Академический Документы

Профессиональный Документы

Культура Документы

Testing of Materials

Загружено:

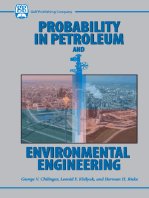

Arvin ArviniОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Testing of Materials

Загружено:

Arvin ArviniАвторское право:

Доступные форматы

Manufacturing, Engineering & Technology, Fifth Edition, by Serope Kalpakjian and Steven R. Schmid.

ISBN 0-13-148965-8. 2006 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

Chapter 2

Mechanical Behavior, Testing, and

Manufacturing Properties of Materials

Manufacturing, Engineering & Technology, Fifth Edition, by Serope Kalpakjian and Steven R. Schmid.

ISBN 0-13-148965-8. 2006 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

Relative Mechanical Properties of Materials

Manufacturing, Engineering & Technology, Fifth Edition, by Serope Kalpakjian and Steven R. Schmid.

ISBN 0-13-148965-8. 2006 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

Tensile-test Specimen and Machine

Figure 2.1 (a) A standard tensile-test

specimen before and after pulling,

showing original and final gage lengths.

(b) A tensile-test sequence showing

different stages in the elongation of the

specimen.

Engineering Stess, o =

P

A

o

Engineering Strain, e =

l l

o

l

o

Modulus of Elasticity, E =

o

e

True stress,o =

P

A

True strain, c = ln

l

l

o

|

\

|

.

|

Manufacturing, Engineering & Technology, Fifth Edition, by Serope Kalpakjian and Steven R. Schmid.

ISBN 0-13-148965-8. 2006 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

Tension Test Stress-strain Curve

Figure 2.2 A typical stress-strain curve obtained

from a tension test, showing various features

Manufacturing, Engineering & Technology, Fifth Edition, by Serope Kalpakjian and Steven R. Schmid.

ISBN 0-13-148965-8. 2006 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

Mechanical Properties of Materials

Manufacturing, Engineering & Technology, Fifth Edition, by Serope Kalpakjian and Steven R. Schmid.

ISBN 0-13-148965-8. 2006 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

Loading and Unloading of Tensile-test Specimen

Figure 2.3 Schematic illustration

of the loading and the unloading

of a tensile-test specimen. Note

that, during unloading, the curve

follows a path parallel to the

original elastic slope.

Manufacturing, Engineering & Technology, Fifth Edition, by Serope Kalpakjian and Steven R. Schmid.

ISBN 0-13-148965-8. 2006 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

Elongation vs. Tensile-reduction

Figure 2.4 Approximate relationship between elongation

and tensile reduction of area for various groups of metals

Manufacturing, Engineering & Technology, Fifth Edition, by Serope Kalpakjian and Steven R. Schmid.

ISBN 0-13-148965-8. 2006 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

Tension and Stress Curves

Figure 2.5 (a) Load elongation

curve in tension testing of a

stainless steel specimen. (b)

Engineering stress-engineering

strain curve, drawn from the data

in Fig. 2.5a. (c) True stress-true

strain curve, drawn from the data

in Fig. 2.5b. Note that this curve

has a positive slope, indicating

that the material is becoming

stringer as it is strained. (d) True

stress-true strain curve plotted on

the log-log paper and based on

the corrected curve in Fig. 2.5c.

The correction is due to the

triaxial state of stress tat exists in

the necked region of the

specimen.

Manufacturing, Engineering & Technology, Fifth Edition, by Serope Kalpakjian and Steven R. Schmid.

ISBN 0-13-148965-8. 2006 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

Power Law Constitutive Model

o =Kc

n

where

K = strength coefficient

n = strain hardening

exponent

Manufacturing, Engineering & Technology, Fifth Edition, by Serope Kalpakjian and Steven R. Schmid.

ISBN 0-13-148965-8. 2006 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

True Stress-strain Curves

Figure 2.6 True stress-

strain curves in tension at

room temperature for

various metals. The

curves start at a finite

level of stress: The elastic

regions have too steep a

slope to be shown in this

figure, and thus each

curve starts at the yield

stress, Y, of the material

Manufacturing, Engineering & Technology, Fifth Edition, by Serope Kalpakjian and Steven R. Schmid.

