Академический Документы

Профессиональный Документы

Культура Документы

Chapter 07

Загружено:

albgatmtyИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Chapter 07

Загружено:

albgatmtyАвторское право:

Доступные форматы

Wallace J. Hopp, Mark L. Spearman, 1996, 2000 http://www.factory-physics.

com

1

Basic Factory Dynamics

Physics should be explained as simply as possible,

but no simpler.

Albert Einstein

Wallace J. Hopp, Mark L. Spearman, 1996, 2000 http://www.factory-physics.com

2

HAL Case

Large Panel Line: produces unpopulated printed circuit boards

Line runs 24 hr/day (but 19.5 hrs of productive time)

Recent Performance:

throughput = 1,400 panels per day (71.8 panels/hr)

WIP = 47,600 panels

CT = 34 days (663 hr at 19.5 hr/day)

customer service = 75% on-time delivery

What data do we need to decide?

I s HAL lean?

I f not, what are levers for improvement?

Wallace J. Hopp, Mark L. Spearman, 1996, 2000 http://www.factory-physics.com

3

HAL - Large Panel Line Processes

Lamination (Cores): press copper and prepreg into core blanks

Machining: trim cores to size

Internal Circuitize: etch circuitry into copper of cores

Optical Test and Repair (Internal): scan panels optically for defects

Lamination (Composites): press cores into multiple layer boards

External Circuitize: etch circuitry into copper on outside of composites

Optical Test and Repair (External): scan composites optically for defects

Drilling: holes to provide connections between layers

Copper Plate: deposits copper in holes to establish connections

Procoat: apply plastic coating to protect boards

Sizing: cut panels into boards

End of Line Test: final electrical test

Wallace J. Hopp, Mark L. Spearman, 1996, 2000 http://www.factory-physics.com

4

HAL Case - Science?

External Benchmarking

but other plants may not be comparable

Internal Benchmarking

capacity data: what is utilization?

but this ignores WIP effects

Need relationships between WI P, TH, CT, service!

Wallace J. Hopp, Mark L. Spearman, 1996, 2000 http://www.factory-physics.com

5

Basic Definitions

Workstation: a collection of one or more identical machines.

Part: a component, sub-assembly, or an assembly that moves through the

workstations.

End Item: part sold directly to customers; relationship to constituent

parts defined in bill of material.

Consumables: bits, chemicals, gasses, etc., used in process but do not

become part of the product that is sold.

Routing: sequence of workstations needed to make a part.

Order: request from customer.

Job: transfer quantity on the line.

Wallace J. Hopp, Mark L. Spearman, 1996, 2000 http://www.factory-physics.com

6

Basic Measures

Throughput (TH): for a line, throughput is the average quantity of

good (non-defective) parts produced per unit time.

Work in Process (WIP): inventory between the start and endpoints of

a product routing.

Raw Material Inventory (RMI): material stocked at beginning of

routing.

Crib and Finished Goods Inventory (FGI): crib inventory is

material held in a stockpoint at the end of a routing; FGI is material

held in inventory prior to shipping to the customer.

Cycle Time (CT): time between release of the job at the beginning of

the routing until it reaches an inventory point at the end of the

routing.

Wallace J. Hopp, Mark L. Spearman, 1996, 2000 http://www.factory-physics.com

7

Factory Physics

Definition: A production system is a goal-oriented network of

processes and stockpoints through which parts flow.

Structure: Network is made up of routings (lines), which in turn are

made up of processes.

Focus: Factory Physics is concerned with the network and flows at

the routing (line) level.

Wallace J. Hopp, Mark L. Spearman, 1996, 2000 http://www.factory-physics.com

8

Parameters

Descriptors of a Line:

1) Bottleneck Rate (r

b

): Rate (parts/unit time or jobs/unit time)

of the workstation with the highest long-term utilization.

2) Raw Process Time (T

0

): Sum of the long-term average

process times of each station in the line.

3) Congestion Coefficient (o): A unitless measure of

congestion.

Zero variability case, o = 0.

Practical worst case, o = 1.

Worst possible case, o = W

0

.

Note: we wont use o quantitatively,

but point it out to recognize that lines

with same r

b

and T

0

can behave very

differently.

