Академический Документы

Профессиональный Документы

Культура Документы

4 Rotary Engine

Загружено:

Ssp VillalbaИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

4 Rotary Engine

Загружено:

Ssp VillalbaАвторское право:

Доступные форматы

The Rotary (Wankel) Engine

Ben Larson Peter Shreffler Scott Steinmetz

History

Ideas have existed since the 16th century German scientist Felix Wankel was the first to put the idea into a working design

Funded by the German Aviation Ministry during WWII Germany believed that the rotary engine would propel their industry into eventual greatness

Wankel perfected his design and sold the rights for the design to several car companies Mazda produced its first rotary power car in 1961 and created their Rotary Engine Division in 1963

History

Popularity for the rotary powered vehicles increased rapidly until the gas crisis in the mid 70s

Rotary engines were not very fuel efficient compared to piston engines Strict emissions standards could not be met with current rotary technology

These two factors severely hurt the sale and development of rotary engines Mazda was the only car company that continued to produce cars with rotary engines through the 90s

History

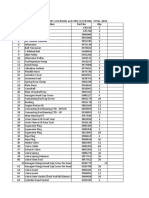

This graph demonstrates the rise and decline of the rotary engines popularity through the mid to late 90s

Automotive Success with Rotaries

In 1991, the Mazda 787B won the 24-hour Le Mans endurance race

Rotary engines were then banned from the C2 circuit

The RX-8 is able to produce 238 hp from its 1.3L engine and with good gas mileage and favorable emissions

Intake

Begins when apex passes intake port Increase in chamber volume Creates low pressure zone Pulls in Fuel/Air mixture Completes when next apex passes intake port

Compression

Begins after intake Volume of chamber decreases Fuel/Air mixture compressed Chamber compresses to its minimum size

Combustion

Spark plugs ignite mixture Two spark plugs to maximize amount of fuel ignited Causes rapid chamber expansion Turns rotor which produces work output on shaft Power stroke continues until apex passes exhaust port.

Exhaust

Chamber decreases in size Forces combustion biproducts out the exhaust port Continues until next apex passes exhaust port. Entire cycle repeats

The Cycle

Rotor mounted eccentrically on shaft One rotation of rotor provides three rotations of shaft Spark plugs fire 3 times per rotor revolution One rotation of shaft for each firing of spark plugs

Port Timing

Intake ports shape and size can be altered to change engine timing Limited by oil and coolant track Overlap is when intake port opens before exhaust port closes Support at least 50% of apex seal Street ports

Moved up to delay intake closing Moved out to open intake earlier Limited overlap and with reasonable limits of oil tracks

Very close to oil tracks Reduced engine life Sometimes large overlap Increased power at high RPM Decreased power at low RPM

Racing ports

Advantages

Vibration

No unbalanced reciprocating masses

For similar displacements, rotaries are generally 30% lighter and produce twice as much power Contain half as many moving parts Have no connecting rods, crankshaft, or valve trains

Power/Weight

Simplicity

Disadvantages

Fuel Efficiency and Emission

The shape of the combustion chamber, which is long instead of small and concentrated, makes the combustion travel longer than a piston engine Due to the longer combustion chamber, the amount of unburned fuel is higher which is released into the environment

The lack of infrastructure and development for the rotary engine has caused their production and maintenance costs generally to be more

Cost

Future Trends: Hydrogen

Highly Flammable Production Energy from

Crude Oil, Coal, Natural Gas, and Nuclear

Combustion Results in Water and NOx Energy Density

High Per Unit Mass Low Per Unit Volume

Challenges of Hydrogen

Storage

Requires Large Tank

High Temperatures

Combustion

Pre-ignition causes backfiring, excessive wear NOx formation

Injection Components

Low temp rubber seals

Rotary Hydrogen Solutions

Low Operating Temperature

No Backfiring Very Low Levels of NOx

Rubber Injector Seals Exposed Only to Intake

Separate Intake & Combustion Chambers

Hydrogen Rotary Timeline

1991

HR-X

1993

HR-X2

1997

Demio FC-EV

2001

Premacy FC-EV

2004

RX-8 RE

2006

Mazda5 RE

RENESIS Hydrogen Rotary

Dual Fuel

Switches from Hydrogen to Gasoline

Electronically Controlled Extended Seal Life Increased Injection Volume Control Valve

Direct Injection

Twin Injectors

Adjusts pressure of injected hydrogen

Hydrogen Conclusion

Cleaner Burning

Water, Minimum NOx

Low Temperature Separate Induction and Combustion Chambers Practical For Gas-Hydrogen Transition

Rotary Engine Solves Combustion Issues

Dual Fuel Mazda5 RE

Вам также может понравиться

- Wankel Engine PresentationДокумент15 страницWankel Engine PresentationHarish TalluriОценок пока нет

