Академический Документы

Профессиональный Документы

Культура Документы

HKP Gas Turbine Power Plants

Загружено:

Harshad PatelИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

HKP Gas Turbine Power Plants

Загружено:

Harshad PatelАвторское право:

Доступные форматы

Gas Turbine

Power Plants

BY : HARSHAD PATEL

Outline

Brayton cycle

Open

Close

Advantages of gas turbine plant

Improvement of efficiency of gas turbine plant

Brayton Cycles Ideal For Gas Turbine Engines

Brayton Cycle :

Proposed by George Brayton for use in the Reciprocating Oil-Burning

Engine at around 1870.

Fresh air at Ambient Conditions is drawn into

the Compressor, where its Temp. and Pr. are

raised.

High-Pr. air proceeds into the Combustion

Chamber, where the fuel is burned at

Constant Pr., with Increase in Temp.

Resulting High-Temp. gases then enter the

Turbine, where they expand to the Atm. Pr.

while producing Power.

Exhaust Gases leaving the turbine are thrown

out (not recirculated), as an Open Cycle.

Brayton Open Cycle

Location Pr. Level Temp. Level

1 atm atm

2

3

4

Gas Turbines usually operate on an Open Cycle.

Brayton Open Cycle

Brayton Closed Cycle

Compression and Expansion processes remain the same.

Combustion process is replaced by a Constant-Pressure Heat Addition process

from an external source.

Exhaust process is replaced by a Constant-Pressure Heat Rejection Process to

the ambient air.

Brayton Closed Cycle

Combustion process is replaced by a Constant-Pressure

Heat Addition process from an external source.

Exhaust process is replaced by a Constant-Pressure

Heat Rejection Process to the ambient air.

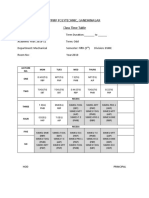

ME0207 SEM-IV Applied Thermodynamics II

Gas Turbine

ME0207 SEM-IV Applied Thermodynamics II

Gas Turbine

ME0207 SEM-IV Applied Thermodynamics II

Gas Turbine

ME0207 SEM-IV Applied Thermodynamics II

Gas Turbine

ME0207 SEM-IV Applied Thermodynamics II

Gas Turbine Power Plant

ME0207 SEM-IV Applied Thermodynamics II

Gas Turbine Power Plant

ME0207 SEM-IV Applied Thermodynamics II

Gas Turbine Power Plant

ME0207 SEM-IV Applied Thermodynamics II

Gas Turbine Power Plant

ME0207 SEM-IV Applied Thermodynamics II

Gas Turbine Power Plant

ME0207 SEM-IV Applied Thermodynamics II

Made up of Four Internally Reversible processes:

Brayton Closed Cycle Analysis

1-2 Isentropic Compression (in a Compressor)

2-3 Constant-Pressure Heat Addition

3-4 Isentropic Expansion (in a Turbine)

4-1 Constant-Pressure Heat Rejection

ME0207 SEM-IV Applied Thermodynamics II

Brayton Closed Cycle Analysis

Neglecting changes in Kinetic and Potential energies, the Energy Balance

for a Steady-Flow Process, on a UnitMass Basis :

( ) ( ) ( )

in out in out exit inlet

q q w w h h + =

( ) ( )

3 2 3 2 in P

q h h C T T = =

( ) ( )

4 1 4 1 out P

q h h C T T = =

Thermal Efficiency of Ideal Brayton Cycle :

( )

( )

( )

( )

4 1

,

3 2

1 4 1

2 3 2

1 1

1

1

1

P

net out

th Brayton

in in

P

C T T

w q

q q

C T T

T T T

T T T

q

= = =

ME0207 SEM-IV Applied Thermodynamics II

Processes 1-2 and 3-4 are Isentropic,

P

2

= P

3

and P

4

= P

1

.

