior to delivery. Rail can be curved either convex or concave as required. Terms convex or concave refer to the direction curved, outward or inward, relative to the trafc face of the rail.

King Block

Post Bolt (one required)

Wood Block

Post Bolt (one required)

Post Bolt (one required)

The diagrams & chart provide data for locating posts and curves. For assistance, please contact our Sales Ofces.

TO FIND THE RADIUS FOR A CURVED RAIL:

Cloth Tape

Rail

B 6-3

Traffic Face

C 12-6

41 36 28 26 22 20 18 16 14 11 5/8 9 1/2 7 3/4 6 3/4 6 5 1/4 4 5/8 4 1/4 4 3 5/8 3 3/8 3 1/4 3 2 3/4 5 2 /8 1 2 /2 2 3/8 2 1/8 2 3 1 /4 5 1 /8 1 1/2

5 6 8 9 10 12 13 15 16 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100 110 120 130 140 150

1041 914 711 660 559 508 457 406 356 295 241 197 171 152 133 117 108 102 92 86 83 76 70 67 64 60 54 51 44 41 38

1.5 1.8 2.4 2.7 3.1 3.7 4.0 4.6 4.9 6.1 7.6 9.1 10.7 12.2 13.7 15.2 16.8 18.3 19.8 21.3 22.9 24.4 25.9 27.4 29.0 30.5 33.5 36.6 39.6 42.7 45.7

27 to 28 typical (686 to 762)

27 to 28 typical (686 to 762)

28 to 30 typical (686 to 762)

Post W6 x 8.5 (W150 x 12.6)

Post W6 x 8.5 (W150 x 12.6)

Post S3 x 5.7 (S75 x 8.5)

(with soil plate)

STRONG POST WITH KING BLOCK

STRONG POST WITH WOOD BLOCK

WEAK POST

1-51/2 (444)

6-3 (1905)

12-6 (3810)

PLAN

THRIE BEAM POST SYSTEMS

Post Bolt (two required)

Post Bolt (two required)

Post Bolt (one required)

STEP 1: Starting at the last post in the straight run (point A), lay cloth tape along the path that the curved guard rail will follow.

STEP 4: Measure from the rst mark-off point (point B) over to the mid-point of the taut string. This measurement (D) is the Rise.

Mark-off two points along the curved cloth tape: One at 63, or 1905 mm (point B) and the second at 12-6 or 3810 mm (point C).

STEP 2:

Check the chart to nd the Radius (R), given the Rise (D). Example: a Rise of 4 inches (102 mm) would result in a radius of 60 feet (18.3 m).

STEP 5:

Post W6 x 8.5 (W150 x 12.6)

Post W6 x 8.5 (W150 x 12.6)

Post W6 x 8.5 (W150 x 12.6)

Pull string directly from starting point (point A) to the second mark-off point (point C).

STEP 3:

Note: Follow the steps above for each piece of rail section in the curved run. The arc may not be consistent and each consecutive piece of rail may differ in radius from the previous one. Please consult with an individual approved by the governmental authority specifying and supervising the installation of the guardrail.

STRONG POST WITH KING BLOCK

STRONG POST WITH WOOD BLOCK

STRONG POST WITH MODIFIED STEEL BLOCK (TEST LEVEL 4)

19

18

SALES CONTACTS

TRINITY

HIGHWAY PRODUCTS

Principal Place of Business

2525 N. Stemmons Freeway Dallas, TX 75207 800-527-6050 Domestic 800-644-7976 International +1-214-589-8140

DALLAS, TX 2525 Stemmons Freeway Dallas, TX 75207 800-527-6050 214-589-8423 (Fax) Sales for Arizona, Arkansas, Colorado, Iowa, Kansas, Louisiana, Missouri, Nebraska, New Mexico, Oklahoma, Texas, InternationalPuerto Rico

ORANGEBURG, SC 600 Prosperity Road Orangeburg, SC 29115 800-835-9307 803-536-3413 (Fax) Sales for District of Columbia, Maryland, New Jersey, New York, North Carolina, Pennsylvania, South Carolina, Virginia

GIRARD, OH 1170 N. State Street Girard, OH 44420 800-321-2755 330-545-3718 (Fax) Sales for Canada, Connecticut, Delaware, Maine, Massachusetts, Michigan, New Hampshire, Ohio (North), Pennsylvania, Rhode Island, Vermont

CENTERVILLE, UT 950 West 400 South Centerville, UT 84014 800-772-7976 801-292-2145 (Fax) Sales for Alaska, California, Hawaii, Idaho, Montana, Nevada, North Dakota, Oregon, South Dakota, Utah, Washington, Wyoming

ELIZABETHTOWN, KY 655 East Dixie Avenue Elizabethtown, KY 42701 800-282-7668 270-234-9433 (Fax) Sales for Alabama, Florida, Georgia, Illinois, Indiana, Kentucky, Minnesota, Mississippi, Ohio(South), Tennessee, West Virginia, Wisconsin

TRINITY

HIGHWAY PRODUCTS

800-527-6050, Domestic 800-644-7976 International +1-214-589-8140 www.highwayguardrail.com

20

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Ulb 023 11 27Документ223 страницыUlb 023 11 27rastogi_akОценок пока нет

- Brifen Wire Rope Safety BarrierДокумент16 страницBrifen Wire Rope Safety Barrierrastogi_akОценок пока нет

- Save Life On Road/Highway by Using TrinityДокумент5 страницSave Life On Road/Highway by Using Trinityrastogi_akОценок пока нет

- Save Life On Road/Highway by Using TrinityДокумент5 страницSave Life On Road/Highway by Using Trinityrastogi_akОценок пока нет

- Brifen e BrochureДокумент16 страницBrifen e Brochurerastogi_akОценок пока нет

- Is 5986Документ8 страницIs 5986rastogi_ak100% (1)

- Product Details AVANTECHДокумент13 страницProduct Details AVANTECHrastogi_akОценок пока нет

- Top Places to Visit in Kathmandu CityДокумент3 страницыTop Places to Visit in Kathmandu Cityrastogi_akОценок пока нет