Академический Документы

Профессиональный Документы

Культура Документы

MP Steam Boiler Package Familiarisation - Attachment 1

Загружено:

simba8661Исходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

MP Steam Boiler Package Familiarisation - Attachment 1

Загружено:

simba8661Авторское право:

Доступные форматы

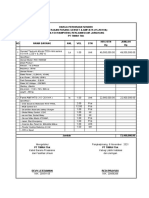

PETROFAC - GS JV RUWAIS 4TH NGL TRAIN

RUWAIS, UAE Gallarate - Italy Basic Engineering DEPT N 5 TITAN M 180 t/h, 30 barg, 355C

Doc No. Rev. Date

1015-C-310 2 05/12/2011

BOILER DATA SHEET

Boiler type: Circulation: Arrangement: Number of burners: Burners type: Fuels: Firing: HRSG type: Recovery: Desuperheater type: 2 Pressure parts materials: Calculation code: TITAN M - Bidrum - Bottom supported - TAG 7V-454 A/B/C/D/E Natural circulation Horizontal 3 Macchi Low NOx burners - MHM type Fuel Gas Lean Gas/Deo Gas Single Firing Not Applicable External economizer finned type Interstage - Injection type U.N.I. AFNOR Performance test code: ASME PTC 4-2000 ASME PTC 4.4 E.N. A.S.T.M. ASME With Stamp T.R.D. ASME PTC 4.1(Abbreviated Test) D.I.N. 1942 A.S.M.E. D.I.N. ISPESL P.E.D. ASME PTC 4 N.F.E. ASME Without Stamp

MAIN DESIGN DATA Steam capacity at MCR Superheated steam temp. at B/L Steam pressure at B/L Boiler feed water temperature Boiler efficiency on LHV at MCR Steam temperature control range Boiler automatic control range Boiler design pressure Superheater design pressure Economizer design pressure Start-Up vent capacity design 25%MCR Load variation Blow down flow @1% Blow down design flow @ 5% [2] [3] [4] [1] : : : : : : : : : : : : : : 180000 355(+5 ) /-0 30 110/149 90 25110 25110 41 41 41 45000 15 1800 9000 kg/h C barg C % % MCR barg barg barg kg/h % / min kg/h kg/h COILS HEATING SURFACE Indicated quantities are for 1 ( one ) boiler SECTION Final Superheater Primary Superheater Boiler Bank #1 Boiler Bank #2 Economizer Tubes per row 10 9 17 17 26 Tubes deep 10 10 34 33 10 Tubes 60 54 578 561 260

Pitch [mm] Out. Diam. long.

Boiler heating surface

Total heating surf. (including SH + ECO)

: : : : : : : : : : [5] :

1886 4517 74,8 62,0 1,8 1,7 2,6 264,4 342,00 8000 46,0

m2 m2 m3 m3 m3 m3 m3 m2 m3 mm barg

Total water volume Water volume at normal level Volume of final superheater Volume of primary superheater E.P.R.S. geometrical Furnace volume Drums centerline Boiler feedwater pressure

% MCR Volume of economizer

thk [mm] 3,6 3,6 3,6 3,6 3,6

in parall. tr.

[mm] 50,8 50,8 63,5 63,5 50,8

Exchang. Length [m] 5,85 5,85 6,53 6,53 6,00

Fins type solid

Fins/m 157

Fins [mm] Surface h thk [m2] 180 162 752 730 2289

103 101 103 101 120 100 120 100 100 102

19 1,25

Sheet

of

13

PETROFAC - GS JV RUWAIS 4TH NGL TRAIN

RUWAIS, UAE Gallarate - Italy Basic Engineering DEPT N 5 TITAN M 180 t/h, 30 barg, 355 C

Doc No. Rev. Date

1015-C-310 2 05/12/2011

BOILER DATA SHEET

BOILER TUBES - MEMBRANED WALLS Indicated quantities are for 1 ( one ) boiler FURNACE Depth Volume 10443 342 mm m3 889 Width E.P.R.S. Pitch Description [mm] TUBES "D" wall Side wall Front wall Rear wall HEADERS Front wall header Rear wall header RISERS AND FEEDERS Risers Feeders [9] 4350 4000 76,1 76,1 4 4 1,0 1,0 26 20 SA 210 Gr. A1 SA 210 Gr. A1 41 41 276 276 88,5 88,5 88,5 88,5 [11] 4625 4625 219,1 219,1 18,26 18,26 3,2 3,2 2 2 SA 106 Gr. B SA 106 Gr. B 41,0 41,0 276 276 16500 7765 8050 8050 63,5 63,5 63,5 63,5 3,6 3,6 3,6 3,6 1,0 1,0 1,0 1,0 117 98 43 51 SA 210 Gr. A1 SA 210 Gr. A1 SA 210 Gr. A1 SA 210 Gr. A1 41,0 41,0 41,0 41,0 385 385 385 385 4513,5 264,4 Avg. length [mm] [7] mm m2 Outside diam. [mm] [mm] Avg. height Heat transf. Surf. 508 Thick. mmH2O Corrosion Number allowance of tubes [mm] Material Design pressure [barg] Design temp. [ C] [8] [6] 7130 280,8 mm m2 Outlet width Outlet height 1593 7175 mm mm

