Академический Документы

Профессиональный Документы

Культура Документы

MEMS Product Survey of EPSON

Загружено:

Muhamed ShereefИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

MEMS Product Survey of EPSON

Загружено:

Muhamed ShereefАвторское право:

Доступные форматы

EPSON?

Printing Technology

QMEMS

Gyro sensor

Inertial Sensor

Pressure sensor

Product Survey of EPSON

Presented by MUHAMED SHEREEF P M2 AEI, ROLL NO:07

EPSON

College of Engineering, Trivandrum

EPSON?

Printing Technology

QMEMS

Gyro sensor

Inertial Sensor

Pressure sensor

Overview

EPSON?

EPSON

College of Engineering, Trivandrum

EPSON?

Printing Technology

QMEMS

Gyro sensor

Inertial Sensor

Pressure sensor

Overview

EPSON? Printing Technology

EPSON

College of Engineering, Trivandrum

EPSON?

Printing Technology

QMEMS

Gyro sensor

Inertial Sensor

Pressure sensor

Overview

EPSON? Printing Technology QMEMS

EPSON

College of Engineering, Trivandrum

EPSON?

Printing Technology

QMEMS

Gyro sensor

Inertial Sensor

Pressure sensor

Overview

EPSON? Printing Technology QMEMS Gyro sensor

EPSON

College of Engineering, Trivandrum

EPSON?

Printing Technology

QMEMS

Gyro sensor

Inertial Sensor

Pressure sensor

Overview

EPSON? Printing Technology QMEMS Gyro sensor Inertial Sensor

EPSON

College of Engineering, Trivandrum

EPSON?

Printing Technology

QMEMS

Gyro sensor

Inertial Sensor

Pressure sensor

Overview

EPSON? Printing Technology QMEMS Gyro sensor Inertial Sensor Pressure sensor

EPSON

College of Engineering, Trivandrum

EPSON?

Printing Technology

QMEMS

Gyro sensor

Inertial Sensor

Pressure sensor

EPSON?

EPSON was founded in May 18, 1942(Suwa, Nagano, Japan) Producers of information-related equipments, Electronic devices, Precision products It has a paid in capital of 53,204 million yen It has a net sale of 973,663 million yen (scal year ended March 31, 2011)

EPSON

College of Engineering, Trivandrum

EPSON?

Printing Technology

QMEMS

Gyro sensor

Inertial Sensor

Pressure sensor

Printing Technology

Long established as one of the worlds leading printer manufacturers, Epson is dedicated to supporting the diverse needs of its customers worldwide It oers a wide range of products designed to meet specic needs Printer Types Inkjet printers Laser printers POS printers SIDM printers

EPSON

College of Engineering, Trivandrum

EPSON?

Printing Technology

QMEMS

Gyro sensor

Inertial Sensor

Pressure sensor

Epson Micro Piezo Technology

The most advanced inkjet print head technology

Epson introduced its rst printer that used piezoelectric technology for its print heads in October 1984: the Epson SQ-2000

In 1990 developed an advanced piezoelectric inkjet head for future generations of Epson printers

Micro Piezo print head that was rst used in the Epson Stylus 800 which was launched in March 1993

Figure: Micro Piezo print head

EPSON

College of Engineering, Trivandrum

EPSON?

Printing Technology

QMEMS

Gyro sensor

Inertial Sensor

Pressure sensor

How does an Epson Micro Piezo print head work?

Stage 1:An electrical pulse is applied to the piezoelectric element behind each nozzle. This causes the element to bend,creating a negative pressure that draws ink from the main ink chamber into the ring chamber.

Stage 2:The electrical charge is altered, causing the piezoelectric element to rapidly push in the opposite direction, propelling the ink droplet out.

EPSON

College of Engineering, Trivandrum

EPSON?

Printing Technology

QMEMS

Gyro sensor

Inertial Sensor

Pressure sensor

Epsons Variable Sized Dot Technology (VSDT)

Epsons Micro Piezo print head technology allows extremely accurate control over the size of ink droplets that are ejected from the print head nozzles.

This is done by varying the electrical charge given to the piezoelectric elements.

This enables Epsons printers to achieve variable sized ink droplets as small as 1.5 picoliters - This is what Epson calls Variable Size Droplet Technology (VSDT).

