Академический Документы

Профессиональный Документы

Культура Документы

Module 7 - Gas Measurement (v.01)

Загружено:

widcakИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Module 7 - Gas Measurement (v.01)

Загружено:

widcakАвторское право:

Доступные форматы

PRODUCTIONOPERATIONSCOMPETENCYLEARNINGMODULE

Module7:

GasMeasurement

No. #:

Category:

Operations Production

Version:

01

Date:

February 2009

Initial Writing by:

Sardjono

Review by:

Kodeco Operations Team

Copyright to:

KODECOENERGYCO.,LTD.

GASMEASUREMENT

ORIFICEMETERMEASUREMENT

To measure volume of vapor/gas or liquid commonly use differential measurement device, orifice

meter.

Definitions:

DifferentialTaps:Formeterusingflangetapsthecenteroftheupstreampressuretapisplacedone

inchfromtheupstreamfaceoftheorificeplate.Thecenterofthedownstreampressuretapisplaced

one inch from the downstream face of the orifice plate. For meters using pipe tap the upstream

pressuretapisplacedtwoandonehalftimestheactualinsidepipediameterfromtheupstreamfaceof

theorificeplateandthedownstreampressuretapisplacedeighttimestheactualinsidepipediameter

fromthedownstreamfaceoftheorificeplate.

Differential Pressure : Differential pressure is the difference between two pressures. The differential

pressureacrossandorificeinametertubeisthedifferencebetweenthepressureattheupstreamtap

before the gas passes through the orifice and the pressure at the downstream tap after it has passes

throughtheorifice.

StaticorLinePressure : Static Pressure is usually measured by a coiled metal tube with a flattened

crosssection(apressurespring).Thepressureofthegasinthelineisadmittedtoandactsontheinside

of the tube and the atmospheric pressure acts upon the outside of the tube. Therefore the pressure

spring measures the difference between the pressure in the line and the atmospheric pressure. The

pressureinthelinemaybegreaterorlessthantheatmosphericpressure.Thestaticpressuremaybe

takenfromeithertheupstreamorthedownstreampressuretap.

Absolute Pressure : Absolute Pressure is the pressure above the absolute zero, or above a perfect

vacuum.Theatmosphericpressureisalwaysexpressedasanabsolutepressure.Ifthepressureofthe

gasinalineisgreaterthantheatmosphericpressure,theatmosphericpressureinpsiaisaddedtothe

gagepressureinpsigtoobtaintheabsolutepressureofthegasintheline.Ifthegagepressureis40psig

(above atmospheric pressure) and the atmospheric pressure is 14.4 psia, the absolute pressure Pf, is

54.4psia.

Tomeasurepressurebelowatmosphericpressurewithgagescalibratedininchesofmercuryvacuum.

In such cases it is necessary to convert the vacuum from inches of mercury into pounds per square

Page1

inchbymultiplyingbytheconversionfactor0.491;forexample,10inchesofmercuryvacuum=4.91

psig(10x0.491)belowtheabsolutepressureoftheatmosphere.

PressureBase:Thepressurebaseisthepressureatwhichthecubicfootistheunitofmeasurement

accordingtothecontract.Thebasicorificeflowfactorsinthispublicationwerecalculatedforapressure

baseof14.73psia.

Absolute Temperature : On the Fahrenheit thermometer scale the temperature is expressed in the

degreesaboveorbelowanarbitraryzero,whichis32degreesbelowthefreezingpointofwater.The

absolute zero is 460 degrees below the zero of the Fahrenheit thermometer scale. The absolute

temperatureisthetemperatureabovetheabsolutezeroandisobtainedbyadding460degreestothe

reading of the thermometer. If the reading of the Fahrenheit thermometer is 60, the corresponding

absolute temperature is 60 added to 460 or 520 F absolute. If the reading is 20 F, the absolute

temperatureis20F+460For440Fabsolute.

TemperatureBase : The temperature base is the temperature at which the cubic foot is the unit of

measurementaccordingtothecontact.Theorificeflowfactorsinthispublicationwerecalculatedfora

temperaturebaseconditionof520Fabsolute(60F).

SpecificGravity:Therealspecificgravityofagasistheweightofacubicfootofgascomparedtothe

weight of a cubic foot of dry air under the same pressure and temperature condition. If the specific

gravityofgasis2.0,itistwiceasheavyasair,orifthespecificgravityofagasis0.6,itissixtenthsas

heavyasair.

Acorrectlyinstalledorificecanprovideanoverallaccuracywithinplusorminus2%.

Theorificemeterconsistsofstaticpressureanddifferentialpressure recording gauges connected to

anorificeflangeororificefitting.

Theorificemetertube(meterrun)consistsofupstreamanddownstreamsectionofpipe.

Theorificeplateisheldperpendiculartoflowbyflangesorfitting.Borecircumference,edgesharpness.

Page2

ORIFICEFITTING

(3TypesofOrificeFitting)

StandardOrificeFlange.Requirethatthelineneedtobeshut down and depressurized in

ordertoinspectorchangetheorificeplate.

Single Chamber Orifice Fitting. This fitting also requires that the line be shut down and

depressurizedinordertoinspectorchangetheorificeplate.

SeniorOrificeFitting.Thisfittingallowstheremovalandinspectionofanorificeplatewhilethe

lineremainsunderpressure.

Page3

Page4

Page5

ORIFICEPLATE

Thethicknessoftheorificeplatefor2inchthrough10inchnominaldiameterpipeshallbeat

least0.115in.,for12inpipeshallbeatleast0.175in.

Theupstreamfaceoftheorificeplateshallbeflatandperpendiculartotheaxisofthemeter

tube,wheninposition betweentheorificeflangesorintheorificefitting,squareand sharp,

shallnothaveaburredorfeatherededgeandshallbe maintainedinthisconditionatalltimes.

