Академический Документы

Профессиональный Документы

Культура Документы

Quality Control: Mcgraw-Hill/Irwin

Загружено:

Minal SinghОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Quality Control: Mcgraw-Hill/Irwin

Загружено:

Minal SinghАвторское право:

Доступные форматы

McGraw-Hill/Irwin

Copyright 2007 by The McGraw-Hill Companies, Inc. All rights reserved.

10

Quality Control

10-2

Learning Objectives

List and briefly explain the elements of the

control process.

Explain how control charts are used to

monitor a process, and the concepts that

underlie their use.

Use and interpret control charts.

Use run tests to check for nonrandomness

in process output.

Assess process capability.

10-3

Phases of Quality Assurance

Acceptance

sampling

Process

control

Continuous

improvement

Inspection of lots

before/after

production

Inspection and

corrective

action during

production

Quality built

into the

process

The least

progressive

The most

progressive

Figure 10.1

10-4

Inspection

How Much/How Often

Where/When

Centralized vs. On-site

Inputs Transformation Outputs

Acceptance

sampling

Process

control

Acceptance

sampling

Figure 10.2

10-5

C

o

s

t

Optimal

Amount of Inspection

Inspection Costs

Cost of

inspection

Cost of

passing

defectives

Total Cost

Figure 10.3

10-6

Where to Inspect in the Process

Raw materials and purchased parts

Finished products

Before a costly operation

Before an irreversible process

Before a covering process

10-7

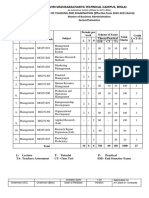

Examples of Inspection Points

Type of

business

Inspection

points

Characteristics

Fast Food Cashier

Counter area

Eating area

Building

Kitchen

Accuracy

Appearance, productivity

Cleanliness

Appearance

Health regulations

Hotel/motel Parking lot

Accounting

Building

Main desk

Safe, well lighted

Accuracy, timeliness

Appearance, safety

Waiting times

Supermarket Cashiers

Deliveries

Accuracy, courtesy

Quality, quantity

Table 10.1

10-8

Statistical Process Control:

Statistical evaluation of the output of a

process during production

Quality of Conformance:

A product or service conforms to

specifications

Statistical Control

10-9

Control Chart

Control Chart

Purpose: to monitor process output to see

if it is random

A time ordered plot representative sample

statistics obtained from an on going

process (e.g. sample means)

Upper and lower control limits define the

range of acceptable variation

10-10

Control Chart

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

UCL

LCL

Sample number

Mean

Out of

control

Normal variation

due to chance

Abnormal variation

due to assignable sources

Abnormal variation

due to assignable sources

Figure 10.4

10-11

Statistical Process Control

The essence of statistical process

control is to assure that the output of a

process is random so that future output

will be random.

10-12

Statistical Process Control

The Control Process

Define

Measure

Compare

Evaluate

Correct

Monitor results

10-13

Statistical Process Control

Variations and Control

Random variation: Natural variations in the

output of a process, created by countless

minor factors

Assignable variation: A variation whose

source can be identified

10-14

Sampling Distribution

Sampling

distribution

Process

distribution

Mean

Figure 10.5

10-15

Normal Distribution

Mean

3o 2o +2o +3o

95.44%

99.74%

o = Standard deviation

Figure 10.6

10-16

Control Limits

Sampling

distribution

Process

distribution

Mean

Lower

control

limit

Upper

control

limit

Figure 10.7

10-17

SPC Errors

Type I error

Concluding a process is not in control

when it actually is.

Type II error

Concluding a process is in control when it

is not.

10-18

Type I and Type II Errors

In control Out of control

In control No Error Type I error

(producers risk)

Out of

control

Type II Error

(consumers risk)

No error

Table 10.2

10-19

Type I Error

Mean

LCL UCL

o/2 o/2

o = Probability

of Type I error

Figure 10.8

10-20

Observations from Sample

Distribution

Sample number

UCL

LCL

1 2 3 4

Figure 10.9

10-21

Control Charts for Variables

Mean control charts

Used to monitor the central tendency of a

process.

X bar charts

Range control charts

Used to monitor the process dispersion

R charts

Variables generate data that are measured.