EPSON

College of Engineering, Trivandrum

EPSON?

Printing Technology

QMEMS

Gyro sensor

Inertial Sensor

Pressure sensor

By capitalizing on its semiconductor expertise, Epson reengineered its world-renowned Micro PiezoTM inkjet print head in 2008, making it capable of producing 360 dots per inch

This is the industrys highest density for a print head based on piezoelectric technology to date.

Figure: Micro Piezo Head Size Comparison

EPSON College of Engineering, Trivandrum

EPSON?

Printing Technology

QMEMS

Gyro sensor

Inertial Sensor

Pressure sensor

Electronic device market needs

The market needs electronic devices that oer the same high performance even after they are downsized QMEMS is Seiko Epsons response to this need

EPSON

College of Engineering, Trivandrum

EPSON?

Printing Technology

QMEMS

Gyro sensor

Inertial Sensor

Pressure sensor

What is QMEMS?

QMEMS is a combination of Quartz, a crystal material with excellent characteristics such as high stability and high precision, and MEMS To a semiconductor MEMS material, we apply precision microprocessing based on quartz material to create a quartz device that we call QMEMS It supports a lot of functions such as mechanicals,electronics,optical and chemicals and oers very much adding values in the form of high accuracy and high stability

EPSON College of Engineering, Trivandrum

EPSON?

Printing Technology

QMEMS

Gyro sensor

Inertial Sensor

Pressure sensor

Tuning-fork crystal units

Sub-miniature tuning-fork crystal units & sub-miniature real-time clock modules

3-D photolithographic processing of crystal chips Miniaturizing crystal chips with a conventional structure reduces the area of the electrodes (indicated in red). Fabricating the chips with an H-groove structure provides a larger electrode area and raises electrolytic eciency This design enables miniaturized crystal with CI values as low as those on ordinary-sized crystals

EPSON College of Engineering, Trivandrum

EPSON?

Printing Technology

QMEMS

Gyro sensor

Inertial Sensor

Pressure sensor

The CI value of a crystal fabricated using QMEMS technology remains constant,at a level equivalent to that of conventional crystals, even as crystal size decreases

Applications

EPSON

College of Engineering, Trivandrum

EPSON?

Printing Technology

QMEMS

Gyro sensor

Inertial Sensor

Pressure sensor

Some popular sub-miniature tuning-fork crystal units & sub-miniature real-time clock modules

kHz range crystal units Crystal oscillators

Real time clock modules

EPSON

College of Engineering, Trivandrum

EPSON?

Printing Technology

QMEMS

Gyro sensor

Inertial Sensor

Pressure sensor

HFF crystal unit / HFF crystal oscillator

In order to increase the frequency of oscillators, it is necessary to make the chip thinner, but conventional processing methods imposed limitations on producing thin chips

A high-frequency fundamental was enabled by photolithographically processing only the oscillating portion of the chip so as to form an extremely thin inverted-mesa structure having a thickness of only several microns.

EPSON College of Engineering, Trivandrum

EPSON?

Printing Technology

QMEMS

Gyro sensor

Inertial Sensor

Pressure sensor

Advantage of high frequency oscillation at the fundamental frequency

High-frequency fundamental oscillation helps stabilize high-speed, high-volume data transmissions because nearby high-frequency components can be suppressed.

EPSON

College of Engineering, Trivandrum

EPSON?

Printing Technology

QMEMS

Gyro sensor

Inertial Sensor

Pressure sensor

Some of most popular HFF crystal units / HFF crystal oscillators

Crystal oscillators 60 MHz or higher

EPSON

College of Engineering, Trivandrum

EPSON?

Printing Technology

QMEMS

Gyro sensor

Inertial Sensor

Pressure sensor

Photo AT

Compact AT crystal units and Oscillators using photolithography processing technology

Photolithographic process enables the formation of uniformly shaped crystal chips, and oer outstanding temperature characteristics

EPSON College of Engineering, Trivandrum

EPSON?

Printing Technology

QMEMS

Gyro sensor

Inertial Sensor

Pressure sensor

Temperature characteristics

Frequency-temperature coecient of a 2.0 x 1.6 mm AT crystal unit (26 MHz)

Applications Contribute to smaller mobile devices with greater functionality.

EPSON

College of Engineering, Trivandrum

EPSON?