Thethicknessoftheorificeplateattheorificeedgeshallnot exceedthesmallerof:

a.1/50ofthepipediameterD

b.1/8oftheorificediameterd

Page6

Page7

BETARATIO(d/D).

Theorificetometertubediameterratio,,beta=d/D,shouldbelimitedasfollows:

a.Withmetersusingflangetaps,betashallbebetween0.15and0.70

b.Withmetersusingpipetaps,betashallbebetween0.20and0.67

Whenusingtheabovebetaratio,thetoleranceoftheorificecoefficient(Fbfactors)isplusor

minus0.5%forflangetapsandplusorminus0.75%forpipetaps.Betaratiosdownto0.10and

upto0.75maybeusedforflangetapsbutthecoefficienttoleranceincreases.Betaratiosdown

to0.10andupto0.70maybeusedforpipetapsbutthecoefficienttoleranceincreases.

Page8

METERTUBE

The Meter Tube mean the straight upstream pipe of the same diameter (of length A and A)

betweentheorificeflangesorfittings,andthesimilardownstreampipe(lengthBbeyondthe

orifice).

Thesectionofpipetowhichtheorificeflangesareattachedshallcomplywiththefollowing:

a. Seamless pipe , the pipe walls may be honed, machined, or ground. The wall finish

shouldsimulatethatofnewsmoothpipe.

b. Grooves,scoring,pits,raisedridgesresultingfromseams,distortioncausedbywelding

whichaffecttheinsidediametershallnotbepermitted.

Page9

Page10

STRAIGHTENINGVANES

Thepurposeofstraighteningvanesistoeliminateswirlsandcrosscurrentssetupbythepipe

fittingsandvalvesupstreamofthemetertube.

Theconstructionofvanesthemaximumtransversedimensionaofanypassagethroughthe

vanes shall not exceed the inside diameter, Dof the pipe. The crosssectional area A of

anypassagewithintheassembledvanesshallnotexceed1/16 of the crosssectional area of

thecontainingpipe.ThelengthLofthevanesshallbeatleast10timesthelargesinsidea

dimension.Allthevanespassagesisnotnecessarythesame sizebutshouldbesymmetrical.

Thevanestubeshouldbesecurelyweldedtogetherateachtangentpoint.Allweldmetalshould

begroundoffsmoothtopreventdisturbancestotheflowandshouldbesecurelyanchoredin

themetertubebyuseofaflangeringorsetscrews.

Page11

Page12

Page13

Page14

GASMEASUREMENT.

Inthemeasurementofgasbyorificemeter,thechartcontainsrecordsofthedifferentialandthestatic

pressure.Fromtheserecordsthequantityofgasmeasuredisdeterminedbytheuseoftheformula:

,inwhich

Qh

=C

Qh

=rateofflowatbaseconditionincu.Ft.perhr.

C=orificeflowconstant.Itistherateofflowincu.Ft.perhr.atbaseconditionwhenthe

Pressureextension

hw

=differentialininchesofwater.

Pf

=staticpressureinpsia.

=1.000

=pressureextension

C=FbxFrxYxFpbxFtbxFtfxFgxFpvxFmxFaxF

Fb

:basicorificeflowfactor

Fr

:Reynoldsnumberfactor

:expansionfactor

Fpb

:pressurebasefactor

Ftf

:flowingtemperaturefactor

Fg

:specificgravityfactor

Fpv

:supercompressibilityfactor

Fm

:manometerfactor(formercurytypemetersonly)

Fa

:orificethermalexpansionfactor

:gagelocationfactor

Page15

Note:Fororificeconstantfactor,pleaseseetableonpage1through62oforificeconstant

factor.

BasicOrificeFlowfactor,Fb : The orifice factor is based upon the conditions : pressure base, Pb =

14.73 psia; temperature base, Tb = 60F (520 F absolute); specific gravity, G = 1.000; flowing

temperature,Tf=60F.(520Fabsolute);andunderconditionswheretheReynoldsnumberisinfinite

andexpansionfactorisunity.Thevalueofthisfactordependsonupon:thelocationofdifferentialtaps;

thediameteroftheorifice,d;andupontheinternaldiameterofthepipe,D.

TableofFbareshownonpage2through4forflangetaps.

ReynoldsNumberfactor,Fr:TheReynoldsnumberfactortakesintoaccountthevariationsofthe

discharge coefficient of an orifice with Reynolds number. The discharge coefficient of the orifice

decreases as the Reynolds number increases until the Reynolds number infinite, when the discharge

coefficientwillhavetheleastpossiblevalueforthatparticularinstallation.Dischargecoefficientsvary

considerablywithReynoldsnumberinthemeasurementofviscousliquids;theytendtobecomemore

constant as the viscosity of the liquid decreases, and as the Reynolds number correspondingly

increases.Withinthelimitsofcommercialmeasurementofgases,thedischargecoefficientispractically

constant, varying only slightly with Reynolds number. The variation is sufficiently slight, and the

viscosities of commercial gases are sufficiently constant to warrant arbitrarily using the average value

forthegasviscosityincomputingReynoldsnumberfactors.Forallpracticalpurposes,thisleavesthe

Reynolds number factor as a function of the orifice and meter tube dimensions, the location of the

differentialpressuretaps,andtherateofflowafunctionofthepressureextension,

When gases with other characteristics are to be measured, the Reynolds Number factor should be

adjustedasfollows:

(Fc),

Fc=5124

,whereistheabsolutevicosityinlb/ftsec

TablesofbvaluesfromwhichtheReynoldsnumberfactorcanbereadilyobtainedareshownonpage

10through15forflangetaps,andpages32through37forpipetaps.

