Академический Документы

Профессиональный Документы

Культура Документы

Bucket Elevator

Загружено:

koripella_prasadИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Bucket Elevator

Загружено:

koripella_prasadАвторское право:

Доступные форматы

BUCKET ELEVATOR

Mechanical Engineering Department Carlos III University

BUCKET ELEVATOR

TRANSPORTATION

BUCKET ELEVATOR

BUCKET ELEVATORS Bucket elevators are the most used systems for vertical transport of bulk, dry, wet and even liquid materials.

Designed with various options of height, speed and constructive details depending on the type of material to be transported. Are constructed by pieces or units to allow to define efficiently the needed height.

BUCKET ELEVATOR

COMPONENTS

Head hood Drive and pulley Discharge spout

Engine Casing

Belt Bucket Clean outdoors Boot inlet hopper Boot

Tensioning device

BUCKET ELEVATOR

DEPENDING ON THE LOAD Directly to the input hopper

Used for transport of abrasive and big size materials. Chain/belt travelling speed is low.

By digging

Used for transport of materials that offer no resistance to extraction, like fine grain and dusty materials.

BUCKET ELEVATOR

DEPENDING ON THE TYPE OF DISCHARGE Centrifugal

It is the most common. Great travelling speeds (1.2 and 1.4 m/s). Loading is carried out by dredging the material at the bottom of the elevator. The separation distance between the buckets is 2 to 3 times the bucket height.

BUCKET ELEVATOR

DEPENDING ON THE TYPE OF DISCHARGE Gravity or continuous

Lower travelling speeds (0.5 and 1.0 m/s). It is taken advantage of self weight. Classification: Free gravity. It is necessary to change the free branch line or incline the bucket.

Forced. The buckets are situated one after the other without separation between them. The discharge takes place due to gravity by means of the lower part of the preceding bucket that acts as a discharge spout.

BUCKET ELEVATOR

DEPENDING ON THE TYPE OF DISCHARGE Positive

Similar to the gravity elevator safe that buckets are fitted at the edges with two cords. Bucket speed is low are appropriate for light, aired, sticky materials.

Cords

BUCKET ELEVATOR

MATERIAL TRANSPORTED FLUX

Bucket volume (l) Material weight (kg) Fill in bucket coefficient (0,6 0,9)

Pc = i j

Density (kg/l)

Transported material flux (t/h)

Q = 3.6

Pc v t

Travelling speed (m/s)

Pitch:

Standard buckets: Flake bucket:

t [2h,3h]

t=h

Bucket height For chains:

t = cte tchain

BUCKET ELEVATOR

POWER

The force the drive pulley needs to move the belt (kg):

Fa =

Q (H + H0 ) 3.6 v

Load system

From the inlet hopper

Material size

Value of H0 (m)

3.8

Little By digging Medium Big

7.6 11.4 15.3

Fictitious height (m) Power of the engine (CV):

Elevating height (m)

Na =

Fa v 75

Engine efficiency

BUCKET ELEVATOR

MAXIMUM TENSION OF THE BELT

Maximum tension of the belt (kg):

Ta = Fa k

Coefficient that depends on the pulley

Pulley conditions

Humid smooth Dry smooth Humid layer Dry layer

K

3.20 1.64 1.73 1.49

BUCKET ELEVATOR

MATERIAL DISCHARGING

m g cos

m v2 R

FR =

m v2 m g cos R

m g sin

mg

A

FR v2 = cos m g g R

m

< = 0 >

mg

BUCKET ELEVATOR

MATERIAL DISCHARGING

FR v2 = cos m g g R

+

0

v2 cos 2 gR

Predominance of gravity forces

v2 cos 1 gR

O

cos

v2 gR

Predominance of the centrifugal forces

0 90

v2 <1 gR

BUCKET ELEVATOR

MATERIAL DISCHARGING

FR v2 = cos m g g R

+

B C O

cos

v2 gR

90

v2 =1 gR

v2 <1 gR

BUCKET ELEVATOR

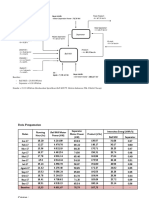

MATERIAL DISCHARGING

Pulley diameter

Fc = Fg m V2 = m g R

R= V2 g

Material path

v = 0.5 m/s

TIME (s) 0.1 0.2 0.3 0.4 0.5 Sh (m) 120 240 360 480 600 Sv (m) 50 195 440 780 1220

1 s = v t + a t2 2 sh sv

BUCKET ELEVATOR

EXAMPLE

Design the features of a belt conveyor that has to transport dry clay of density 1700 kg/m3 with an approximate capacity of 15t/h:

Size of the bucket Spacing Belt speed Pulley diameter

BUCKET ELEVATOR

EXAMPLE

BUCKET ELEVATOR

EXAMPLE

Load weight=(2/3)bucket volumedensity= (2/3)0,741700=0,84 kg per bucket To move 15t/h we need: (15000/0,84)=17857 buckets/h=5 buckets/s Spacing

Pitch=[2h,3h] if bucket height is 105mm Pitch=300 mm

Belt speed=5 bucket/s 300 mm=1,5 m/s Pulley diameter: D=2R=2(v2/g)=460 mm

Вам также может понравиться

- Bucket Elevator PresentationДокумент8 страницBucket Elevator PresentationSalmanОценок пока нет

- DTS AS Aeroslide - V3.3 - 2009 11Документ3 страницыDTS AS Aeroslide - V3.3 - 2009 11BRUNA NASCIMENTOОценок пока нет

- Bucket ElevatorsДокумент11 страницBucket ElevatorsMehmet CОценок пока нет

- Iso 3684 1990Документ8 страницIso 3684 1990joaquin fuentealba moralesОценок пока нет

- Belt Bucket Elevator DesignДокумент14 страницBelt Bucket Elevator Designking100% (1)

- MAMMUT Single-Shaft Hammer Crusher: HilfsvorrichtungenДокумент1 страницаMAMMUT Single-Shaft Hammer Crusher: HilfsvorrichtungenpeymanОценок пока нет

- Comminution 2Документ159 страницComminution 2Kumar RajeshОценок пока нет

- Dura FlexДокумент16 страницDura FlexJohn ChivОценок пока нет

- Sturt Air ClassifierДокумент6 страницSturt Air ClassifierHenry Vladimir VianchaОценок пока нет

- "Design and Model of Bucket Elevator": Under The Guidance ofДокумент92 страницы"Design and Model of Bucket Elevator": Under The Guidance ofSekson JunsukplukОценок пока нет

- 1.1 Design Features of Bucket Elevator: Package M10: Auxiliary Equipment - Maintenance and RepairДокумент56 страниц1.1 Design Features of Bucket Elevator: Package M10: Auxiliary Equipment - Maintenance and RepairDilnesa EjiguОценок пока нет

- Failure Analysis of Belt Conveyor Damage Caused by The Falling Material. Part 1 PDFДокумент9 страницFailure Analysis of Belt Conveyor Damage Caused by The Falling Material. Part 1 PDFCezar PajaresОценок пока нет

- Hydrochloric Acid Regeneration - Wikipedia, The Free EncyclopediaДокумент5 страницHydrochloric Acid Regeneration - Wikipedia, The Free EncyclopediazamburittiОценок пока нет

- (Esteban, Perez Bernal) Spring Stiffness and Grinding ForceДокумент31 страница(Esteban, Perez Bernal) Spring Stiffness and Grinding ForceRaúl Marcelo VelozОценок пока нет

- SinomaДокумент52 страницыSinomansprasad88Оценок пока нет

- Design and Analysis of Screw ConveyorДокумент21 страницаDesign and Analysis of Screw Conveyoravinash1987Оценок пока нет

- Baghouse Filter Modular Pulse Jet Type: Operation and ApplicationДокумент5 страницBaghouse Filter Modular Pulse Jet Type: Operation and ApplicationBudy AndikaОценок пока нет

- AUMUND Bucket Elevators 180801Документ16 страницAUMUND Bucket Elevators 180801Tino TorehОценок пока нет

- Bucket ElevatorsДокумент30 страницBucket ElevatorsarhescobarОценок пока нет

- NM3Документ1 страницаNM3Venkatesan RamalingamОценок пока нет

- DTS-BE-Bucket Elevator - 10-04-2007Документ3 страницыDTS-BE-Bucket Elevator - 10-04-2007BRUNA NASCIMENTOОценок пока нет

- FLSPfister IB05000 I GBTRWSD0216 MailДокумент26 страницFLSPfister IB05000 I GBTRWSD0216 MailLuis Angel BusturiaОценок пока нет

- VSK SeparatorДокумент3 страницыVSK Separatorm_verma21Оценок пока нет

- Ball MillДокумент10 страницBall MillLuthfanОценок пока нет

- Services For Bulk Material Handling Projects: Project Formulation Phase Project Engineering PhaseДокумент29 страницServices For Bulk Material Handling Projects: Project Formulation Phase Project Engineering PhasesrichmechОценок пока нет

- Ventomatic Packing MachineДокумент85 страницVentomatic Packing MachineMudassir RafiqОценок пока нет