ISBN 0-13-148965-8. 2006 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

Temperature Effects on Stress-strain Curves

Figure 2.7 Typical effects of temperature on stress-strain curves. Note that

temperature affects the modulus of elasticity, the yield stress, the ultimate tensile

strength, and the toughness (area under the curve) of materials.

Manufacturing, Engineering & Technology, Fifth Edition, by Serope Kalpakjian and Steven R. Schmid.

ISBN 0-13-148965-8. 2006 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

Strain and Deformation Rate in Manufacturing

Manufacturing, Engineering & Technology, Fifth Edition, by Serope Kalpakjian and Steven R. Schmid.

ISBN 0-13-148965-8. 2006 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

Effect of Strain Rate on Tensile Strength of Al

Figure 2.8 The effect of strain

rate on the ultimate tensile

strength for aluminum. Note

that, as the temperature

increases, the slopes of the

curves increase; thus, strength

becomes more and more

sensitive to strain rate as

temperature increases.

Source: After J.H. Holloman

Manufacturing, Engineering & Technology, Fifth Edition, by Serope Kalpakjian and Steven R. Schmid.

ISBN 0-13-148965-8. 2006 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

Disk Test

Figure 2.9 Disk test on a brittle material,

showing the direction of loading and the

fracture path.

Tensile stress, o =

2P

tdt

where

P = load at fracture

d = diameter of disk

t = thickness of disk

Manufacturing, Engineering & Technology, Fifth Edition, by Serope Kalpakjian and Steven R. Schmid.

ISBN 0-13-148965-8. 2006 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

Torsion-Test Specimen

Figure 2.10 A typical torsion-test specimen; it is

mounted between the two heads of a testing

machine and twisted. Note the shear

deformation of an element in the reduced

section of the specimen.

Shear stress,t =

T

2tr

2

t

Shear strain, =

r|

l

where

T = torque

r = average tube radius

t = thickness of tube at

narrow section

l = length of tube subjected

to torsion

| = angle of twist

Manufacturing, Engineering & Technology, Fifth Edition, by Serope Kalpakjian and Steven R. Schmid.

ISBN 0-13-148965-8. 2006 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

Bend-test Methods

Figure 2.11 Two bend-test methods for brittle materials: (a) three-point

bending; (b) four-point bending. The areas on the beams represent the

bending-movement diagrams, described in texts on mechanics of solids. Note

the region of constant maximum bending movement in (b); by contrast, the

maximum bending moment occurs only at the center of the specimen in (a).

Manufacturing, Engineering & Technology, Fifth Edition, by Serope Kalpakjian and Steven R. Schmid.

ISBN 0-13-148965-8. 2006 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

Hardness-testing Methods and Formulas

Figure 2.12 General characteristics of hardness-

testing methods and formulas for calculating hardness.

Manufacturing, Engineering & Technology, Fifth Edition, by Serope Kalpakjian and Steven R. Schmid.

ISBN 0-13-148965-8. 2006 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

Indentation Geometry for Brinnel Testing

Figure 2.13 Indentation

geometry in Brinell hardness

testing: (a) annealed metal; (b)

work-hardened metal; (c)

deformation of mild steel under a

spherical indenter. Note that the

depth of the permanently

deformed zone is about one

order of magnitude larger that

the depth of indentation. For a

hardness test to be valid, this

zone should be developed fully in

the material. Source: Courtesy

of M.C. Shaw and C.T. Yang

Manufacturing, Engineering & Technology, Fifth Edition, by Serope Kalpakjian and Steven R. Schmid.

ISBN 0-13-148965-8. 2006 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

Hardness

Scale

Conversions

Figure 2.14 Chart for converting

various hardness scales. Note

the limited range of most scales.

Because of the many factors

involved, these conversions are

approximate.

Manufacturing, Engineering & Technology, Fifth Edition, by Serope Kalpakjian and Steven R. Schmid.

ISBN 0-13-148965-8. 2006 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

S-N Curves

Figure 2.15 (a) Typical S-N curves for two metals. Note that, unlike steel,

aluminum does not have an endurance limit. (b) S-N curves for common polymers

Manufacturing, Engineering & Technology, Fifth Edition, by Serope Kalpakjian and Steven R. Schmid.