ExpansionFactor,Y:

Whenagasflowsthroughanorifice,thechangeinvelocityandpresureisaccompaniedbyachangein

specificweightandafactormustbeappliedtothecoefficienttoallowforthischange.Theexpansion

factor depends upon the location of the differential pressure taps, the location of the static pressure

tap,andtheratiooftheorificediametertothediameterofthemetertube.Itisalsodependentupon

theratioofdifferential pressuretostaticpressureanduponofspecificheatsfortheflowinggas.The

Page16

variationofthefactorisslightandtheratioofspecificheatsforcommercialgasesissufficientlyconstant

towarrantusinganassumedconstantratioofspecificheats.Anassumedratioofspecificheatsofk=1.3

was used in calculating the expansion factors in A.G.A Report no.3 and this publication (Singer Orifice

Meter Constant Handbook). This permits tabulation of the factors according to the diameter ratio, ,

andtheratioofdifferentialpressuretostaticpressure,hw/pf.Inthetablespfisindicatedaspforpf

dependinguponwhetherthestaticpressureisobtainedfromtheupstreamtaporfromthedownstream

tap.

When gases being measured have a significantly different ratio of specific heats than the value of 1.3

assumed in Report No.31969, the desirability of using adjusted Y values can be determined from the

following:

)

AdjustedvalueofY=

AdjustedvalueofY=Y

Tablesofexpansionfactorsareshownonpages17through20forflangetaps.

Pressure Base Factor, F pb : The orifice factors were calculated to give gas volumes at a base

pressure,pb,of14.73psia.Ifthemeasurementatanyotherbasepressureisdesired,thenapressure

basefactormustbeapplied.Thesefactors,andtheequationrepresentingthefactors,areindicatedon

page16.(Fpb=14.73basepressure,psia.).

Temperature Base Factor, F tb : The orifice factors were calculated to give gas volumes at a base

temperature,Tb,of60F.(520F.absolute).Ifmeasurementatanyothertemperaturebaseisdesired,

then a temperature base factor must be applied. These factors, and the equation representing the

factors,areindicatedonpage16.(Ftb=

Flowing Temperature Factor, Ftf : The orifice factors were calculated, assuming that the gas is

flowingthroughthemetertubeatatemperature,Tf,of60F.(520F.absolute).Ifmeasurementistobe

made at any other flowing temperature, then a flowing temperature factor must be applied. These

factors,andtheequationrepresentingthefactor,areindicatedonpage21.

Ftf=

SpecificGravityfactor,Fg:Theorificefactorswerecalculatedtogivegasvolumesbaseduponthe

flowinggashavingaspecificgravity,G,of1.000.Forgaseshavingaspecificgravityotherthan1.000a

Page17

specific gravity factor must be applied. These factors, and the equation representing the factors, are

indicatedonpage16.Fg=

SupercompressibilityFactor,Fpv:Thesupercompressibilityfactoraccountsfordeviationfromideal

gaslaw.Inthebasicflowequations,gasvolumesareassumedtovarywithpressureandtemperature

in accordance with Boyles and Charles laws ( the ideal gas laws). Actually the volume occupied by

individualgasesdeviate,byaslightdegree,fromthevolumeswhichtheidealgaslawsindicate.The

amountofdeviationisafunctionofthecompositionofthegasandvariesprimarilywithstaticpressure

andtemperature.Theactualdeviationmaybeobtainedbyalaboratorytestconductedonasampleof

thegas,carefullytakenatlineconditionsofpressureandtemperature.

Practicalrelationshipshavebeenestablishedbywhichthisdeviationcanbecalculatedandtabulatedfor

natural gases containing normal mixtures of hydrocarbon components, considering the presence of

smallquantitiedofcarbondioxideandnitrogenandalsorelatingthedeviationtotheheatingvalueof

thegas.

TheA.G.AmanualfortheDeterminationofSupercompressibilityFactorsforNaturalGasshouldbeused

fordeterminationofthefactorFpv.ThevalueofthesupercompressibilityfactorFpvcanbedetermined

fromtablesonpages44through58.Illustrativeexamplesareincludedwiththesetablestoclarifythe

methodbywhichthesefactorsareobtained.

ManometerFactor,Fm:Themanometerfactorisusedwith themercurytypedifferentialgageto

correcttheslighterrorinmeasurementcausedbytheweightoftheunbalancedcolumnofdensegas

above the mercury. This factor is not applicable where measurement is made with bellowstype

differentialgagessincethereisnounbalancedcolumnofdensegasinamanometerofthattype.Atable

ofmanometerfactorsisshownonpage21.

Orifice Thermal Expansion Fator, F a : The thermal expansion factor is used to adjust for the

deviationoforificediameter,fromthatofitsmanufacture,withextremetemperaturechange.Withina

temperature range of 0F to 120F, this deviation ordinarily is no greater than tolerances assigned to

orifice plate manufacture. Therefore, it is recommended that this factor be ignored in natural gas

measurement. The thermal expansion factor is usually appied to steam and high temperature liquid

measurement. A table of thermal expansion factors for stainless steel and monel orifices is shown on

page22.

GageLocationFactor,Fl:Thegagelocationfactorisincludedinordertoadjustforlocationother

than45latitudeandsealevel.Atableoflocationfactorsisshownonpage22.

Page18

EXAMPLES

DETERMINATIONOFTHEORIFICEFACTOR,Fb

Thevalueoftheorificefactor,Fb,isexpressedbytheformula:

Fb=338.17Kod,inwhich

338.17 = constant for measurement when the pressure base is 14.73 psia, the temperature

basis60F,theflowingtemperatureis60F,andthespecificgravityis1.000.

Ko

=dischargecoefficientwhentheReynoldsnumberisinfinite.

=diameteroforificeininches.