Brayton Closed Cycle Analysis

1 1

2 2 3 3

1 1 4 4

T P P T

T P P T

| | | |

= = =

| |

| |

\ . \ .

Substituting and simplifying the equation :

,

1

1

1

th Brayton

p

r

q

| |

|

\ .

=

(

2

1

p

P

r

P

=

where;

ME0207 SEM-IV Applied Thermodynamics II

Gas Turbine Power Plants Applications

Two Major Application Areas :

1. Aircraft Propulsion

2. Electric Power Generation.

Electric Power Generation

Aircraft Propulsion

ME0207 SEM-IV Applied Thermodynamics II

Compared to Steam-Turbine and Diesel Propulsion Systems, Gas Turbine offers :

1. Greater Power for a given size and weight,

2. High Reliability,

3. Long Life,

4. More Convenient Operation.

5. Engine Start-up Time reduced from 4 hrs to less than 2 min!!

Gas Turbine Power Plants Advantages

ME0207 SEM-IV Applied Thermodynamics II

2. Increasing the Efficiencies of Turbomachinery Components :

1. Increasing the Turbine Inlet (Firing) Temperatures :

- 540 C in the 1940s to 1425 C and even higher today.

- Development of New Materials +

Innovative Cooling Techniques for the critical components.

Cycle Efficiency - Improvements

- Advanced techniques for Computer-Aided Design.

- Aerodynamic Design with minimal losses.

3. Adding Modifications to Basic Cycle :

- Efficiencies of early gas turbines are practically doubled by incorporating

Intercooling,

Regeneration (or Recuperation), and

Reheating.

ME0207 SEM-IV Applied Thermodynamics II

Gas Turbine Cycle Intercooling

Net Work Output of Gas Turbine can be by the Compressor Work Input.

Multistage + Intercooling!!!

ME0207 SEM-IV Applied Thermodynamics II

Gas Turbine Cycle Intercooling

Three Internally Reversible processes:

1-c Isentropic Compression,

till Pr. is P

i

c-d Constant-Pressure Cooling,

from T

c

to T

d

d-2 Isentropic Compression,

State 2.

ME0207 SEM-IV Applied Thermodynamics II

Work Input per unit Mass Flow on the PV Diagram : 1cd2ab1.

Gas Turbine Cycle Intercooling

Without Intercooling : Single Stage Isentropic Compression from State 1 to State 2.

Work Area 12ab1.

Crosshatched Area Reduction in work due to

Intercooling.

ME0207 SEM-IV Applied Thermodynamics II

Air is compressed from 100 kPa, 300 K to 1000 kPa in a two-stage compressor with

Intercooling between stages. The intercooler pressure is 300 kPa. The air is cooled back to

300 K in the intercooler before entering the second compressor stage. Each compressor

stage is isentropic. For steady-state operation and negligible changes in kinetic and

potential energy from inlet to exit, determine :

(a) the temperature at the exit of the second compressor stage .and,

(b) the total compressor work input per unit of mass flow.

(c) Repeat for a single stage of compression from the given inlet state to the final

pressure.

Example 3

ME0207 SEM-IV Applied Thermodynamics II

Example 3.cntd.

Process 1c :

( )

K

kPa

kPa

K T

P

P

T

T

c

c c

62 . 410

100

300

300

4 . 1

1 4 . 1

1

1 1

=

|

|

.

|

\

|

=

|

|

.

|

\

|

=

Process d2 :

( )

K

kPa

kPa

K T

P

P

T

T

d d

17 . 423

300

1000

300

4 . 1

1 4 . 1

2

1

2 2

=

|

|

.

|

\

|

=

|

|

.

|

\

|

=

ANS

ME0207 SEM-IV Applied Thermodynamics II

Example 3.cntd.

Total Compressor Work Input per unit of Mass :

( ) ( )

( ) ( ) { }

( ) ( ) { }

kg

kJ

K kg

kJ

T T T T C

h h h h

m

W

d c P

d c

C

96 . 234

300 17 . 423 300 62 . 410

.