Printing Technology

QMEMS

Gyro sensor

Inertial Sensor

Pressure sensor

Some of most popular compact AT crystal units and Oscillators using photolithography processing technology

MHz range crystal units

Oscillators

EPSON

College of Engineering, Trivandrum

EPSON?

Printing Technology

QMEMS

Gyro sensor

Inertial Sensor

Pressure sensor

Gyro sensor

Vibration gyro sensors sense angular velocity from the Coriolis force applied to a vibrating object

EPSON

College of Engineering, Trivandrum

EPSON?

Printing Technology

QMEMS

Gyro sensor

Inertial Sensor

Pressure sensor

There are Five dierent types of Vibration gyro sensors depending on Applications XV-8100CB,XV-8000LK,XV-8000CB For portable GPS applications XV-3700CB Motion UI RC helicopter and hobby with high detection range needs XV-3500CB Detection picture stabilization of DVC and DSC Detection of moving with man machine interface

EPSON

College of Engineering, Trivandrum

EPSON?

Printing Technology

QMEMS

Gyro sensor

Inertial Sensor

Pressure sensor

Features of EPSON Gyrosensors

Low noise level Stability over temperature Vibration and shock resistance

EPSON

College of Engineering, Trivandrum

EPSON?

Printing Technology

QMEMS

Gyro sensor

Inertial Sensor

Pressure sensor

SAW Filter

SAW Filters Fundamentals SAW device consists of two transducers with interdigital transducers(IDT) of thin metal electrodes deposited on a piezoelectric substrate such as quartz or lithiun tantalite. One of these acts as the device input and converts signal voltage variations into mechanical surface acoustic waves. The other IDT is used as an output receiver to convert mechanical SAW vibrations back into output voltages.

EPSON

College of Engineering, Trivandrum

EPSON?

Printing Technology

QMEMS

Gyro sensor

Inertial Sensor

Pressure sensor

SAW Filters

FF-32N Dimension:3.8 3.8 0.98mm Frequency range : 300 MHz to 500 MHz Narrow band for SRD Front-end lters FF-555 Dimension:4.8 5.2 1.5mm Frequency range : 300 MHz to 500 MHz Excellent shock resistance and environmental capability

EPSON

College of Engineering, Trivandrum

EPSON?

Printing Technology

QMEMS

Gyro sensor

Inertial Sensor

Pressure sensor

Applications

Wireless remote-control Security(Automotive keyless entry)

EPSON

College of Engineering, Trivandrum

EPSON?

Printing Technology

QMEMS

Gyro sensor

Inertial Sensor

Pressure sensor

Inertial Sensor

Inertial sensor is a sensing device that has mounted 3-axis gyro plus 3-axis accelerometer It has two types of Inetial sensors:AH-6120LR and AP-6110LR Package size 10.0 x 8.0 x 3.8mm

EPSON

College of Engineering, Trivandrum

EPSON?

Printing Technology

QMEMS

Gyro sensor

Inertial Sensor

Pressure sensor

Product summary

3-axis gyro plus 3-axis accelerometer Factory adjusted accuracy scale factor and bias Analog output for mixed signaling systems Low noise and stability over temperature angular rate detection Low current consumption Applications Motion tracking and measurement Dead reckoning and Healthcare

EPSON College of Engineering, Trivandrum

EPSON?

Printing Technology

QMEMS

Gyro sensor

Inertial Sensor

Pressure sensor

Pressure sensor

Pressure sensor is a sensing device that is used to various kinds of pressure measurement for industrial use Operating Principle

When stress is applied to a twin tuning fork quartz oscillator, its resonance frequency becomes almost linear By using this property, the twin tuning fork quartz oscillator in exure vibration mode (highly sensitive to stress) can be used as a pressure -sensitive device

EPSON College of Engineering, Trivandrum

EPSON?

Printing Technology

QMEMS

Gyro sensor

Inertial Sensor

Pressure sensor

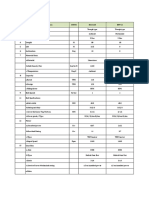

Product specications

EPSON

College of Engineering, Trivandrum

EPSON?

