Академический Документы

Профессиональный Документы

Культура Документы

DD60-08 Watts Air Dryer Dessicant Dryer

Загружено:

MROstop.comИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

DD60-08 Watts Air Dryer Dessicant Dryer

Загружено:

MROstop.comАвторское право:

Доступные форматы

Air Preparation Systems

1/4", 3/8", 1/2", 3/4", 1"

Catalog 0722

Inline Desiccant Dryers DD Series

DD Inline Desiccant Dryers

Features

n

A

D

These Inline Desiccant Dryers are a

Convenient and Cost Effective Means

of Ensuring Your Sensitive Pneumatic

Applications are Never Exposed to

Damaging Moisture.

Compact Size for Point-Of-Use

Applications.

Drying Efficiency Down to -40F Pressure

Dew Point.

Easily and Quickly Serviced.

Sightglass in Bowl to Monitor Desiccant.

Built-In Particulate After Filter Prevents

Downstream Dust.

No Electricity Needed.

Low Pressure Drop.

No Purge Air Lost as with Other Dryer

Types.

DD15-03

Dimensions

Performance

The rated flow capacities are nominal ratings provided for

reference. These capacities are recommended for minimal

pressure drop and average desiccant life. A supply of low

flow / low humidity air will provide longer desiccant life:

whereas, high flow / high humidity air will require more

frequent desiccant changes. Installed in an application

with intermittent flow, these desiccant dryers will typically

dry air for weeks before the silica gel desiccant requires

replacement or regeneration.

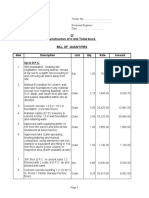

Model

Number

D*

DD15

4.94

(125)

12.69

(322)

.84

(21)

4.06

(103)

13.5

(343)

DD30

4.94

(125)

22.44

(570)

.84

(21)

4.06

(103)

23.25

(591)

DD60

4.94

(125)

29.44

(748)

.84

(21)

4.06

(103)

30.25

(768)

* Dimension does not include reducer bushings for 1/4", 3/8", 1/2" versions.

Inches (mm)

Model Selection

Applications

Port Size

15 SCFM

30 SCFM

60 SCFM

Desiccant

Capacity

2.5 lb

5 lb.

10 lb.

1/4"

DD15-02

N/A

N/A

3/8"

DD15-03

N/A

N/A

1/2"

DD15-04

DD30-04

DD60-04

3/4"

DD15-06

DD30-06

DD60-06

1"

N/A

DD30-08

DD60-08

n Paint

Spraying

n Instrument

Air

n Laboratory

Instruments

n Control

n Air

Air Systems

Blanketing

Notes:

1. Desiccant must be ordered separately.

2.These units supplied with reducer bushings.

20

Parker Hannifin Corporation

Pneumatic Division

Richland, Michigan

www.parker.com/pneumatics

Air Preparation Systems

Inline Desiccant Dryers

Catalog 0722

Technical Specifications DD Series

Installation Tips

As the wet compressed air enters through the inlet, the air

travels down through the bed of desiccant which adsorb the

water vapor and aerosols. The silica gel desiccant beads

will reduce the humidity down to a -40F pressure dew point.

After the moisture has been removed, the dry air passes

through a sintered bronze filter element (eliminating dust

downstream), up the tube and out the outlet port.

As the desiccant becomes saturated with moisture, the

dew point will begin to rise. This is evident when the blue

silica gel desiccant beads in the sight glass change to pink,

indicating the need for desiccant replacement. Simply

remove the flange and bowl and replace with new desiccant

or regenerate saturated desiccant by heating to 275F.

Wet Air In

Always place a moisture separator / particulate filter to

remove bulk moisture and a coalescing filter to remove oil

upstream of desiccant dryer. Desiccant coated with oil will

not adsorb oil.

Automatic drains should be used in prefilters

A spring ball check valve should be installed at the dryer

inlet to maximize the life of the desiccant.