When the orifice factor is to be determined for a meter tube of standard internal diameter and an

orificeofevensizethevalueofthebasicfactorcanbefoundfromtablescontainedonpages2through

4forflangetaps,andonpage24through26forpipetaps.

Example:Ifa2.375inchorificeisusedwithflangetapsina9.564inchI.D.line,theorificefactor,Fbis

foundfromthetableonpage3tobe1140.1.

Intheformula,Fb=338.17Kod,thedischargecoefficientKoforanygivenvaluefor,variesslightly

withthesizeoftheline.Theorificefactorforvarioussizesoforificesandforthelinesizesnotgivenin

thetablescanbecomputedbytheuseofthetablesonpages5through9forflangetaps,andonpages

27through31forpipetaps.

The basic empirical equations from which values of Ko are calculated are quite complex. It was felt

desirable to develop a method by which orifice factors could be determined without resorting to the

basicequations.

Inordertodothis,theformulafortheorificefactorisconvertedto:

Fb=FFddinwhich

=338.17Kofor4.026inchline.

Fd

=factorforconvertingKofor4.026inchlineforacertainvalueof,intoKoforthe

samevalueof,forothersizeoflines.

=diameteroftheorificeininches.

Page19

Fb=FxFdDinwhich

Fx

=338.17Kofora4.026inchlineorFx=F

Fd

=factorforconvertingKofor4.026inchlineforacertainvalueof,intoKoforthe

samevalueof,forothersizeoflines.

=internaldiameterofthepipeininches.

Example : If a 3.800inch orifice is used with pipe taps in a line 7.981 inches in diameter, = 3.800

7.981=0.47613.Refferingtopage31,

For=0.477,

Fx=54.994

For=0.476,

Fx=54.713

Byinterpolation,for=0.47613;Fx=54.749

Seepage29,for=0.476andD=7.981;Fd=0.9999

ThenFb=54.749x0.9999x7.981=3487.0

DETERMINATIONOFPRESSUREBASEFACTOR,Fpb

Using the table on page 16 for a pressure base of 14.65 psia the pressure base factor, Fpb, will be

1.0055.Tocomputeapressurebasefactor,Fpb,foranyvalueofpressurebasenotshown,thefollowing

relationshipcanbeused:

Fpb=

,where:

Pb=therequiredcontractpressurebaseinpsia.

Ifthecontractpressurebaseis14.65psiathenthepressurebasefactorequal

Fpb=

=1.0055

DETERMINATIONOFTEMPERATUREBASEFACTOR,Ftb

Tochangetoanybasetemperatureotherthan60F,thetableonpage16maybeused.Iftherequired

contracttemperaturebaseis70F,thenfromthetablethetemperaturebasefactorFtb=1.0192.Ifthe

contracttemperaturebaseisnotshowninthetablethefactorcanbedeterminedfromtheexpression:

Ftb=

,where:

Tb=theabsolutetemperaturebasespecifiedbythecontract,(460+F).

Page20

Using70Fasrequiredcontracttemperaturebase,thetemperaturebasefactor,

,=1.0192

Ftb=

DETERMINATIONOFSPECIFICGRAVITYFACTOR,Fg

Thespecificgravityfactor,Fg,canbedeterminedfromthetableonpage16.Ifthespecificgravityisnot

foundinthistablethenthefactorcanbedeterminedfromtheexpression:

Fg=

,where:G=specificgravityoftheflowinggas,air=1.000

Example:Ifthespecificgravityoftheflowinggasis0.450,thenthespecificgravityfactor,

=1.4907

Fg=

DETERMINATIONOFFLOWINGTEMPERATUREFACTOR,Ftf

When the flowing temperature of the gas being measured is something other than 60 F a flowing

temperaturefactor,Ftf,mustbeapplied.Foraflowingtemperatureof146Fafactorof0.9263canbe

obtainedfromthetableonpage21.Ifthetemperatureoftheflowingfluidisnotshowninthetablethe

factorcanbedeterminedfromtheexpression:

Ftf=

,where:

Tf=actualflowingtemperatureindegreesFabsolute,(460+F).

Iftheactualflowingtemperatureis146FthenFtf=

=0.9263

DETERMINATIONOFREYNOLDSNUMBERFACTOR,Fr

WhentheReynoldsnumberfactor,Fr,isrequiredusingastandardsizepipeandanevensizeorifice,

thisfactorcanbedeterminedusingthebfactorsonpages10through12forflangetaps,andpage32

through34forpipetaps.

Example : If an 8.000inch orifice is used in a 19.000inch meter tube, and the average extension,

, is 115, using flange taps, the Reynolds number factor,

1.0001.

Page21

DETERMINATIONOFEXPANSIONFACTOR,Y

Valuesofexpansionfactor,Y,arecontainedinthetablesonpages17through20forflangetapsandon

pages38through41forpipetaps.Sincetheexpansionfactordependsuponthepointwherethestatic

pressuretapsislocated,twotablesofexpansionfactorsforflangetapsarerequired:Y,forupstream

static pressure and Y, for downstream static pressure. For expansion factor using pipe taps, two

additionaltablesareprovided:Y,forupstreamstaticpressure,andY,fordownstreamstaticpressure.

Example:Usingflangetaps,withadifferentialof53inchesandwithastaticpressureof264.4psia(250

psig)observedatthedownstreamtap;=

=0.20.Ifthevalueofis0.40,thepropervalueof

theexpansionfactorcanbeobtainedfromthetableonpage19.Y=1.0013

DETERMINATIONOFSUPERCOMPRESSIBILITYFACTOR,Fpv

Thevalueofthisfactorcanbeevaluatedfromthetableslistedanddescribedonpages44through58.

