Академический Документы

Профессиональный Документы

Культура Документы

MECH3300 - Lecture 4: Introduction To 2D Finite Elements

Загружено:

sqaiba_gИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

MECH3300 - Lecture 4: Introduction To 2D Finite Elements

Загружено:

sqaiba_gАвторское право:

Доступные форматы

MECH3300 - Lecture 4

Introduction to 2D finite elements

Displacement interpolation

In 2 or 3D, in order to write equations at nodes, we must

approximate boundary conditions between the nodes somehow.

Suppose we assume a linear displacement variation between

the values at 2 corner nodes. This implies a particular variation

of load per length along that edge which makes this happen.

While we dont have to, it is usual to relate the displacement

anywhere over the whole area (in 2D) or volume (in 3D) of an

element, to that at the nodes.

This implies the strain is everywhere related to the nodal

displacements.

Hence by integrating over an element its strain energy can be

found.

Strain energy written in terms of displacements at nodes leads

to estimated stiffness values.

Eg 1/2 k u

2

for a spring

Meshing in 2D

A mesh can be created in several ways.

A surface mapped from a rectangle may be defined first and

then subdivided into n by m elements, giving a mapped mesh.

A surface of more complex shape may be automatically subdivided

into triangles of similar size, using the Delaunay algorithm.

A row of 1D elements (beams) can be extruded to give 2D elements.

The constant strain triangle

The simplest possible 2D finite element is a triangle with

constant strain.

The state of strain in any small area becomes more constant as

the size of the area is reduced. Hence this element is capable

of getting the right answers if enough are used.

Consider arbitrary linear displacements in x and y directions, u

and v.

u = Ax + By + C v = D + Ex + Fy

There are 6 constants. These can be expressed in terms of 6

nodal displacement components at the 3 corner nodes. Hence

we can relate displacement anywhere to the nodal values.

Strain-displacement relations

Direct strain is change in length per length. For small strain this is

displacement/(increment in length). That is

Shear strain is change in a right angle. This is approximated as

(x displacement)/(increment in y) + (y displacement/increment in x).

y

v

x

u

y x

c

c

=

c

c

= c c

Ax

u

u+Au

Av

Au

Ax

Ay

x

v

y

u

xy

c

c

+

c

c

=

Why strain needs relating to displacement

Using u = Ax + By + C and v = D + Ex + Fy the strains are

c

x

= A, c

y

= F

xy

= B +E ie the strains are constant.

Strain-displacement relations enable us to write strain energy in

terms of the nodal displacements. This enables stiffness terms

to be found, as strain energy of of element is (1/2)u

T

[K

e

]u

Once the displacements have been found, then the strains in an

element can be found from them.

Types of finite elements

2D elements are normally triangles or quadrilaterals.

They typically use either linear interpolation with corner nodes only or

quadratic interpolation with corner and mid-side nodes. (A quadratic

curve fits through 3 points along a side)

3D elements are tetrahedra, pentahedra (wedges), and hexahedra

(bricks), also with corner or corner plus mid-side nodes.

h v p finite element methods

The conventional approach to obtaining better accuracy is to

refine the mesh, using the same polynomial order.

This is called the h finite element method as h is a symbol that

has been used to represent the side length of an element.

An alternative is to increase the polynomial order used to

interpolate displacement in each element, avoiding remeshing.

This is the p (for polynomial) finite element method.

The p method is easily automated, with a local measure of

accuracy being used to decide where to increase the polynomial

order. It has been embedded in some CAD software.

A p mesh looks coarse, but the elements have curved surfaces,

so that accurate geometry is captured with the coarse mesh.

This requires more data to describe each element.

Accuracy of answers

Clearly, with the constant strain triangle, the stresses change at

element boundaries. The accuracy is less where these changes

are larger.

Other elements permit linear or quadratic strain variations but

still show jumps in stress at element boundaries.

To improve accuracy, and give unique nodal values of stress,

stresses are usually averaged between elements at nodes when

plotting contours. This averaging has less effect at edges where

fewer elements meet.

The most accurate stresses are those estimated at element

centroids, away from the discontinuities at the edges.

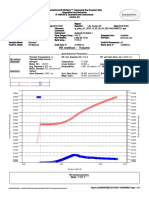

Averaged v unaveraged nodal stresses

Averaged x stress Unaveraged x stress

These contour plots are generated by first finding nodal

stress values and element centre stress values. Each

quadrilateral is divided into 4 triangles and contours are

drawn as series of straight lines, each crossing one of

these subtriangles.