ISBN 0-13-148965-8. 2006 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

Endurance Limit vs. Tensile Strength

Figure 2.16 Ratio of

endurance limit to tensile

strength for various metals,

as a function of tensile

strength. Because

aluminum does not have an

endurance limit, the

correlations for aluminum

are based on a specific

number of cycles, as is

seen in Fig. 2.15.

Manufacturing, Engineering & Technology, Fifth Edition, by Serope Kalpakjian and Steven R. Schmid.

ISBN 0-13-148965-8. 2006 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

Creep Curve

Figure 2.17 Schematic illustration of a typical creep curve. The linear segment of

the curve (secondary) is used in designing components for a specific creep life.

Manufacturing, Engineering & Technology, Fifth Edition, by Serope Kalpakjian and Steven R. Schmid.

ISBN 0-13-148965-8. 2006 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

Impact Test Specimens

Figure 2.18 Impact test specimens: (a) Charpy; (b) Izod.

Manufacturing, Engineering & Technology, Fifth Edition, by Serope Kalpakjian and Steven R. Schmid.

ISBN 0-13-148965-8. 2006 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

Material Failures

Figure 2.19 Schematic illustrations of types of failures in materials:

(a) necking and fracture of ductile materials; (b) buckling of ductile

materials under a compressive load; (c) fracture of brittle materials

in compression; (d) cracking on the barreled surface of ductile

materials in compression

Manufacturing, Engineering & Technology, Fifth Edition, by Serope Kalpakjian and Steven R. Schmid.

ISBN 0-13-148965-8. 2006 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

Fracture Types in Tension

Figure 2.20 Schematic illustration of the types of fracture in tension: (a) brittle

fracture in polycrystalline metals; (b) shear fracture in ductile single crystals see

also Fig 1.6a; (c) ductile cup-and-cone fracture in polycrystalline metals; (d)

complete ductile fracture in polycrystalline metals, with 100% reduction of area.

Manufacturing, Engineering & Technology, Fifth Edition, by Serope Kalpakjian and Steven R. Schmid.

ISBN 0-13-148965-8. 2006 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

Ductile Fracture in Low-carbon Steel

Figure 2.21 Surface of

ductile fracture in low-

carbon steel, showing

dimples. Fracture

usually is initiated at

impurities, inclusions,

or preexisting voids

(microporosity) in the

metal. Source:

Courtesy of K. H.

Habig and D. Klaffke

Manufacturing, Engineering & Technology, Fifth Edition, by Serope Kalpakjian and Steven R. Schmid.

ISBN 0-13-148965-8. 2006 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

Progression of a Fracture

Figure 2.22 Sequence of events in the necking and fracture of a tensile-test specimen:

(a) early stage of necking; (b) small voids begin to form within the necked region; (c)

voids coalesce, producing an internal crack; (d) the rest of the cross-section begins to

fail at the periphery, by shearing; (e) the final fracture surfaces, known as cup- (top

fracture surface) and cone- (bottom surface) fracture.

Manufacturing, Engineering & Technology, Fifth Edition, by Serope Kalpakjian and Steven R. Schmid.

ISBN 0-13-148965-8. 2006 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

Deformation of Inclusions and Their Effect on Void Formation

Figure 2.23 Schematic illustration of the deformation of soft and hard inclusions and of

their effect on void formation in plastic deformation. Note that, because they do not

conform to the overall deformation of the ductile matrix, hard inclusions can cause

internal voids.

Manufacturing, Engineering & Technology, Fifth Edition, by Serope Kalpakjian and Steven R. Schmid.

ISBN 0-13-148965-8. 2006 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

Temperature Transition in Metals

Figure 2.24 Schematic illustration of transition temperature in metals.

Manufacturing, Engineering & Technology, Fifth Edition, by Serope Kalpakjian and Steven R. Schmid.

ISBN 0-13-148965-8. 2006 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

Fracture Surface of Steel

Figure 2.25 Fracture surface of steel that has failed in a brittle manner. The fracture

path is transgranular (through the grains). Magnification: 200x. Source: Courtesy of

B. J. Schulze and S.L. Meinley and Packer Engineering Associates, Inc.

Manufacturing, Engineering & Technology, Fifth Edition, by Serope Kalpakjian and Steven R. Schmid.