It is recommended that the appropriate alternate method determining adjusting factor Fp and FT, be

usedforgasmixturesexceedingaspecificgravityof0.75.Forgasmixturesexceedingaspecificgravity

of1.00,itisrecommendedthatcompressibilitytestsberuntodeterminethesuitabilityofapplyingthe

standardoranalternatemethod.Thediluentcontentofanygasmixturetowhichthemethodistobe

appliedshouldbelimitedto15mol.percentcarbondioxideand15mol.percentnitrogen,andactual

testsarerecommendedfordiluentcontentexceedingthesequantities.

Thespecificgravity,carbondioxideandnitrogencontents,inconjunctionwiththeflowingpressureand

temperature,areusedtodeterminetheadjustingpressureandtemperaturenecessaryforrelatingany

gas to the supercompressibility data of the 0.600 specific gravity, hydrocarbon gas. The adjusted

pressureisobtainedbymultiplyingthegagepressureoftheflowinggasbythepressureadjustingfactor

Fp, and the adjusted temperature is obtained by multiplying the absolute temperature of the flowing

gasbythetemperatureadjustingfactorFTandsubtracting460fromthisproduct.AdjustingfactorFp

andFTarecalculatedasfollows:

WhereKpisthediluentpressureconstant,Kp=Mc0.392Mnand

WhereKTisthediluenttemperatureconstant,KT=Mc+1.681Mnand

G=specificgravity;Mc=Mol.Percentcarbondioxide;Mn=Mol.Percentnitrogen.

Adjustedpressure=PfFppsig;adjustedtemperature=TfFT460F

Page22

After the adjusted pressure and the adjusted temperature are determined, the supercompressibility

factorFpvcanbefoundintableA(page44through58)usingtheadjustedvalues.

Tables B (page 59 through 60) and C (page 61 through 62) give the values of Fp and FT for specific

gravities between 0.550 and 1.000 and appropriate ranges of the diluent constants. In the ranges

coveredbythesetables,conditionsmaybeindicatedwhichwouldneverexist;however,incommercial

measurementtheuseoftheseareaswillseldomoccur.

ThefollowingexampleillustratestheAGAspecificgravitymethodofcalculatingthesupercompressibility

factorFpv.

Example : Assume a gas having a specific gravity of 0.570, zero percent carbon dioxide and 1.1 mol.

Percentnitrogen,atapressureof370psigand65F.

Pressureconstant:Kp=00.392(1.1)=0.431

Referring to Table B, the pressure adjusting factor, Fp, for G = 0.570 and Kp = 0.431 is found by

interpolationas:Fp=1.0014.

Temperatureconstant:KT=0+1.681(1.1)=1.849

ReferringtoTableC,thetemperaturearenowcalculatedfrom:

Adjustedpressure=PfFp=370(1.0014)=370.5psig

Adjustedtemperature=TfFT460=525(1.0376)460=84.7F

Referring to TableAand usingtheadjustedpressure(370.5psig)andadjustedtemperature(84.7F),

thesupercompressibilityfactor,Fpvisfoundbyinterpolationas:Fpv=1.0254

DETERMINATIONOFTHEMANOMETERFACTOR,Fm

This factor is used with mercurytype meters where the gas comes in contact with mercury surfaces.

Thisfactorcanbeobtainedfromthetableonpage21.

DETERMINATIONOFTHETHERMALEXPANSIONFACTOR,Fa

Thisfactormaybeusedwhenflowingtemperatureareoutsidethelimitsof0Fto120Fandcanbe

obtainedfromthetableonpage22.

DETERMINATIONOFTHEGAGELOCATIONFACTOR,Fl

Thisfactorisspecificallyapplicabletothemanometer.Thisfactorisrepresentedbythetableonpage

22.

Page23

CALCULATIONOFORIFICECONSTANT,C

Thevalueoftheorificeconstant,C,correspondstotheexpression:

C=FbxFrxYxFpbxFtbxFtfxFgxFpvxFmxFaxFl

In the following examples the conditions of measurement and some of the calculations are

givenontheleft.Thefactorsrequiredtoobtaintheorificeconstant,withcorrespondingpage

references,aregivenontheright.

Example1.

ConditionAtMeter

MeterequippedwithPipeTaps

ValueOffactor

AndReferencePage

d=diameteroforifice=3.000inches

D=internaldiameterofmetertube=7.981inches.. Fb=2012.7

24

Staticpressureobtainedatupstreampipetap

Averagedifferential=64.5inches

Averagestaticpressure=539.4psia(525psig)

=3.0007.981=0.38

=pressureextension(average)=187.

Seepage36.For=0.38andD=7.981;b=0.0214

Fr=1+(0.0214187)Fr=1.0001 36

Differentialratio,hwPf=64.5539.4=0.12

Seepage38.For=0.38andhwPf=0.12.. Y=0.9983

38

Page24

Pb=pressurebase,4oz,above14.4=14.65psia. Fpb=1.0055

16

Tb=temperaturebase=60F. Ftb=1.0000

16

Tf=flowingtemperature=60F Ftf=1.0000

21

G=specificgravity=0.64. Fg=1.2500

16

Itisassumedinthisexamplethatthesupercompressibilityfactor

isnotused,bytermsofcontract.

Manometerfactor. Fm=0.9989

21

ThenC=2012.7x1.0001x0.9983x1.0055x1.0000x1.0000x1.2500x0.9989=2522.9

Foranaveragepressureextension,

Qh=C

=186.52,theflowratewouldbe

=2522.9x186.52=470,570cu.Ft.perhr.

Example2.

ConditionAtMeter

ValueOffactor

MeterequippedwithFlangeTaps

AndReferencePage

d=diameteroforifice=4.200inches

D=internaldiameterofmetertube=9.800inches

=4.2009.800=0.42857;interpolatingforFfromthetable,

page5,F=206.87

Interpolatingfromthetable,page7,Fd=0.9992

Fb=FxFdxd=206.87x0.9992x4.200.