Design pressure

mmH2O Test pressure

BOILER BANK SIDE WALLS Depth Volume 10443 147 mm m3 Width E.P.R.S. Pitch Description [mm] TUBES Side wall Double side wall SH Front Wall Screen [10] 88,5 100 120 354/100 8050 7667 7000 7500 63,5 76,1 76,1 63,5 3,6 4 4 3,6 1,0 1,0 1,0 1 111 26 17 6 SA 210 Gr. A1 SA 210 Gr. A1 SA 210 Gr. A1 SA 210 Gr. A1 41 41 41 41 385 385 385 385 2160 140 Avg. length [mm] mm m2 Outside diam. [mm] [mm] Avg. height Heat transf. Surf. Thick. 6525 147,1 mm m2 Design Material pressure [barg] Design temp. [ C]

Corrosion Number allowance of tubes [mm]

Sheet

of

13

PETROFAC - GS JV RUWAIS 4TH NGL TRAIN

RUWAIS, UAE Gallarate - Italy Basic Engineering DEPT N 5 TITAN M 180 t/h, 30 barg, 355 C

Doc No. Rev. Date

1015-C-310 2 05/12/2011

BOILER DATA SHEET

BOILER TUBES - SUPERHEATER Indicated quantities are for 1 ( one ) boiler

FINAL SUPERHEATER

Arrangement Tubes per row In line 10 Number of rows Pitch Description TUBES SH tubes 103 96 9400 [11] 1061,5 1061,5 400 300 355,6 355,6 355,6 355,6 23,83 23,83 27,79 27,79 3,2 3,2 3,2 3,2 1 1 1 1 SA 335 Gr. P11 SA 335 Gr. P11 SA 335 Gr. P11 SA 335 Gr. P11 41 41 41 41 352 385 352 385 50,8 3,6 1,3 120 SA 213 Gr. T22 41 490 tr. long [mm] Avg. length [mm] [7] Staggered 10 Flow Outside diam. [mm] [mm] Thick. Parallel 60 Corrosion Number allowance of tubes [mm] Material Counter Avg. exchanging height Cross 5850 Design pressure [barg] mm Design temp. [ C] [8] Tubes in parallel

HEADERS / NOZZLES / JUMPERS Inlet header Outlet header 1 Inlet Nozzle 1 Outlet Nozzle

INLET HEADER Saturated steam diaphragm Superheated steam to DSH OUTLET HEADER Superheated steam from DSH

Superheated steam outlet to BL

refractory

INLET HEADER OUTLET HEADER

Tubes to be protected

Sheet

of

13

PETROFAC - GS JV RUWAIS 4TH NGL TRAIN

RUWAIS, UAE Gallarate - Italy Basic Engineering DEPT N 5 TITAN M 180 t/h, 30 barg, 355 C

Doc No. Rev. Date

1015-C-310 2 05/12/11

BOILER DATA SHEET

BOILER TUBES - SUPERHEATER Indicated quantities are for 1 ( one ) boiler

PRIMARY SUPERHEATER

Arrangement Tubes per row In line 9 Number of rows Pitch tr. long [mm] TUBES SH tubes 103 96 9400 [11] 1010 1010 400 750 355,6 355,6 355,6 355,6 23,83 23,83 27,79 27,79 3,2 3,2 3,2 3,2 1 1 1 1 SA 335 Gr. P11 SA 335 Gr. P11 SA 335 Gr. P11 SA 335 Gr. P11 41 41 41 41 352 385 352 385 50,8 3,6 1,3 108 SA 213 Gr. T22 41 465 Avg. length [mm] [7] Staggered 10 Flow Outside diam. [mm] Thick. [mm] Parallel 54 Corrosion Number allowance of tubes [mm] Counter Avg. exchanging height Material Cross 5850 Design pressure [barg] mm Design temp. [ C] [8] Tubes in parallel

Description

HEADERS / NOZZLES / JUMPERS Inlet header Outlet header 1 Inlet Nozzle 1 Outlet Nozzle

FURNACE

PRIMARY SUPERHEATER

FINAL SUPERHEATER

BOILER BANK #1

Sheet

of

13

PETROFAC - GS JV RUWAIS 4TH NGL TRAIN

RUWAIS, UAE Gallarate - Italy Basic Engineering DEPT N 5 TITAN M 180 t/h, 30 barg, 355 C