- Long Filter BagДокумент1 страницаLong Filter BagAlbar BudimanОценок пока нет

- Basic Hydraulics and Pneumatics Training1Документ74 страницыBasic Hydraulics and Pneumatics Training1birhanu sintayehuОценок пока нет

- Bucket Elevator: Instruction Manual MaintenanceДокумент26 страницBucket Elevator: Instruction Manual MaintenanceJ Dany T. Delgado100% (1)

- 09.30 Cemengal Tanger BK6 FDДокумент18 страниц09.30 Cemengal Tanger BK6 FDMohd AliОценок пока нет

- RABH-sugest by SatputeДокумент1 страницаRABH-sugest by Satputegvrr1954Оценок пока нет

- 04 General Frames Pedestals Lower HousingДокумент13 страниц04 General Frames Pedestals Lower HousingDavid Vilca MamaniОценок пока нет

- IPCC ConceptДокумент24 страницыIPCC ConceptTapadev DasОценок пока нет

- Ball MillДокумент23 страницыBall MillSajjad Rasool ChaudhryОценок пока нет

- BEUMER Bucket ElevatorsДокумент12 страницBEUMER Bucket ElevatorsIsmailОценок пока нет

- Pipe Conveyor: Sheet 1 of 3Документ3 страницыPipe Conveyor: Sheet 1 of 3Ravi KumarОценок пока нет

- Conveyor Speed Calculation: ResultsДокумент2 страницыConveyor Speed Calculation: ResultsyusefriОценок пока нет

- Screw ConveyorДокумент7 страницScrew ConveyorTots HolaresОценок пока нет

- Raw Mill Check ListДокумент2 страницыRaw Mill Check Listlaxman JoshiОценок пока нет

- Belt Conveyors: Mechanical Engineering Department Carlos III UniversityДокумент19 страницBelt Conveyors: Mechanical Engineering Department Carlos III UniversityAlfredo VelasquezОценок пока нет

- Shutdown Maintenance Activites at Mechanical Clinker (Line-1)Документ4 страницыShutdown Maintenance Activites at Mechanical Clinker (Line-1)salman saleemОценок пока нет

- Technical Manual Sample PagesДокумент4 страницыTechnical Manual Sample PagesmkpqОценок пока нет

- Multitrans UkДокумент4 страницыMultitrans UknmaafonsoОценок пока нет

- Jaypee Cement Project ReportДокумент29 страницJaypee Cement Project ReportPurnendu MishraОценок пока нет

- 90 Belt Transfer Unit or Steerable Diverter Latest Product Shorting Technology For ConveyorДокумент7 страниц90 Belt Transfer Unit or Steerable Diverter Latest Product Shorting Technology For ConveyorImpel IntralogisticsОценок пока нет

- S3 Product Range - EnglishДокумент35 страницS3 Product Range - EnglishJuan Esteban Luque ZegarraОценок пока нет

- 09 - C - Belt Conveyor SelectionДокумент22 страницы09 - C - Belt Conveyor SelectionaldoarthoОценок пока нет

- Successful Applications Using Alternative Fuels in The Philippines - Luc ReibelДокумент25 страницSuccessful Applications Using Alternative Fuels in The Philippines - Luc Reibelnathaniel villanuevaОценок пока нет

- 5,000,000 Kilowatts of Installed ExpertiseДокумент16 страниц5,000,000 Kilowatts of Installed ExpertiseRahul RoyОценок пока нет

- Rex High Performance Chain Bucket Elevator - Manual PDFДокумент170 страницRex High Performance Chain Bucket Elevator - Manual PDFJohnОценок пока нет

- Department:Production: Cement Mill Process Control and OperationДокумент6 страницDepartment:Production: Cement Mill Process Control and OperationZegera MgendiОценок пока нет

- Packer Machine (Ia)Документ34 страницыPacker Machine (Ia)Safi'i AchmadОценок пока нет

- 01 Basic Principle and TerminologyДокумент4 страницы01 Basic Principle and TerminologyNatsuko KayamaОценок пока нет

- Bucket - elevator-ME Carlos III UДокумент9 страницBucket - elevator-ME Carlos III Ujack-bcОценок пока нет

- Chapter 9Документ37 страницChapter 9Nebiyou KorraОценок пока нет

- Material Handling SC 3.3.2019Документ43 страницыMaterial Handling SC 3.3.2019Manoy BermeoОценок пока нет

- ConveyДокумент6 страницConveyAbnetastroОценок пока нет

- Copia de Bucket and Screw ConveyorДокумент37 страницCopia de Bucket and Screw ConveyorjuandchiОценок пока нет

- Pneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshОт EverandPneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshОценок пока нет

- 747-400F Specifications - Atlas AirДокумент1 страница747-400F Specifications - Atlas AirRoel PlmrsОценок пока нет

- A.zerrouki Et El The Natural Circulation Solar Water Heater ModelДокумент11 страницA.zerrouki Et El The Natural Circulation Solar Water Heater ModelJuan-Pierre HerbothОценок пока нет

- Performance of Coffee Farmers Marketing Cooperatives in Yiragcheffe and Wonago Woredas, SNNPRS, Ethiopia PDFДокумент166 страницPerformance of Coffee Farmers Marketing Cooperatives in Yiragcheffe and Wonago Woredas, SNNPRS, Ethiopia PDFesulawyer2001Оценок пока нет

- Job and Process IДокумент19 страницJob and Process IsajjadОценок пока нет

- G11 W8 The Consequences of My ActionsДокумент3 страницыG11 W8 The Consequences of My Actionslyka garciaОценок пока нет

- As A Developing Country, Who Should Be The Primary Managers of Our National Development?Документ3 страницыAs A Developing Country, Who Should Be The Primary Managers of Our National Development?wheathering withyouОценок пока нет

- Master Formula New UpdateДокумент5 страницMaster Formula New UpdateAdhoОценок пока нет

- TextДокумент2 страницыTextArron LuОценок пока нет

- Louis Vuitton Out Let On Lines LVДокумент24 страницыLouis Vuitton Out Let On Lines LVLiu DehuaОценок пока нет

- Bou CatddДокумент2 страницыBou CatddDJОценок пока нет

- PDS Class Test 2: Let Us Establish The Pointer From Autumn Break To PDS!!!Документ26 страницPDS Class Test 2: Let Us Establish The Pointer From Autumn Break To PDS!!!Abhinaba SahaОценок пока нет

- TNC 426 TNC 430: User's Manual Conversational ProgrammingДокумент374 страницыTNC 426 TNC 430: User's Manual Conversational ProgrammingСлоба ЈовановићОценок пока нет

- Regional Memorandum: Adjusted Search Timeline Activity Date RemarksДокумент2 страницыRegional Memorandum: Adjusted Search Timeline Activity Date RemarksKimttrix WeizsОценок пока нет

- Saved-20220203 1028 25955Документ14 страницSaved-20220203 1028 25955Akshay GautamОценок пока нет

- I Used To Be A Desgin StudentДокумент256 страницI Used To Be A Desgin StudentMLОценок пока нет

- An130b6fph (2006)Документ96 страницAn130b6fph (2006)Kira FulgencioОценок пока нет

- Engineering Mechanics: StaticsДокумент44 страницыEngineering Mechanics: StaticsDaya AhmadОценок пока нет

- Siemens - Sitrans Lr200Документ192 страницыSiemens - Sitrans Lr200Jonathan Olivier Salgado NesbetОценок пока нет

- CS Training With See YesДокумент8 страницCS Training With See Yesvjkaha100% (4)

- Oil and Gas Dessertation TopicsДокумент8 страницOil and Gas Dessertation TopicsNitin SharmaОценок пока нет

- Itron Meter Data Management With MicrosoftДокумент4 страницыItron Meter Data Management With MicrosoftBernardo Mendez-aristaОценок пока нет

- Malhotra 01Документ30 страницMalhotra 01adiba10mktОценок пока нет

- Research Work08072021 01Документ41 страницаResearch Work08072021 01Mohammad AliОценок пока нет

- Stick DiagramДокумент72 страницыStick DiagramBhanu Bond0% (1)

- Risen 300-350 WP MonoДокумент2 страницыRisen 300-350 WP MonoAgoesPermanaОценок пока нет

- Quaid-e-Azam (Rahmatullah) Said Very Clearly That The Rights of The - Will Be Fully Protected in PakistanДокумент7 страницQuaid-e-Azam (Rahmatullah) Said Very Clearly That The Rights of The - Will Be Fully Protected in PakistanAmna ShahzadОценок пока нет

- MetricsДокумент50 страницMetricsArjun VaranasiОценок пока нет

- Hose Reel System For Primary School at Alor Setar KedahДокумент6 страницHose Reel System For Primary School at Alor Setar KedahSyafiqah ShahuriОценок пока нет

- Audit Quality and Audit Firm ReputationДокумент10 страницAudit Quality and Audit Firm ReputationEdosa Joshua AronmwanОценок пока нет

- FOREX 101: Nancy C. Batalon XM AffiliateДокумент24 страницыFOREX 101: Nancy C. Batalon XM AffiliateNancy BatalonОценок пока нет