005 . 1

2 1

2 1

=

+

(

=

+ =

+ =

-

-

ANS

ME0207 SEM-IV Applied Thermodynamics II

Example 3.cntd.

For Single Stage Isentropic Compression :

Process 13 : ( )

K

kPa

kPa

K T

P

P

T

T

c

21 . 579

100

1000

300

4 . 1

1 4 . 1

1

1

3

1

3

=

|

|

.

|

\

|

=

|

|

.

|

\

|

=

Compressor Work Input per unit of Mass :

( ) ( )

( )

|

|

.

|

\

|

=

=

= =

-

-

kg

kJ

to Compared

kg

kJ

K kg

kJ

T T C h h

m

W

P

C

96 . 234 60 . 280

300 21 . 579

.

005 . 1

1 3 1 3

ANS

ME0207 SEM-IV Applied Thermodynamics II

Gas Turbine Cycle Reheat

For Metallurgical Reasons, the Temperature of the Gaseous Combustion Products

entering the turbine must be limited.

This temperature can be controlled by providing Air in Excess of the Amount

required to Burn the Fuel in the combustor.

As a consequence, the gases exiting the combustor contain Sufficient Air to support

the Combustion of Additional Fuel.

Gas Turbine Power Plants take advantage of the Excess Air by means of a Multistage

Turbine with a Reheat Combustor between the stages. With this arrangement the Net

Work per Unit of Mass Flow can be increased.

NOTE : Reheat is used for in Output Power.

It may not the Efficiency!!

ME0207 SEM-IV Applied Thermodynamics II

Gas Turbine Cycle Reheat

After expansion from State 3 to State a in the first turbine, the gas is Reheated at

Constant Pressure from State a to State b.

The expansion is then completed in the second turbine from State b to State 4.

ME0207 SEM-IV Applied Thermodynamics II

From the earlier results,

kg

kJ

W

kg

kJ

Q

kg

kJ

W

T

in

C

43 . 624

81 . 992

19 . 213

=

=

=

-

-

-

Let the turbine in the basic plant of Example 1 have one reheat. If the inlet temperature

at the second stage is same as that of first, compute the net power and efficiency.

Example 5

ME0207 SEM-IV Applied Thermodynamics II

bar P P P

i

55 . 2 ) 5 . 6 1 ( ) (

2 1

= = =

Optimum Intermediate Pr :

Process 3a : ( )

K

bar

bar

K T

P

P

T

T

a

i a

11 . 1148

55 . 2

5 . 6

1500

4 . 1

1 4 . 1

1

3 3

=

|

|

.

|

\

|

=

|

|

.

|

\

|

=

Turbine Work :

( ) ( )

( )| |

(

=

= =

kg

kJ

K

K kg

kJ

T T C h h W

a P a T

64 . 353

114811 1500

.

005 . 1

3 3 1 ,

Example 5.cntd.

ME0207 SEM-IV Applied Thermodynamics II

(

=

(

=

= + =

kg

kJ

kg

kJ

W W W W

T T T Total T

3 . 707

64 . 353 2

2

1 , 2 , 1 , ,

ANS

Example 5.cntd.

Optimum Intermediate Pr. +

Same Inlet Temp @ both Stages (i.e. T

3

= T

b

)

Heat Input to Reheater :

( ) ( ) ( )| |

(

=

(

= = =

-

kg

kJ

K

K kg

kJ

T T C h h Q

a b P a b heater in

65 . 353 11 . 1148 1500

.

005 . 1

Re ,

ME0207 SEM-IV Applied Thermodynamics II

Example 5.cntd.

Efficiency :

% 7 . 36

) 65 . 353 81 . 992 (

) 19 . 213 3 . 707 (

Re ,

=

+

=

+

=

- -

kg

kJ

kg

kJ

Q Q

W W

heater in in

C T

th

q

ANS

NOTE : Efficiency from 41.42 % to 36.7 %.