Wallace J. Hopp, Mark L. Spearman, 1996, 2000 http://www.factory-physics.com

9

Definition of Bottleneck

Why do we use highest utilization instead of slowest to define

the bottleneck?

A B

r

1 min 2 min

y

1-y

5 . 0 if ) 2 ( ) 1 (

2

5 . 0

) 2 (

1

) 1 (

capacity

in rate

> s

=

=

= =

=

y u u

ry

y r

u

r

r

u

u

If yield loss is greater than 50% then station 1 becomes the bottleneck

because it processes more jobs than station 2. The same thing

happens with systems that have multiple routings.

Wallace J. Hopp, Mark L. Spearman, 1996, 2000 http://www.factory-physics.com

10

A Simple Relationship

Critical WIP (W

0

): WIP level in which a line having no

congestion would achieve maximum throughput (i.e., r

b

) with

minimum cycle time (i.e., T

0

).

W

0

= r

b

T

0

Wallace J. Hopp, Mark L. Spearman, 1996, 2000 http://www.factory-physics.com

11

The Penny Fab

Characteristics:

Four identical tools in series.

Each takes 2 hours per piece (penny).

No variability.

CONWIP job releases.

Parameters:

r

b

=

T

0

=

W

0

=

o =

Wallace J. Hopp, Mark L. Spearman, 1996, 2000 http://www.factory-physics.com

12

The Penny Fab

WIP TH CT TH x CT

1

2

3

4

5

6

7

8

9

Wallace J. Hopp, Mark L. Spearman, 1996, 2000 http://www.factory-physics.com

13

TH vs. WIP: Best Case

T

h

r

o

u

g

h

p

u

t

(

J

o

b

s

/

h

r

)

0 2 4 6 8 10 12 14

0

.2

.4

.3

.5

.1

WIP (Jobs)

Wallace J. Hopp, Mark L. Spearman, 1996, 2000 http://www.factory-physics.com

14

CT vs. WIP: Best Case

C

y

c

l

e

t

i

m

e

(

H

o

u

r

s

)

0 2 4 6 8 10 12 14

0

8

16

12

20

4

WIP (Jobs)

Wallace J. Hopp, Mark L. Spearman, 1996, 2000 http://www.factory-physics.com

15

Best Case Performance

Best Case Law: The minimum cycle time (CT

best

) for a given

WI P level, w, is given by

The maximum throughput (TH

best

) for a given WI P level, w is

given by,

s

=

otherwise.

if

, /

,

) ( CT

0 0

best

W w

r w

T

w

b

s

=

otherwise.

if

,

, /

) ( TH

0 0

best

W w

r

T w

w

b

Wallace J. Hopp, Mark L. Spearman, 1996, 2000 http://www.factory-physics.com

16

Best Case Performance (cont.)

Example: For Penny Fab, r

b

= 0.5 and T

0

= 8, so W

0

= 0.5 8 = 4,

which are exactly the curves we plotted.

s

=

otherwise.

4 if

, 2

, 8

) ( CT

best

w

w

w

s

=

otherwise.

4 if

, 5 . 0

, 8 /

) ( TH

best

w w

w

Wallace J. Hopp, Mark L. Spearman, 1996, 2000 http://www.factory-physics.com

17

A Manufacturing Law

Little's Law: The fundamental relation between WI P, CT, and

TH over the long-term is:

Insights:

Fundamental relationship

Simple units transformation

Definition of cycle time (CT = WIP/TH)

CT TH WIP =

hr

hr

parts

parts =

Wallace J. Hopp, Mark L. Spearman, 1996, 2000 http://www.factory-physics.com

18

Penny Fab Two

10 hr

2 hr

5 hr 3 hr

Wallace J. Hopp, Mark L. Spearman, 1996, 2000 http://www.factory-physics.com

19

Penny Fab Two

Station

Number

Number of

Machines

Process

Time

Station

Rate

1 1 2 hr j/hr

2 2 5 hr j/hr

3 6 10 hr j/hr

4 2 3 hr j/hr

r

b

= ____________ T

0

= ____________ W

0

= ____________

Wallace J. Hopp, Mark L. Spearman, 1996, 2000 http://www.factory-physics.com

20

Worst Case

Observation: The Best Case yields the minimum cycle time and

maximum throughput for each WIP level.