Doc No. Rev. Date

1015-C-310 2 05/12/2011

BOILER DATA SHEET

BOILER TUBES - EVAPORATOR Indicated quantities are for 1 ( one ) boiler

BOILER BANK #1

Arrangement 1 Tubes per row 17 In line Number of rows Pitch Description TUBES Tubes 120 100 7000 63,5 3,6 1,0 578 SA 210 Gr. A1 41 385 tr. long [mm] Staggered 34 Avg. length [mm] [7] Tubes in parallel Outside diam. [mm] [mm] Thick. 578 Avg. exchanging length Material 6525 Design pressure [barg] mm Design temp. [ C] [8] Corrosion Number allowance of tubes [mm]

BOILER BANK #2

Arrangement 1 Tubes per row 17 In line Number of rows Pitch Description TUBES Tubes 120 100 7000 63,5 3,6 1,0 561 SA 210 Gr. A1 41 385 tr. long [mm] Staggered 33 Avg. length [mm] Tubes in parallel Outside diam. [mm] [mm] Thick. 561 Avg. exchanging length Material 6525 Design pressure [barg] mm Design temp. [ C] [8] Corrosion Number allowance of tubes [mm]

Sheet

of

13

PETROFAC - GS JV RUWAIS 4TH NGL TRAIN

RUWAIS, UAE Gallarate - Italy Basic Engineering DEPT N 5 TITAN M 180 t/h, 30 barg, 355 C

Doc No. Rev. Date

1015-C-310 2 05/12/2011

BOILER DATA SHEET

BOILER TUBES - ECONOMIZER Indicated quantities are for 1 ( one ) boiler

ECONOMIZER

Arrangement Tubes per row In line 26 Number of rows Pitch Description TUBES Tubes 100 102 6150 [11] 2950 2950 219,1 219,1 15,09 15,09 3,2 3,2 1 1 SA 106 Gr. B SA 106 Gr. B 41 41 276 276 50,8 3,6 1,0 260 SA 210 Gr. A1 41 385 tr. long [mm] Avg. length [mm] [7] Staggered 10 Flow Outside diam. [mm] [mm] Thick. Parallel 26 Corrosion Number allowance of tubes [mm] Material Counter Avg. exchanging length Cross 5997 Design pressure [barg] mm Design temp. [ C] [8] Tubes in parallel

HEADERS / NOZZLES / JUMPERS Inlet header Outlet header

FINS Finned Description Type length [mm] Tubes

solid

Fins x meter [fins/m] 157

Height [mm] 19

Thick. [mm] 1,25

Segment Material [23] [mm] EN 10130 DC04

Max Fin Temperature [ C] 454

5997

Sheet

of

13

PETROFAC - GS JV RUWAIS 4TH NGL TRAIN

RUWAIS, UAE Gallarate - Italy Basic Engineering DEPT N 5 TITAN M 180 t/h, 30 barg, 355 C

Doc No. Rev. Date

1015-C-310 2 05/12/2011

BOILER DATA SHEET

PRESSURE PARTS Indicated quantities are for 1 ( one ) boiler

STEAM DRUM

Outside diameter Shell thickness Cylindrical length Corr. allowance Shell material Levels from centerline High-High level High level Normal level Low level Low-Low level Internal details Cyclones number 42 Dryers number 30 Dryers type 6 [14] 200 100 0 -150 -300 mm mm mm mm mm 1800 60 11000 3,2 mm mm mm mm Heads type Heads outside diam. Heads thickness Heads corr. allow. Heads material Water volumes Full of water High-High level High level Normal level Low level Low-Low level 25,63 16,7 14,8 12,8 9,9 7,1 Spherical 1800 55 3,2

[12] Manhole mm mm mm Hold up m3 m3 m3 m3 m3 m3 From HL to HHL From NL to HL From NL to LL From LL to LLL [14] From NL to HHL Form NL to LLL 31,2 31,8 47,5 46 63 93,3 257x762x313 sec sec sec sec sec sec mm Design pressure Design temperature [13] 20"x24" inch 41 253+25 barg C

SA 516 Gr. 70

SA 516 Gr. 70

Dryers dimensions HxLxW

WATER DRUM

Outside diameter Shell thickness Cylindrical length Corr. allowance Shell material 1150 45 11000 3,2 mm mm mm mm Heads type Heads outside diam. Heads thickness Heads corr. allow. Heads material Spherical 1150 35 3,2 mm mm mm Manhole Design pressure Design temperature [13] 16"x20" inch 41 253+25 barg C

SA 516 Gr. 70

SA 516 Gr. 70

SAFETY VALVES Set Description Number pressure [barg] Superheater Steam drum Steam drum 1 1 1 34,5 41,0 42,0 Over pressure [%] 3 3 3 Blow down pressure [%] 4 4 4 Spring Loaded Spring Loaded Spring Loaded Total [15] Type Capacity [t/h] 52,00 78,00 78,00 208,0 [%] 25 37,5 37,5 100