Compressor Room

Air Preparation Equipment

Point-Of-Use

Air Preparation Equipment

Dry Air Out

Quick Remove

Flange

Check

Valve

Aftercooler

Compressor

Particulate Coalescing

Filter

Filter

Bulk Liquid

Separator

Blue Silica Gel

Desiccant

Desiccant

Dryer

Sight Glass

Desiccant Dryers Kits & Accessories

Filter Element Rating

DD15, DD30......................................................................90 micron

DD60.................................................................................40 micron

Desiccant - Environmentally Friendly Silica Gel

100% Indicating

DD15......................................................................DRP-14-447/003

DD30......................................................................DRP-14-447/006

DD60......................................................................DRP-14-447/012

Pressure & Temperature Ratings

Optimum working temperature ................................... Below 100 F

Pressure Range......................................................... 0 to 300 PSIG

Temperature Range.................................................... 32F to 180F

Flow Tube Repair Kit (Tube, Filter Element(s), Adaptor)

DD15........................................................................ RKDD15-02-06

DD30........................................................................ RKDD30-03-08

DD60........................................................................ RKDD60-03-08

Weight (Housing Only)

DD15 (add 2.5 lb for weight full).................................... 8 lb. (3.6 kg)

DD30 (add 5 lb for weight full)..................................... 13 lb. (5.9 kg)

DD60 (add 10 lb for weight full)................................... 20 lb. (9.1 kg)

Mounting Brackets (Recommended for DD15 & DD30 only)

1/4 Inch Pipe Size (Pair of Pipe Mounted Brackets)..... SA200YW57

1 Inch Pipe Size (Pair of Pipe Mounted Brackets)........SA200CW57

Materials of Construction

Bowl

DD15, DD30......................................................................Aluminum

DD60........................................................................................ Steel

Spring Check Valve for Inlet (250 PSIG max.)

(Maximizes Life of Desiccant)

1/4 Inch NPT...................................................................003393001

3/8 Inch NPT...................................................................003393002

1/2 Inch NPT...................................................................003393003

3/4 Inch NPT...................................................................003393004

Flow Tube ..................................................................................CPVC

Filter Elements . ........................................................Sintered Bronze

Head & Flange Ring ....................................................................Zinc

Specifications

Other Hardware . ....................................................................... Brass

Desiccant Capacity (Desiccant must be ordered separately)

DD15....................................................................................... 2.5 lb.

DD30.......................................................................................... 5 lb.

DD60........................................................................................ 10 lb.

Seals ....................................................................................... Buna-N

Sight Glass . ..................................................................Glass & Steel

21

Parker Hannifin Corporation

Pneumatic Division

Richland, Michigan

www.parker.com/pneumatics

Вам также может понравиться

- Quotation - RefrigDryer D600IN-A To D5400IN-AДокумент9 страницQuotation - RefrigDryer D600IN-A To D5400IN-Abiberius100% (1)

- Quality Air Solutions: Heatless Desiccant Dryers OverviewДокумент31 страницаQuality Air Solutions: Heatless Desiccant Dryers OverviewMohamad BahrodinОценок пока нет

- How Industrial Businesses Can Reduce Production Costs With Reverse Osmosis: Industrial Reverse OsmosisОт EverandHow Industrial Businesses Can Reduce Production Costs With Reverse Osmosis: Industrial Reverse OsmosisРейтинг: 5 из 5 звезд5/5 (1)

- MRO Stop Industrial Supply LinecardДокумент2 страницыMRO Stop Industrial Supply LinecardMROstop.comОценок пока нет

- MRO Stop Industrial Fastener CatalogДокумент53 страницыMRO Stop Industrial Fastener CatalogMROstop.comОценок пока нет

- LR Format 1.2Документ1 страницаLR Format 1.2Ch.Suresh SuryaОценок пока нет

- Qualifi Level 6 Diploma in Occupational Health and Safety Management Specification October 2019Документ23 страницыQualifi Level 6 Diploma in Occupational Health and Safety Management Specification October 2019Saqlain Siddiquie100% (1)

- Dehumidifier SizeДокумент2 страницыDehumidifier SizeSouradeep PaulОценок пока нет