Question: What conditions would cause the maximumcycle time

and minimumthroughput?

Analysis:

throughput cannot be worse than one job in empty line

use Littles law to get worst possible cycle time

Results are exactly what you get if every job in the line is moved in

a single batch between stations.

Wallace J. Hopp, Mark L. Spearman, 1996, 2000 http://www.factory-physics.com

21

Worst Case Performance

Throughput: TH >

1/T

0

0

0.1

0.2

0.3

0.4

0.5

0.6

0 1 2 3 4 5 6 7 8 9 10 11 12

WIP

T

H

r

b

W

0

1/T

0

Best Case

Worst Case

0

4

8

12

16

20

24

28

32

0 1 2 3 4 5 6 7 8 9 10 11 12

WIP

C

T

T

0

W

0

Best Case

Worst Case

0

0

/ 1

wT

T

WIP

TH

WIP

CT = s =

Littles Law:

Wallace J. Hopp, Mark L. Spearman, 1996, 2000 http://www.factory-physics.com

22

Worst Case Performance

Worst Case Law: The worst case cycle time for a given WI P

level, w, is given by,

CT

worst

(w) = w T

0

The worst case throughput for a given WI P level, w, is given

by,

TH

worst

(w) = 1 / T

0

Randomness?

None - perfectly predictable, but bad!

Wallace J. Hopp, Mark L. Spearman, 1996, 2000 http://www.factory-physics.com

23

Practical Worst Case

Observation: There is a BIG GAP between the Best Case and

Worst Case performance.

Question: Can we find an intermediate case that:

divides good and bad lines, and

is computable?

Experiment: consider a line with a given r

b

and T

0

and:

1. single machine stations

2. balanced lines

3. variability such that all WIP configurations (states) are equally

likely

Wallace J. Hopp, Mark L. Spearman, 1996, 2000 http://www.factory-physics.com

24

PWC Example 3 jobs, 4 stations

State Vector State Vector

1 (3,0,0,0) 11 (1,0,2,0)

2 (0,3,0,0) 12 (0,1,2,0)

3 (0,0,3,0) 13 (0,0,2,1)

4 (0,0,0,3) 14 (1,0,0,2)

5 (2,1,0,0) 15 (0,1,0,2)

6 (2,0,1,0) 16 (0,0,1,2)

7 (2,0,0,1) 17 (1,1,1,0)

8 (1,2,0,0) 18 (1,1,0,1)

9 (0,2,1,0) 19 (1,0,1,1)

10 (0,2,0,1) 20 (0,1,1,1)

clumped

up states

spread

out states

Note: average WI P at any station is 15/20 =0.75,

so jobs are spread evenly between stations.

Wallace J. Hopp, Mark L. Spearman, 1996, 2000 http://www.factory-physics.com

25

Practical Worst Case

Let w = jobs in system, N = no. stations in line, and t =

process time at all stations:

CT(single) = (1 +(w-1)/N) t

CT(line) = N [1 +(w-1)/N] t

= Nt +(w-1)t

= T

0

+(w-1)/r

b

TH =WI P/CT

=[w/(w+W

0

-1)]r

b

From Littles Law

Wallace J. Hopp, Mark L. Spearman, 1996, 2000 http://www.factory-physics.com

26

Practical Worst Case Performance

Practical Worst Case Definition: The practical worst case

(PWC) cycle time for a given WI P level, w, is given by,

The PWC throughput for a given WI P level, w, is given by,

where W

0

is the critical WI P.

b

r

w

T w

1

) ( CT

0 PWC

+ =

,

1

) ( TH

0

PWC b

r

w W

w

w

+

=

Wallace J. Hopp, Mark L. Spearman, 1996, 2000 http://www.factory-physics.com

27

TH vs. WIP: Practical Worst Case

0

0.1

0.2

0.3

0.4

0.5

0.6

0 1 2 3 4 5 6 7 8 9 10 11 12

WIP

T

H

r

b

W

0

1/T

0

Best Case

Worst Case

PWC

Good (lean)

Bad (fat)

Wallace J. Hopp, Mark L. Spearman, 1996, 2000 http://www.factory-physics.com

28

CT vs. WIP: Practical Worst Case

0

4

8

12

16

20

24

28

32

0 1 2 3 4 5 6 7 8 9 10 11 12

WIP

C

T

T

0

W

0

Best Case

Worst Case

PWC

Bad (fat)

Good

(lean)

Wallace J. Hopp, Mark L. Spearman, 1996, 2000 http://www.factory-physics.com

29

0

0.1

0.2

0.3

0.4

0.5

0 2 4 6 8 10 12 14 16 18 20 22 24 26

WIP

TH

Penny Fab Two Performance

Worst Case

Best Case

1/T

0

r

b

W

0

Why is PF2

better than

PWC?