ISBN 0-13-148965-8. 2006 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

Intergranular Fracture

Figure 2.26 Intergranular fracture, at two different magnifications. Grains and grain

boundaries are clearly visible in this micrograph. The fracture path is along the grain

boundaries. Magnification: left, 100x; right, 500x. Source: Courtesy of B.J. Schulze

and S.L. Meiley and Packer Engineering Associates, Inc.

Manufacturing, Engineering & Technology, Fifth Edition, by Serope Kalpakjian and Steven R. Schmid.

ISBN 0-13-148965-8. 2006 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

Fatigue-Fracture Surface

Figure 2.28 Typical fatigue-fracture surface on metals, showing beach marks.

Magnification: left, 500x; right, 1000x. Source: Courtesy of B.J. Schulze and S.L.

Meiley and Packer Engineering Associates, Inc.

Manufacturing, Engineering & Technology, Fifth Edition, by Serope Kalpakjian and Steven R. Schmid.

ISBN 0-13-148965-8. 2006 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

Reduction in Fatigue Strength vs. Ultimate Tensile Strength

Figure 2.28 Reductions in fatigue

strength of cast steels subjected to

various surface-finishing operations.

Note that the reduction becomes

greater as the surface roughness

and the strength of steel increase.

Source: Courtesy of M. R. Mitchell

Manufacturing, Engineering & Technology, Fifth Edition, by Serope Kalpakjian and Steven R. Schmid.

ISBN 0-13-148965-8. 2006 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

Residual Stresses in Bending a Beam

Figure 2.29 Residual stresses developed in bending a beam having a

rectangular cross-section. Note that the horizontal forces and moments

caused by residual stresses in the beam must be balanced internally.

Because of nonuniform deformation and especially during cold-

metalworking operations, most parts develop residual stresses.

Manufacturing, Engineering & Technology, Fifth Edition, by Serope Kalpakjian and Steven R. Schmid.

ISBN 0-13-148965-8. 2006 Pearson Education, Inc., Upper Saddle River, NJ. All rights reserved.

Distortion with Residual Stresses

Figure 2.30 Distortion of parts, with residual stresses, after cutting or slitting:

(a) flat sheet or plate; (b) solid round rod; (c) thin-walled tubing or pipe.

Вам также может понравиться

- Brake and DynamometerДокумент51 страницаBrake and DynamometerArvin Arvini100% (1)

- Brake and DynamometerДокумент51 страницаBrake and DynamometerArvin Arvini100% (1)

- Lecture 3Документ30 страницLecture 3M.HОценок пока нет

- Lab Report Example 2Документ20 страницLab Report Example 2MECHANICAL ENGINEERINGОценок пока нет

- Aircraft Structures Complete NotesДокумент443 страницыAircraft Structures Complete NotesParvesh kambojОценок пока нет

- Mos Lab Manual PDFДокумент34 страницыMos Lab Manual PDFs.rihanaОценок пока нет

- Book of Spindles Part 1Документ46 страницBook of Spindles Part 1Archana MohanОценок пока нет

- Analysis of Statically Indeterminate Structures by The Force MethodДокумент57 страницAnalysis of Statically Indeterminate Structures by The Force MethodArvin ArviniОценок пока нет

- Expansion Wave Prandti - MEDДокумент10 страницExpansion Wave Prandti - MEDMohammed SalmanОценок пока нет

- Technical Guide For Solar Thermal SystemsДокумент197 страницTechnical Guide For Solar Thermal SystemsArvin ArviniОценок пока нет

- Mil Tos (1ST Quarter)Документ3 страницыMil Tos (1ST Quarter)Rhea Carillo100% (14)

- Fin 320 - Individual AssignmentДокумент14 страницFin 320 - Individual AssignmentAnis Umaira Mohd LutpiОценок пока нет

- Battle Group Builder + Commonwealth Infantry Roster - Wargames DesignДокумент12 страницBattle Group Builder + Commonwealth Infantry Roster - Wargames DesignPete PoliОценок пока нет

- Pure Bending - Multiple Materials & Plastic BendingДокумент6 страницPure Bending - Multiple Materials & Plastic BendingDemi MaОценок пока нет