Sheet

of

13

PETROFAC - GS JV RUWAIS 4TH NGL TRAIN

RUWAIS, UAE Gallarate - Italy Basic Engineering DEPT N 5 TITAN M 180 t/h, 30 barg, 355 C

Doc No. Rev. Date

1015-C-310 2 05/12/2011

BOILER DATA SHEET

BURNERS Indicated quantities are for 1 ( one ) boiler FUELS: Burners duty at Burners duty at Burners duty at Burners duty at Burners turn-down Single Burner Design 56 100 110 81 25 %MCR %MCR %MCR %MCR 1 : Fuel Gas/Lean Gas/Deo Gas 147,1 162,7 117,9 36,6 5 MW MW MW MW MW (126450000 (139866000 (101389596 (31435150 Kcal/h) Kcal/h) Kcal/h) Kcal/h)

with all fuel gas ( 48150000 Kcal/h)

MECHANICAL DATA Furnace average height Furnace depth Furnace width Number of burners ds-bottom h1 dp h2 dp average height h2 depth h1 ds-bottom width Furnace peephole 6" 7130 10443,0 4513,5 3 1405,0 2050 2050 2179,75 mm mm mm mm mm mm mm

Sheet

of

13

PETROFAC - GS JV RUWAIS 4TH NGL TRAIN

RUWAIS, UAE Gallarate - Italy Basic Engineering DEPT N 5 TITAN M 180 t/h, 30 barg, 355 C

Doc No. Rev. Date

1015-C-310 2 05/12/2011

BOILER DATA SHEET

PIPING AND DUCTs Indicated quantities are for 1 ( one ) boiler MAIN PIPEWORK WITHIN ASME JURISDICTION Line description Outside diam. [mm] Boiler feed water line (from check to eco) Economizer - steam drum line (from eco) Saturated steam drum nozzle Steam drum - primary superheater line Primary superheater - desuperheater line Desuperheater - final superheater line Main steam line 168,3 168,3 273,0 323,9 355,6 355,6 355,6 [mm] 10,97 10,97 12,7 9,52 9,52 9,52 19,05 Thick. Corrosion Number allowance of tubes [mm] 1,6 1,6 3,2 1,6 1,6 1,6 1,6 1 1 3 1 1 1 1 SA 106 Gr. B SA 106 Gr. B SA 106 Gr. B SA 106 Gr. B SA 106 Gr. B SA 106 Gr. B SA 106 Gr. B 600 600 600 600 600 600 600 Material Rating Design pressure [barg] 51,25 41 41 41 41 41 41 Design temp. [ C] 276 276 276 276 352 352 385

AIR AND GAS DUCTS Max Velocity Duct description [17] [m/s] Air duct single fan Air duct delivery Windbox Gas duct from boiler to economizer Gas duct from economizer to stack [18] [18] 11 11 7 15 12 Cross Area [m2] 2,50 4,80 7,60 8,00 7,25 Design Design Temp. [ C] [16] 111 111 111 427 270 pressure [mmH2O] 1470 1470 1470 200 50 5 5 5 6 6 S275 JR [21] S275 JR [21] S275 JR [21] S275 JR [21] S275 JR [21] Min.Thick. [mm] Material

MAIN STACK Base diameter Height Insulation type Design pressure Corrosion allowance 2600 40 mm Base thickness m Material Thickness mmH2O 3 mm 20 60 S275 JR [21]

[19] [20] 2600 mm Top thickness 8 mm

mm Top diameter mm Material 270

Internal lining 50

refractory with anchor C

Design temperature :

Sheet

10

of

13

PETROFAC - GS JV RUWAIS 4TH NGL TRAIN

RUWAIS, UAE Gallarate - Italy Basic Engineering DEPT N 5 TITAN M 180 t/h, 30 barg, 355 C

Doc No. Rev. Date

1015-C-310 2 05/12/2011

BOILER DATA SHEET

INTERNAL INSULATION Indicated quantities are for 1 ( one ) boiler INTERNAL TYPE INSULATION GAS DUCT FROM BOILER TO ECONOMIZER INTERNAL LINING Material Thickness type density refractory 50 1340 mm kg/m 3 Insulating castable Layer 2 Material Thickness HES cement 1 mm Casing [22] Material Thickness Design pressure Design temperature GAS DUCT FROM ECONOMIZER TO STACK INTERNAL LINING Material Thickness type density refractory 50 1340 mm kg/m 3 Insulating castable Layer 2 Material Thickness HES cement 1 mm Casing [22] Material Thickness Design pressure Design temperature 6 50 270 S275 JR [21] mm mmH2O C S275 JR [21] 6 200 427 mm mmH2O C

