Академический Документы

Профессиональный Документы

Культура Документы

Rockwell Hardness Test

Загружено:

nitte57680 оценок0% нашли этот документ полезным (0 голосов)

413 просмотров6 страницRockwell Hardness Test HR = e - e F0 = preliminary minor load in kgf, e = permanent increase in depth of penetration due to major load F1 measured in units of 0.002 mm Brinell Hardness Test Brinell Hardness Test advantages: 1. One scale covers the entire hardness range. 2. A wide range of test forces and ball sizes to suit every application. 3. Nondestructive, sample can normally be reused.

Исходное описание:

Авторское право

© Attribution Non-Commercial (BY-NC)

Доступные форматы

PPTX, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документRockwell Hardness Test HR = e - e F0 = preliminary minor load in kgf, e = permanent increase in depth of penetration due to major load F1 measured in units of 0.002 mm Brinell Hardness Test Brinell Hardness Test advantages: 1. One scale covers the entire hardness range. 2. A wide range of test forces and ball sizes to suit every application. 3. Nondestructive, sample can normally be reused.

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PPTX, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

413 просмотров6 страницRockwell Hardness Test

Загружено:

nitte5768Rockwell Hardness Test HR = e - e F0 = preliminary minor load in kgf, e = permanent increase in depth of penetration due to major load F1 measured in units of 0.002 mm Brinell Hardness Test Brinell Hardness Test advantages: 1. One scale covers the entire hardness range. 2. A wide range of test forces and ball sizes to suit every application. 3. Nondestructive, sample can normally be reused.

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PPTX, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 6

Rockwell Hardness Test

Rockwell Hardness Test

HR = E - e F0 = preliminary minor load in kgf, F1 = additional major load in kgf, F = total load in kgf, e = permanent increase in depth of penetration due to major load F1 measured in units of 0.002 mm, E = a constant depending on form of indenter: 100 units for diamond indenter, 130 units for steel ball indenter, HR = Rockwell hardness number, D = diameter of steel ball

Brinell Hardness Test

D = Ball diameter d = impression diameter F = load HB = Brinell result

Brinell Hardness Test

Advantages: 1. One scale covers the entire hardness range, although comparable results can only be obtained if the ball size and test force relationship is the same. 2. A wide range of test forces and ball sizes to suit every application. 3. Nondestructive, sample can normally be reused. Disadvantages: 1. The main drawback of the Brinell test is the need to optically measure the indent size. This requires that the test point be finished well enough to make an accurate measurement. 2. Slow. Testing can take 30 seconds not counting the sample preparation time.

Vickers Hardness Test

Vickers Hardness Test

Strengths 1) One scale covers the entire hardness range. 2) A wide range of test forces to suit every application. 3) Nondestructive, sample can normally be used. 4) The advantages of the Vickers hardness test are that extremely accurate readings can be taken. 5) It is very precise for testing the softest and hardest of materials, under varying loads Weaknesses (1) The main drawback of the Vickers test is the need to optically measure the indent size. This requires that the test point be highly finished to be able to see the indent well enough to make an accurate measurement. (2) Slow. Testing can take 30 seconds not counting the sample preparation time. (3) Vickers machine is a floor standing unit that is rather more expensive than the Brinell or Rockwell machines

Вам также может понравиться

- Pressure VesselsДокумент63 страницыPressure Vesselsكرار نعيمОценок пока нет

- Pressure MeasurementДокумент24 страницыPressure MeasurementOssy DewintaОценок пока нет

- Impact Test of Metal SpecimenДокумент18 страницImpact Test of Metal SpecimenmosaddakОценок пока нет

- CLB 21303 Process Instrumentatio N and ControlДокумент48 страницCLB 21303 Process Instrumentatio N and ControlanisОценок пока нет

- Rockwell Hardness TestДокумент12 страницRockwell Hardness Testinnocentsoul100% (1)

- Metrology in MicromachiningДокумент34 страницыMetrology in MicromachiningDeepakОценок пока нет

- Loss of Head in BendsДокумент6 страницLoss of Head in BendsaikareiОценок пока нет

- Calibrate Vernier Caliper Using Slip GaugesДокумент3 страницыCalibrate Vernier Caliper Using Slip GaugesVikram BillalОценок пока нет

- Complete Tensile Test On MS BarДокумент9 страницComplete Tensile Test On MS Barafzal taiОценок пока нет

- Torsion Test Determines Modulus of RigidityДокумент4 страницыTorsion Test Determines Modulus of RigidityMohanad HazemОценок пока нет

- Leak testing standards and classes for industrial valvesДокумент1 страницаLeak testing standards and classes for industrial valvesDurga Prasad SharmaОценок пока нет

- Measuring InstrumentsДокумент45 страницMeasuring InstrumentsRavinder Minhas100% (1)

- JJ104 Workshop Technology CHAPTER9 Arc WeldingДокумент14 страницJJ104 Workshop Technology CHAPTER9 Arc WeldingAh Tiang50% (4)

- Lab 3 3-Phase Induction Motor Characteristics - r2Документ9 страницLab 3 3-Phase Induction Motor Characteristics - r2aaronОценок пока нет