- Column BaseДокумент18 страницColumn BaseHarsh RajОценок пока нет

- AET Question Bank For AUC R2013 - SДокумент5 страницAET Question Bank For AUC R2013 - SGurunath AeroОценок пока нет

- Department of Aeronautical / Aerospace Engineering U20AE301 - Aero Engineering Thermodynamics 50 Big QuestionsДокумент8 страницDepartment of Aeronautical / Aerospace Engineering U20AE301 - Aero Engineering Thermodynamics 50 Big QuestionsGurunath AeroОценок пока нет

- AE460F16 AirfoilPressDist LabДокумент19 страницAE460F16 AirfoilPressDist LabsaumjОценок пока нет

- 2 Marks - U20AE301 AET - DS R2020 - 20210713 - SДокумент18 страниц2 Marks - U20AE301 AET - DS R2020 - 20210713 - SGurunath AeroОценок пока нет

- RCH Som 01 IntroductionДокумент51 страницаRCH Som 01 IntroductionSatish DhanyamrajuОценок пока нет

- Tail DesignДокумент4 страницыTail DesignMuhammed NayeemОценок пока нет

- Stress TransformationДокумент5 страницStress TransformationCh TalhaОценок пока нет

- Assignment 2Документ2 страницыAssignment 2just0% (2)

- AE2030 - Fatigue and FractureДокумент1 страницаAE2030 - Fatigue and FractureArun Raja K K100% (1)

- Wind Tunnel CorrectionДокумент13 страницWind Tunnel CorrectionSetyo NugrohoОценок пока нет

- Rosette Strain GaugeДокумент4 страницыRosette Strain GaugeKarthikayan BalajiОценок пока нет

- 5 Shear-CentreДокумент6 страниц5 Shear-CentreRishОценок пока нет

- Iii Mech Vi Sem QB 2013 2014 Even PDFДокумент137 страницIii Mech Vi Sem QB 2013 2014 Even PDFSiva RamanОценок пока нет

- Practical 10 - Shear CentreДокумент4 страницыPractical 10 - Shear CentreTbyTanОценок пока нет

- Chapter 6 Bending: Moments Forces Perpendicular To AxisДокумент13 страницChapter 6 Bending: Moments Forces Perpendicular To AxisSumaya MahmoodОценок пока нет

- Notes On Beam Deflection ExperimentДокумент6 страницNotes On Beam Deflection ExperimentViccknesh BalakrishnanОценок пока нет

- Smoke TunnelДокумент55 страницSmoke TunnelABHIMANYU KHADGAОценок пока нет

- Pressure Distribution Over An AirfoilДокумент10 страницPressure Distribution Over An AirfoilAkash RoyОценок пока нет

- Experiment 1Документ5 страницExperiment 1Timmy TrinhОценок пока нет

- S-N Curve and Stress Concentration Factor (Week-02) PDFДокумент17 страницS-N Curve and Stress Concentration Factor (Week-02) PDFMuhammad TalhaОценок пока нет

- Open Ended Full Report CEWB121Документ18 страницOpen Ended Full Report CEWB121Nur FarehaОценок пока нет

- Experiment # 15: LABORATORY MANUAL For ENGR2860U-Fluid MechanicsДокумент10 страницExperiment # 15: LABORATORY MANUAL For ENGR2860U-Fluid MechanicsAbdullah Alshihri100% (1)

- Alignment 1Документ64 страницыAlignment 1eng_moh04Оценок пока нет

- Combustion AssignmentДокумент30 страницCombustion AssignmentMichael AlvarezОценок пока нет

- Y11 Mechanics and Structures NotesДокумент33 страницыY11 Mechanics and Structures NotesicecreambeanОценок пока нет

- Torsion Test ResultsДокумент19 страницTorsion Test ResultswaleedkhalillahmedОценок пока нет

- Propulsion - II 2 Marks by Nambi RajanДокумент12 страницPropulsion - II 2 Marks by Nambi RajanNambi RajanОценок пока нет

- 1Документ16 страниц1Shaqir AzmanОценок пока нет

- Tensile Testing of Ferrous and Non-Ferrous AlloyДокумент7 страницTensile Testing of Ferrous and Non-Ferrous Alloyrama100% (1)