Sheet

11

of

13

PETROFAC - GS JV RUWAIS 4TH NGL TRAIN

RUWAIS, UAE Gallarate - Italy Basic Engineering DEPT N 5 TITAN M 180 t/h, 30 barg, 355 C

Doc No. Rev. Date

1015-C-310 2 05/12/2011

BOILER DATA SHEET

CASING AND EXTERNAL INSULATION Indicated quantities are for 1 ( one ) boiler EXTERNAL TYPE INSULATION AIR DUCT -ACOUSTIC INSULATION Hot wall 1 Material Thickness 2 Design pressure Design temperature S275 JR [21] 5 1470 111 mm C WINDBOX-ACOUSTIC INSULATION Hot wall 1 Material Thickness 2 Design pressure Design temperature S275 JR [21] 5 1470 111 mm C BOILER Boiler wall 1 Material Design pressure

SA 210 Gr. A1 / A696

Insulation 1 Material Density Mineral Wool 100 75 kg/m3 mm

Insulation 2 Material Density Thickness N.A. N.A. N.A. kg/m3 mm

Cladding Material

Alluminium 3003-H14

mmH2O Thickness

Insulation 1 Material Density Mineral Wool 100 75 kg/m3 mm

Insualtion 2 Material Density Thickness N.A. N.A. N.A. kg/m3 mm

Cladding Material

Alluminium 3003-H14

mmH2O Thickness

Insulation 1 Material Thickness Mineral Wool 100 150 kg/m3 mm 889 mmH2O Density

Insulation 2 Material Density Thickness N.A. N.A. N.A. kg/m3 mm

Cladding Material

Alluminium 3003-H14

GAS DUCT FROM BOILER TO ECONOMIZER Casing 1 Material Thickness Design pressure Design temperature S275 JR [21] 6 200 427 mm C GAS DUCT FROM ECONOMIZER TO STACK Casing 1 Material Thickness Design pressure Design temperature S275 JR [21] 6 50 270 mm C Insulation 1 Material Density Mineral Wool 100 100 kg/m3 mm Insualtion 2 Material Density Thickness N.A. N.A. N.A. kg/m3 mm Cladding Material

Alluminium 3003-H14

Insulation 1 Material Density Mineral Wool 100 150 kg/m3 mm

Insualtion 2 Material Density Thickness N.A. N.A. N.A. kg/m3 mm

Cladding Material

Alluminium 3003-H14

mmH2O Thickness

mmH2O Thickness

Sheet

12

of

13

PETROFAC - GS JV RUWAIS 4TH NGL TRAIN

RUWAIS, UAE Gallarate - Italy Basic Engineering DEPT N 5 TITAN M 180 t/h, 30 barg, 355 C

Doc No. Rev. Date

1015-C-310 2 05/12/2011

BOILER DATA SHEET NOTES [1] [2] [3] [4] Peak load 110%MCR only 2hrs/24hrs. Normal steam demand is 81%MCR. Void Design Temperature: 183 C Based on design ambient condition 25 C/60%RH @ MCR with all fuel gas and T BFW equal to 110 C.During Molecular sieve regeneration efficiency is 89%@MCR on design ambient condition 25 C/60%RH with all fue l gas and T BFW equal to 149 C. Minimum BFW pressure @ BL. Boiler feedwater is variable pressure. Access door 600x600mm for Furnace, Superheater and Economizer Approximate lenght. Design temperature according DGS-0000-020, par.4.1 and Macchi Standard. Headers: Design Temperature = maximum ( Tsat @ Pdesign; T @ maximum continuous operating + 30 C) Superheater tubes: Design Temperature = Maximum(Metal Temperature at MCR + 30 Metal temperature in unbalanced C; condition) Design temperature of Boiler tubes is 385 instea d of 371 according DIP sec.3 (Company Comments, C C mail 23/12/09) External to flue gas path Membraned wall. Headers shall be seamless, of the same material as connecting tubes, and shall have flanged 6" inch diameter handholes to permit inspection of internal surfaces (DGS 0150 001,par.10.7.19). The minimum size for all steam drum connection is 2" inches. Two Manholes for each drum According DGS 0150-001 rev.1 par. 10.7.5 Based on 5% margin on peak load (110%MCR) Design temperature for duct: Air duct: Maximum operating temperature + 56 C Flue Gas duct: The calculated metal temperature + 56 based on the maximum flue gas temperature C Maximum velocity according DGS 0150 001 rev.1, par.10.18.2 and 10.18.3 The flue gas ducts shall be refractory-lined and externally insulated. The stack shall be refractory-lined. No external insulation only personnel protection. Stack mechanical and structural design shall be compatible with 45m height. Equivalent to ASTM A36 Acid proof high strength cement. Material Equivalent to ASTM 1008 DDS

[5] [6] [7] [8]

[9] [10] [11]

[12] [13] [14] [15] [16]