Wallace J. Hopp, Mark L. Spearman, 1996, 2000 http://www.factory-physics.com

30

Penny Fab Two Performance (cont.)

0

10

20

30

40

50

60

70

80

0 2 4 6 8 10 12 14 16 18 20 22 24 26

WIP

CT

Worst Case

Best Case

T

0

1/r

b

W

0

Wallace J. Hopp, Mark L. Spearman, 1996, 2000 http://www.factory-physics.com

31

Back to the HAL Case - Capacity Data

Process Rate (p/hr) Time (hr)

Lamination 191.5 4.7

Machining 186.2 0.5

Internal Circuitize 114.0 3.6

Optical Test/Repair - Int 150.5 1.0

Lamination Composites 158.7 2.0

External Circuitize 159.9 4.3

Optical Test/Repair - Ext 150.5 1.0

Drilling 185.9 10.2

Copper Plate 136.4 1.0

Procoat 117.3 4.1

Sizing 126.5 1.1

EOL Test 169.5 0.5

rb, T0 114.0 33.9

Wallace J. Hopp, Mark L. Spearman, 1996, 2000 http://www.factory-physics.com

32

HAL Case - Situation

Critical WIP: r

b

T

0

= 114 33.9 = 3,869

Actual Values:

CT = 34 days = 663 hours (at 19.5 hr/day)

WIP = 47,600 panels

TH = 71.8 panels/hour

Conclusions:

Throughput is 63% of capacity

WIP is 12.3 times critical WIP

CT is 24.1 times raw process time

Wallace J. Hopp, Mark L. Spearman, 1996, 2000 http://www.factory-physics.com

33

HAL Case - Analysis

Conclusion?

TH Resulting from PWC with WIP = 47,600?

Wallace J. Hopp, Mark L. Spearman, 1996, 2000 http://www.factory-physics.com

34

Labor Constrained Systems

Motivation: performance of some systems are limited by labor or

a combination of labor and equipment.

Full Flexibility with Workers Tied to Jobs:

WIP limited by number of workers (n)

capacity of line is n/T

0

Best case achieves capacity and has workers in zones

ample capacity case also achieves full capacity with pick and run

policy

Wallace J. Hopp, Mark L. Spearman, 1996, 2000 http://www.factory-physics.com

35

Labor Constrained Systems (cont.)

Full Flexibility with Workers Not Tied to Jobs:

TH depends on WIP levels

TH

CW

(n) s TH(w) s TH

CW

(w)

need policy to direct workers to jobs (focus on downstream is

effective)

Agile Workforce Systems

bucket brigades

kanban with shared tasks

worksharing with overlapping zones

many others

Wallace J. Hopp, Mark L. Spearman, 1996, 2000 http://www.factory-physics.com

36

Factory Dynamics Takeaways

Performance Measures:

throughput

WIP

cycle time

service

flexibility

Range of Cases:

best case

practical worst case

worst case

Diagnostics:

simple assessment based on r

b

, T

0

, actual WIP,actual TH

evaluate relative to practical worst case

Вам также может понравиться

- Studio4 - LEED - Green - Associate - Study - Guide - Master 2nd Edition PDFДокумент310 страницStudio4 - LEED - Green - Associate - Study - Guide - Master 2nd Edition PDFyu zhangОценок пока нет

- Asme B36.10M-2018Документ36 страницAsme B36.10M-2018امينОценок пока нет

- 1 Simplex Method: Maximization ProblemДокумент10 страниц1 Simplex Method: Maximization ProblemSayed AlhussainiОценок пока нет

- Anchors and Fall Arrest System A Guide To Good Practice: PublicationДокумент22 страницыAnchors and Fall Arrest System A Guide To Good Practice: PublicationEdward C100% (1)