10-22

Mean and Range Charts

UCL

LCL

UCL

LCL

R-chart

x-Chart

Detects shift

Does not

detect shift

Figure 10.10A

(process mean is

shifting upward)

Sampling

Distribution

10-23

x-Chart

UCL

Does not

reveal increase

Mean and Range Charts

UCL

LCL

LCL

R-chart

Reveals increase

Figure 10.10B

(process variability is increasing)

Sampling

Distribution

10-24

Control Chart for Attributes

p-Chart - Control chart used to monitor

the proportion of defectives in a process

c-Chart - Control chart used to monitor

the number of defects per unit

Attributes generate data that are counted.

10-25

Use of p-Charts

When observations can be placed into

two categories.

Good or bad

Pass or fail

Operate or dont operate

When the data consists of multiple

samples of several observations each

Table 10.4

10-26

Use of c-Charts

Use only when the number of

occurrences per unit of measure can be

counted; non-occurrences cannot be

counted.

Scratches, chips, dents, or errors per item

Cracks or faults per unit of distance

Breaks or Tears per unit of area

Bacteria or pollutants per unit of volume

Calls, complaints, failures per unit of time

Table 10.4

10-27

Use of Control Charts

At what point in the process to use

control charts

What size samples to take

What type of control chart to use

Variables

Attributes

10-28

Run Tests

Run test a test for randomness

Any sort of pattern in the data would

suggest a non-random process

All points are within the control limits -

the process may not be random

10-29

Nonrandom Patterns in Control

charts

Trend

Cycles

Bias

Mean shift

Too much dispersion

10-30

Counting Above/Below Median Runs (7 runs)

Counting Up/Down Runs (8 runs)

U U D U D U D U U D

B A A B A B B B A A B

Figure 10.12

Figure 10.13

Counting Runs

10-31

NonRandom Variation

Managers should have response plans to

investigate cause

May be false alarm (Type I error)

May be assignable variation

10-32

Tolerances or specifications

Range of acceptable values established by

engineering design or customer

requirements

Process variability

Natural variability in a process

Process capability

Process variability relative to specification

Process Capability

10-33

Process Capability

Lower

Specification

Upper

Specification

A. Process variability

matches specifications

Lower

Specification

Upper

Specification

B. Process variability

well within specifications

Lower

Specification

Upper

Specification

C. Process variability

exceeds specifications

Figure 10.15

10-34

Process Capability Ratio

Process capability ratio, Cp =

specification width

process width

Upper specification lower specification

6o

Cp =

|

|

.

|

\

|

o o 3

X - UTL

or

3

LTL X

min = C

pk

If the process is centered use Cp

If the process is not centered use Cpk

10-35

Limitations of Capability Indexes

1. Process may not be stable

2. Process output may not be normally

distributed

3. Process not centered but C

p

is used

10-36

Example 8

Machine

Standard

Deviation

Machine

Capability

C

p

A 0.13 0.78 0.80/0.78 = 1.03

B 0.08 0.48 0.80/0.48 = 1.67

C 0.16 0.96 0.80/0.96 = 0.83

Cp > 1.33 is desirable

Cp = 1.00 process is barely capable

Cp < 1.00 process is not capable

10-37

Process

mean

Lower

specification

Upper

specification

1350 ppm

1350 ppm

1.7 ppm 1.7 ppm

+/- 3 Sigma

+/- 6 Sigma

3 Sigma and 6 Sigma Quality

10-38

Improving Process Capability

Simplify

Standardize

Mistake-proof

Upgrade equipment

Automate

10-39

Taguchi Loss Function

Cost

Target

Lower

spec

Upper

spec

Traditional

cost function

Taguchi

cost function

Figure 10.17

10-40

Video: Defect Prev.

Вам также может понравиться

- NseДокумент9 страницNseMinal SinghОценок пока нет

- Growth Drivers RetailДокумент4 страницыGrowth Drivers RetailMinal SinghОценок пока нет

- SSRN Id1203322Документ75 страницSSRN Id1203322Minal SinghОценок пока нет

- SSRN Id1203322Документ75 страницSSRN Id1203322Minal SinghОценок пока нет

- Synopsis On Brand AarenessДокумент2 страницыSynopsis On Brand AarenessMinal SinghОценок пока нет

- Celebrity EndorsementsДокумент35 страницCelebrity EndorsementssharadiitianОценок пока нет

