Академический Документы

Профессиональный Документы

Культура Документы

Study The Effect of Increasing Gamma Ray Doses On Some Physical Properties of Carboxy Methyl Cellulose

Загружено:

Alexander DeckerОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Study The Effect of Increasing Gamma Ray Doses On Some Physical Properties of Carboxy Methyl Cellulose

Загружено:

Alexander DeckerАвторское право:

Доступные форматы

Advances in Physics Theories and Applications ISSN 2224-719X (Paper) ISSN 2225-0638 (Online) Vol 6, 2012

www.iiste.org

Study the effect of increasing Gamma ray doses on some physical properties of Carboxy methyl cellulose

Prof. Dr. Abdul-Kareem J. Al-Bermany (Corresponding author) Babylon University / Facility of Science / Physics department/Advanced polymer laboratory PO box 4, Babylon, Iraq E-mail: dr.abdulkaream@yahoo.com Rusul Abdul-Amir Ghazi Babylon University / Facility of Science / Physics department/Advanced polymer laboratory PO box 4, Babylon, Iraq E-mail: Rusulaag@yahoo.com Abstract

In this study some of the physical properties of Carboxymethyle cellulose dissolves in distilled water with different concentration had been studies before and after irradiation by gamma ray of variable dose (5000rad, 7000rad, 9000rad).These properties are firstly the Rheological properties such as shear viscosity, relative viscosity specific viscosity and reduced viscosity are measured, secondly the mechanical properties such as ultrasonic velocity had been measured at frequency (40KHz). Other mechanical properties had been calculated such as absorption coefficient of ultrasonic waves, relaxation time, relaxation amplitude, specific acoustic impedance, bulk modules and compressibility. The results show that all these properties are affected with variation in density and viscosity because of the intermolecular interactions Gamma radiation made degradation to polymer molecular chains that affect the physical properties as a result ultrasonic absorption increased and molecular weight decreased after irradiation.

Keywords: CMC solution, ultrasound technique, degradation, rheological properties, mechanical properties.

1. Introduction: Carboxy methyl cellulose is an ionic linear polymer and used in more varied applications worldwide than any other water-soluble polymer known today. One of its import applications is using to increase petroleum production as (drilling fluid) from its original traps in our country. CMC solutions are pseudo plastic that is the 1

Advances in Physics Theories and Applications ISSN 2224-719X (Paper) ISSN 2225-0638 (Online) Vol 6, 2012

www.iiste.org

measured viscosity decreases with increasing shear rate and its also thixotropic [1,2] some times when solutions are subjected to high shear rate conditions ,then may be a time lag in the tendency of the apparent viscosity to increase again to its earlier (at rest), this time delay behavior is called thixotropy [2]. CMC is a cellulose derivative with carboxy methyl groups (-CH2-COOH) bound to some of the hydroxyl groups of the glucopyranose monomers that make up the cellulose backbone [3] . It is often used as its sodium salt, sodium carboxy methyl cellulose (Gerhard Buchman -Germany). Irradiation process on polymer causes some changes in its physical and chemical properties such as increasing its softness and decreasing its solubility [4, 5].The polymer will suffer either degradation or cross-linking when it is interact with radiation. In case of degradation the mean molecular weight reduce and may be brittle or more flexible and its solubility either increase or decrease depending of the type of interactions with radiation [5]. The use of ultrasound as a tool in material science is increasing; the effect of ultrasound on organic synthesis, polymer reaction, electro plating, electro synthesis and electro polymerization has been exploited to good effect [6]. Ultrasonic technique is one of the basic International non-destructive methods for evaluation of materials and structures, a significant part of every ultrasonic inspection is the way in which the ultrasonic energy is transferred between the transducer and the tested object, different types of commercial liquids and gels are used as a coupling medium. Studies of ultrasonic irradiation show that it can be used for degradation of polymers, the breakage of chemical bonds is due to cavitations into the medium .Cavitations are the formation and violent collapse of small bubbles. This leads to shearing forces of sufficient magnitude to cause the rupture of chemical bonds Solvent effects might therefore be expected to influence the ultrasonic relation behavior, the absorption of ultrasonic in liquid polymer systems is governed by local modes of motion (segmental conformation change) and cooperative whole molecule movement (normal or Rouse modes), because of the existence of strong intermolecular interaction within the polymer. It should be possible to observe cooperative motion in the ultrasonic range [7]. Ultrasonic technique is good method for studying the structural changes associated with the information of mixture assist in the study of molecular interaction between two species [8, 9].