- ME302 Assignment Test-1 2019-20Документ2 страницыME302 Assignment Test-1 2019-20choudary garuОценок пока нет

- Lab 6 - Maximum Power Transfer and PF Improvement - 2012Документ5 страницLab 6 - Maximum Power Transfer and PF Improvement - 2012劉成Оценок пока нет

- Elementary Cascade TheoryДокумент3 страницыElementary Cascade Theoryapoorvs75100% (1)

- Experiment 4 Flange Coupling CommandsДокумент11 страницExperiment 4 Flange Coupling CommandsMohammed AkramОценок пока нет

- To Determine The Moment of Inertia of A FlywheelДокумент2 страницыTo Determine The Moment of Inertia of A FlywheelCHEE HONG CHANОценок пока нет

- BXEДокумент79 страницBXEAnkita WankhadeОценок пока нет

- Air Bearings ReportДокумент8 страницAir Bearings ReportAnurag SrivastavaОценок пока нет

- Machine DesignДокумент26 страницMachine Designrajasekar21Оценок пока нет

- Question Bank AerodynamicДокумент7 страницQuestion Bank AerodynamicAjay DeshmukhОценок пока нет

- Mechanics of MaterialsДокумент21 страницаMechanics of MaterialsUbaid Ahmed Mughal100% (1)

- PKG 825 Lab 1 Mechanical PropertiesДокумент8 страницPKG 825 Lab 1 Mechanical PropertiesFanni09Оценок пока нет

- 9A21603 Aerospace Propulsion - IIДокумент4 страницы9A21603 Aerospace Propulsion - IIsivabharathamurthyОценок пока нет

- Smoke FlowДокумент9 страницSmoke FlowArunSutharОценок пока нет

- Engineering Mechanics Assignment 4 PDFДокумент5 страницEngineering Mechanics Assignment 4 PDFRaja Sekhar KonathamОценок пока нет

- Torsion LabДокумент22 страницыTorsion LabNeoXana01Оценок пока нет

- Aerodynamics - IIДокумент10 страницAerodynamics - IIVejay RamОценок пока нет

- Ae 430 3 PDFДокумент14 страницAe 430 3 PDFcrimelife6100% (1)

- UNIT-1 Electrical Resistance Strain GaugeДокумент74 страницыUNIT-1 Electrical Resistance Strain GaugehemarajuОценок пока нет

- Lab 3 Sheet Buckling-21Sep11Документ3 страницыLab 3 Sheet Buckling-21Sep11Mohd FazliОценок пока нет

- Exp-5 Heat Balance Sheet PDFДокумент5 страницExp-5 Heat Balance Sheet PDFNarender NarruОценок пока нет

- Nanofluid in Heat Exchangers for Mechanical Systems: Numerical SimulationОт EverandNanofluid in Heat Exchangers for Mechanical Systems: Numerical SimulationОценок пока нет

- Modern Developments in the Mechanics of ContinuaОт EverandModern Developments in the Mechanics of ContinuaSalamon EskinaziОценок пока нет

- Technical Specifications of Multi-Layer pipes-Firmopress-Technical-Document-2016-v2-1Документ24 страницыTechnical Specifications of Multi-Layer pipes-Firmopress-Technical-Document-2016-v2-1Arvin ArviniОценок пока нет

- Technical Specifications of Multi-Layer pipes-Firmopress-Technical-Document-2016-v2-1Документ24 страницыTechnical Specifications of Multi-Layer pipes-Firmopress-Technical-Document-2016-v2-1Arvin ArviniОценок пока нет

- Lab Report-Strength of MaterialsДокумент23 страницыLab Report-Strength of MaterialsArvin ArviniОценок пока нет

- 09 Impact TestingДокумент13 страниц09 Impact TestingArvin ArviniОценок пока нет

- Theory of Machine-Problems-Solutions PDFДокумент8 страницTheory of Machine-Problems-Solutions PDFArvin ArviniОценок пока нет

- Rubber Mould TeknikДокумент4 страницыRubber Mould TeknikAnonymous kYcX3YENОценок пока нет

- Design and Analysis of Thick Walled Cylinders With HolesДокумент47 страницDesign and Analysis of Thick Walled Cylinders With HolesKeryn Pelled-FeldmanОценок пока нет