Printing Technology

QMEMS

Gyro sensor

Inertial Sensor

Pressure sensor

THANK YOU

EPSON

College of Engineering, Trivandrum

Вам также может понравиться

- s5 1450 ZervakisДокумент28 страницs5 1450 ZervakisAbyan RaidhОценок пока нет

- Micro EpsilonДокумент36 страницMicro EpsilonOrnélio ClossОценок пока нет

- Optical Metrology - OlympusДокумент2 страницыOptical Metrology - OlympusMc PammarОценок пока нет

- Action Sensing Speech Using iMEMS: KBN College of EngineeringДокумент62 страницыAction Sensing Speech Using iMEMS: KBN College of EngineeringShafiq Ahmed ShahbazОценок пока нет

- Gyro Sensor: Epson Europe Electronics GMBHДокумент6 страницGyro Sensor: Epson Europe Electronics GMBHGil ReisОценок пока нет

- Aitek Magnetic Pickups MPU Cat08 - SensorsДокумент40 страницAitek Magnetic Pickups MPU Cat08 - SensorsJose Luis Castro Aguilar0% (1)

- High Speed Sensor: Pratyush ParimalДокумент5 страницHigh Speed Sensor: Pratyush ParimalAnonymous mlYYLRe7HОценок пока нет

- TN16 - Sensor Selection GuideДокумент13 страницTN16 - Sensor Selection GuideAsitha KulasekeraОценок пока нет

- Cat OptoNCDT enДокумент36 страницCat OptoNCDT enNikhil SharmaОценок пока нет

- Vibration Analysis For IoT Enabled Predictive MaintenanceДокумент12 страницVibration Analysis For IoT Enabled Predictive MaintenanceKleber VieiraОценок пока нет

- AlTek PickupsДокумент40 страницAlTek PickupsLuis Alfonso Andler C.100% (1)

- TowerJazz 2010Документ23 страницыTowerJazz 2010zeljavalybiОценок пока нет

- Somatom Emotion 6Документ3 страницыSomatom Emotion 6ansarhussain012Оценок пока нет

- Endoscopic Microscopy Using OCTДокумент10 страницEndoscopic Microscopy Using OCTMahyarОценок пока нет

- CMOS Image Sensors - IntroductionДокумент15 страницCMOS Image Sensors - IntroductionthikgaidepОценок пока нет

- ME189 - Chapter 1Документ43 страницыME189 - Chapter 1Vijay KambleОценок пока нет

- Fingerprint Recognisation Technology (F.R.T)Документ37 страницFingerprint Recognisation Technology (F.R.T)Gemechu AyanaОценок пока нет

- E.cam Brochure SpecsДокумент24 страницыE.cam Brochure Specsdurwood987Оценок пока нет

- NDTДокумент6 страницNDTYasir SiddiquiОценок пока нет

- Micro Electro Mechanical SystemДокумент19 страницMicro Electro Mechanical SystemTejes NilankarОценок пока нет

- What Is Mems?: Mems M E M SДокумент25 страницWhat Is Mems?: Mems M E M SjeyrajiОценок пока нет

- (Tutorial) CMOS Image Sensors PDFДокумент15 страниц(Tutorial) CMOS Image Sensors PDFAdam112211Оценок пока нет

- Geosense Brochure 2011 V1.2Документ46 страницGeosense Brochure 2011 V1.2jnfОценок пока нет

- Veeco TSV Metrology Semicon West 2010Документ24 страницыVeeco TSV Metrology Semicon West 2010Hoang HaiОценок пока нет

- Accelerometer Selection and InstallationДокумент16 страницAccelerometer Selection and InstallationLake HouseОценок пока нет

- Intelligent Wireless Video CameraДокумент25 страницIntelligent Wireless Video CameraSaiprasanna Lakshmi73% (11)

- Ah100b SpecificationДокумент10 страницAh100b SpecificationEdo KesumaОценок пока нет

- Mineaturization Concepts, Benefits and Materials For MEMSДокумент48 страницMineaturization Concepts, Benefits and Materials For MEMSVaibhav RanaОценок пока нет

- Recent Developments of Mems Based Sensors in AutomobilesДокумент6 страницRecent Developments of Mems Based Sensors in AutomobilesMano MacОценок пока нет

- 10.1109 Icde.2017.170 j5k1Документ12 страниц10.1109 Icde.2017.170 j5k1sima.sobhi70Оценок пока нет