Fb=3646.3

Staticpressureobtainedatdownstreamflangetap

Averagedifferential,hw=55.0inches

Page25

Averagestaticpressure,Pf=1523psia(1510psig)

=pressureextension(average)=290.

Seepage14,interpolatingfor=0.43andD=9.800,b=0.0227

=1+0.0227290

Fr=1.0001

14

Y=1.0002

19

Fpb=14.7313.625.

Fpb=1.0811

16

Tb=temperaturebase=50F.

Ftb=0.9808

16

Tf=flowingtemperature=70F

Ftf=0.9905

21

G=specificgravity=0.68..

Fg=1.2127

16

Differentialratio,hwPf=0.04

Seepage19,interpolatingforhwPf=0.04and=0.43..

Pb=pressurebase,10oz,above13.0=13.625psia

Supercompressibility,asdeterminedbyanactualtestfactor

Onasampleofgas..

Fpv=1.1130

Manometerfactor...

Fm=0.9957

21

ThenC=3646.3x1.0001x1.0002x1.0811x0.9808x0.9905x1.2127x1.1130x0.9957=5148.3

Foranaveragepressureextension,

Qh=C

=289.42,theflowratewouldbe

=5148.3x289.42=1,490,000cu.Ft.perhr.

Example3.

ConditionAtMeter

ValueOffactor

MeterequippedwithFlangeTaps

AndReferencePage

d=diameteroforifice=3.500inches

Page26

D=internaldiameterofmetertube=6.065inches.. Fb=2654.9

Staticpressureobtainedatdownstreamflangetap

Averagedifferential=52.5inches

Averagestaticpressure=562.7psia(548psig)

=3.5006.065=0.577

=pressureextension(average)=171.877

Seepage10.For=0.577andD=6.065;b=0.0426

Fr=1+(0.0426171.877) Fr=1.0002

10

Differentialratio,hwPf=52.5562.7=0.093

Seepage19.For=0.577andhwPf=0.093.

Y=1.0006

19

Pb=pressurebase,14.7psia..

Fpb=1.0020

16

Tb=temperaturebase=60F. Ftb=1.0000

16

Tf=flowingtemperature=120F Ftf=0.9469

21

G=specificgravity=0.74. Fg=1.1625

16

Supercompressibilityfactor,N2=0.0856Mol.%,CO2=0.6087Mol.%

Thisfactorwouldbecalculatedinaccordancewiththeformulabelow:

Kp=Mc0.392Mn=0.60870.392(0.0856)=0.60870.03355=0.57515

=1.0102

KT=Mc+1.681Mn=0.6087+1.681x0.0856=0.7526

=0.8867

Adjustedpressure=PfFp=562.7x1.0102=568.43psig.

AdjustedTemperature=TfFT460=580(0.8867)460=514.286460=54.286F

Page27

ReferringtoTableAandusingtheadjustedpressure(568.43psig)andadjustedtemperature(54.286

F),thesupercompressibilityfactorbyinterpolationas:.Fpv=1.04948

44

ManometerfactorFmandFlisneglected(notmercurytypemeter)

Areafactor,Fa(flowingtemperature120F):..Fa=1.0010

22

ThenC=2654.9x1.0002x1.0006x1.0020x1.0000x0.9469x1.1625x1.04948x1.0010=3078.7084

Foranaveragepressureextension,

Qh=C

=171.877,theflowratewouldbe

=3078.7084x171.877=529,159.1636cu.Ft.perhr.(12,699,819.9280cu.Ft.perday).

Page28

ExampleofGasAnalyzeReport:

INSTITUT TEKNOLOGI SEPULUH NOPEMBER SURABAYA

LEMBAGA PENELITAN DAN PENGABDIAN PADA

MASYARAKAT

GAS COMPOSITION ANALYSIS

SPESIFIC GRAVITY AND CALORIFIC VALUE CALCULATIONS

Sample

: BW

Date of Sampling : July 28, 2008 at 17.00

Pressure

: 548 Psig

Temperatur

:

Opening Condition :

- Opening Press : 548 psig

- Opening Temp : 120 oF

Page29

Page30

Page31

Вам также может понравиться

- Dewpoint in Compressed Air FAQДокумент4 страницыDewpoint in Compressed Air FAQamirthalingam_b671Оценок пока нет

- Dewpoint Compressed Air Application NoteДокумент4 страницыDewpoint Compressed Air Application NoteKarthick Velayutham100% (1)

- Measurement of Pressure - Direct ReadingДокумент12 страницMeasurement of Pressure - Direct ReadingVedanta NairОценок пока нет

- What Is Absolute, Gauge and Differential Pressure? Differentiate Those TerminologiesДокумент10 страницWhat Is Absolute, Gauge and Differential Pressure? Differentiate Those TerminologiesRuleen Y. BerezoОценок пока нет

- Using Tsi Incorporated Micromanometers: To Measure Pressure and VelocityДокумент4 страницыUsing Tsi Incorporated Micromanometers: To Measure Pressure and VelocityRusu IulianОценок пока нет

- Gas LawsДокумент35 страницGas LawsHossam atefОценок пока нет

- Experiment 5 (Calibration of Pressure Measuring Devices - A4)Документ17 страницExperiment 5 (Calibration of Pressure Measuring Devices - A4)Jamiel Catapang100% (1)

- Frederick Terry's Lab Report Fluid Dynamics - AsdДокумент19 страницFrederick Terry's Lab Report Fluid Dynamics - AsdFreddie TerryОценок пока нет

- Marcet Boiler Lab ReportДокумент12 страницMarcet Boiler Lab ReportShameerSamsuriОценок пока нет

- Gauges and Ancillary EquipmentДокумент26 страницGauges and Ancillary EquipmentAlbertoОценок пока нет