Obtaining an approximate stiffness matrix

An approximate element stiffness matrix can be derived in a

number of ways.

One way is to differentiate the elastic strain energy V of a

structure wrt each nodal displacement, each time generating an

equation for the resultant force on a node.

This is a special case of what is done to find equations of motion

using Lagranges equations, as each nodal displacement is a

generalized coordinate.

Eg for a spring joining node 1 to node 2, the energy stored is

V = 1/2 k (u

2

- u

1

)

2

In matrix notation

i

i

F

u

V

=

c

c

2 1 2

2

2 1 1

1

ku ku F

u

V

ku ku F

u

V

+ = =

c

c

= =

c

c

(

=

(

2

1

2

1

u

u

k k

k k

F

F

Interpolation functions

Instead of writing polynomials in terms of coefficients to be

determined, we can write displacement at an arbitrary location

(x,y) within an element directly in terms of nodal values.

For linear interpolation over a triangle with nodal x-

displacements, u

1

, u

2

and u

3

this is

u(x,y) = N

1

(x,y) u

1

+ N

2

(x,y) u

2

+ N

3

(x,y) u

3

N

1

, N

2

and N

3

are called interpolation functions. They evaluate

to 1 at one node and to zero at the others, so that u at node 1 is

u

1

etc.

N

1

Node 1 Node 2

Node 3

1

x

y

Properties of interpolation functions

The functions N

i

must be a partition of unity. That is they must

sum to 1 at ant point in the element.

This is necessary to represent rigid body motion, as for instance

with a 3 node triangular element, if all nodes move a distance of

1 in the x direction (a rigid body mode), u = N

1

+ N

2

+ N

3

They must also capture states of constant strain correctly, as an

element tends to constant strain as it gets smaller. This means

the displacements must capture an arbitrary linear variation in

all coordinates. The functions for the constant strain triangle

are the simplest ones to meet this requirement.

Weighted residual formulation

A more general view of how the approximate nodal equations

are obtained, which is applicable to any set of partial differential

equations, is as follows.

Consider a scalar function of position (say). Say temperature T

is a function of position in space T(x,y,z).

A PDE like Laplaces equation can be written generally as

A(T,x,y,z) = 0

Instead of insisting that the PDE A be true exactly, we

approximate the spatial variation of T with interpolation functions

N

i

and nodal values T

i

(T = E N

i

T

i

).

We evaluate A approximately, then multiply A by a weighting

function w(x,y,z) and integrate over the volume of one finite

element, then set the result to zero.

This makes the equation true in an approximate weighted

residual sense. Ie the error in wA integrates to zero.

The Galerkin method

By choosing different w functions, we can penalize the error in

different locations in an element. For instance if we make w =

N

1

the error is penalized near node 1, where w is a maximum.

By choosing w to be each interpolation function in turn, we

generate equations for each node (eg for a triangle we get 3

equations relating nodal temperatures T

1

, T

2

and T

3

).

Applying this approach to elastic problems, the same equations

result that we obtain by differentiating energy.

This choice of making the weighting function the same as the

interpolation function is called the Galerkin method of

approximation. The finite element method is a type of Galerkin

method.

Вам также может понравиться

- Frequency Response Cylinder - EnglishДокумент7 страницFrequency Response Cylinder - Englishback1949Оценок пока нет

- Chapter3 180616192627Документ55 страницChapter3 180616192627SALEEM MALIKОценок пока нет

- The Material Obeys Hooke's Law. 3. Forces Are Applied Only at The Ends of The Bar. 4. The Bar Supports Axial Loading Only Bending, Torsion, and Shear Are NotДокумент16 страницThe Material Obeys Hooke's Law. 3. Forces Are Applied Only at The Ends of The Bar. 4. The Bar Supports Axial Loading Only Bending, Torsion, and Shear Are NotMuket AgmasОценок пока нет

- 02 Me1 PDFДокумент5 страниц02 Me1 PDFvat007Оценок пока нет

- Fem Short AnswersДокумент8 страницFem Short Answers21k95a0324Оценок пока нет

- Vectors and Dirac Delta FunctionДокумент39 страницVectors and Dirac Delta FunctionSubrata RakshitОценок пока нет

- Emtl Unit1 PDFДокумент49 страницEmtl Unit1 PDFnelapatikoteswarammaОценок пока нет