2. Experimental: 2.1 Preparation of Solutions:

Advances in Physics Theories and Applications ISSN 2224-719X (Paper) ISSN 2225-0638 (Online) Vol 6, 2012

www.iiste.org

CMC solutions were prepared by addition a known weight of CMC powder to affixed volume of distilled water then heating the mixture under reflux while agitating with magnetic stirrer to complete solubility of polymer. The solutions were then cooled to room temperature when a clear solution was obtained of concentration ranging (0.05 ,0.15 ,0.25 ,0.35 ,0.45 ,0.55, 0.65 and 0.75) gm/ml after that CMC irradiated by gamma ray with variable doses (5000, 7000 and 9000 rad) ,other solution of same concentrations were prepared after irradiation.

2.2 Density and Rheological measurements:

The density of the solution () was determined by the density bottle method and the viscosity measured before and after Radiation for all concentrations using Ostwald viscometer with accuracy of 1.05%, the method of measurement has been described elsewhere [10], different types of shear viscosity were determined before and after Radiation by the equations (1, 2, 3 and 4) [10]. The shear viscosity had been calculated by the following

equation [11]:

t s = s s (1) 0 t00

Where s , 0 shear viscosity of solution and distilled water respectively.

s , 0

are densities of solution and distilled water respectively.

Relative viscosity (rel) was calculated by the following equation

rel =

t s s = t 0 0

(2)

t s ,t0

are flow time of solution and distilled water respectively.

The specific viscosity

( sp )

and reduced viscosity

( red )

was calculated by the equations:

sp =

(s 0 )

= rel 1

(3)

Advances in Physics Theories and Applications ISSN 2224-719X (Paper) ISSN 2225-0638 (Online) Vol 6, 2012

www.iiste.org

red =

sp

C

(4)

Where (C) is the concentration. The intrinsic viscosity

[ ] was measured by plotting a graph between reduced

viscosities against the concentration when the extrapolation of the slope as (C) goes to zero represents the value of intrinsic viscosity as shown in fig (5). This value of intrinsic viscosity compared with that obtained theoretically by Arrhenius equation below: [10]

ln rel = [ ]C

(5)

And also was theoretically calculated by using Philip-off equation below: [10]

rel

C = 1 + [ ] 8

(6)

The viscosity average molecular weight (Mv) was calculated by using the following equation: [10]

[ ] = KMa (7) v

Where k, a are constant depends on the type of the polymer, for CMC the values of constants are (a=0.91, K=1.23*10-4 [12]. The effective molecular radius(r) was calculated by the following equations:[ 13, 14]

rel = 1+ 6.3 *1024 r 3Cm

slope = 6.3 10 24 r 3

r = 3 slope / 6.3 1024

(8)

(9)

... (10)

Where slope equal to the value of slope plotted between relative viscosities against concentration 2.3 Ultrasonic measurements:

Advances in Physics Theories and Applications ISSN 2224-719X (Paper) ISSN 2225-0638 (Online) Vol 6, 2012

www.iiste.org

Ultrasonic measurements were made at constant frequency (f=40 kHz) using pulse technique of sender-receiver type (SV-DH-7A/SVX-7 velocity of sound instrument) .The receiver quartz crystal mounted on a digital vernier scale of slow motion, the sender and receiver pulses (waves) were displaced on two traces of cathode ray oscilloscope, and the digital delay time of received pulses were recorded with respect to the distance. The pulses height on oscilloscope (CH1) represents incident ultrasonic waves amplitude (A0) and the pulses height on oscilloscope (CH2) represents the received ultrasonic waves amplitude (A) after passing the solution. 2.4 Theoretical calculation: The ultrasonic wave velocity (v) was calculated using the following equation [15]: v=x/t .. (11)