- Membrane DryerДокумент4 страницыMembrane DryerMuhammad SaifОценок пока нет

- BD+ CD+ XD+ - tcm833-3534072Документ20 страницBD+ CD+ XD+ - tcm833-3534072MisterMMОценок пока нет

- Sullair - Air Treatment BrochureДокумент19 страницSullair - Air Treatment BrochureJosi ElizeteОценок пока нет

- Atlas CopcoДокумент9 страницAtlas Copcojrsdve100% (1)

- At ThermostarДокумент8 страницAt ThermostarLam Ch100% (1)

- Atlas Copco MD Dryer Brochure 2Документ12 страницAtlas Copco MD Dryer Brochure 2MistysParts100% (1)

- Filters Ingersoll-RandДокумент4 страницыFilters Ingersoll-RandAnonymous bcdUbxoОценок пока нет

- DGHДокумент8 страницDGHEdison F Montaluisa100% (1)

- Drying Your Compressed Air System Will Save Real MoneyДокумент4 страницыDrying Your Compressed Air System Will Save Real Moneyjoe_pulaskiОценок пока нет

- Air DryersДокумент4 страницыAir Dryersmanpreetsodhi08Оценок пока нет

- Deno Air Dryer Manual SD210 16757Документ58 страницDeno Air Dryer Manual SD210 16757ImmorthalОценок пока нет

- FD Dryers CatalogДокумент13 страницFD Dryers CatalogmasrooorОценок пока нет

- Arrow Neumatic Filtering SystemsДокумент135 страницArrow Neumatic Filtering SystemsDavidRiveraОценок пока нет

- Liquid Filter AircondДокумент16 страницLiquid Filter AircondMuhammad Zulhelmi Zawawi100% (1)

- Total Quality Air Package: Atlas CopcoДокумент8 страницTotal Quality Air Package: Atlas CopcoCastillo PercyОценок пока нет

- Lasting Values: Desiccant Compressed Air DryersДокумент6 страницLasting Values: Desiccant Compressed Air DryersBhavesh PatelОценок пока нет

- TZДокумент8 страницTZSaku-Jessy CamposОценок пока нет

- Sullair Compressed Air Filtration and Mist EliminatorsДокумент12 страницSullair Compressed Air Filtration and Mist EliminatorsganiablachimОценок пока нет

- Desiccant DryerДокумент1 страницаDesiccant DryerKASHIFОценок пока нет

- CAGI Article Types of Compressed Air DryersДокумент5 страницCAGI Article Types of Compressed Air DryersHalima LAARARIОценок пока нет

- Брошюра - Осушители Bd100-3000Документ8 страницБрошюра - Осушители Bd100-3000airpartОценок пока нет

- Basics - Dew Point Measurement - P60 P63 PDFДокумент4 страницыBasics - Dew Point Measurement - P60 P63 PDFAnonymous o38k1iEKFОценок пока нет

- Donaldson CoolerДокумент4 страницыDonaldson CoolerabuahnfОценок пока нет

- Dal Am A TicДокумент12 страницDal Am A TicMiguelAngelDavilaОценок пока нет

- Engineering Bulletin CDQ Desiccant DehumidificationДокумент28 страницEngineering Bulletin CDQ Desiccant DehumidificationsdvitkoОценок пока нет

- Desiccant Regenerative Dryers: 3-10,000 SCFMДокумент12 страницDesiccant Regenerative Dryers: 3-10,000 SCFMarifОценок пока нет

- Air Drying ProcessДокумент2 страницыAir Drying Processmarcoo8Оценок пока нет

- DcamanualДокумент21 страницаDcamanualClaire ApapОценок пока нет

- Air DryerДокумент20 страницAir DryerINDEPENDENTLINENОценок пока нет

- FDbrochureДокумент13 страницFDbrochureAyman Mohammed Ibrahim AbdouОценок пока нет

- Suburban Filter Dryer: User Manual Installation InstructionsДокумент8 страницSuburban Filter Dryer: User Manual Installation InstructionsMistysPartsОценок пока нет

- ZR 75 160 VSD Plus Sales Leaflet en AntwerpДокумент24 страницыZR 75 160 VSD Plus Sales Leaflet en AntwerpVijay - Spantech EngineersОценок пока нет