- Usn LM2500 Asme Paper GT2010-22811 61410 JalДокумент7 страницUsn LM2500 Asme Paper GT2010-22811 61410 Jalferrerick0% (1)

- DFMA Hand Written AssignmentДокумент1 страницаDFMA Hand Written AssignmentNEERAJ TILARA100% (1)

- 15 Integrated Manufacturing Systems Lecture #15 HandoutДокумент2 страницы15 Integrated Manufacturing Systems Lecture #15 HandoutFelipeОценок пока нет

- Challenges in PavementsДокумент23 страницыChallenges in PavementsSomeshwar Rao ThakkallapallyОценок пока нет

- Permeability: The Key to ProductionДокумент30 страницPermeability: The Key to ProductionDarshak Sakhreliya100% (1)

- A320 Aircraft CharacteristicsДокумент387 страницA320 Aircraft CharacteristicsEder LucianoОценок пока нет

- Sheet 3 Charting and Diagram Chapter 9Документ12 страницSheet 3 Charting and Diagram Chapter 9AhmedAhmed100% (2)

- Curves & SplinesДокумент49 страницCurves & SplinesAmit DostОценок пока нет

- Solving Facility Location Problems with Center of Gravity and P-Median ApproachesДокумент30 страницSolving Facility Location Problems with Center of Gravity and P-Median ApproachesAbhishek PadhyeОценок пока нет

- Capacity and Demand in Units Period Regular Time Overtime Subcontract DemandДокумент3 страницыCapacity and Demand in Units Period Regular Time Overtime Subcontract DemandVinay Kumar0% (1)

- Chapter 3 - Consumer and Organizational Buyer BehaviorДокумент61 страницаChapter 3 - Consumer and Organizational Buyer Behavioralbgatmty100% (3)

- Feed Water and Boiler Water of Steam GeneratorsДокумент2 страницыFeed Water and Boiler Water of Steam GeneratorsIvicaT0% (2)

- Sensitivity Analysis InterpretationДокумент8 страницSensitivity Analysis Interpretationronit brahmaОценок пока нет

- Kepb003404 PDFДокумент472 страницыKepb003404 PDFELIAS100% (1)

- DR System ConciseДокумент37 страницDR System ConciseJiten KarmakarОценок пока нет

- Top-Down Digital VLSI Design: From Architectures to Gate-Level Circuits and FPGAsОт EverandTop-Down Digital VLSI Design: From Architectures to Gate-Level Circuits and FPGAsОценок пока нет

- Cyber Security Research Proposal - SandboxingДокумент23 страницыCyber Security Research Proposal - SandboxingAnonymous Sa6jc83D100% (4)

- Thu Thiem Tunnel Construction - Sequence - Immersed - Tunnel PDFДокумент36 страницThu Thiem Tunnel Construction - Sequence - Immersed - Tunnel PDFThông PhanОценок пока нет

- Time Study: Avg. Observed Time (Or Actual Time (AT) )Документ8 страницTime Study: Avg. Observed Time (Or Actual Time (AT) )Musa Can ArslanОценок пока нет

- Decision Modeling Applications and Spreadsheet SolutionsДокумент25 страницDecision Modeling Applications and Spreadsheet SolutionsaniketkaushikОценок пока нет

- ISYE 3450 Homework 1Документ2 страницыISYE 3450 Homework 1Brandon HarrisОценок пока нет

- Linear Programming IntroductionДокумент22 страницыLinear Programming IntroductionAndrés AvilésОценок пока нет

- Assignment 2Документ3 страницыAssignment 2Sodhani AnkurОценок пока нет

- Modern Control Technology Components & Systems (2nd Ed.)Документ2 страницыModern Control Technology Components & Systems (2nd Ed.)musarraf172Оценок пока нет

- Solutions ManualДокумент200 страницSolutions ManualNguyễn Tấn TàiОценок пока нет

- Simulation of Plant Scale ManufacturingДокумент6 страницSimulation of Plant Scale ManufacturingTim ChegeОценок пока нет

- Chapter 9 & Chapter 10 SolutionsДокумент7 страницChapter 9 & Chapter 10 SolutionsSaeed IqbalОценок пока нет