1 1 1 1

[17] [18] [19] [20] [21] [22] [23]

Sheet

13

of

13

Вам также может понравиться

- Boiler Performance & Technical Data JT-K13467-E01-0Документ15 страницBoiler Performance & Technical Data JT-K13467-E01-0Puntanata Siagian0% (1)

- Proceedings of the Twelfth International Cryogenic Engineering Conference Southampton, UK, 12–15 July 1988От EverandProceedings of the Twelfth International Cryogenic Engineering Conference Southampton, UK, 12–15 July 1988R. G. ScurlockОценок пока нет

- MQ SP I 7015 PDFДокумент66 страницMQ SP I 7015 PDFJaseelKanhirathinkalОценок пока нет

- Steam Boiler Inspections Using Remote Field Testing: by Mynor Celis, P.Eng, Russell NDE SystemsДокумент11 страницSteam Boiler Inspections Using Remote Field Testing: by Mynor Celis, P.Eng, Russell NDE SystemsAnonymous lmCR3SkPrKОценок пока нет

- Engineering 360 - Engineer's Guide To Boiler Tube InspectionsДокумент3 страницыEngineering 360 - Engineer's Guide To Boiler Tube InspectionsIsmal AdrianОценок пока нет

- 18105-Abg-01-Me-das-033 Rev-A Mechanical Data Sheet O2 Stripper Condense...Документ5 страниц18105-Abg-01-Me-das-033 Rev-A Mechanical Data Sheet O2 Stripper Condense...Avinash ShuklaОценок пока нет

- Boiler Tube FailureДокумент7 страницBoiler Tube FailureBhupendra GobadeОценок пока нет

- Ex ProtectionДокумент44 страницыEx ProtectionAnil MarkaleОценок пока нет

- Heater Tube Life ManagementДокумент19 страницHeater Tube Life ManagementWeniton Oliveira100% (1)

- 7T04-CS-00-TS-018 R01 Project Specificationfor Cleaning Reequirements For Piping SystemsДокумент9 страниц7T04-CS-00-TS-018 R01 Project Specificationfor Cleaning Reequirements For Piping Systemsel_sharkawy2011100% (1)

- Summary of ASME BPVC Section VIII Div 1 (Part 2) - Welding & NDTДокумент14 страницSummary of ASME BPVC Section VIII Div 1 (Part 2) - Welding & NDTTin Aung KyiОценок пока нет

- Condensate in HRSG PDFДокумент15 страницCondensate in HRSG PDFCoalhouse Walker JuniorОценок пока нет

- HRSG Itp 03Документ42 страницыHRSG Itp 03Otong NurshobahОценок пока нет

- Mollier Diagram SteamДокумент2 страницыMollier Diagram SteamPeter AshrafОценок пока нет

- Chapter 14 Boiler System Failures: Deaerator CrackingДокумент22 страницыChapter 14 Boiler System Failures: Deaerator CrackingVijay RajaindranОценок пока нет

- G-Me-250 - 2 Genreal Standard For Pressure and Vacuum Relief DevicesДокумент35 страницG-Me-250 - 2 Genreal Standard For Pressure and Vacuum Relief DevicesSaleh EttehadiОценок пока нет

- Introduction To GTL Process: Yassir Abdulkareem Department of Chemical Engineering University of Technology 2021Документ33 страницыIntroduction To GTL Process: Yassir Abdulkareem Department of Chemical Engineering University of Technology 2021ياسرشلالالحسني100% (1)

- Boilers Basic Components (Att. VIII)Документ28 страницBoilers Basic Components (Att. VIII)Vijay RajОценок пока нет

- Description of Damage: 5.1.1.1 Amine Corrosion 5.1.1.1.1Документ5 страницDescription of Damage: 5.1.1.1 Amine Corrosion 5.1.1.1.1Ajmi HmidaОценок пока нет

- BoilerДокумент7 страницBoilerXie ShjОценок пока нет

- Cap Boiler ManualДокумент43 страницыCap Boiler Manualdnageshm4n244100% (1)

- How To Select A Heat PipeДокумент3 страницыHow To Select A Heat PipeAdrian NiżnikowskiОценок пока нет

- C Pi 370Документ22 страницыC Pi 370sadeghmsgОценок пока нет

- 545Документ11 страниц545hiyeonОценок пока нет

- Potential Damage PKTДокумент7 страницPotential Damage PKTFebri Ramdani NugrahaОценок пока нет

- Pressure Drop Table For HosesДокумент1 страницаPressure Drop Table For Hosesparthasarathyk69@gmail.comОценок пока нет

- Air Cooled Heat Exchanger CourseДокумент2 страницыAir Cooled Heat Exchanger Courserodrigoperezsimone100% (1)

- 02 50061-MR-003-ST Equipment Installation Description For Ammonia Flare SystemДокумент10 страниц02 50061-MR-003-ST Equipment Installation Description For Ammonia Flare SystemPhucChuVanОценок пока нет