BUT, W

T

from 624.43 kJ/kg to 707.3 kJ/kg...!!

ME0207 SEM-IV Applied Thermodynamics II

Gas Turbine Cycle Regeneration

Turbine Exhaust Temperature of a gas turbine is normally much above the ambient

temperature.

Accordingly, the Turbine Exhaust Gas has a potential for use (Availability or

Exergy) that would be irrevocably lost if the gas would discarded directly to the

surroundings.

One way of utilizing this potential is by means of a Heat Exchanger called a

Regenerator, which allows the air exiting the compressor to be preheated before

entering the combustor, thereby reducing the amount of fuel required to be burned

in the combustor.

ME0207 SEM-IV Applied Thermodynamics II

Gas Turbine Cycle Regeneration

Regenerator : Counterflow Heat Exchanger.

Hot Turbine Exhaust Gas and the Air leaving the Compressor pass in

Opposite Directions.

ME0207 SEM-IV Applied Thermodynamics II

Turbine exhaust gas is cooled from State 4 to State y, while the air exiting the

compressor is heated from State 2 to State x.

Gas Turbine Cycle Regeneration

Hence, a heat transfer is required only to the air temperature from State x to State

3, rather than from State 2 to State 3.

ME0207 SEM-IV Applied Thermodynamics II

Net Work Developed per unit of mass flow is not altered by the addition of a

regenerator.

Gas Turbine Cycle Regeneration

Since the Q

in

is , .

Q

in

as h

x

; and thus T

x

.

ME0207 SEM-IV Applied Thermodynamics II

Gas Turbine Cycle Regenerator Effectiveness

1 2 A

T

Hot Fluid

Cold Fluid

T

h1

T

c1

T

h2

T

c2

T

h

T

c

1 2 A

T

Hot Fluid

Cold Fluid

T

h1

T

c1

T

h2

T

c2

T

h

T

c

T

cold,exit

< T

hot,in

Limiting Case : T

cold,exit

= T

hot,in

.Reversibility!!!

Regenerator Effectiveness =

Ratio of the Actual Enthalpy

Increase to the Maximum

Theoretical Enthalpy Increase

of the air flowing through the

compressor side of the

regenerator.

ME0207 SEM-IV Applied Thermodynamics II

Gas Turbine Cycle Regenerator Effectiveness

2 4

2

h h

h h

x

regen

= q

2 4

2

T T

T T

x

=

As Q

in

approaches Reversibility,

h

x

approaches h

4

.

tends to Unity. (100%).!!!

ME0207 SEM-IV Applied Thermodynamics II

Assuming that the regenerator incorporated into the basic plant of Example 1 is 90 %

efficient, calculate the increase in thermal efficiency.

Example 6

From the earlier results,

kg

kJ

W

kg

kJ

Q

kg

kJ

W

K T K T

K T bar P

K T bar P

T

in

C

43 . 624

81 . 992

19 . 213

679 . 878 1500

132 . 512 5 . 6

300 1

4 3

2 2

1 1

=

=

=

= =

= =

= =

-

-

-

T

3

=1500 K

T

1

=300 K

ME0207 SEM-IV Applied Thermodynamics II

Example 6.cntd.

| |

| |

K T

K

K T

T T

T T

h h

h h

x

x

x x

regen

0 . 842

) 132 . 512 679 . 878 (

) 132 . 512 (

9 . 0

2 4

2

2 4

2

=

= q

T

3

=1500 K

T

1

=300 K

Heat Input :

( ) ( ) ( )| |

|

|

.

|

\

|

(

=

(

= = =

-

kg

kJ

to Compared

kg

kJ

K

K kg

kJ

T T C h h Q

x P x in

81 . 992

26 . 661 842 1500

.