- Math 201 Multivariable CalculusДокумент5 страницMath 201 Multivariable Calculuszeeshan_haider000Оценок пока нет

- Ce5610: Finite Element AnalysisДокумент27 страницCe5610: Finite Element AnalysisArjun RajОценок пока нет

- 1Документ15 страниц1manognya salendraОценок пока нет

- Unit4 TJДокумент39 страницUnit4 TJMohammed ImranОценок пока нет

- Vector AlgebraДокумент21 страницаVector AlgebraMaxОценок пока нет

- ForcesДокумент30 страницForcesMohd Azhari Mohd RodziОценок пока нет

- Vectors and TensorsДокумент13 страницVectors and TensorsBittuОценок пока нет

- 1.hafta-Fundamental Concepts and PrinciplesДокумент37 страниц1.hafta-Fundamental Concepts and PrinciplesplnozkbnОценок пока нет

- Lec 6Документ5 страницLec 6stathiss11Оценок пока нет

- Vector CalculusДокумент52 страницыVector CalculusYeri KimОценок пока нет

- EMF Theory by Sangeen PanezaiДокумент100 страницEMF Theory by Sangeen PanezaiSangeen Panezai0% (1)

- AP Physics Chapter 3 Motion in Two DimensionsДокумент33 страницыAP Physics Chapter 3 Motion in Two DimensionsStewie Dog100% (1)

- Review of Vector Algebra and Co-Ordinate SystemsДокумент77 страницReview of Vector Algebra and Co-Ordinate SystemsmumamaduraiОценок пока нет

- Measurements and UncertaintiesДокумент53 страницыMeasurements and UncertaintiesDavid ReeseОценок пока нет

- Analisis Peubah Ganda 2Документ61 страницаAnalisis Peubah Ganda 2Azmi FaisalОценок пока нет

- Mechanics: Study of What Happens To A "Thing" (The Technical Name Is "Body") When FORCES Are Applied To ItДокумент39 страницMechanics: Study of What Happens To A "Thing" (The Technical Name Is "Body") When FORCES Are Applied To Itdinosaur x-drakeОценок пока нет

- My Revision Notes (Entire Unit) c4 Edexcel NotesДокумент15 страницMy Revision Notes (Entire Unit) c4 Edexcel Notesjun29Оценок пока нет

- Transforms PDFДокумент30 страницTransforms PDFmuskan agarwalОценок пока нет

- Peter's Index Lecture 2b Course Index: Physics HomeДокумент6 страницPeter's Index Lecture 2b Course Index: Physics Homereza mohammadianОценок пока нет

- Pi. These Forces Are Shown Acting On A Body in Fig.: One-Dimensional ProblemsДокумент7 страницPi. These Forces Are Shown Acting On A Body in Fig.: One-Dimensional ProblemsManander SInghОценок пока нет

- Chapter 19Документ6 страницChapter 19Douglas SoaresОценок пока нет

- Notes 2Документ7 страницNotes 2Musab AinekarОценок пока нет

- 1d Finite Elements - TheoryДокумент34 страницы1d Finite Elements - TheoryKristina OraОценок пока нет

- 2 Scalar Vector TensorsДокумент15 страниц2 Scalar Vector TensorsKaushal PatelОценок пока нет

- By Pooja BhatiДокумент39 страницBy Pooja BhatiAbineshОценок пока нет

- Important Stuff On Continuum MechanicsДокумент26 страницImportant Stuff On Continuum MechanicsAndrew GarfieldОценок пока нет

- ME1 Concurrent Forces and Static Equilibrium: ObjectivesДокумент5 страницME1 Concurrent Forces and Static Equilibrium: ObjectivesAhmed AbuNasserОценок пока нет

- TOPIC 2 TransformationДокумент28 страницTOPIC 2 Transformationjonathanmaithya9Оценок пока нет

- ClusteringДокумент127 страницClusteringkamaruddin0% (1)

- Chap-2 Motion Along Straight LineДокумент77 страницChap-2 Motion Along Straight LineSajjad TahirОценок пока нет

- F Ma Summer 1Документ5 страницF Ma Summer 1in the maze.Оценок пока нет

- Parallel TransportДокумент16 страницParallel TransportSantiago CasasОценок пока нет

- AP CH 3 PP-teacherДокумент31 страницаAP CH 3 PP-teacherSyd MalaxosОценок пока нет