- SSRN Id1203322Документ75 страницSSRN Id1203322Sherihan MujeebОценок пока нет

- Impact of Celebrity EndorsementДокумент133 страницыImpact of Celebrity EndorsementMinal Singh93% (14)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Presentation Analysis and Interpretation of Data in Research Paper SampleДокумент5 страницPresentation Analysis and Interpretation of Data in Research Paper SamplegvzcrpymОценок пока нет

- How To Design A Sociology Research ProjectДокумент51 страницаHow To Design A Sociology Research ProjectBetim MetkamberiОценок пока нет

- Experiment 1 - Disturbed Soil Sampling, Labelling, and StorageДокумент5 страницExperiment 1 - Disturbed Soil Sampling, Labelling, and StorageIan Dalisay100% (1)

- STQM Chapter 1 & 2 NotesДокумент10 страницSTQM Chapter 1 & 2 NotesJenayl MillerОценок пока нет

- HANDOUTrmДокумент9 страницHANDOUTrmdeepti_sahoo_3Оценок пока нет

- Article ReviewДокумент2 страницыArticle ReviewJein PОценок пока нет

- Soil Survey Mapping - LectureNotes2Документ132 страницыSoil Survey Mapping - LectureNotes2Udaya KumarОценок пока нет

- Project Directions and RubricДокумент2 страницыProject Directions and RubricStephRunn44Оценок пока нет

- Seniors' Willingness to Use Alternative Transit ExploredДокумент8 страницSeniors' Willingness to Use Alternative Transit ExploredShan BasnayakeОценок пока нет

- Marta Birhanu Final 1Документ65 страницMarta Birhanu Final 1BereketabОценок пока нет

- The Impact of The Time of Usage of Modern Devices On The General Average of Senior High School Students in Gubat National High SchoolДокумент15 страницThe Impact of The Time of Usage of Modern Devices On The General Average of Senior High School Students in Gubat National High SchoolAnton EnajeОценок пока нет

- Study On Retail Banking in IndiaДокумент12 страницStudy On Retail Banking in IndiashwethaОценок пока нет

- Book Research MethodologyДокумент28 страницBook Research MethodologyMiguel Alberto Dávila SacotoОценок пока нет

- Quality of Work Life - Penfos Systems PVT LTDДокумент58 страницQuality of Work Life - Penfos Systems PVT LTDkartikОценок пока нет

- Lewis BeckДокумент46 страницLewis BeckJesica Juarez ReyesОценок пока нет

- Managing Money in High SchoolДокумент18 страницManaging Money in High SchoolAlfredo Vergara100% (1)

- Chapter 2 Data Collection Methods and Sampling TechniquesДокумент12 страницChapter 2 Data Collection Methods and Sampling TechniquesWindyОценок пока нет

- Saba Reprt Fairness CreamДокумент29 страницSaba Reprt Fairness CreamSaba MalikОценок пока нет

- MBA Business Analytics IBM PDFДокумент117 страницMBA Business Analytics IBM PDFSrijana Shet0% (1)

- Chao WattpadДокумент45 страницChao WattpadChao Ranit100% (1)

- QRM PDFДокумент31 страницаQRM PDFSuraj KambleОценок пока нет

- Winter Project by VrajeshДокумент36 страницWinter Project by VrajeshYash KikaniОценок пока нет

- 1 s2.0 S2773139122000039 MainДокумент11 страниц1 s2.0 S2773139122000039 MainlaythsalmsnОценок пока нет

- MBA Semester II SyllabusДокумент28 страницMBA Semester II SyllabusAmandeep KaurОценок пока нет

- South Sudan Gender AssessmentДокумент81 страницаSouth Sudan Gender AssessmentAroub AlameenОценок пока нет

- CH 4 1 Transport PlanningДокумент26 страницCH 4 1 Transport Planningelias teshomeОценок пока нет

- Head Teachers' Leadership Styles' and Teachers Job Satisfaction in Primary Schools in Ekiti State, NigeriaДокумент11 страницHead Teachers' Leadership Styles' and Teachers Job Satisfaction in Primary Schools in Ekiti State, NigeriaDoc GuembourОценок пока нет

- 99-018 Optimal Grade Control Using Geostatistics and Economics PDFДокумент13 страниц99-018 Optimal Grade Control Using Geostatistics and Economics PDFDaniel Sanchez100% (1)