- Micro Epslon PDFДокумент76 страницMicro Epslon PDFAlan VisintinОценок пока нет

- Customized Mcps For Analytical Instruments: An MCP For Every ApplicationДокумент18 страницCustomized Mcps For Analytical Instruments: An MCP For Every ApplicationDhananjayОценок пока нет

- 01 Fingerprint Sensing TechniquesДокумент47 страниц01 Fingerprint Sensing TechniquesJáyásïmhā RēddiëОценок пока нет

- Somatom Scope: Answers For LifeДокумент44 страницыSomatom Scope: Answers For LifeSalvador CordovaОценок пока нет

- IDM Lab1Документ5 страницIDM Lab1gudursrinath11Оценок пока нет

- 01 Fingerprint Sensing TechniquesДокумент47 страниц01 Fingerprint Sensing TechniquesNileshNemadeОценок пока нет

- Mems and Microsystems Design and ManufactureДокумент57 страницMems and Microsystems Design and ManufactureAbcОценок пока нет

- 01 Fingerprint Sensing TechniquesДокумент47 страниц01 Fingerprint Sensing TechniquesumeshОценок пока нет

- Camera For Machine VisionДокумент34 страницыCamera For Machine VisionArijit NathОценок пока нет

- Asset 1216Документ12 страницAsset 1216Soma GhoshОценок пока нет

- A Technical Seminar On: Wearable BiosensorsДокумент28 страницA Technical Seminar On: Wearable BiosensorsMushfique HussainОценок пока нет

- Captura de MovimientoДокумент6 страницCaptura de MovimientoWilliam GalindoОценок пока нет

- Key Technologies and Research Development of CMOS Image Sensors - SEMINARДокумент19 страницKey Technologies and Research Development of CMOS Image Sensors - SEMINARSurajRNОценок пока нет

- Inspection of Composite Rocket Nozzle PDFДокумент10 страницInspection of Composite Rocket Nozzle PDFHari KrishnaОценок пока нет

- Cat ThermoMETER InfraredДокумент56 страницCat ThermoMETER InfraredspyrosОценок пока нет

- Multitype ICP Emission Spectrometer (ICPE-9000)Документ16 страницMultitype ICP Emission Spectrometer (ICPE-9000)mr_stali2987Оценок пока нет

- Advanced SensorsДокумент23 страницыAdvanced SensorsAzharuddin MansooriОценок пока нет

- Vibration Sensors - SKFДокумент44 страницыVibration Sensors - SKFnekoNcen100% (1)

- CereTom BrochureДокумент8 страницCereTom BrochuresenthilОценок пока нет

- Telehealth Monitoring Based Myoelectric Prosthetic ArmДокумент27 страницTelehealth Monitoring Based Myoelectric Prosthetic ArmAll Engineering ElectronicsОценок пока нет

- Mass Flow Meter: Product Manual AFM3000Документ12 страницMass Flow Meter: Product Manual AFM3000SOCDI SASОценок пока нет

- 13 5Документ5 страниц13 5jaiganeshv1991Оценок пока нет

- AMBiOS - QscopeSeries - AFM-SPM PDFДокумент8 страницAMBiOS - QscopeSeries - AFM-SPM PDFdejavu77Оценок пока нет

- Raith e LiNE e BeamДокумент4 страницыRaith e LiNE e BeaminsanemanabОценок пока нет

- ST Sensors MM 201910Документ103 страницыST Sensors MM 201910Yiannis PapadopoulosОценок пока нет

- PMD 2005 USA BrochureДокумент6 страницPMD 2005 USA BrochureErica BeasleyОценок пока нет

- C12 - In-Place Inclinometer - Rev02 25.01.12Документ4 страницыC12 - In-Place Inclinometer - Rev02 25.01.12ssecaesОценок пока нет

- MEMS Product Development: From Concept to CommercializationОт EverandMEMS Product Development: From Concept to CommercializationОценок пока нет

- DEEP SEA - DSE8620-MKII - Installation InstructionsДокумент2 страницыDEEP SEA - DSE8620-MKII - Installation InstructionsGustavo DuarteОценок пока нет

- Doosan Diesel Engine DL06Документ211 страницDoosan Diesel Engine DL06mnowaq98% (42)

- 6GK52053BB002AB2 Datasheet enДокумент4 страницы6GK52053BB002AB2 Datasheet enCelio Ricardo Quaio GoettenОценок пока нет