005 . 1

3 3

ME0207 SEM-IV Applied Thermodynamics II

Example 6.cntd.

T

3

=1500 K

T

1

=300 K

Efficiency :

( ) % 42 . 41 % 19 . 62

26 . 661

) 19 . 213 43 . 624 (

to Compared

kg

kJ

kg

kJ

Q

W W

in

C T

th

=

(

=

- -

q

ANS

ME0207 SEM-IV Applied Thermodynamics II

Gas Turbine Cycle Intercooling + Reheat + Regenerator

Thank You !

Вам также может понравиться

- 5B. - Steam Turbine Control - Petrotech PDFДокумент4 страницы5B. - Steam Turbine Control - Petrotech PDFJaviStg1100% (1)

- NTPC PresentationДокумент19 страницNTPC PresentationYogesh Gurjar100% (1)

- Power PlantДокумент62 страницыPower PlantIkhlas KittaОценок пока нет

- Training Report CCPPДокумент38 страницTraining Report CCPPTaresh MittalОценок пока нет

- Dead Weight TestersДокумент5 страницDead Weight TestersShrikant EkboteОценок пока нет

- Prepared By: DR - Ahmed BaalehДокумент14 страницPrepared By: DR - Ahmed Baalehscribdkhatn100% (1)

- Steam Generator ControlДокумент16 страницSteam Generator Controlمصطفى أحمد عبد الرزاق هاديОценок пока нет

- Tech Sheet 110 - HEI StandardДокумент15 страницTech Sheet 110 - HEI StandardzulryОценок пока нет

- An Investigation of Air-Swirl Design Criteria For Gas Turbine Combustors Through A Multi-Objective CFD OptimizationДокумент16 страницAn Investigation of Air-Swirl Design Criteria For Gas Turbine Combustors Through A Multi-Objective CFD Optimizationperules100% (1)

- GE Demostratres LM600Документ3 страницыGE Demostratres LM600Jose Fernando Barrera ValderramaОценок пока нет

- Thermo Flow Brochure 2002Документ14 страницThermo Flow Brochure 2002marco_a_salasОценок пока нет

- 2500 KW Forced Draft Cooling TowerДокумент2 страницы2500 KW Forced Draft Cooling Towerleojay24Оценок пока нет

- Protect Your Power Plant With Continuous Security.: SPPA-T3000 R8.2Документ8 страницProtect Your Power Plant With Continuous Security.: SPPA-T3000 R8.2Melchor VasquezОценок пока нет

- Manual de Transferencia de Datos de AMS Machinery Healt ManagerДокумент106 страницManual de Transferencia de Datos de AMS Machinery Healt ManagerJuan Carlos Rios EsparzaОценок пока нет

- E&M Combustion Presentation EnglishДокумент24 страницыE&M Combustion Presentation EnglishGurcharan Singh100% (1)

- Mark 6Документ2 страницыMark 6mahuzierОценок пока нет

- Co2 Capture and Storage in IGCC PlantsДокумент23 страницыCo2 Capture and Storage in IGCC PlantsAbhiram KukunuriОценок пока нет

- Requirement of Protection Systems Engineering: Knowledge Management SystemДокумент27 страницRequirement of Protection Systems Engineering: Knowledge Management SystemSamОценок пока нет

- What Is ATEXДокумент21 страницаWhat Is ATEXBymohamedfb DrillerОценок пока нет

- WW HMI SCADA-04 Discover The New Situational Awareness Library in InTouch 2014Документ45 страницWW HMI SCADA-04 Discover The New Situational Awareness Library in InTouch 2014steam100deg8229Оценок пока нет

- 04 Monitoring DMSДокумент13 страниц04 Monitoring DMSJESSОценок пока нет

- Steampowerplant Complete 150624210524 Lva1 App6892 PDFДокумент57 страницSteampowerplant Complete 150624210524 Lva1 App6892 PDFbajrangОценок пока нет