- Dryer DW - OptДокумент6 страницDryer DW - OptVolodymyrОценок пока нет

- Compressed Air Treatment, Drier and StorageДокумент24 страницыCompressed Air Treatment, Drier and StorageAna PrisacariuОценок пока нет

- Plant CommissioningДокумент12 страницPlant CommissioningMuhammad ImranОценок пока нет

- Keller VDN VenturiДокумент8 страницKeller VDN Venturijpdavila205Оценок пока нет

- Air DryersДокумент2 страницыAir DryersAnnas FauzyОценок пока нет

- Compressed Air Filters PDFДокумент70 страницCompressed Air Filters PDFdj22500Оценок пока нет

- Брошюра - Осушители BdДокумент12 страницБрошюра - Осушители Bdairpart100% (1)

- Atlas Copco: Quality Air Solutions Compressed Air FiltersДокумент12 страницAtlas Copco: Quality Air Solutions Compressed Air Filtersbetraial100% (1)

- Adsorption Dryer CatalogueДокумент8 страницAdsorption Dryer CatalogueAmirArmanОценок пока нет

- Can Moisture Damage My Compressed Air SystemДокумент5 страницCan Moisture Damage My Compressed Air SystemRam RanjanОценок пока нет

- TS Refrigerated Dryer Brochure - A4Документ4 страницыTS Refrigerated Dryer Brochure - A4Yashiro AlvaradoОценок пока нет

- HRD Heatless Regenerative Desiccant Air DryerДокумент3 страницыHRD Heatless Regenerative Desiccant Air DryerMUHAMMAD WaqarОценок пока нет

- Operating & Instructions: ManualДокумент20 страницOperating & Instructions: ManualjujuroyaleОценок пока нет

- RAF Baghouse Filter MikropulДокумент4 страницыRAF Baghouse Filter MikropulCharik JainОценок пока нет

- The Smart Way To Dry Air: BOGE Absorption Dryer D 20 AДокумент2 страницыThe Smart Way To Dry Air: BOGE Absorption Dryer D 20 AAir Repair, LLCОценок пока нет

- GRACO King 45-1 PartsДокумент10 страницGRACO King 45-1 Partssamgivp2869Оценок пока нет

- Refrig Dryers - High Inlet Temperature Dryers D25IT-A To D170IT-AДокумент2 страницыRefrig Dryers - High Inlet Temperature Dryers D25IT-A To D170IT-AChanОценок пока нет

- Hankison H-Unit March06Документ40 страницHankison H-Unit March06SAUL OSPINOОценок пока нет

- Air Dryer ManualДокумент12 страницAir Dryer ManualNIHAR BEHERAОценок пока нет

- MD DryerДокумент5 страницMD DryerSovan NandyОценок пока нет

- Condensate Management: OWS Series CS SeriesДокумент4 страницыCondensate Management: OWS Series CS SeriesEthan HuntОценок пока нет

- Ingersoll Rand Desiccant DryersДокумент12 страницIngersoll Rand Desiccant DryersAnonymous Jd6v1D6rОценок пока нет

- Gosol Solar Power BoxДокумент2 страницыGosol Solar Power BoxMROstop.comОценок пока нет

- MROStop 2015 LineCardДокумент2 страницыMROStop 2015 LineCardMROstop.comОценок пока нет

- Parker Industrial Hose Catalog 4800Документ258 страницParker Industrial Hose Catalog 4800MROstop.comОценок пока нет

- Parker Hose Fittings Equipment 4400 CatalogДокумент418 страницParker Hose Fittings Equipment 4400 CatalogMROstop.comОценок пока нет

- Mitsubishi FR-V500L VFD Instruction Manual-BasicДокумент114 страницMitsubishi FR-V500L VFD Instruction Manual-BasicMROstop.comОценок пока нет

- Mitsubishi D700 VFD POCKET - GUIDE - 2009-03Документ2 страницыMitsubishi D700 VFD POCKET - GUIDE - 2009-03MROstop.comОценок пока нет