Where (t) is the delay time of ultrasonic wave and (x) is the sample thickness or distance the wave passing through it. The absorption coefficient () was calculated from Lambert Beer law [14]: A/A0 = e (- x) .. (12) Where (A0) is the initially amplitude of the ultrasonic waves, (A) is the wave amplitude after absorption. Attenuation is generally proportional to the square of sound frequency so the relaxation amplitude (D) was calculated from the following equation [16]: D = / f2 . (13)

Where (f) is the ultrasonic frequency of the instrument. Bulk modulus (K) of a solution is the substance's resistance to uniform compression; it was calculated by Laplace equation [16]: K=v2 . (14)

Where () is the density. Compressibility (B) was calculated by the following equation [16]: B = ( v2)-1 . (15)

The acoustic impedance (Z) of a medium was calculated by equation [16]: Z=v 3. Results and Discussion: 3.1 Rheological properties: .(16)

Advances in Physics Theories and Applications ISSN 2224-719X (Paper) ISSN 2225-0638 (Online) Vol 6, 2012

www.iiste.org

The values of density with concentration are shown in (Fig.1)this Fig shows the density is increasing with increase of the concentration, this behavior also shown by [13], Gamma radiation causes degradation to the polymer molecules chains which responsible for a lower values of density than before irradiation [6]. Shear Viscosity shown in (Fig .2) is increasing with concentration before and after Radiation, this attributed to the mechanism that hydrogen bonding of water attached to oxygen sites, this leads to salvation sheaths and increase the size of the molecules, Gamma radiations caused degradation to the polymer chains which are responsible for

reduction values of viscosity than that before irradiation [12, 13]. Relative, specific and reduce viscosities show in (Fig.3), (Fig.4) and (Fig.5) respectively posses the same behaviors of shear viscosity because they derived from it as shown in equations (2,3and 4). Intrinsic viscosity had been experimentally and theoretically obtained experimentally when the extrapolation of the slope to y axis of Fig.(5) when(C=0) goes to zero represent intrinsic viscosity and theoretically obtained by using Phillip-off and Arrhenius equations no(5,6)respectively ,the values of intrinsic viscosity experimentally and theoretically shown in table (1).This table shows that when increasing radiation doses by gamma, the value of intrinsic viscosity decreasing and the lowest value of intrinsic viscosity obtained at highest doses of radiation this attributed that intrinsic viscosity related to the size of polymer molecules, since radiation produced degradation then reduced the size of polymer molecular chains that lead to reduce intrinsic viscosity [17] ,and this table shows there are good agreement between experimental and theoretical values of Intrinsic viscosity. The viscosity average molecular weight was calculated by using equation (7). Results show that molecular weight after irradiation has lower values than that before which are show in table (1).This attributed to the fact that radiation made break as a result of degradation to molecular chains produced untie break chains which have reduction in repeat polymer chemical unit therefore reduced its molecular weight [12]. Effective molecular radius for High and Low concentration were decreased after Radiation as show in table (2), since radiation reduced the size of polymer chains because of degradation and this new chains randomly coiled in the solution they must have the smaller radius than that before irradiation [18]. 3.2 Mechanical properties: A useful method of studying mechanical properties of liquids is based on ultrasound. (Fig.6) shows that ultrasonic velocity is decreasing after irradiation and dose (9000) has the lowest value of velocity this attributed that radiation

Advances in Physics Theories and Applications ISSN 2224-719X (Paper) ISSN 2225-0638 (Online) Vol 6, 2012