- SGT QuotationДокумент5 страницSGT QuotationvanshguptaactorfilmОценок пока нет

- Burner Logic System PDFДокумент5 страницBurner Logic System PDFshiviitd02Оценок пока нет

- Ubaid RaanДокумент31 страницаUbaid RaanUbaid RaanОценок пока нет

- APCДокумент25 страницAPCTawanda Precious SingiziОценок пока нет

- AVEVA PADO - Sub Solution - Performance Monitoring System PMSДокумент44 страницыAVEVA PADO - Sub Solution - Performance Monitoring System PMSMuhammad RizaldiОценок пока нет

- Cogeneration Class PDFДокумент66 страницCogeneration Class PDFeselcosacОценок пока нет

- Lecture 28 Modeling of GTДокумент59 страницLecture 28 Modeling of GTCindy CarvalhoОценок пока нет

- Evaluating Boiler EfficienciesДокумент52 страницыEvaluating Boiler EfficienciesdebelaОценок пока нет

- Thermodynamic Performance Testing and MonitoringДокумент3 страницыThermodynamic Performance Testing and MonitoringNicole FelicianoОценок пока нет

- CV of GTДокумент5 страницCV of GTMD ASIF ALIОценок пока нет

- Gas TurbineДокумент56 страницGas TurbinenaserОценок пока нет

- SME On Kondapalli ToysДокумент55 страницSME On Kondapalli Toysmanasa vangetiОценок пока нет

- Testing of Porcelain Enamel Powder PropertiesДокумент4 страницыTesting of Porcelain Enamel Powder PropertiesMiroslav LukačevićОценок пока нет

- NGCC Plant Case - FClass With CCS - 051607Документ4 страницыNGCC Plant Case - FClass With CCS - 051607DWWillsonОценок пока нет

- Conversion of Fuel Data To MWHДокумент12 страницConversion of Fuel Data To MWHdanferreiro8318Оценок пока нет

- CompAir Turboscrew BrochureДокумент8 страницCompAir Turboscrew BrochureBoban StanojlovićОценок пока нет

- Pre-Combustion Technology For Coal-Fired Power Plants: Thomas F. EdgarДокумент23 страницыPre-Combustion Technology For Coal-Fired Power Plants: Thomas F. Edgaranon_938213605Оценок пока нет

- Torque ConvertersДокумент61 страницаTorque ConvertersJay FarabeeОценок пока нет

- GE IP Bus For Static UPSДокумент44 страницыGE IP Bus For Static UPSesoares1990Оценок пока нет

- Shaangu For Metalurgical Industry 2013Документ49 страницShaangu For Metalurgical Industry 2013zzgiadinhzzОценок пока нет

- Combined Cycle Power Plant Performance Enhancement Based On Inlet Air Cooling Techniques A Technical Review IJERTV6IS120126Документ5 страницCombined Cycle Power Plant Performance Enhancement Based On Inlet Air Cooling Techniques A Technical Review IJERTV6IS120126Mai DangОценок пока нет

- Speedtronic Mark Vie Training Course Section 8Документ31 страницаSpeedtronic Mark Vie Training Course Section 8cucumelero barrios100% (1)

- GT Various Systems (G)Документ62 страницыGT Various Systems (G)shtiwari2002100% (2)

- Power Diagnostics ServiceДокумент20 страницPower Diagnostics ServiceShahid KhanОценок пока нет

- SGC - GT Gas Turbine HHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHДокумент3 страницыSGC - GT Gas Turbine HHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHjeromejoeОценок пока нет

- Kawasaki GPB SeriesДокумент1 страницаKawasaki GPB SeriesThanapaet Rittirut100% (1)

- Professional: October 2017 DR - Hans-Peter WolfДокумент34 страницыProfessional: October 2017 DR - Hans-Peter WolfJeeEianYann100% (2)