- Rotary EngineДокумент22 страницыRotary EngineIshanShikarkhaneОценок пока нет

- EGSA HandbookДокумент295 страницEGSA Handbookzhu_shaobo88Оценок пока нет

- D3K, D4K, and D5K Track-Type Tractor Hydraulic and Power Train SystemДокумент2 страницыD3K, D4K, and D5K Track-Type Tractor Hydraulic and Power Train Systemjulio peña limaОценок пока нет

- Manual Transmissions (Gearbox)Документ29 страницManual Transmissions (Gearbox)raviОценок пока нет

- Installation Manual PDFДокумент20 страницInstallation Manual PDFAprajita KayasthaОценок пока нет

- ATI CatalogДокумент84 страницыATI CatalogJimmy CrackKornОценок пока нет

- Yanmar 3G Marine Instrument Panel OPMДокумент38 страницYanmar 3G Marine Instrument Panel OPMSky NetОценок пока нет

- Yamaha Banshee Parts Manual 5FK6 - 2000Документ55 страницYamaha Banshee Parts Manual 5FK6 - 2000Felipe Antonio Pinto VillarroelОценок пока нет

- Tractorul EF312TEF352T PDFДокумент70 страницTractorul EF312TEF352T PDFFlorinОценок пока нет

- Start: Ault Finding Flow Chart For Motorcycle Charging SystemsДокумент4 страницыStart: Ault Finding Flow Chart For Motorcycle Charging SystemsJay ScizzoОценок пока нет

- Jari Monarch Manual 2015Документ7 страницJari Monarch Manual 2015Dara Donelson100% (1)

- Guide To Spark PlugsДокумент8 страницGuide To Spark PlugsXomBОценок пока нет

- Carburetor Basic PrinciplesДокумент6 страницCarburetor Basic PrinciplesjgcalocaОценок пока нет

- US Army Mechanic Principles Gas Diesel Fuel SystemsДокумент127 страницUS Army Mechanic Principles Gas Diesel Fuel SystemsSpace_Hulker100% (1)

- Carburetor Troubleshooting Repair Guide For HondaДокумент9 страницCarburetor Troubleshooting Repair Guide For HondaRoyal EОценок пока нет

- User Manual ETK-20180803Документ59 страницUser Manual ETK-20180803ricarsenioОценок пока нет

- Crash Analysis Criteria 1.6.2Документ90 страницCrash Analysis Criteria 1.6.2Gustavo MoralesОценок пока нет

- 5.accidental Car Impact Analysis and CFDДокумент6 страниц5.accidental Car Impact Analysis and CFDprojectzfourОценок пока нет

- DENSO - Spark Plug TT CatalogueДокумент255 страницDENSO - Spark Plug TT CatalogueVõ Trí NamОценок пока нет

- 100series Hires 071113Документ62 страницы100series Hires 071113Souleymane BambaОценок пока нет

- Air Bag Parameter StudyДокумент7 страницAir Bag Parameter StudyGeorge TsakatarasОценок пока нет

- VTX1300Repair PDFДокумент349 страницVTX1300Repair PDFDeeBeeОценок пока нет

- 2022 TRA Base BEMM Publishable 25-07-2022Документ135 страниц2022 TRA Base BEMM Publishable 25-07-2022Jack Norhy100% (1)

- Tools OBDIIpinjumpДокумент1 страницаTools OBDIIpinjumpbob loblawОценок пока нет

- ABE223 TextBook 2016Документ335 страницABE223 TextBook 2016Bianca ChanОценок пока нет

- Cursor SeriesДокумент45 страницCursor SeriesFranCanav100% (1)

- Nissan Silvia S14 SR20DE - Turbo Conversion: A Guide by Rudi BosmanДокумент9 страницNissan Silvia S14 SR20DE - Turbo Conversion: A Guide by Rudi BosmanRussell FergussonОценок пока нет

- s60 Marine Training 2005Документ184 страницыs60 Marine Training 2005Antony MorenoОценок пока нет

- Rotary CatalogДокумент58 страницRotary CatalogMicki MisamoreОценок пока нет

- 2016 Indmar Marine Engines Operators ManualsДокумент96 страниц2016 Indmar Marine Engines Operators ManualsRoberts BenjaminОценок пока нет

- SK Codes of Practice GasesДокумент50 страницSK Codes of Practice GaseseimrehОценок пока нет

- Strange Drag Racing Parts Catalog SMДокумент174 страницыStrange Drag Racing Parts Catalog SMKeine AngbeОценок пока нет