- ElectrodynamicsДокумент35 страницElectrodynamicsRajuОценок пока нет

- Module 1Документ45 страницModule 1MD SHAHRIARMAHMUDОценок пока нет

- Iso Parametric FormulationДокумент16 страницIso Parametric FormulationTahaKhanОценок пока нет

- Torsion Test: Department of Power Engineering and Turbomachinery Silesian University of Technology, GliwiceДокумент8 страницTorsion Test: Department of Power Engineering and Turbomachinery Silesian University of Technology, GliwiceThe White WolfОценок пока нет

- Chapter 2 Force SystemДокумент45 страницChapter 2 Force SystemeyuducОценок пока нет

- 10-Linear Strain Triangle and Other Types of 2d ElementsДокумент31 страница10-Linear Strain Triangle and Other Types of 2d Elementskranthi142434Оценок пока нет

- h03 Essential MathДокумент13 страницh03 Essential Mathakyadav123Оценок пока нет

- Tutorial 1Документ21 страницаTutorial 1kila122803Оценок пока нет

- Vector Calculus in Two DimensionsДокумент27 страницVector Calculus in Two DimensionsAndreea MoldoveanuОценок пока нет

- Chapter 8 DerivativesДокумент23 страницыChapter 8 DerivativesSong KimОценок пока нет

- Lecture 14Документ21 страницаLecture 14amjadtawfeq2Оценок пока нет

- Applied Physics LectureДокумент16 страницApplied Physics LectureKashif AliОценок пока нет

- 08 - Center of Gravity and CentroidДокумент24 страницы08 - Center of Gravity and CentroidMohammad AhmdОценок пока нет

- VDB 1023 Engineering Mechanics: Geometric Properties of Area and Solids Part I - Center of Gravity, CentroidДокумент28 страницVDB 1023 Engineering Mechanics: Geometric Properties of Area and Solids Part I - Center of Gravity, CentroidwengsungОценок пока нет

- Digital Image Processing 2 Lecture 4 PDFДокумент45 страницDigital Image Processing 2 Lecture 4 PDFsnake teethОценок пока нет

- A Prelude To Euler's Pentagonal Number Theorem: Preliminaries: PartitionsДокумент7 страницA Prelude To Euler's Pentagonal Number Theorem: Preliminaries: PartitionsEpic WinОценок пока нет

- Microproject PPT (MATHS)Документ26 страницMicroproject PPT (MATHS)BURHANUDDIN RATLAMWALAОценок пока нет

- Physical Sciences Grade 11 Term 1 Week 2 - 2021Документ10 страницPhysical Sciences Grade 11 Term 1 Week 2 - 2021tsholofelomdhlanaОценок пока нет

- Beam Design ConceptДокумент5 страницBeam Design ConceptCamille MillangОценок пока нет

- Understanding Vector Calculus: Practical Development and Solved ProblemsОт EverandUnderstanding Vector Calculus: Practical Development and Solved ProblemsОценок пока нет

- A-level Maths Revision: Cheeky Revision ShortcutsОт EverandA-level Maths Revision: Cheeky Revision ShortcutsРейтинг: 3.5 из 5 звезд3.5/5 (8)

- Black Belt BrochureДокумент2 страницыBlack Belt Brochuresqaiba_gОценок пока нет

- Residential Plot / Land For Sale in Tambaram East, Chennai 28.8 LakhsДокумент2 страницыResidential Plot / Land For Sale in Tambaram East, Chennai 28.8 Lakhssqaiba_gОценок пока нет

- North: Ele CT Ro Spanish Village - Highlight SДокумент3 страницыNorth: Ele CT Ro Spanish Village - Highlight Ssqaiba_gОценок пока нет

- Address of Islamic SchoolДокумент1 страницаAddress of Islamic Schoolsqaiba_gОценок пока нет

- Team-BHP PDI ChecklistДокумент3 страницыTeam-BHP PDI Checklistsqaiba_gОценок пока нет

- Mini TabДокумент19 страницMini Tabsqaiba_gОценок пока нет

- DMAIC Process IllustrationДокумент14 страницDMAIC Process Illustrationsqaiba_gОценок пока нет

- Sizing Procedures Chapter 2 - Airframe Stress Analysis and Sizing (Niu)Документ9 страницSizing Procedures Chapter 2 - Airframe Stress Analysis and Sizing (Niu)sqaiba_gОценок пока нет

- External Loads Chapter 3 - Airframe Stress Analysis and Sizing (Niu) & Chapter 3 - Airframe Structural Design (Niu)Документ19 страницExternal Loads Chapter 3 - Airframe Stress Analysis and Sizing (Niu) & Chapter 3 - Airframe Structural Design (Niu)sqaiba_gОценок пока нет