- Chapter 1 - Mechanical MeasurementДокумент51 страницаChapter 1 - Mechanical MeasurementVraj PatelОценок пока нет

- Impacts Tests (Astm E23) : Impact Test Is Performed To Study The Behavior of MaterialsДокумент7 страницImpacts Tests (Astm E23) : Impact Test Is Performed To Study The Behavior of Materialsjayhuacat7743Оценок пока нет

- Electrical Terms in WeldingДокумент11 страницElectrical Terms in WeldingRaviОценок пока нет

- Pressure Measurements NotesДокумент15 страницPressure Measurements NotesManjunath MohiteОценок пока нет

- Mechanical MeasurementsДокумент3 страницыMechanical MeasurementsneerubandaОценок пока нет

- Fluid Ch-1-1 Introduction and DimensionsДокумент34 страницыFluid Ch-1-1 Introduction and Dimensionsأزهار برديОценок пока нет

- Interchangeability in MetrologyДокумент5 страницInterchangeability in Metrologyesakkiraj05100% (1)

- Metal - Brazing and Soldering - ProcessesДокумент8 страницMetal - Brazing and Soldering - Processeshisham_eyes100% (1)

- Bimetallic Thermometer: Working PrincipleДокумент1 страницаBimetallic Thermometer: Working Principleyessa gamuedaОценок пока нет

- Week 10 - WeldingДокумент133 страницыWeek 10 - WeldingFattihi EkhmalОценок пока нет

- WeldingДокумент27 страницWeldingsuman kumarОценок пока нет

- Exp-6 Creep TestДокумент6 страницExp-6 Creep TestHanamant HunashikattiОценок пока нет

- 2021 Theme 1 - Homework ProblemsДокумент6 страниц2021 Theme 1 - Homework ProblemsMartin MugoniОценок пока нет

- 03a Direct Stiffness Method Spring and BarДокумент23 страницы03a Direct Stiffness Method Spring and BarAnamolОценок пока нет

- Hardness TestДокумент8 страницHardness TestlvasuthavanОценок пока нет

- Hand Tools in BenchworkДокумент4 страницыHand Tools in BenchworkmarkvillaplazaОценок пока нет

- Measurement of Pressure Using McLeod GaugeДокумент5 страницMeasurement of Pressure Using McLeod GaugeSantosh SharmaОценок пока нет

- Mechanical QuizДокумент56 страницMechanical QuizsigmasundarОценок пока нет

- Welded Connection Weld DesignДокумент12 страницWelded Connection Weld Designlram70Оценок пока нет

- CAM and FollowerДокумент13 страницCAM and Followerpratik thakareОценок пока нет

- Comparator:: Essential Parts of A ComparatorДокумент5 страницComparator:: Essential Parts of A ComparatorAnonymous bl0G8KОценок пока нет

- Accurate Steel Blocks for Dimensional ChecksДокумент14 страницAccurate Steel Blocks for Dimensional ChecksShyam VimalKumarОценок пока нет

- Compression Test On MS and CI RevisedДокумент7 страницCompression Test On MS and CI Revisedafzal taiОценок пока нет

- Experiment Name: Study and Operation of Bench Drilling MachineДокумент13 страницExperiment Name: Study and Operation of Bench Drilling MachineHashim Al-mahdliОценок пока нет

- Hydraulics Topic 6 Hydraulic Machinery PDFДокумент48 страницHydraulics Topic 6 Hydraulic Machinery PDFVictoria JungОценок пока нет

- Testing MechanicalДокумент42 страницыTesting MechanicalSadique ChakoleОценок пока нет

- Hardness Testing Methods ExplainedДокумент9 страницHardness Testing Methods ExplainedMohan S kumarОценок пока нет

- Strength of Material Exp 4 Rockwell Hardness TestДокумент11 страницStrength of Material Exp 4 Rockwell Hardness Testhayder alaliОценок пока нет

- Acd Lab ManualДокумент31 страницаAcd Lab Manualdestro29Оценок пока нет

- Force Measurement Methods and ApplicationsДокумент57 страницForce Measurement Methods and ApplicationsmeghanaОценок пока нет

- Perform Manual Metal Arc WeldingДокумент107 страницPerform Manual Metal Arc WeldingroostercockburnОценок пока нет

- Hydrotest Test FormatДокумент27 страницHydrotest Test FormatRähûl Prätäp SïnghОценок пока нет

- Creep Lab ManualДокумент11 страницCreep Lab ManualapproachtheprobОценок пока нет

- Pressure VesselsДокумент63 страницыPressure Vesselsكرار نعيمОценок пока нет

- Piping Engineering FundamentalsДокумент19 страницPiping Engineering Fundamentals26 PRATHAMESH KATKARОценок пока нет

- Distructive & Non-Destructive Testing of MaterialДокумент16 страницDistructive & Non-Destructive Testing of MaterialEngr.Hamid Ismail CheemaОценок пока нет

- Cantilever Flex ExperimentДокумент8 страницCantilever Flex ExperimentJhonattan PardoОценок пока нет