www.iiste.org

breaks the bonds of polymer chains and there are small molecules in the solutions and since ultrasonic waves propagate as compression and rarefaction ,so these small molecules followed and attenuated these waves and changing its density when passing through the medium (sample)so the velocity must decreased when radiation increased [19,20], so there are more attenuation by these molecules to sound wave and the absorption coefficient increasing after radiation as shown in (Fig.7). The compressibility is decreasing with the increase of concentration as shown in (Fig.8) and attributed to the fact Laplace equation No (14) there are inverse proportionality between compressibility and ultrasonic velocity. Radiation Reduces the values of compressibility that make changes in structural relaxation which is responsible for reducing polymer compressibility[16]as shown in (Fig.8). Ultrasonic relaxation amplitude was calculated by using equation(13) and shown in (Fig.9) these values are increasing with concentration, this behavior is the same to that given by [6] for other polymers ,and attributed to the fact that ultrasonic energy depends on viscosity ,thermal conductivity, scattering and intermolecular processes .Thermal conductivity, scattering are known to be negligible , so viscosity is responsible for the increase of relaxation amplitude for this reason absorption coefficient commonly known as visco- absorption [7]. Specific acoustic impedance shown in (Fig.11) is decreasing with ultrasonic velocity. This behavior same to that given by [21] for other polymers and attributed that equation No.(16) has only one variable parameter which is velocity and density has very small variations with respect to the variation of velocity. 4. Conclusion 1-This study shows that intermolecular processes are responsible for the relaxation, and indicating decrease in the size of molecules in bath of ultrasonic waves as a result of gamma radiation. 2-Irradiation was increased the solubility of polymer in water it cased strong degradation to the polymer chains. 3-Irradiation decreased the molecular weight, so there were small and strong chains of molecules as a result of degradation and hydrogen bonds attached to the oxygen sites of polymer and decrease the size of the polymer chains. 4-By radiation can we obtain different molecular weight for this polymer means different industrial applications.

Advances in Physics Theories and Applications ISSN 2224-719X (Paper) ISSN 2225-0638 (Online) Vol 6, 2012

www.iiste.org

5-Irradiation enhances the absorption coefficient for CMC polymer so it can be applied as coated materials for objects that want be observed by sonar which used ultrasonic waves. References [1] Robert L.Davidson hand book of water-soluble gums and resinsM.C.Graw-hill., 1980. [2] Norbert M.bikales of leon segal cellulose and cellulose derivating vol .v part v. jhon wiely of sons ,Inc . 1971. [3] http://en.wikipedia.org/wiki/Carboxymethyl_cellulose(2011). [4] Carroll R.O.Radiation affection organic materials academic prees, New York,2003. [5] Sa. R. and Jarnes , H.O. The effect of Radiation on high technology ACS symposium series, 2000. [6] Uzun.M ,Patel .I, "Mechanical properties of ultrasonic washed organic and traditional cotton yarns", Journal of Achievements in Materials and Manufacturing Engineering , Vol. 43,No. 2,pp.608-612 ,2010. [7] Jayanta Chakraborty, Jayashri Sarkar, Ravi Kumar and Giridhar MadrasUltrasonic Degradation of Polybutadiene and Isotactic Polypropylene, Polymer Degradation and Stability, Vol.85 ,pp.555-558, 2004.

[8] Abdul-Kareem Al-Bermany , Burak Yahya Kadem , Rawaa Mizher Obiad , Lamis F. Nasser, "Study of some mechanical and rheological properties of PVA/FeCl3 by ultrasonic", International journal of Advanced Scientific and Technical Research , Vol 2.,No.1, pp. 2249-9954,2010. [9] Abdul-Kareem J. a Al-Bermany and Burak Y. Kadem,"Effect of variable ultrasonic frequencies on some physical properties of Iraqi palm fiber PVA composite" Journal of Asian Scientific Research, Vol.1,No.7, pp.359365, 2010.

[10]Abdul-Kareem J. Al-Bermany,"Astudy of the physhical properties of some cellulose Derivative polymers", ph.D. Thesis, Babylon University,1995.

[11] Abdul-Kareem Jawad Rashid ,Rawaa Mizher,Burak Yahya Kadem "Study the rheological and mechanical properties of PVA/NH4Cl by ultrasonic ,chemistry and material research ,iiste, Vol.1, No.1, 2011.

Advances in Physics Theories and Applications ISSN 2224-719X (Paper) ISSN 2225-0638 (Online) Vol 6, 2012

www.iiste.org

[12] Samir H. Al-Nesrawy, " Gamma radiation effect of some physical properties of High and Low viscosity Carboxymethyl cellulose", M.Sc. Thesis, Babylon University,1998.

[13] G.S. Guru1, P.Prasad, H.R. Shivakumar, S. K. Rai,"Studies on the Compatibility of Pullulan Carboxymethyl Cellulose Blend using Simple Techniques", Malaysian Polymer Journal , Vol. 3, No. 2, p 13-23, 2008 ", Journal of Babylon University,Vol.8,No.3,pp.639-645,2003

[14] Boutouyrie P, Briet M, Collin C, Vermeersch S and Pannier B "Assessment of pulse wave velocity ". Artery Research ,Vol. 3 ,No.1, pp.3 10, 2007.