- Service Delivery Manager Resume SampleДокумент3 страницыService Delivery Manager Resume SampleManish KumarОценок пока нет

- Humidity Ebook 2017 B211616ENДокумент17 страницHumidity Ebook 2017 B211616ENgustavohdez2Оценок пока нет

- NMA 5V, 12V & 15V Series: Isolated 1W Dual Output DC/DC ConvertersДокумент6 страницNMA 5V, 12V & 15V Series: Isolated 1W Dual Output DC/DC ConvertersJoel Eljo Enciso SaraviaОценок пока нет

- 320/330 Hydraulic Excavators: Technical PresentationДокумент104 страницы320/330 Hydraulic Excavators: Technical Presentationramon hidalgo100% (3)

- T2265 PDFДокумент0 страницT2265 PDFMerlin PokamОценок пока нет

- The Multi Billion Dollar Industry You Can Make Money From EasilyДокумент34 страницыThe Multi Billion Dollar Industry You Can Make Money From EasilyJoshuaОценок пока нет

- Characteristics of Digital DataДокумент6 страницCharacteristics of Digital DataArdi DiraОценок пока нет

- Prediction of Overshoot and Crosstalk of Low Voltage GaN HEMTДокумент27 страницPrediction of Overshoot and Crosstalk of Low Voltage GaN HEMTfirststudentОценок пока нет

- UPS 348-01-01 PowerWAVE 3000T PDFДокумент4 страницыUPS 348-01-01 PowerWAVE 3000T PDFShahin ShajahanОценок пока нет

- Roland Vs 640 Mechanical DrawingДокумент40 страницRoland Vs 640 Mechanical DrawingEdwardo RamirezОценок пока нет

- FS2Crew Airbus X Voice Control Manual PDFДокумент49 страницFS2Crew Airbus X Voice Control Manual PDFViorica Sburlea-MarinОценок пока нет

- Flat Work IronerДокумент9 страницFlat Work Ironerdhruv_tyagiОценок пока нет

- NTT Data Ai Governance v04Документ23 страницыNTT Data Ai Governance v04radhikaseelam1Оценок пока нет

- Data SheetДокумент24 страницыData Sheetbashok20Оценок пока нет

- HIAB14000XGДокумент267 страницHIAB14000XGMigueОценок пока нет

- Requirements of Push NotificationДокумент14 страницRequirements of Push Notificationdarshan89Оценок пока нет

- HT32F1655-1656 Datasheet v100Документ48 страницHT32F1655-1656 Datasheet v100Viktor SpeicherОценок пока нет

- Rajesh BansalДокумент14 страницRajesh BansalTapasОценок пока нет

- Eurocell Panel Vertical Polarization Half-Power Beam WidthДокумент1 страницаEurocell Panel Vertical Polarization Half-Power Beam WidthGEORGEОценок пока нет

- Basic FPGA Tutorial Vivado VHDLДокумент273 страницыBasic FPGA Tutorial Vivado VHDLTito SaulОценок пока нет

- Generic PapersizesДокумент3 страницыGeneric PapersizesConarch StudioОценок пока нет

- Doseuro Rapida Em01 Plus - ManualДокумент16 страницDoseuro Rapida Em01 Plus - ManualDragisa DjukicОценок пока нет

- 10-Inch Daylight Radar: 1932 MARK-2Документ2 страницы10-Inch Daylight Radar: 1932 MARK-2Thien NguyenОценок пока нет

- Warehouse ProjectДокумент21 страницаWarehouse Projectpakshaheen75% (4)

- Angela M. Cirucci, Urszula M. Pruchniewska - UX Research Methods For Media and Communication Studies - An Introduction To Contemporary Qualitative MethodsДокумент203 страницыAngela M. Cirucci, Urszula M. Pruchniewska - UX Research Methods For Media and Communication Studies - An Introduction To Contemporary Qualitative MethodsJessica ValenzuelaОценок пока нет

- Restructuring of The Swedish National Grid Control Centres: Session 2004Документ7 страницRestructuring of The Swedish National Grid Control Centres: Session 2004ramsesiОценок пока нет

- Resume - Ahad Siddiqui - Telecom Engg - 11+YOEДокумент6 страницResume - Ahad Siddiqui - Telecom Engg - 11+YOEahad siddiquiОценок пока нет