- PowerFilm Solar Energy Product LineДокумент9 страницPowerFilm Solar Energy Product LineMROstop.comОценок пока нет

- Mitsubishi v500 VFD Instruction ManualДокумент119 страницMitsubishi v500 VFD Instruction ManualMROstop.com100% (1)

- A700 Pocket Guide 2006-05Документ8 страницA700 Pocket Guide 2006-05TetsusaigaОценок пока нет

- Mitsubishi F700 VFD Instruction Manual-Basic-Japanese DomesticДокумент147 страницMitsubishi F700 VFD Instruction Manual-Basic-Japanese DomesticMROstop.comОценок пока нет

- A700 Pocket Guide 2006-05Документ8 страницA700 Pocket Guide 2006-05TetsusaigaОценок пока нет

- Mitsubishi v500 VFD Brochure UpdatedДокумент12 страницMitsubishi v500 VFD Brochure UpdatedMROstop.comОценок пока нет

- Mitsubishi F700 VFD Instruction Manual-BasicДокумент149 страницMitsubishi F700 VFD Instruction Manual-BasicMROstop.comОценок пока нет

- Mitsubishi v500 VFD IB NA 0600134E-A FR-V560 Instruction Manaul-BasicДокумент123 страницыMitsubishi v500 VFD IB NA 0600134E-A FR-V560 Instruction Manaul-BasicMROstop.comОценок пока нет

- Mitsubishi v500 VFD IB NA 0600135E-A FR-V560 Instruction Manaul-DetailedДокумент243 страницыMitsubishi v500 VFD IB NA 0600135E-A FR-V560 Instruction Manaul-DetailedMROstop.comОценок пока нет

- Mitsubishi F700 VFD Installation GuidelineДокумент29 страницMitsubishi F700 VFD Installation GuidelineMROstop.com100% (1)

- Mitsubishi v500 VFD Instruction ManualДокумент119 страницMitsubishi v500 VFD Instruction ManualMROstop.com100% (1)

- Mitsubishi v500 VFD IB NA 0600065-F FR-V500-NA Instruction Manual-DetailedДокумент221 страницаMitsubishi v500 VFD IB NA 0600065-F FR-V500-NA Instruction Manual-DetailedMROstop.comОценок пока нет

- Mitsubishi F700 Series VFD ManualДокумент309 страницMitsubishi F700 Series VFD ManualMROstop.comОценок пока нет

- Mitsubishi F700 VFD Instruction Manual-BasicДокумент142 страницыMitsubishi F700 VFD Instruction Manual-BasicMROstop.com0% (1)

- Mitsubishi F700 VFD Manual-Applied-Japanese DomesticДокумент303 страницыMitsubishi F700 VFD Manual-Applied-Japanese DomesticMROstop.comОценок пока нет

- IB NA 0600131-C FR-V500L Instruction Manual-DetailedДокумент231 страницаIB NA 0600131-C FR-V500L Instruction Manual-DetailedMROstop.comОценок пока нет

- Mitsubishi F700 VFD Instruction Manual-AppliedДокумент327 страницMitsubishi F700 VFD Instruction Manual-AppliedMROstop.com100% (1)

- Mitsubishi F700 VFD Quick Reference GuideДокумент18 страницMitsubishi F700 VFD Quick Reference GuideMROstop.comОценок пока нет

- Mitsubishi F700 VFD Single Phase Input InformationДокумент2 страницыMitsubishi F700 VFD Single Phase Input InformationMROstop.comОценок пока нет

- Mitsubishi F700 VFD Dimensional DrawingsДокумент6 страницMitsubishi F700 VFD Dimensional DrawingsMROstop.comОценок пока нет

- Mitsubishi F700 VFD Rating SystemДокумент2 страницыMitsubishi F700 VFD Rating SystemMROstop.comОценок пока нет

- F700 Pocket Guide 2006-05Документ8 страницF700 Pocket Guide 2006-05TetsusaigaОценок пока нет

- 1 075 Syn4e PDFДокумент2 страницы1 075 Syn4e PDFSalvador FayssalОценок пока нет