[15] Zong fang Wu1 and Dong C. Liu , Method of improved scatterer size estimation without attenuation known a priori, IEEE ,vol.8 ,no.10, 2011.

[16] Abdul-Kareem J. a Al-Bermany"Visco Relaxation study of Gamma effect on Polyethylene Oxide by Ultrasonic( Method of determining new Molecular Weight)", Journal of Babylon University , Vol.12 ,No.3, 2005.

[17] Illiger S R, Rao K.P. and Demappa,"Miscibility studies of HPMC/PVA blends in water by viscosity, density, refractive index and ultrasonic velocity method" ,Carbohydrate Polymer",Vol. 74, pp. 779-782, 2008.

[18] Hughes ,G.Radiration chemistry, claredon press Oxford.j ,1973.

[19] Khalid Sileh, Ehssan D. Jawad," Study of some Mechanical and Rheological properties of polymer Kaolin by ultrasonic",Journal of Babylon University,Vol.2,No.15,pp.585-595,2008. [20] Jabbar Hussan," Effect of Gamma Radiation on physical properties of " Properties of Styrene Butadiene Rubber", Journal of Babylon University,Vol.7,No.1,pp.79-85,2009. [21] Antun R., Jasan R. , e-polymers Journal , No.36 ,2008.

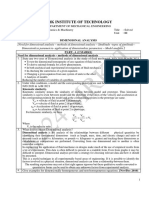

Table (1) comparison between experimental and theoretical results of intrinsic viscosity, Viscosity average Molecular

Advances in Physics Theories and Applications ISSN 2224-719X (Paper) ISSN 2225-0638 (Online) Vol 6, 2012

www.iiste.org

weight.

Intrinsic Polymer (dl/gm) Theor. CMC Arrhe. Non.radiation 10.8 8.4 6 3.78

Viscosity

[]

Viscosity weight (Mv) Theor.

average

Molecular

Exp. Philip. 11.2 8.7 6.2 3.8 11 8 5.5 3 Arrhe. 267906 203302 140505 84599 Philip. 278821 211288 145656 58091

Exp.

273358 140505 127703 65639

Irr.(5000rad) Irr.(7000rad) Irr.(9000rad)

Table (2) Comparison between effective radius for High and Low concentration

Effective radius (r) (cm) CMC polywer Non.radiation High con. Low con.

2.467 10 8

2.010 10 8

1.828 10 8

Irr.(5000rad)

2.212 10 8 2.082 10 8 1.892 10 8

Irr.(7000rad)

1.405 10 8 1.054 10 8

Irr.(9000rad)

10

Advances in Physics Theories and Applications ISSN 2224-719X (Paper) ISSN 2225-0638 (Online) Vol 6, 2012

www.iiste.org

(Fig.1) Density vs. concentration

(Fig.2) Shear viscosity vs. concentration

11

Advances in Physics Theories and Applications ISSN 2224-719X (Paper) ISSN 2225-0638 (Online) Vol 6, 2012

www.iiste.org

(Fig.3)Relative viscosity vs. concentration

(Fig.4)Specific viscosity vs. concentration

(Fig.5) Reduce viscosity vs. concentration

12

Advances in Physics Theories and Applications ISSN 2224-719X (Paper) ISSN 2225-0638 (Online) Vol 6, 2012

www.iiste.org

(Fig.6)Ultrasonic velocity vs. concentration

(Fig.7)Absorption coefficient vs. concentration

(Fig.8)Compressibility vs. concentration

13

Advances in Physics Theories and Applications ISSN 2224-719X (Paper) ISSN 2225-0638 (Online) Vol 6, 2012