- TYm Tractors Operators Manuals - Team Tractor and Equipment, ArizonaДокумент58 страницTYm Tractors Operators Manuals - Team Tractor and Equipment, ArizonaAnastasiya DorfmanОценок пока нет

- Caterpillar Marine Propulsion Engines - Design and Construction Review FormДокумент15 страницCaterpillar Marine Propulsion Engines - Design and Construction Review FormdubimouОценок пока нет

- Engine: An Engine Is Motor Which Converts Chemical Energy of A Fuel Into The Mechanical EnergyДокумент61 страницаEngine: An Engine Is Motor Which Converts Chemical Energy of A Fuel Into The Mechanical EnergyMuhammad BilalОценок пока нет

- Gti Gti Rfi XP Di GTX 4 Tec SC LTD SC We RXP 4 Tec SC Tehnicheskie DannyeДокумент22 страницыGti Gti Rfi XP Di GTX 4 Tec SC LTD SC We RXP 4 Tec SC Tehnicheskie DannyeAlexandru DiaconuОценок пока нет

- Manual Motor Hyundai Elantra - Unlocked PDFДокумент164 страницыManual Motor Hyundai Elantra - Unlocked PDFloky13100% (1)

- How To Shift The Spicer PRO-SHIFT 18 Speed Transmission: Starting Vehicle From A StopДокумент2 страницыHow To Shift The Spicer PRO-SHIFT 18 Speed Transmission: Starting Vehicle From A StopMA RIOОценок пока нет

- Indian Scout-Spirit 2003 Service ManualДокумент309 страницIndian Scout-Spirit 2003 Service ManualRodrigo FischОценок пока нет

- SOS Kit PDFДокумент22 страницыSOS Kit PDFHectorDeJesusОценок пока нет

- 02 - Power BalancingДокумент8 страниц02 - Power Balancingveer sainОценок пока нет

- Linked PDFДокумент488 страницLinked PDFIonОценок пока нет

- CBR929 ElecДокумент1 страницаCBR929 ElecFerdinand SinadumaОценок пока нет

- Crankshaft Position Sensor Inductive, Referenced, Voltage During CrankingДокумент7 страницCrankshaft Position Sensor Inductive, Referenced, Voltage During Crankingdanieldario33Оценок пока нет

- LV06 - Engines - Issue 1Документ72 страницыLV06 - Engines - Issue 1Valentin Silvan Valentin SilvanОценок пока нет

- Harmonic Drive Ultra Flat Component SpecsheetДокумент4 страницыHarmonic Drive Ultra Flat Component SpecsheetElectromateОценок пока нет

- Operators Manual 500 SeriesДокумент36 страницOperators Manual 500 SeriesAutochthon GazetteОценок пока нет

- Tribology Brochure PrintДокумент20 страницTribology Brochure PrintVito Digeo100% (1)

- Manual Motor Popa 60hpДокумент61 страницаManual Motor Popa 60hplucianoОценок пока нет

- HT Series Brochure Eng 2011 LQДокумент8 страницHT Series Brochure Eng 2011 LQJunaid YОценок пока нет

- Vetus Diesel EngineДокумент80 страницVetus Diesel EnginestartaxisОценок пока нет

- Rotary Wankel EngineДокумент31 страницаRotary Wankel EngineAbdelrahman MagdyОценок пока нет

- Advantages of 4 Stroke EngineДокумент6 страницAdvantages of 4 Stroke EngineJILLIEN KAITH ARELLANOОценок пока нет

- Why Can T They Think of Some Light Weight Engine and Small Volume Engine ?? I Am Fed Up of Carrying This Weight in The Air I Might Go Down One DayДокумент57 страницWhy Can T They Think of Some Light Weight Engine and Small Volume Engine ?? I Am Fed Up of Carrying This Weight in The Air I Might Go Down One DayRanjith KaruturiОценок пока нет

- LV34 Engines (3) : Student WorkbookДокумент70 страницLV34 Engines (3) : Student WorkbookMichael OdomОценок пока нет

- Rotary EnginesДокумент4 страницыRotary Engines20007134009Оценок пока нет

- Design of The SR20Документ11 страницDesign of The SR20hugostvОценок пока нет

- Otto CyclePowePointДокумент27 страницOtto CyclePowePointVamsi KrishnaОценок пока нет

- Nano Ic EngineДокумент24 страницыNano Ic EngineUjjwal Kumar0% (1)

- 08 Fuel Supply System 2Документ122 страницы08 Fuel Supply System 2ramalingeswarao annamdevulaОценок пока нет

- ME Engine Shows Real Fuel Savings: DieselfactsДокумент16 страницME Engine Shows Real Fuel Savings: DieselfactsKamal WanniarachchiОценок пока нет