- Industrial Instrumentation & Control BasicsДокумент70 страницIndustrial Instrumentation & Control BasicsSilo MiyanОценок пока нет

- Temperature and Its Conversions: Temperature Is Usually UsedДокумент9 страницTemperature and Its Conversions: Temperature Is Usually UsedSafeen Y HurmzОценок пока нет

- TF Lab 2Документ12 страницTF Lab 2Mahrukh ChaudharyОценок пока нет

- 3 Process Variables Part 2Документ22 страницы3 Process Variables Part 2Snow DropОценок пока нет

- Lecture 3Документ117 страницLecture 3gebreslassie gereziherОценок пока нет

- Thermo ManualДокумент24 страницыThermo ManualRajakhalidОценок пока нет

- Pressure MeasurementДокумент24 страницыPressure MeasurementOssy DewintaОценок пока нет

- Marcet Boiler Lab ReportДокумент27 страницMarcet Boiler Lab ReportamiraaikharahОценок пока нет

- E4 - Marcet Boiler - NewДокумент7 страницE4 - Marcet Boiler - NewSalahuddin NorazmiОценок пока нет

- Experiment No 1: Objectives: ApparatusДокумент7 страницExperiment No 1: Objectives: ApparatusXodab21683Оценок пока нет

- 2 Nozzle Pressure DistributionДокумент4 страницы2 Nozzle Pressure DistributionKonul AlizadehОценок пока нет

- Marcet Boiler Lab ReportДокумент15 страницMarcet Boiler Lab ReportAnna Kay100% (7)

- Equipment and Accessories: (M. Anees Akhtar)Документ53 страницыEquipment and Accessories: (M. Anees Akhtar)Muhammad Anees AkhtarОценок пока нет

- Lecture 5 Latest JuДокумент117 страницLecture 5 Latest JuSolomon GebremariamОценок пока нет

- Unit 5/P - I M P & V: ART Easurement of Ressure AcuumДокумент31 страницаUnit 5/P - I M P & V: ART Easurement of Ressure Acuumgowri26Оценок пока нет

- Knowledge Troubleshooting AC SystemДокумент13 страницKnowledge Troubleshooting AC SystemRupak KumarОценок пока нет

- 3 Anesthesia - Vaporizers (64 94)Документ31 страница3 Anesthesia - Vaporizers (64 94)racut_khansatra100% (1)

- EXP4 PRESSURE TEMP-minДокумент16 страницEXP4 PRESSURE TEMP-mingoblinsbrideОценок пока нет

- Ex 1Документ4 страницыEx 120-MCE-63 SYED HASSAN KUMAILОценок пока нет

- Calibration of A Bourdon Pressure GaugeДокумент4 страницыCalibration of A Bourdon Pressure GaugesubyОценок пока нет

- Instrumentation Presentation (23!12!2010)Документ183 страницыInstrumentation Presentation (23!12!2010)Muhammad Abdul Rauf100% (1)

- Marcet Boiler AppartusДокумент13 страницMarcet Boiler AppartusNIKHIL DHIMANОценок пока нет

- Comparative Study of Pressure Measurement of Water by Using Bourdon Tube Pressure Gauge and U-Tube Differential ManometerДокумент6 страницComparative Study of Pressure Measurement of Water by Using Bourdon Tube Pressure Gauge and U-Tube Differential ManometerYash PatilОценок пока нет

- ECE Module 5 6Документ35 страницECE Module 5 6June Paulo TejereroОценок пока нет

- Instrument QuestionsДокумент71 страницаInstrument QuestionsFA AyОценок пока нет

- Instrumentation Question & AnswerДокумент65 страницInstrumentation Question & AnswerBalakumar100% (2)

- Assign ThermoДокумент5 страницAssign ThermoShahzaib KhanОценок пока нет

- Topic Name:Pressure Gauge: Guided By:-Prof. Ankit V Sata Prof. Ravi K ParagdaДокумент14 страницTopic Name:Pressure Gauge: Guided By:-Prof. Ankit V Sata Prof. Ravi K Paragdakiran babyОценок пока нет

- Pi I Unit 2 Pressure MeasurementДокумент41 страницаPi I Unit 2 Pressure MeasurementRahmat ElyasaОценок пока нет

- Delivered By:: Rahat SarwarДокумент39 страницDelivered By:: Rahat SarwarinamОценок пока нет

- Automatic Control System CompressДокумент116 страницAutomatic Control System Compressswapnil28.08 k100% (1)

- 14.04 Measuring PressureДокумент4 страницы14.04 Measuring PressurePio SitumorangОценок пока нет

- Geothermal Well Design Handbook (US DOEДокумент103 страницыGeothermal Well Design Handbook (US DOEAdil Aytekin100% (1)

- Compressed Air Engine Efficiency CalculationsДокумент59 страницCompressed Air Engine Efficiency Calculationsnikhil0% (1)

- Pressure Dew Point CalculationДокумент2 страницыPressure Dew Point CalculationSelvaraji MuthuОценок пока нет

- Absolute and Relative PressureДокумент18 страницAbsolute and Relative PressurewakhalewakhaleОценок пока нет

- Basics of VacuumДокумент7 страницBasics of Vacuumsanthosh_yash1Оценок пока нет

- Pressure Measurement: MADE BY:-Uttam TrasadiyaДокумент33 страницыPressure Measurement: MADE BY:-Uttam Trasadiyacyrel bajenОценок пока нет

- Important Inst Q & AДокумент64 страницыImportant Inst Q & ABalakumarОценок пока нет

- Introduction To Static PressureДокумент4 страницыIntroduction To Static Pressure63ragtop100% (2)

- Lecture 3Документ74 страницыLecture 3Alhaj MassoudОценок пока нет

- Instrumentation Interview QuestionsДокумент72 страницыInstrumentation Interview QuestionsGowtham An94% (18)