www.iiste.org

(Fig.9)Relaxation amplitude vs. concentration

(Fig.10) Bulk modulus vs. concentration

(Fig.11) Acoustic impedance vs. concentration

14

This academic article was published by The International Institute for Science, Technology and Education (IISTE). The IISTE is a pioneer in the Open Access Publishing service based in the U.S. and Europe. The aim of the institute is Accelerating Global Knowledge Sharing. More information about the publisher can be found in the IISTEs homepage: http://www.iiste.org The IISTE is currently hosting more than 30 peer-reviewed academic journals and collaborating with academic institutions around the world. Prospective authors of IISTE journals can find the submission instruction on the following page: http://www.iiste.org/Journals/ The IISTE editorial team promises to the review and publish all the qualified submissions in a fast manner. All the journals articles are available online to the readers all over the world without financial, legal, or technical barriers other than those inseparable from gaining access to the internet itself. Printed version of the journals is also available upon request of readers and authors. IISTE Knowledge Sharing Partners EBSCO, Index Copernicus, Ulrich's Periodicals Directory, JournalTOCS, PKP Open Archives Harvester, Bielefeld Academic Search Engine, Elektronische Zeitschriftenbibliothek EZB, Open J-Gate, OCLC WorldCat, Universe Digtial Library , NewJour, Google Scholar

Вам также может понравиться

- Assessment of Knowledge, Attitude and Practices Concerning Food Safety Among Restaurant Workers in Putrajaya, MalaysiaДокумент10 страницAssessment of Knowledge, Attitude and Practices Concerning Food Safety Among Restaurant Workers in Putrajaya, MalaysiaAlexander DeckerОценок пока нет

- Assessment For The Improvement of Teaching and Learning of Christian Religious Knowledge in Secondary Schools in Awgu Education Zone, Enugu State, NigeriaДокумент11 страницAssessment For The Improvement of Teaching and Learning of Christian Religious Knowledge in Secondary Schools in Awgu Education Zone, Enugu State, NigeriaAlexander DeckerОценок пока нет

- Assessing The Effect of Liquidity On Profitability of Commercial Banks in KenyaДокумент10 страницAssessing The Effect of Liquidity On Profitability of Commercial Banks in KenyaAlexander DeckerОценок пока нет

- Analysis of Teachers Motivation On The Overall Performance ofДокумент16 страницAnalysis of Teachers Motivation On The Overall Performance ofAlexander DeckerОценок пока нет

- An Overview On Co-Operative Societies in BangladeshДокумент11 страницAn Overview On Co-Operative Societies in BangladeshAlexander DeckerОценок пока нет

- Analysis of Blast Loading Effect On High Rise BuildingsДокумент7 страницAnalysis of Blast Loading Effect On High Rise BuildingsAlexander DeckerОценок пока нет

- An Experiment To Determine The Prospect of Using Cocoa Pod Husk Ash As Stabilizer For Weak Lateritic SoilsДокумент8 страницAn Experiment To Determine The Prospect of Using Cocoa Pod Husk Ash As Stabilizer For Weak Lateritic SoilsAlexander DeckerОценок пока нет

- Agronomic Evaluation of Eight Genotypes of Hot Pepper (Capsicum SPP L.) in A Coastal Savanna Zone of GhanaДокумент15 страницAgronomic Evaluation of Eight Genotypes of Hot Pepper (Capsicum SPP L.) in A Coastal Savanna Zone of GhanaAlexander DeckerОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Comparison of Co-Current and Counter-Current Flow Fields On Extraction Performance in Micro-ChannelsДокумент12 страницComparison of Co-Current and Counter-Current Flow Fields On Extraction Performance in Micro-ChannelsAshutosh SharmaОценок пока нет

- Viking Spur Gear Single Pumps SG-04 SG-05Документ18 страницViking Spur Gear Single Pumps SG-04 SG-05celsofortoulОценок пока нет

- BS en 12595-2014Документ22 страницыBS en 12595-2014dipakОценок пока нет

- Fluid Mechanics Activity 1Документ1 страницаFluid Mechanics Activity 1Jay CanobarОценок пока нет

- M20 Plate Heat ExchangerДокумент47 страницM20 Plate Heat ExchangerBimalka WeerasekaraОценок пока нет

- Aspen Exchanger Design and Rating Shell & Tube V9: Tema SheetДокумент7 страницAspen Exchanger Design and Rating Shell & Tube V9: Tema SheetTuấn VũОценок пока нет

- Wall Flows in A Cyclone Separator A Description of Internal PhenomenaДокумент16 страницWall Flows in A Cyclone Separator A Description of Internal PhenomenaRANAIVOARIMANANAОценок пока нет

