Академический Документы

Профессиональный Документы

Культура Документы

Sludge and Grit Removal Solutions

Загружено:

drramsayАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Sludge and Grit Removal Solutions

Загружено:

drramsayАвторское право:

Доступные форматы

Integrated solutions to treat and/or prevent sludge and grit accumulation in Wastewater Treatment Plants and Surface Market

disruptive, step Lagoons

change. CleanTech Now

TUMWATER inc. Fadi Kassir

Fadi Kassir, Cell (614) 790-0069, Email

fadi.kassir@gmail.com Post Office Box 20025, Seattle,

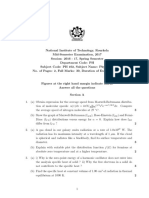

TUMWATER Introduction

New small and medium scale cost-effective next-gen technologies have become available but these often require more examples, proof of life and precedents before they are generally accepted. TUMWATER is a collaborative alliance for newly launched technology companies to cooperate on a substantial level to provide integrated solutions for the delivery of equipment and services to general industry and to sustainable communities. TUMWATER Triple MMO Platform is being built to provide complete integration of alliance partners technologies, products and solutions offering (marketing, process simulations, economical and treatment performance projections). The TripleMMO interface caters to practitioners and will provide them access to configure manageable and affordable integrated solution options to select, approve, fund, and execute at scale renovation projects or new equipment installations.

TUMWATER Introduction

- Continued

Surface Ponds and Lagoons

Secondary and Tertiary Lagoons

In-situ Biodegradation Test A Case Study

Destratification -

Geyser Inertia Pump (GIP)

Less Air for Destratification than Aeration

Artificial Stream

Comparison of Three Pump Types

Pumping Rate Submergence Lift

3000 GPM 15 feet 0.5 feet

Pump Mechanical Pump Airlift Pump Geyser Inertia Pump

Power 11 KW 7.5 KW 3.0 KW

Compare these Pumps

Airlift (AP) Pulse Pump (GPP) Ejection Pump (GEP)

Surface Lagoons Pump Out

Step

Discharge with Disinfection

Plan View

Surface Lagoons Pump Out

Step

Discharge with Disinfection

Side View

Geyser Large Bubble Mixer

Geyser Mixing System I

Also offered as single large bubble generator without the header

Header System with 6 Outlets

Water Jet Covers Tank Periphery

Geyser Mixing System II

Geyser Large Bubble Mixer

Header System with 6 Outlets Water Jet Header with Holes to Lift Settled solids in Hard to Reach Corners

Geyser Mixing System II

Installation Layout

Solution Economics

Geyser Pulse Mixing System vs Mechanical Mixers

Carrolton WWTP, GA (9 MGD) After Retrofit

(8) 4 Hybrid Pumps

Classifier ejects grit to totes

Removed grit increased from 1/16 to 1/8

Existing headers, reused for fast

Conventional Airlift Pump vs. Geyser Pulse Pump

Better Pumping, Lower Energy Requirements Capacity =100,000 GPD Submergence = 10 feet

4 Airlift Pump Air Flow for Aeration [CFM] Blower [HP] Electricity Cost for Aeration [$/year] Air Flow for Sludge Thickening [CFM] Blower [HP] Electricity Cost for Sludge Thickening [$/year] Labor Unit Cost [$/hr] Maintenance Period [hr/day] Labor Cost [$/year] 60 3.5 3,429 30 1.5 1,470 30 1.5 16,425

Lift = 3 feet

4 Pulse Pump 6 0.3 294 6 0.3 294 30 0.3 3,285

TOTAL COST [$/year]

21,324

3,873

Integrated Technical Solutions Problems

Additional Applications

Uneven flows (Flow Equalization and Recirculation for BNR) Carbon starvation in bio-nutrient removal (BNR) High energy consumption (Aeration) Segregation/ Channeling/ Frequent shut downs Grit Trapping/ Sludge Accumulation/ Reduction of capacity

Solutions

Adjusted Flow Equalization and Recirculation rates Eliminated grit and sludge build-up in all tanks/basins Improved sludge mixing in anoxic zones, and in aeration process basins/tanks Enhanced aeration efficiencies, better pumps and mixers

Summary

Hard to Beat Service Opportunities

Replace Rotating Equipment with Geyser Pulse Pumps and Mixers

Geyser reduces electricity consumption, as compared to:

Submersible Pump Centrifugal Pump Airlift Pump

No maintenance No cleaning No clogging Easy to control pumping rate Easy to monitor pumping rate

Вам также может понравиться

- Optimization of Equipment Used in Wastewater Treatment PlantДокумент3 страницыOptimization of Equipment Used in Wastewater Treatment PlantMatthew DelgadoОценок пока нет