- Marcet Boiler Lab Report 2015Документ23 страницыMarcet Boiler Lab Report 2015Sivamani SelvarajuОценок пока нет

- Fluids Lab Experiment No:3 Fundamentals of Pressure MeasurementДокумент14 страницFluids Lab Experiment No:3 Fundamentals of Pressure MeasurementDarivan DuhokiОценок пока нет

- HTTP WWW Red Bag Com Engineering Guides 582 BN Eg k4 Standard Method For Safety Relief Valve Calculations HTMLДокумент9 страницHTTP WWW Red Bag Com Engineering Guides 582 BN Eg k4 Standard Method For Safety Relief Valve Calculations HTMLmashudi_fikriОценок пока нет

- Bermas EXP4 MELAB1Документ18 страницBermas EXP4 MELAB1Jed BermasОценок пока нет

- Vapor Pressure: AIM: To Determine The Vapor Pressure of Gasoline Sample TheoryДокумент3 страницыVapor Pressure: AIM: To Determine The Vapor Pressure of Gasoline Sample Theorymaged1998Оценок пока нет

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsОт EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsОценок пока нет

- Catalog enДокумент69 страницCatalog enRadient MushfikОценок пока нет

- Thermo QuestionsДокумент16 страницThermo QuestionsAndrew Tan LeeОценок пока нет

- Tutorial 4 - The Gaseous State: AnswersДокумент5 страницTutorial 4 - The Gaseous State: AnswersDomОценок пока нет

- SHS Gr.12 Chap 9Документ23 страницыSHS Gr.12 Chap 9Cj NacarioОценок пока нет

- ASME SEC VIII DIV-1 Boiler Pressure Vessel Code 2013 Rules For Construction of Pressure Vessels by American Society of Mechanical Engineers (Z-Lib - Org) (156-160)Документ5 страницASME SEC VIII DIV-1 Boiler Pressure Vessel Code 2013 Rules For Construction of Pressure Vessels by American Society of Mechanical Engineers (Z-Lib - Org) (156-160)Rafael Esteban BarriaОценок пока нет

- CH-18 Boiler WaterДокумент41 страницаCH-18 Boiler WaterkrisОценок пока нет

- Inert Gas OverviewДокумент6 страницInert Gas OverviewRahulChoudharyОценок пока нет

- Plasma Arc MachiningДокумент12 страницPlasma Arc MachiningAfsarShaikhОценок пока нет

- HP Safety Valves Silencers Pressure Drops EstimationДокумент3 страницыHP Safety Valves Silencers Pressure Drops Estimationaegean227Оценок пока нет

- Advantages and Disadvantages of Orifice Meter and Venturi MeterДокумент2 страницыAdvantages and Disadvantages of Orifice Meter and Venturi Meterpraveen55% (11)

- Project Report Suface Facility (Group 17)Документ18 страницProject Report Suface Facility (Group 17)FINAL YEAR PETROLEUM 2020 BATCHОценок пока нет

- Pengolahan Limbah Cair Industri TahuДокумент6 страницPengolahan Limbah Cair Industri TahuDenni RachmawanОценок пока нет

- Water Budget Tool v1.01 FinalДокумент3 страницыWater Budget Tool v1.01 FinalYosses Sang Nahkoda100% (1)

- Supercritical Drying of Food Products, SCDДокумент22 страницыSupercritical Drying of Food Products, SCDyogesh kumarОценок пока нет

- ESAB ExtractPage29-30cДокумент9 страницESAB ExtractPage29-30cDries VandezandeОценок пока нет

- About PraxairДокумент2 страницыAbout Praxairkaruna13420% (1)

- Topics NO No of Hours Marks Weightage in ExamДокумент8 страницTopics NO No of Hours Marks Weightage in ExamSaeed cecos1913Оценок пока нет

- Gas Laws Problem Set (Edited)Документ2 страницыGas Laws Problem Set (Edited)Kurt Bidua0% (1)

- Chapter 9 Flow in Closed ConduitsДокумент61 страницаChapter 9 Flow in Closed ConduitsNader Alaa56% (18)

- CreogénicДокумент80 страницCreogénicTaibi AyoubОценок пока нет

- 15.3 Other Types of DesuperheaterДокумент10 страниц15.3 Other Types of DesuperheaterJose VerdezotoОценок пока нет

- 8 EquipmentДокумент148 страниц8 Equipmentngtchung100% (1)

- Measurement of Groundwater Table and Pore Water Pressure in Deep Excavations PDFДокумент3 страницыMeasurement of Groundwater Table and Pore Water Pressure in Deep Excavations PDFHamza NadeemОценок пока нет

- Chem1110: Using Charles' Law and The Ideal Gas LawДокумент10 страницChem1110: Using Charles' Law and The Ideal Gas LawconnieОценок пока нет

- Gujarat Technological University: Diploma in Civil Engineering Semester: 3Документ4 страницыGujarat Technological University: Diploma in Civil Engineering Semester: 3krunal sutharОценок пока нет

- هيدرولوجيДокумент3 страницыهيدرولوجياسومي الوكحОценок пока нет

- Spesific Gravity HydrometerДокумент7 страницSpesific Gravity HydrometerAbdulmajid OsmanОценок пока нет

- Abstractions From Precipitation: AbstractionДокумент10 страницAbstractions From Precipitation: AbstractionmarkhanОценок пока нет

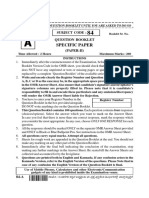

- Specific Paper: Question BookletДокумент32 страницыSpecific Paper: Question BookletrpsirОценок пока нет

- Fundamentals of Refrigeration Part 1Документ7 страницFundamentals of Refrigeration Part 1Sanjay MalhotraОценок пока нет