- C.B.G. (Compressed BioGas) Biogas Purification and Bottling, Environmental Engineering - Biogas C.BДокумент4 страницыC.B.G. (Compressed BioGas) Biogas Purification and Bottling, Environmental Engineering - Biogas C.BMuhammad IrfanОценок пока нет

- Literature SurveyДокумент2 страницыLiterature SurveygmailОценок пока нет

- JANA 17 Spare ListДокумент16 страницJANA 17 Spare Listspecial My showОценок пока нет

- Honda GX120G 160G 200 PDFДокумент1 страницаHonda GX120G 160G 200 PDFClejeanu MihaelaОценок пока нет

- How To Replace Intake Manifold Gaskets On A GMC Jimmy 4.3 - 1 - 2Документ18 страницHow To Replace Intake Manifold Gaskets On A GMC Jimmy 4.3 - 1 - 2vgyyibОценок пока нет

- Cummins M11 Engine Spare Parts CatalogДокумент15 страницCummins M11 Engine Spare Parts CatalogChen Caroline100% (1)

- Project Guide Motor Man B&W K98me-C7-TiiДокумент1 страницаProject Guide Motor Man B&W K98me-C7-TiiErnesto Cal ListaОценок пока нет

- Subaru 600 Service ManualДокумент393 страницыSubaru 600 Service ManualDon B Davidson III100% (5)

- Key Points about Assembling or Disassembling WP6 Diesel Engines 培训资料 Training Material 国际配套服务部 徐衍国Документ27 страницKey Points about Assembling or Disassembling WP6 Diesel Engines 培训资料 Training Material 国际配套服务部 徐衍国Manutenção Base AnápolisОценок пока нет

- ECM PINOUT Chevrolet-Sail PDFДокумент2 страницыECM PINOUT Chevrolet-Sail PDFHernan Gutierrez Herrera100% (4)

- Unit 17 - 03 - Safety & Alarm SystemДокумент16 страницUnit 17 - 03 - Safety & Alarm SystemAisha Zaheer100% (1)

- Sachs Owner's Manual - Suburban and Prima 505-1B, 1A, 1DДокумент21 страницаSachs Owner's Manual - Suburban and Prima 505-1B, 1A, 1DChristopher A ArcherОценок пока нет

- Toyota D4-SДокумент11 страницToyota D4-STheodoros Nikitopoulos100% (1)

- Diagnostic Trouble Codes (DTC) : 14.1 About The Codes Shown in The TableДокумент6 страницDiagnostic Trouble Codes (DTC) : 14.1 About The Codes Shown in The Tablejorgebbcaarg100% (1)

- Us9366187 PDFДокумент12 страницUs9366187 PDFFernando TaleroОценок пока нет

- MANUAL PACIFIC E27 - EG27 Rev 01-17 ENGДокумент94 страницыMANUAL PACIFIC E27 - EG27 Rev 01-17 ENGArturОценок пока нет

- Delete Cancel Egr DPF SCR Adblue Regeneration SystemДокумент3 страницыDelete Cancel Egr DPF SCR Adblue Regeneration SystemScribdTranslations100% (1)

- Unit 1 BCME NotesДокумент23 страницыUnit 1 BCME NotesMANOJKUMAR MОценок пока нет

- 3 PDFДокумент1 страница3 PDFaritw541214Оценок пока нет

- Engine Valve Lash - Inspect - Adjust... 3408E and 3412E Engines For Caterpillar Built Machines #I01625568 CaterpillarДокумент4 страницыEngine Valve Lash - Inspect - Adjust... 3408E and 3412E Engines For Caterpillar Built Machines #I01625568 CaterpillarinduramОценок пока нет

- TSB-Re-J24B-Cylinder-Head CracksДокумент3 страницыTSB-Re-J24B-Cylinder-Head Cracksspamail73887Оценок пока нет

- Introduction To Regenerative Braking SystemДокумент6 страницIntroduction To Regenerative Braking SystemdfgvdfsghdgfОценок пока нет

- C1000D6 Data SheetДокумент3 страницыC1000D6 Data SheetCyril TEMATAHOTOAОценок пока нет

- Triumph Daytona 675 Race Kit ManualДокумент33 страницыTriumph Daytona 675 Race Kit ManualThunderbird3100% (2)

- Simonini Mini 2 Plus ManualДокумент16 страницSimonini Mini 2 Plus ManualOskr RodriguezОценок пока нет

- MOTOR MBE-900 Fuel System PDFДокумент24 страницыMOTOR MBE-900 Fuel System PDFJosue Alvarez Vega100% (1)

- PM 1F (250 Hour Interval)Документ3 страницыPM 1F (250 Hour Interval)Ibrahim AwadОценок пока нет