- Flow in Circular Pipes: ObjectiveДокумент25 страницFlow in Circular Pipes: ObjectivePatrickAndradeОценок пока нет

- Types and Functions - Design Considerations - Sizing Criteria - Calculation Method - Specification Data SheetДокумент21 страницаTypes and Functions - Design Considerations - Sizing Criteria - Calculation Method - Specification Data Sheet3668770Оценок пока нет

- The New BMW 3 Series Coupé.: Joy Defines The Ideal LineДокумент21 страницаThe New BMW 3 Series Coupé.: Joy Defines The Ideal LineCocu IgorОценок пока нет

- Asme B31 - Pressure PipingДокумент3 страницыAsme B31 - Pressure PipingAndhyka Cakrabuana AdhitamaОценок пока нет

- Simulators For Risk AssessmentДокумент20 страницSimulators For Risk Assessmentajrojas1359100% (1)

- When Is Corrosion Not Corrosion A Decade of MFL PipelineДокумент24 страницыWhen Is Corrosion Not Corrosion A Decade of MFL PipelinePrakhar Deep KulshreshthaОценок пока нет

- Info Dec 13Документ13 страницInfo Dec 13Malik Uzair ZafarОценок пока нет

- PumpLab Book 1 PreviewДокумент11 страницPumpLab Book 1 Previewcorey6Оценок пока нет

- C Cross Sectional Area (A)Документ14 страницC Cross Sectional Area (A)Jitheesh SahadevanОценок пока нет

- Hydrocyclones DeoilingДокумент2 страницыHydrocyclones DeoilingJ SlaterОценок пока нет

- 1.1. Process Measurement and Industrial InstrumrntationДокумент34 страницы1.1. Process Measurement and Industrial InstrumrntationKemal GetisoОценок пока нет

- Produced Water PresentationДокумент30 страницProduced Water PresentationAkilesh AravindakshanОценок пока нет

- Hydralic Noise PDFДокумент16 страницHydralic Noise PDFTamil SelvanОценок пока нет

- Alia AFC365 Flow ComputerДокумент4 страницыAlia AFC365 Flow ComputerRexCrazyMindОценок пока нет

- Pressure Drop (Two Phases)Документ38 страницPressure Drop (Two Phases)PROCESOS PROCESOS100% (1)

- Knock Out Drums and SeparatorsДокумент2 страницыKnock Out Drums and SeparatorsAhmed RedaОценок пока нет

- Combination Air ValvesДокумент4 страницыCombination Air ValvesFelipe OliverosОценок пока нет

- Instrumentation & Process ControlДокумент6 страницInstrumentation & Process ControlAnonymous 0zrCNQОценок пока нет

- Jet Pump Technical DataДокумент11 страницJet Pump Technical DataIdelia Cutipa Yauri100% (1)

- Packed Towers: 12.1 Device TypeДокумент10 страницPacked Towers: 12.1 Device TypeSagar BhavsarОценок пока нет

- Intake StructuresДокумент32 страницыIntake StructuresSai Geotechnical LabОценок пока нет

- Distillation Operation DifficultiesДокумент7 страницDistillation Operation DifficultiesSekar ChadarwatiОценок пока нет

- Effluent ClarifierДокумент2 страницыEffluent ClarifierSutra IrawanОценок пока нет

- 3B - Inst - Control ValveДокумент31 страница3B - Inst - Control ValveMystic AamirОценок пока нет

- SteamДокумент146 страницSteamRose ParkОценок пока нет

- Corrugated Plate Separator (CPS) ForДокумент2 страницыCorrugated Plate Separator (CPS) Formib_ajayОценок пока нет

- Pumps - Centrifugal vs. Positive Displacement: Instructor: Edward P. Brunet, JR., PEДокумент11 страницPumps - Centrifugal vs. Positive Displacement: Instructor: Edward P. Brunet, JR., PEyogachemОценок пока нет

- Pipa PendahulianДокумент52 страницыPipa PendahulianYusmanparjianto YusmanparjiantoОценок пока нет

- Ratio Pressure Reducing ValvesДокумент4 страницыRatio Pressure Reducing Valveskanem1Оценок пока нет

- Principal Types of Atmospheric Storage TanksДокумент9 страницPrincipal Types of Atmospheric Storage Tanksmohsen ranjbarОценок пока нет

- Walworth Check ValvesДокумент24 страницыWalworth Check ValvesFahad RockingОценок пока нет

- Aspen Tech Compressor Modeling in AspenДокумент16 страницAspen Tech Compressor Modeling in AspenDesiree MolinaОценок пока нет

- Centrifugal PumpДокумент39 страницCentrifugal PumpGogot Pantja Parijogo100% (1)

- What Is A Performance CurveДокумент8 страницWhat Is A Performance CurveRanjit PaulОценок пока нет