- Deaerators BrochureДокумент4 страницыDeaerators BrochurefahimshkОценок пока нет

- Aiche 26 009 PDFДокумент7 страницAiche 26 009 PDFImmanuelОценок пока нет

- DegassingДокумент11 страницDegassingMKOZERDEMОценок пока нет

- Woc Hse Manual Standards: Woc LP EP DepartmentДокумент12 страницWoc Hse Manual Standards: Woc LP EP DepartmentAkram AlhaddadОценок пока нет

- HRSG Water Chemistry Control OverviewДокумент5 страницHRSG Water Chemistry Control OverviewRahul ChoubeyОценок пока нет

- Corrosion Damage in Waste Heat Boilers Major Root Causes and RemediationДокумент10 страницCorrosion Damage in Waste Heat Boilers Major Root Causes and Remediationvaratharajan g rОценок пока нет

- Failure of PigtailsДокумент32 страницыFailure of Pigtailsbarry nancoo100% (1)

- 1314276003newsletter Reduce Boiler Tube Leakages in Your Power StationДокумент7 страниц1314276003newsletter Reduce Boiler Tube Leakages in Your Power StationNorman IskandarОценок пока нет

- VAI-ME-SPC-111 Pipe Insulation Technical Specification - Rev AДокумент8 страницVAI-ME-SPC-111 Pipe Insulation Technical Specification - Rev AAdvis100% (1)

- Fuel SystemДокумент8 страницFuel SystemManoj UpadhyayОценок пока нет

- AB-507 Installed Fired Heaters GuidelineДокумент36 страницAB-507 Installed Fired Heaters GuidelineRosa galindoОценок пока нет

- Difference Between Pipe and TubeДокумент1 страницаDifference Between Pipe and TubeBaher ElsheikhОценок пока нет

- Nace STD TM 0199-99Документ8 страницNace STD TM 0199-99gabriela troncosoОценок пока нет

- Boil Out ProceduresДокумент11 страницBoil Out ProceduresJorge DiazОценок пока нет

- Certificate of Analysis: National Institute of Standards and TechnologyДокумент5 страницCertificate of Analysis: National Institute of Standards and TechnologyJohn GiannakopoulosОценок пока нет

- BR 170 1Документ7 страницBR 170 1Himanshu ChaturvediОценок пока нет

- Boiler Tube Repair PracticeДокумент1 страницаBoiler Tube Repair PracticejagyanduttaОценок пока нет

- Steam Generating System - Operation OverviewДокумент21 страницаSteam Generating System - Operation Overviewritesh MishraОценок пока нет

- Pressure Regulation Consideration and Issues: Service RegulatorДокумент52 страницыPressure Regulation Consideration and Issues: Service RegulatorRohan Sharma100% (1)

- Electrode BoilerДокумент7 страницElectrode BoilerBrijendra MathurОценок пока нет

- A 1 KДокумент5 страницA 1 KSumantrra ChattopadhyayОценок пока нет

- P-91 Power Piping and Pressure VesselsДокумент10 страницP-91 Power Piping and Pressure VesselsOliver ArauzОценок пока нет

- P P NG Abbrev at Ons: AFC A F CДокумент11 страницP P NG Abbrev at Ons: AFC A F COlajide AkekeОценок пока нет

- 30 Ncmer037Документ16 страниц30 Ncmer037Arslan ArshadОценок пока нет

- Boil Out ProcedureДокумент2 страницыBoil Out Proceduremrizalygani99100% (1)

- 02 Samss 006Документ17 страниц02 Samss 006inatt101Оценок пока нет

- SAEP-88 Appendix J: Materials Selection Table (MST) Template (1 of 2)Документ2 страницыSAEP-88 Appendix J: Materials Selection Table (MST) Template (1 of 2)Afzal AsifОценок пока нет

- Handout PDFДокумент51 страницаHandout PDFSCE SOLAPURОценок пока нет

- Feed Contamination With Sodium and Its ImpactДокумент12 страницFeed Contamination With Sodium and Its Impacttonytayic100% (1)

- Standards For RefineryДокумент11 страницStandards For RefinerykknanduriОценок пока нет

- URDU-Fact Sheet 3 Migration Agents FINALДокумент3 страницыURDU-Fact Sheet 3 Migration Agents FINALsimba8661Оценок пока нет

- Deportation Case Studies AustraliaДокумент6 страницDeportation Case Studies Australiasimba8661Оценок пока нет

- Qatar Liquified Gas Company Limited (II) : QG2, The Designs and Technologies For A 7.8 MTPA TrainДокумент16 страницQatar Liquified Gas Company Limited (II) : QG2, The Designs and Technologies For A 7.8 MTPA TrainweldsvОценок пока нет