- Type BOQ For Construction of 4 Units Toilet Drawing No.04Документ6 страницType BOQ For Construction of 4 Units Toilet Drawing No.04Yashika Bhathiya JayasingheОценок пока нет

- RODECaster Pro II - DataSheet - V01 - 4Документ1 страницаRODECaster Pro II - DataSheet - V01 - 4lazlosОценок пока нет

- CPM W1.1Документ19 страницCPM W1.1HARIJITH K SОценок пока нет

- Dunham Bush Midwall Split R410a InverterДокумент2 страницыDunham Bush Midwall Split R410a InverterAgnaldo Caetano100% (1)

- Land Degradetion NarmДокумент15 страницLand Degradetion NarmAbdikafar Adan AbdullahiОценок пока нет

- Marshall Baillieu: Ian Marshall Baillieu (Born 6 June 1937) Is A Former AustralianДокумент3 страницыMarshall Baillieu: Ian Marshall Baillieu (Born 6 June 1937) Is A Former AustralianValenVidelaОценок пока нет

- Spine Beam - SCHEME 4Документ28 страницSpine Beam - SCHEME 4Edi ObrayanОценок пока нет

- Pyro ShieldДокумент6 страницPyro Shieldmunim87Оценок пока нет

- Consultancy Services For The Feasibility Study of A Second Runway at SSR International AirportДокумент6 страницConsultancy Services For The Feasibility Study of A Second Runway at SSR International AirportNitish RamdaworОценок пока нет

- Database Management System and SQL CommandsДокумент3 страницыDatabase Management System and SQL Commandsdev guptaОценок пока нет

- Dreamfoil Creations & Nemeth DesignsДокумент22 страницыDreamfoil Creations & Nemeth DesignsManoel ValentimОценок пока нет

- Adjectives With Cork English TeacherДокумент19 страницAdjectives With Cork English TeacherAlisa PichkoОценок пока нет

- Sigma Valve 2-WayДокумент2 страницыSigma Valve 2-WayRahimОценок пока нет

- Vylto Seed DeckДокумент17 страницVylto Seed DeckBear MatthewsОценок пока нет

- A Perspective Study On Fly Ash-Lime-Gypsum Bricks and Hollow Blocks For Low Cost Housing DevelopmentДокумент7 страницA Perspective Study On Fly Ash-Lime-Gypsum Bricks and Hollow Blocks For Low Cost Housing DevelopmentNadiah AUlia SalihiОценок пока нет

- Fast Binary Counters and Compressors Generated by Sorting NetworkДокумент11 страницFast Binary Counters and Compressors Generated by Sorting Networkpsathishkumar1232544Оценок пока нет

- 1 s2.0 S0304389421026054 MainДокумент24 страницы1 s2.0 S0304389421026054 MainFarah TalibОценок пока нет

- How To Attain Success Through The Strength of The Vibration of NumbersДокумент95 страницHow To Attain Success Through The Strength of The Vibration of NumberszahkulОценок пока нет

- National Senior Certificate: Grade 12Документ13 страницNational Senior Certificate: Grade 12Marco Carminé SpidalieriОценок пока нет

- Catalog enДокумент292 страницыCatalog enSella KumarОценок пока нет

- Faida WTP - Control PhilosophyДокумент19 страницFaida WTP - Control PhilosophyDelshad DuhokiОценок пока нет

- Safety Inspection Checklist Project: Location: Inspector: DateДокумент2 страницыSafety Inspection Checklist Project: Location: Inspector: Dateyono DaryonoОценок пока нет

- Government of India Act 1858Документ3 страницыGovernment of India Act 1858AlexitoОценок пока нет

- Man Machine Interface SafetyДокумент9 страницMan Machine Interface SafetyVidyesh Viswanathan NairОценок пока нет

- The April Fair in Seville: Word FormationДокумент2 страницыThe April Fair in Seville: Word FormationДархан МакыжанОценок пока нет

- Enumerator ResumeДокумент1 страницаEnumerator Resumesaid mohamudОценок пока нет

- Si KaДокумент12 страницSi KanasmineОценок пока нет