- A New Method For Finding An Optimal Solution For Transportation ProblemsДокумент5 страницA New Method For Finding An Optimal Solution For Transportation ProblemsMarius BotezatuОценок пока нет

- Ex MatlabДокумент7 страницEx MatlabAbdulrhman AL-MasreОценок пока нет

- The Mayor of Cambridge Colorado Wanting To Be EnvironmentallyДокумент1 страницаThe Mayor of Cambridge Colorado Wanting To Be EnvironmentallyAmit PandeyОценок пока нет

- The Principles of Motion EconomyДокумент8 страницThe Principles of Motion Economyrrizz100% (1)

- ChipДокумент7 страницChipOmkar ManeОценок пока нет

- CISE301 Topic8L4&5Документ36 страницCISE301 Topic8L4&5Mohammad RameezОценок пока нет

- Turban Dss9e ch01 PDFДокумент75 страницTurban Dss9e ch01 PDFxdreamahОценок пока нет

- Operations Research BookДокумент3 страницыOperations Research BookRajatОценок пока нет

- QT - Unit 1Документ14 страницQT - Unit 1aakanksha2693Оценок пока нет

- HW Chapter 7 solutions entropy & energy changesДокумент4 страницыHW Chapter 7 solutions entropy & energy changesgoodfellas121Оценок пока нет

- Arena Part 3 Simulation LabДокумент13 страницArena Part 3 Simulation LabMhmd Alrashed100% (1)

- CPP MatrixДокумент32 страницыCPP Matrixcommando23Оценок пока нет

- CH 06Документ55 страницCH 06Swapnil BondeОценок пока нет

- Automation in Manufacturing 10ME757: Department of Mechanical Engineering, SIRMVIT (Ramesh C G & Hanamantraygouda M B)Документ193 страницыAutomation in Manufacturing 10ME757: Department of Mechanical Engineering, SIRMVIT (Ramesh C G & Hanamantraygouda M B)Wtf rajuОценок пока нет

- Silkworm ManualДокумент21 страницаSilkworm ManualFred GrushinОценок пока нет

- HANAOEUENT SCIENCE Viri. It, No. 10, June, 1970Документ9 страницHANAOEUENT SCIENCE Viri. It, No. 10, June, 1970Harsha KasaragodОценок пока нет

- Linear Programming ProjectДокумент5 страницLinear Programming Projectapi-267005931Оценок пока нет

- Seatwork 1Документ3 страницыSeatwork 1Ellaine NacisОценок пока нет

- Soal Latihan DoeДокумент8 страницSoal Latihan DoeMalindaОценок пока нет

- Analysis of FlywheelДокумент17 страницAnalysis of FlywheelShubham SharmaОценок пока нет

- ICE Optim Linea PDFДокумент68 страницICE Optim Linea PDFsatydevsinghnegiОценок пока нет

- Linear Programming ExamplesДокумент5 страницLinear Programming ExamplesEdlyn PangilinanОценок пока нет

- Operations Management 1Документ67 страницOperations Management 1apoorvbabel0% (1)

- Optimal Staffing LPДокумент32 страницыOptimal Staffing LPcarlos fernandezОценок пока нет

- Assignment 2 (Vishnubhai Jayeshbhai Panchal 202285861)Документ8 страницAssignment 2 (Vishnubhai Jayeshbhai Panchal 202285861)Ashish VoraОценок пока нет

- Practice Problem 2Документ3 страницыPractice Problem 2rajatchikuОценок пока нет

- Supp KДокумент14 страницSupp Kshazarafia100% (1)

- Prob Cost DegenДокумент2 страницыProb Cost DegenNikhil ChapleОценок пока нет

- Manufacturing Example PDFДокумент6 страницManufacturing Example PDFAbdul RahmanОценок пока нет

- Arora S IOD Chapter 2Документ40 страницArora S IOD Chapter 2Ivan100% (1)

- MAT130.5 (MTM) Handout #4 and #5 - Trigonometric Substitutions, Spring 2020Документ23 страницыMAT130.5 (MTM) Handout #4 and #5 - Trigonometric Substitutions, Spring 2020Tasnim Alam Piyash 1731712Оценок пока нет

- Experiment NoДокумент9 страницExperiment NoAli RazaОценок пока нет

- Dynamic Programming MatlabДокумент6 страницDynamic Programming MatlabRitesh SinghОценок пока нет