- AMT Module 1 - PartB-1Документ12 страницAMT Module 1 - PartB-1PrathikОценок пока нет

- Subsonic Ejector RamjetДокумент99 страницSubsonic Ejector Ramjetmarco20874Оценок пока нет

- Vacuum DeaeratorДокумент2 страницыVacuum DeaeratorGaurav100% (1)

- Bernoulli Cyclon SeparatorДокумент4 страницыBernoulli Cyclon SeparatorMonk KongОценок пока нет

- A Demister Pad Is Similar To An Air Filter Except Instead of Removing Dust ParticlesДокумент1 страницаA Demister Pad Is Similar To An Air Filter Except Instead of Removing Dust ParticlesyogacruiseОценок пока нет

- JT LTS Vs VortexДокумент4 страницыJT LTS Vs VortexIlya Popik100% (1)

- HEATEXДокумент34 страницыHEATEXSiddharthОценок пока нет

- VGS Vane Separators Are Recommended ForДокумент1 страницаVGS Vane Separators Are Recommended ForSanthu PeelaОценок пока нет

- Reducing Steam Header PressureДокумент1 страницаReducing Steam Header Pressuresj_scribdОценок пока нет

- Pumps PresentationДокумент44 страницыPumps Presentationoida_adОценок пока нет

- Cooling Tower 434Документ15 страницCooling Tower 434arslan MaqboolОценок пока нет

- Controllability in Process DesignДокумент14 страницControllability in Process DesignKokil JainОценок пока нет

- Refrigerated Gas PlantДокумент12 страницRefrigerated Gas PlantHiba GhandourОценок пока нет

- FL1627Документ2 страницыFL1627Isaac Montero BarreraОценок пока нет

- Refrigeration (VCRS &VARS)Документ19 страницRefrigeration (VCRS &VARS)Vinesh TalpankarОценок пока нет

- What's A Screw Pump? Understanding The Unique Characteristics and Operating Principles of 1, 2 and 3 Screw PumpsДокумент4 страницыWhat's A Screw Pump? Understanding The Unique Characteristics and Operating Principles of 1, 2 and 3 Screw PumpsTapas ChaudhuriОценок пока нет

- Plunger LiftДокумент5 страницPlunger LiftrocacantuОценок пока нет

- C3 Recovery StudyДокумент15 страницC3 Recovery StudyengmohosmanОценок пока нет

- Bits, Pilani - K. K. Birla Goa Campus Process Design Principles IiДокумент53 страницыBits, Pilani - K. K. Birla Goa Campus Process Design Principles IiAdheep DasОценок пока нет

- 1.6a Line Sizing SlidesДокумент24 страницы1.6a Line Sizing SlidesPhani Raj M100% (1)

- Case Study 2Документ2 страницыCase Study 2Myrelle CucioОценок пока нет

- How To Achieve Rapid Steam Turbine Start-UpДокумент2 страницыHow To Achieve Rapid Steam Turbine Start-UpNAITIKОценок пока нет

- 1 s2.0 S1359431115000368 MainДокумент12 страниц1 s2.0 S1359431115000368 MainJulio CésarОценок пока нет

- Energy Tips - Pumping Systems: Select An Energy-Efficient Centrifugal PumpДокумент2 страницыEnergy Tips - Pumping Systems: Select An Energy-Efficient Centrifugal PumpBang RegarОценок пока нет

- Planning and Operation of Distributed Generation in Distribution NetworksДокумент8 страницPlanning and Operation of Distributed Generation in Distribution NetworksPervez AhmadОценок пока нет

- Prediction of Flow Behavior of Crude Oil-in-Water Emulsion Through The Pipe by Using Rheological PropertiesДокумент5 страницPrediction of Flow Behavior of Crude Oil-in-Water Emulsion Through The Pipe by Using Rheological PropertiesdrramsayОценок пока нет

- HartДокумент10 страницHartdrramsayОценок пока нет

- Pipeline IntegrityДокумент120 страницPipeline Integritydrramsay100% (5)

- Geyser Product Catalog - March 2014Документ22 страницыGeyser Product Catalog - March 2014drramsay100% (1)

- Geyser Hybrid PumpsДокумент2 страницыGeyser Hybrid PumpsdrramsayОценок пока нет

- Geyser Pumps For Aquaculture ApplicationsДокумент10 страницGeyser Pumps For Aquaculture Applicationsdrramsay0% (1)

- API RP 1102 SpreadsheetДокумент5 страницAPI RP 1102 Spreadsheetdrramsay100% (4)

- C4 Tech Spec Issue 2Документ5 страницC4 Tech Spec Issue 2Дмитрий КалининОценок пока нет