- EEG383 Measurement - Chapter 2 - Characteristics of Measuring InstrumentsДокумент26 страницEEG383 Measurement - Chapter 2 - Characteristics of Measuring Instrumentsايهاب غزالة100% (1)

- Sensors-2 (Strain Gauge)Документ11 страницSensors-2 (Strain Gauge)adilnaseemОценок пока нет

- 2 Marks MMДокумент5 страниц2 Marks MMPappujiОценок пока нет

- Detc2016 59570Документ11 страницDetc2016 59570Muhammad Uzair ShahОценок пока нет

- RRB Mechanical Engineer Model Question Paper With Answer Key 14Документ43 страницыRRB Mechanical Engineer Model Question Paper With Answer Key 14Y Babu0% (1)

- Thermo CalibrationДокумент10 страницThermo CalibrationAngelo De AsisОценок пока нет

- Heat ExchangerДокумент4 страницыHeat ExchangerIzwanaRahimiОценок пока нет

- Material TestingДокумент57 страницMaterial TestingNurfarahin Atiqah Binti MustafaОценок пока нет

- The Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryОт EverandThe Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryОценок пока нет

- 06me46b June July12Документ2 страницы06me46b June July12nitte5768Оценок пока нет

- A1 Adarsh RaiДокумент1 страницаA1 Adarsh Rainitte5768Оценок пока нет

- A2 Adarsh RaiДокумент2 страницыA2 Adarsh Rainitte5768Оценок пока нет

- Voice CMDFДокумент141 страницаVoice CMDFRonaldMartinezОценок пока нет

- E-books Mechanical Engineering Heat Mass Transfer ThermodynamicsДокумент6 страницE-books Mechanical Engineering Heat Mass Transfer Thermodynamicskirankuma.jagtapОценок пока нет

- E-books Mechanical Engineering Heat Mass Transfer ThermodynamicsДокумент6 страницE-books Mechanical Engineering Heat Mass Transfer Thermodynamicskirankuma.jagtapОценок пока нет

- 10ME-AU46B. Dec-Jan 2015-16Документ2 страницы10ME-AU46B. Dec-Jan 2015-16nitte5768Оценок пока нет

- DSMДокумент2 страницыDSMnitte5768Оценок пока нет

- FieldTestModes06142010 Wilson004Документ5 страницFieldTestModes06142010 Wilson004dazagrtОценок пока нет

- 1st Year Revised Syllabus - 2014Документ35 страниц1st Year Revised Syllabus - 2014amitkallerОценок пока нет

- Fluid Mechanics and Machinery Notes 2Документ123 страницыFluid Mechanics and Machinery Notes 2Veera ReddyОценок пока нет

- Fuel PropertiesДокумент2 страницыFuel Propertiesnitte5768Оценок пока нет

- 1st Year Revised Syllabus - 2014Документ35 страниц1st Year Revised Syllabus - 2014amitkallerОценок пока нет

- Crystalstructures 141008215641 Conversion Gate02Документ69 страницCrystalstructures 141008215641 Conversion Gate02nitte5768Оценок пока нет

- VMRДокумент117 страницVMRM Sandesh ShenoyОценок пока нет

- Lename Lename String String String String Old New N NДокумент1 страницаLename Lename String String String String Old New N Nnitte5768Оценок пока нет

- Drilling MachineДокумент30 страницDrilling MachineSujit MuleОценок пока нет

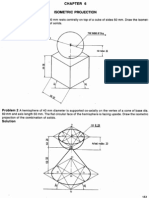

- Isometric Projection0001Документ27 страницIsometric Projection0001nitte5768Оценок пока нет

- 08mba14 July 09Документ4 страницы08mba14 July 09nitte5768Оценок пока нет

- First Semester MBA Degree Examination, May/June 2010: Accounting For ManagersДокумент4 страницыFirst Semester MBA Degree Examination, May/June 2010: Accounting For Managersnitte5768Оценок пока нет

- 2007 - May EC7T4Документ3 страницы2007 - May EC7T4nitte5768Оценок пока нет

- 05mba14 June 08Документ3 страницы05mba14 June 08nitte5768Оценок пока нет

- Askelandphulenotes Ch01printableДокумент24 страницыAskelandphulenotes Ch01printableShivashankrappa BalawatОценок пока нет

- 08MBA14 May - June 2010Документ3 страницы08MBA14 May - June 2010nitte5768Оценок пока нет

- 05mba14 July 07Документ4 страницы05mba14 July 07nitte5768Оценок пока нет

- Step by Step Procedure of ABCДокумент5 страницStep by Step Procedure of ABCApril FisherОценок пока нет

- Development of Lateral Surfaces0001Документ25 страницDevelopment of Lateral Surfaces0001nitte5768Оценок пока нет

- 2008 - Dec.08-Jan.09 (EC42)Документ2 страницы2008 - Dec.08-Jan.09 (EC42)nitte5768Оценок пока нет

- Artificial Bee Colony AlgorithmДокумент25 страницArtificial Bee Colony AlgorithmissayedОценок пока нет

- Problem 1 SolutionДокумент24 страницыProblem 1 Solutionnitte5768Оценок пока нет