- Schaums 2500 Problemas Resueltos de Mecanica de Fluidos e HidrulicaДокумент807 страницSchaums 2500 Problemas Resueltos de Mecanica de Fluidos e HidrulicaJ Andres Gonzalez83% (23)

- Electrical Feed-Drives For Machine Tool - Hans GrossДокумент362 страницыElectrical Feed-Drives For Machine Tool - Hans GrossArvin ArviniОценок пока нет

- LAC BrigadaДокумент6 страницLAC BrigadaRina Mae LopezОценок пока нет

- The USP AdvantageДокумент30 страницThe USP AdvantageGabriel A. RamírezОценок пока нет

- Waste SM4500-NH3Документ10 страницWaste SM4500-NH3Sara ÖZGENОценок пока нет

- Manuall Cryton-Yamaha 2015Документ57 страницManuall Cryton-Yamaha 2015Abel PachecoОценок пока нет

- Irshad KamilДокумент11 страницIrshad Kamilprakshid3022100% (1)

- Bhakra Nangal Project1Документ3 страницыBhakra Nangal Project1Sonam Pahuja100% (1)

- ADM-FR-003 Student Directory FormДокумент2 страницыADM-FR-003 Student Directory FormRahayuОценок пока нет

- Caribbean Career Opportunity - Cayman Island Water Authority - Plant Operator Cayman Brac Plant Operator (Overseas)Документ1 страницаCaribbean Career Opportunity - Cayman Island Water Authority - Plant Operator Cayman Brac Plant Operator (Overseas)Cawasa St-LuciaОценок пока нет

- Effect of Water On Quality and Preservation of FoodДокумент10 страницEffect of Water On Quality and Preservation of FoodrupinisinnanОценок пока нет

- The Sphere Circumscribing A TetrahedronДокумент4 страницыThe Sphere Circumscribing A TetrahedronRaghuveer ChandraОценок пока нет

- Yusof Ishak Secondary School Humanities Study Tour Ho Chi Minh City, VietnamДокумент19 страницYusof Ishak Secondary School Humanities Study Tour Ho Chi Minh City, Vietnamadamant751Оценок пока нет

- What Is NanoWatt TechnologyДокумент1 страницаWhat Is NanoWatt Technologyfolk_sharathОценок пока нет

- Nestle IndiaДокумент74 страницыNestle IndiaKiranОценок пока нет

- Jackson R. Lanning: Profile StatementДокумент1 страницаJackson R. Lanning: Profile StatementJacksonLanningОценок пока нет

- Product Management Mcnaughton - 0Документ4 страницыProduct Management Mcnaughton - 0Andrey MatusevichОценок пока нет

- The Exchange Student (Dedicated To Rotary International)Документ163 страницыThe Exchange Student (Dedicated To Rotary International)Nikita100% (1)

- 1 - CV - SwarupaGhosh-Solutions Account ManagerДокумент2 страницы1 - CV - SwarupaGhosh-Solutions Account ManagerprabhujainОценок пока нет

- Oil RussiaДокумент8 страницOil RussiaAyush AhujaОценок пока нет

- ShowimgДокумент76 страницShowimgROSHAN ROBERTОценок пока нет

- 3.6.4 Details of Courses For Nuclear Medicine TechnologyДокумент2 страницы3.6.4 Details of Courses For Nuclear Medicine TechnologyhemendrasingОценок пока нет

- Frankenstein ExtractДокумент1 страницаFrankenstein ExtractAnneОценок пока нет

- Math912 2Документ7 страницMath912 2Mbq ManbriquaОценок пока нет

- Stock Trak AssignmentДокумент4 страницыStock Trak AssignmentPat ParisiОценок пока нет

- InflibnetДокумент3 страницыInflibnetSuhotra GuptaОценок пока нет

- Router Board Performance TestsДокумент2 страницыRouter Board Performance TestsedkaviОценок пока нет

- AC Hipots 15-200kVДокумент4 страницыAC Hipots 15-200kVfelipe.aounОценок пока нет

- Medicinal Chemistry/ CHEM 458/658 Chapter 8-Receptors and MessengersДокумент41 страницаMedicinal Chemistry/ CHEM 458/658 Chapter 8-Receptors and MessengersMehak SarfrazОценок пока нет