- NEF67 TM3 DS P4A04N018E Mar06Документ2 страницыNEF67 TM3 DS P4A04N018E Mar06altieresmirandaОценок пока нет

- 06 Ba Exakt 80eplus EnglischДокумент154 страницы06 Ba Exakt 80eplus EnglischAya adelОценок пока нет

- Fallsem2016-17 1286 RM001 27-Jul-2016 Mee1003 THДокумент74 страницыFallsem2016-17 1286 RM001 27-Jul-2016 Mee1003 THaman agarwalОценок пока нет

- DC01 (STAT Table) DA01 (Reagent Refrigerator) GA01: Heat ExchangerДокумент2 страницыDC01 (STAT Table) DA01 (Reagent Refrigerator) GA01: Heat ExchangerQuốc CườngОценок пока нет

- Analytical Options For BioChar Adsorption and Surface Area Characterization of Biochar Materials PPT 2012Документ26 страницAnalytical Options For BioChar Adsorption and Surface Area Characterization of Biochar Materials PPT 2012Jean Carlos Gonzalez HernandezОценок пока нет

- ItysДокумент32 страницыItysciohaniОценок пока нет

- Lab ReporttДокумент5 страницLab ReporttAngela BalanjianОценок пока нет

- Manual Qrod PDFДокумент17 страницManual Qrod PDFEzequiel GuerreroОценок пока нет

- Proposed Energy Efficiency Labeling and Standards For Electrical AppliancesДокумент32 страницыProposed Energy Efficiency Labeling and Standards For Electrical AppliancesState House Nigeria100% (1)

- Installation and Operation Manual: 2301A Speed Control With Ma Speed Setting InputДокумент40 страницInstallation and Operation Manual: 2301A Speed Control With Ma Speed Setting Inputsorangel_123Оценок пока нет

- Brochure Ball Mills enДокумент16 страницBrochure Ball Mills enmarviОценок пока нет

- Fundamentals Fundamentals Fundamentals of Crop Science of Crop Science of Crop ScienceДокумент26 страницFundamentals Fundamentals Fundamentals of Crop Science of Crop Science of Crop ScienceAlthea DoradoОценок пока нет

- Casing ScrapersДокумент2 страницыCasing ScrapersthetrevanianОценок пока нет

- Diagnostic Study For Cement Mill OptimizationДокумент9 страницDiagnostic Study For Cement Mill OptimizationHilmy MuhammadОценок пока нет

- 80ZV 2Документ12 страниц80ZV 2mhmd_saad100% (2)

- Air Leak in Test of Esp ProcedureДокумент5 страницAir Leak in Test of Esp Procedurenetygen1Оценок пока нет

- Lugs and Ferrules Technical Information PDFДокумент2 страницыLugs and Ferrules Technical Information PDFkwagga125Оценок пока нет

- Design and Fabrication of Stair Climber TrolleyДокумент21 страницаDesign and Fabrication of Stair Climber TrolleyAnonymous 1mMOyt9zОценок пока нет

- Technical Specification of VSK PDFДокумент28 страницTechnical Specification of VSK PDFmaran.suguОценок пока нет

- Operating Instructions: DishwasherДокумент20 страницOperating Instructions: DishwasherpetrushinОценок пока нет

- Off Grid PV Systems Design GuidelinesДокумент24 страницыOff Grid PV Systems Design Guidelinestantiba100% (1)

- Smpling - Storage - Transportation - Installation ProcedureДокумент75 страницSmpling - Storage - Transportation - Installation ProcedurePaddyОценок пока нет

- Axpert MKS IV Off-Grid Inverter Selection GuideДокумент1 страницаAxpert MKS IV Off-Grid Inverter Selection GuideMax Hernandez RОценок пока нет

- Design - Guide Elastomers and ThermoplasticsДокумент117 страницDesign - Guide Elastomers and ThermoplasticsJuan Miguel CalzadaОценок пока нет

- Micro Scale CFD Modeling of Reactive Mass Transfer in Falling Liquid Films Within Structured Packing MaterialsДокумент11 страницMicro Scale CFD Modeling of Reactive Mass Transfer in Falling Liquid Films Within Structured Packing MaterialsAbdul ZahirОценок пока нет

- 2014 To Study High Temperature Erosion-Corrosion of Detonation 1111111111111111111111111Документ5 страниц2014 To Study High Temperature Erosion-Corrosion of Detonation 1111111111111111111111111Harkulvinder SinghОценок пока нет

- Phy Sci PartIДокумент318 страницPhy Sci PartIsollu786_889163149Оценок пока нет

- PH102Документ2 страницыPH102Shobhit ParkiОценок пока нет

- Quick Exhaust Solenoid Valves: NC NOДокумент4 страницыQuick Exhaust Solenoid Valves: NC NOMuhammad AsadОценок пока нет