- Course Notes: Hållfasthetslära VK MHA100 Fatigue and Fracture Analysis MHA140Документ6 страницCourse Notes: Hållfasthetslära VK MHA100 Fatigue and Fracture Analysis MHA140sqaiba_gОценок пока нет

- Physics of Thin FilmsДокумент250 страницPhysics of Thin Films陳琮方100% (1)

- Gauge Theories Lecture Notes by Matthew de AngelisДокумент84 страницыGauge Theories Lecture Notes by Matthew de Angeliscifarha venant100% (1)

- Xerox 3030 - SM - PCДокумент532 страницыXerox 3030 - SM - PCSam StuartОценок пока нет

- Denavit Hartenberg KinematicsДокумент32 страницыDenavit Hartenberg KinematicshasdaОценок пока нет

- SKF Combi Kit TMMK 10-30Документ2 страницыSKF Combi Kit TMMK 10-30LLОценок пока нет

- SRS-Satellite CommunicationДокумент13 страницSRS-Satellite CommunicationVikrant Shimikeri100% (1)

- Work, Energy and PowerДокумент2 страницыWork, Energy and PowerChaОценок пока нет

- Quantum Theories NewДокумент256 страницQuantum Theories NewmaniacraghuОценок пока нет

- SU05Документ114 страницSU05saopaulo100% (1)

- SPM 1449 2006 Mathematics p2 BerjawapanДокумент18 страницSPM 1449 2006 Mathematics p2 Berjawapanpss smk selandar71% (7)

- Solid MensurationДокумент5 страницSolid MensurationDelfin MendezОценок пока нет

- 02 VergenceДокумент22 страницы02 VergenceHelenОценок пока нет

- Alternate Stresses and Temperature Variation As Factors of Influence of Ultrasonic Vibration On Mechanical and Functional Properties of Shape Memory A PDFДокумент6 страницAlternate Stresses and Temperature Variation As Factors of Influence of Ultrasonic Vibration On Mechanical and Functional Properties of Shape Memory A PDFGAJANAN M NAIKОценок пока нет

- Answer of Midterm Exam 2 PDFДокумент6 страницAnswer of Midterm Exam 2 PDFFaisal Al-assafОценок пока нет

- Determination of Thiomersal Lidocaine and Phenylepherine in Their Ternary Mixture.2157 7064.1000199 PDFДокумент6 страницDetermination of Thiomersal Lidocaine and Phenylepherine in Their Ternary Mixture.2157 7064.1000199 PDFiabureid7460Оценок пока нет

- Radio PharmacologyДокумент32 страницыRadio PharmacologyKaise GuerreroОценок пока нет

- WDM Phasar Technical Background and TutorialsДокумент128 страницWDM Phasar Technical Background and TutorialsMuhammad ArdiansyahОценок пока нет

- Admission Exam A Sheet AnswersДокумент4 страницыAdmission Exam A Sheet AnswersAlejandro SchrameierОценок пока нет

- prEN1999 1 4Документ58 страницprEN1999 1 4Pedro BarataОценок пока нет

- Prelim (2) - Physics-1 ModuleДокумент52 страницыPrelim (2) - Physics-1 ModuleHerrera, Mark NathanielОценок пока нет

- Hasil XRDДокумент1 страницаHasil XRDAissyah LathifahОценок пока нет

- EMTL Lecture NotesДокумент210 страницEMTL Lecture Notesnadheera ayishaОценок пока нет

- Excel Orifice FlowДокумент5 страницExcel Orifice Flowkagaku090% (1)

- Nannoplankton 1Документ73 страницыNannoplankton 1Desi Vivi Janna Pakpahan0% (1)

- Processing X Ray FilmДокумент5 страницProcessing X Ray Filmkanwar1992singhОценок пока нет

- Prof.P. Ravindran,: Lattice Dynamics-1Документ161 страницаProf.P. Ravindran,: Lattice Dynamics-1sajalgiriОценок пока нет

- 2013 Amat (101) Course OutlineДокумент4 страницы2013 Amat (101) Course OutlineMolepoMachaОценок пока нет

- CH 35Документ73 страницыCH 35api-234521500100% (1)

- Naveen Kumar PPT On Projectile MotionДокумент17 страницNaveen Kumar PPT On Projectile MotionBARUN SINGHОценок пока нет