- NTPC Gas Power PlantДокумент32 страницыNTPC Gas Power PlantBlack PantherОценок пока нет

- Precept 4 - Combined CycleДокумент4 страницыPrecept 4 - Combined CycleAlessandro BalduzziОценок пока нет

- Creating and Using Virtual DPUsДокумент20 страницCreating and Using Virtual DPUsDeepak Gupta100% (1)

- Tr-1 Mar2014, Mapna TurbineДокумент36 страницTr-1 Mar2014, Mapna TurbineMehmet ErenОценок пока нет

- Steam Turbine SolutionsДокумент12 страницSteam Turbine Solutionsdanioachim1945Оценок пока нет

- Introduction of Gas Turbine Air Intake Cooling SystemДокумент12 страницIntroduction of Gas Turbine Air Intake Cooling SystemAndry KurniaОценок пока нет

- Technical Training For Siemens SB5-17-0039-GT-EN-02cДокумент5 страницTechnical Training For Siemens SB5-17-0039-GT-EN-02cbabunidoniОценок пока нет

- Multimedia CBTДокумент4 страницыMultimedia CBTsesharamanaОценок пока нет

- Engineering Software: Brayton Cycle (Gas Turbine) For Propulsion Application AnalysisДокумент16 страницEngineering Software: Brayton Cycle (Gas Turbine) For Propulsion Application AnalysisagoezОценок пока нет

- ME364 Forming SheetДокумент11 страницME364 Forming SheetVed Prakash ChoudharyОценок пока нет

- List of Govt HolidaysДокумент4 страницыList of Govt HolidaysAlpesh PatelОценок пока нет

- Evaluation SystemДокумент2 страницыEvaluation SystemVignat VoraОценок пока нет

- List of Govt HolidaysДокумент4 страницыList of Govt HolidaysAlpesh PatelОценок пока нет

- GrindingДокумент4 страницыGrindingHarshad PatelОценок пока нет

- Review of Electrical Sensors and ActuatorsДокумент21 страницаReview of Electrical Sensors and ActuatorsManjula Udayanga HemapalaОценок пока нет

- MD TorqueДокумент12 страницMD TorqueHarshad PatelОценок пока нет

- Admi Schedule DetailДокумент3 страницыAdmi Schedule DetailHarshad PatelОценок пока нет

- VPMP Polytechnic, Gandhinagar Class Time Table: NO. MON Tues WED Thurs FRI SATДокумент2 страницыVPMP Polytechnic, Gandhinagar Class Time Table: NO. MON Tues WED Thurs FRI SATHarshad PatelОценок пока нет

- Metrology - Laser (EDocFind (1) .Com)Документ1 страницаMetrology - Laser (EDocFind (1) .Com)Harshad PatelОценок пока нет

- Gears CyrusДокумент1 страницаGears CyrusHarshad PatelОценок пока нет

- New Microsoft Office PowerPoint PresentationДокумент1 страницаNew Microsoft Office PowerPoint PresentationGbsReddyОценок пока нет

- Chapter-Cooling TowersДокумент17 страницChapter-Cooling TowersSAGIS ETIENNEОценок пока нет

- EvaluationScheme From2010-11Документ4 страницыEvaluationScheme From2010-11Amrat PatelОценок пока нет

- 4 App Physics 22EL Q I VДокумент17 страниц4 App Physics 22EL Q I VRizwan MОценок пока нет

- Australian Castolin Eutectic: Flame Spray Equipment and PowdersДокумент18 страницAustralian Castolin Eutectic: Flame Spray Equipment and PowdersАлмаз КенжетаевОценок пока нет

- Fosroc Conplast CNI: Constructive SolutionsДокумент2 страницыFosroc Conplast CNI: Constructive SolutionsVincent JavateОценок пока нет

- Penetration of Bituminous PDFДокумент8 страницPenetration of Bituminous PDFMaslisa AffenddyОценок пока нет