- Gardco: Standard Ford, Ford Dip, and Mini Ford Viscosity CupsДокумент6 страницGardco: Standard Ford, Ford Dip, and Mini Ford Viscosity CupsRuselkis FloresОценок пока нет

- FMM - Unit Iii QBДокумент50 страницFMM - Unit Iii QBThiruvasagamoorthy KaОценок пока нет

- Formula of Definite Point Overburden PressureДокумент8 страницFormula of Definite Point Overburden PressureThanh Duc NguyenОценок пока нет

- CEP Refresher Problem Set4Документ8 страницCEP Refresher Problem Set4Alyssa Camille Malig-onОценок пока нет

- Importance of Dimensionless Numbers in Mass TransferДокумент27 страницImportance of Dimensionless Numbers in Mass TransferAli AmmarОценок пока нет

- A Holistic Approach On The Simulation of Rotary-Friction-WeldingДокумент6 страницA Holistic Approach On The Simulation of Rotary-Friction-WeldingMohammed SakhlainОценок пока нет

- S 841 - 846 - Manual - 2006Документ176 страницS 841 - 846 - Manual - 2006Centrifugal SeparatorОценок пока нет

- Dip Viscosity Cups, Zahn Type: Assembly & Operating InstructionsДокумент2 страницыDip Viscosity Cups, Zahn Type: Assembly & Operating InstructionsSayed WaqasОценок пока нет

- UntitledДокумент720 страницUntitledMr BigОценок пока нет

- PGP 500 Series PGM 500 Series: Single or Multiple Aluminum Pumps & MotorsДокумент24 страницыPGP 500 Series PGM 500 Series: Single or Multiple Aluminum Pumps & MotorspinkoskyОценок пока нет

- Applied Mathematical Modelling: S.J. Karabelas, B.C. Koumroglou, C.D. Argyropoulos, N.C. MarkatosДокумент20 страницApplied Mathematical Modelling: S.J. Karabelas, B.C. Koumroglou, C.D. Argyropoulos, N.C. MarkatosNMarkatosОценок пока нет

- Modeling and Simulation of Membrane Separation Process Using Computational Fluid DynamicsДокумент26 страницModeling and Simulation of Membrane Separation Process Using Computational Fluid DynamicsBrenda DavisОценок пока нет

- Partical TechnologyДокумент54 страницыPartical TechnologyEhtisham ZiaОценок пока нет

- Fluid Flow Phenomena Lecture NotesДокумент13 страницFluid Flow Phenomena Lecture NotesdesdainedmanОценок пока нет

- Pd-Va.4 (1996)Документ15 страницPd-Va.4 (1996)Santiago GarciaОценок пока нет

- General Properties Rheological Properties: PVC Paste Resin (Copolymer)Документ2 страницыGeneral Properties Rheological Properties: PVC Paste Resin (Copolymer)AminulIslamОценок пока нет

- IARI PHD Entrance Question Paper 2011 - Post Harvest (Post Harvest Engineering and Technology)Документ12 страницIARI PHD Entrance Question Paper 2011 - Post Harvest (Post Harvest Engineering and Technology)Abhay Kumar100% (1)

- FM - HT - Unit 1Документ100 страницFM - HT - Unit 1Monica ChandniОценок пока нет

- The Journal of Supercritical Fluids: Francesco Nasuti, Marco PizzarelliДокумент14 страницThe Journal of Supercritical Fluids: Francesco Nasuti, Marco PizzarelliThamil ThedalОценок пока нет

- Technical Bulletin Skydrol 4Документ28 страницTechnical Bulletin Skydrol 4Albert SomendraОценок пока нет

- COOL - 006 Advances in Liquid Coolant Technologies For Electronics Cooling 2005Документ7 страницCOOL - 006 Advances in Liquid Coolant Technologies For Electronics Cooling 2005Leslie Diaz JalaffОценок пока нет

- Unit OperationДокумент57 страницUnit OperationSunjida Ali RiyaОценок пока нет

- European Journal of Mechanics B/Fluids: Ahmad Shoja-Sani, Ehsan Roohi, Mohsen Kahrom, Stefan StefanovДокумент16 страницEuropean Journal of Mechanics B/Fluids: Ahmad Shoja-Sani, Ehsan Roohi, Mohsen Kahrom, Stefan StefanovasdasddasОценок пока нет