- For EnemyДокумент1 страницаFor Enemysimba8661Оценок пока нет

- Numerical Index of DEPsДокумент15 страницNumerical Index of DEPssimba8661Оценок пока нет

- Lecture 19 Problem On Boiler Performance & Heat BalanceДокумент81 страницаLecture 19 Problem On Boiler Performance & Heat BalanceDr. BIBIN CHIDAMBARANATHANОценок пока нет

- Assignment 1 MEPPEДокумент5 страницAssignment 1 MEPPEFrancis Paulo CruzОценок пока нет

- Course Plan Power Plant EngineeringДокумент3 страницыCourse Plan Power Plant EngineeringM.ThirunavukkarasuОценок пока нет

- 11 Photovoltaic CellДокумент2 страницы11 Photovoltaic CellHéctor Sanmanuel TorresОценок пока нет

- Mikee EncodedДокумент2 страницыMikee EncodedjaysonОценок пока нет

- TEG200W EnglishДокумент2 страницыTEG200W EnglishChirila CristinelОценок пока нет

- 山东中天科技工程有限公司 Installation diagram of heat tracingДокумент9 страниц山东中天科技工程有限公司 Installation diagram of heat tracingMizanul HoqueОценок пока нет

- Solar Cell I-V Characteristic and The Solar Cell I-V CurveДокумент5 страницSolar Cell I-V Characteristic and The Solar Cell I-V CurveMuhammad BalyanОценок пока нет

- 540W Era Solar - Data SheetДокумент2 страницы540W Era Solar - Data SheetclyziasОценок пока нет

- Welding Report For Tank 1Документ1 страницаWelding Report For Tank 1Rifki HasyaОценок пока нет

- Esterilización Techfors-SДокумент11 страницEsterilización Techfors-SIgnacio Rodriguez CarrascosaОценок пока нет

- Mouna Raagalu-Jalsa - TKДокумент136 страницMouna Raagalu-Jalsa - TKyenki80% (5)

- Operation and Maintenance Instructions: Korinoikaisusarjat Body Repair KitsДокумент3 страницыOperation and Maintenance Instructions: Korinoikaisusarjat Body Repair KitsAlain DefoeОценок пока нет

- Official Website Department of Occupational Safety and Health - Steam Boiler Manufacturer CompanyДокумент1 страницаOfficial Website Department of Occupational Safety and Health - Steam Boiler Manufacturer CompanyHaziqОценок пока нет

- 12.stirling BoilerДокумент3 страницы12.stirling BoilerawsdotcdotawsОценок пока нет

- SODECA. Manufacturer of Fans and Industrial ExtractorsДокумент3 страницыSODECA. Manufacturer of Fans and Industrial Extractorsmohsen_267Оценок пока нет

- Solar Tracking System Literature ReviewДокумент5 страницSolar Tracking System Literature Reviewafmzeracmdvbfe100% (1)

- HPS Genset K3lh Air Jangkang - KosongДокумент4 страницыHPS Genset K3lh Air Jangkang - KosongAndira ElectrikОценок пока нет

- V1 - Surname First Name M.I Laboratory Activity No.3 Hybrid Solar PV SimulationДокумент28 страницV1 - Surname First Name M.I Laboratory Activity No.3 Hybrid Solar PV Simulationluna genilОценок пока нет

- Monitoring of Grid Tied Photovoltaic System Efficiency in Operating ConditionsДокумент4 страницыMonitoring of Grid Tied Photovoltaic System Efficiency in Operating ConditionskubikОценок пока нет

- BrightSource EnergyДокумент6 страницBrightSource Energyashish2783Оценок пока нет

- Ase202 MCQSДокумент2 страницыAse202 MCQSyadu yadunathОценок пока нет

- Electrical Lecture 1 - Basic of Power PlantДокумент92 страницыElectrical Lecture 1 - Basic of Power PlantNoli OtebaОценок пока нет

- Diamond DESERT FoilДокумент4 страницыDiamond DESERT FoilMuddasir CoinОценок пока нет

- Chapter 2 Pelton TurbineДокумент17 страницChapter 2 Pelton TurbineSachin MohalОценок пока нет

- Sizing and Selection of Steam TurbineДокумент12 страницSizing and Selection of Steam TurbineChe AguilarОценок пока нет

- Solar EnergyДокумент37 страницSolar EnergySri WahyuniОценок пока нет

- MIASOLÉ - MR-107 (108 W) : The Advantages at A GlanceДокумент4 страницыMIASOLÉ - MR-107 (108 W) : The Advantages at A GlancePower EngОценок пока нет

- Question Bank of Renewable Energy SourcesДокумент2 страницыQuestion Bank of Renewable Energy SourcesSanjayChauhanОценок пока нет

- ROE-086-Lecture 53Документ12 страницROE-086-Lecture 53Ankit SrivastavaОценок пока нет