- Fundamentos de ExergíaДокумент15 страницFundamentos de ExergíaTomás PrócelОценок пока нет

- Is417 Ettringite Formation and The Performance of ConcreteДокумент16 страницIs417 Ettringite Formation and The Performance of ConcreteMayank Singh100% (1)

- Product Information Flyer: CIMTECH® 495-OIДокумент2 страницыProduct Information Flyer: CIMTECH® 495-OIsobheysaidОценок пока нет

- Interlace, SingaporeДокумент16 страницInterlace, Singaporeameliabib89% (27)

- Zbrojenie-Srednica PretowДокумент2 страницыZbrojenie-Srednica PretowMichał KłysОценок пока нет

- Cupones Astm D2688-05 PDFДокумент7 страницCupones Astm D2688-05 PDFJorge Iván Garcia SozaОценок пока нет

- Piping Flexibility Analysis (B 31.3)Документ151 страницаPiping Flexibility Analysis (B 31.3)Majid Sattar100% (1)

- Part List - 69NT40-511-300 To 399Документ92 страницыPart List - 69NT40-511-300 To 399cloviskrelling100% (1)

- Injector Autolub PDFДокумент4 страницыInjector Autolub PDFpengelana satuОценок пока нет

- Important PointsДокумент4 страницыImportant PointsRashid MinhasОценок пока нет

- Installation Manual: Energy Recovery VentilatorДокумент24 страницыInstallation Manual: Energy Recovery VentilatorBryan HuОценок пока нет

- UNILAB SHARK - Shell&Tube Database (October 2015)Документ66 страницUNILAB SHARK - Shell&Tube Database (October 2015)Unilab100% (1)

- Snap-On Wall System Extrusion: 3 MTR Length Anodized / Powder Coated - Aluminium Cover Mill Finish Aluminium Base 50% MovementДокумент12 страницSnap-On Wall System Extrusion: 3 MTR Length Anodized / Powder Coated - Aluminium Cover Mill Finish Aluminium Base 50% MovementVarunn VelОценок пока нет

- brQnm2E4ai5C7yh3uxCdop4HA PDFДокумент1 страницаbrQnm2E4ai5C7yh3uxCdop4HA PDFKwammy BrownОценок пока нет

- Pile Cap 4Документ8 страницPile Cap 4Anonymous v1blzDsEWAОценок пока нет

- Hardness TestДокумент6 страницHardness TestRanu GamesОценок пока нет

- ACI Design Mix ExampleДокумент5 страницACI Design Mix Examplejay_medrano_1Оценок пока нет

- Chemical Mechanical PolishingДокумент2 страницыChemical Mechanical Polishingraja30gОценок пока нет

- BIRCOsir en 03 2017Документ58 страницBIRCOsir en 03 2017raghebomОценок пока нет

- Module 4Документ25 страницModule 4CHANDAKA TARUN SAI MALLESHОценок пока нет

- ESTAR HVACRaterChecklistДокумент4 страницыESTAR HVACRaterChecklistMeshal Al-mutairiОценок пока нет

- Name of Teacher Issues &concers Strategies Time Frame Person Involved SignatureДокумент9 страницName of Teacher Issues &concers Strategies Time Frame Person Involved SignatureMerlinda LibaoОценок пока нет

- Vitus Bering, Centre For Higher Education: Jens Bertelsen & Jens Peder PedersenДокумент50 страницVitus Bering, Centre For Higher Education: Jens Bertelsen & Jens Peder PedersenAnca IscruОценок пока нет

- Tabel BajaДокумент45 страницTabel BajaHerdy DwiyanaОценок пока нет

- Theory of Indeterminate Structure by Syed Ali Rizwan PDFДокумент470 страницTheory of Indeterminate Structure by Syed Ali Rizwan PDFZain Ashfaq100% (2)

- Chinese Detailing StandardДокумент107 страницChinese Detailing StandardMisgun Samuel100% (2)