- 07 Poles and Zeros of Transfer FunctionДокумент33 страницы07 Poles and Zeros of Transfer FunctionRyan VasquezОценок пока нет

- CoreДокумент38 страницCorePîñëàpplè ĶîđОценок пока нет

- Carleton University Carpool Project ProposalДокумент5 страницCarleton University Carpool Project ProposalsihargabeОценок пока нет

- DWA OptimizationsДокумент12 страницDWA OptimizationssannyzhouОценок пока нет

- Chapter 3 Resource PlanningДокумент70 страницChapter 3 Resource PlanningHieu TruongОценок пока нет

- Sample For Solution Manual Fundamentals of Machine Component Design 7th EMEA Edition by Jvinall & MarshekДокумент13 страницSample For Solution Manual Fundamentals of Machine Component Design 7th EMEA Edition by Jvinall & MarshekNeta Lavi100% (1)

- Factorization Methods for Discrete Sequential EstimationОт EverandFactorization Methods for Discrete Sequential EstimationОценок пока нет

- Monk CoffeeДокумент7 страницMonk CoffeealbgatmtyОценок пока нет

- Case - Whole Foods MarketДокумент21 страницаCase - Whole Foods Marketalbgatmty100% (1)

- Chapter 2 Administración EstratégicaДокумент37 страницChapter 2 Administración EstratégicaalbgatmtyОценок пока нет

- Pia Sales Equipo 9 Social MediaДокумент12 страницPia Sales Equipo 9 Social MediaalbgatmtyОценок пока нет

- Administración de Ventas - Chapter 3Документ61 страницаAdministración de Ventas - Chapter 3albgatmtyОценок пока нет

- VENTAS - The Entertainment IndustryДокумент15 страницVENTAS - The Entertainment IndustryalbgatmtyОценок пока нет

- Administración de Ventas Capítulo 2 PDFДокумент40 страницAdministración de Ventas Capítulo 2 PDFalbgatmtyОценок пока нет

- Market Audit Strategies for Sales Forecasting & BudgetingДокумент40 страницMarket Audit Strategies for Sales Forecasting & BudgetingalbgatmtyОценок пока нет

- Chapter 3 AdminДокумент40 страницChapter 3 AdminalbgatmtyОценок пока нет

- 1 MarketingДокумент113 страниц1 MarketingalbgatmtyОценок пока нет

- SALES CelularesДокумент19 страницSALES CelularesalbgatmtyОценок пока нет

- Sales Management - Chapter 5Документ45 страницSales Management - Chapter 5albgatmtyОценок пока нет

- Estrategias de Ventas en El Mercado de BebidasДокумент10 страницEstrategias de Ventas en El Mercado de BebidasalbgatmtyОценок пока нет

- Supermarket SalesДокумент14 страницSupermarket SalesalbgatmtyОценок пока нет

- Cooperativas MondragonДокумент13 страницCooperativas MondragonalbgatmtyОценок пока нет

- Collaborative ConsumptionДокумент14 страницCollaborative ConsumptionalbgatmtyОценок пока нет

- Collaborative ConsumptionДокумент19 страницCollaborative ConsumptionalbgatmtyОценок пока нет

- SALES CelularesДокумент19 страницSALES CelularesalbgatmtyОценок пока нет

- Supermarket SalesДокумент14 страницSupermarket SalesalbgatmtyОценок пока нет

- Consumer and Organizational Buyer BehaviorДокумент61 страницаConsumer and Organizational Buyer BehavioralbgatmtyОценок пока нет

- Presentacion The Entertainment IndustryДокумент15 страницPresentacion The Entertainment IndustryalbgatmtyОценок пока нет

- Chapter 08Документ46 страницChapter 08albgatmtyОценок пока нет

- Communication and Consumer BehaviourДокумент22 страницыCommunication and Consumer BehaviouralbgatmtyОценок пока нет

- Selling and Sales Management - Chapter 5Документ45 страницSelling and Sales Management - Chapter 5albgatmtyОценок пока нет

- Sesion 18Документ6 страницSesion 18albgatmtyОценок пока нет

- Employee Safety, Health and Wellness ProgramДокумент30 страницEmployee Safety, Health and Wellness ProgramalbgatmtyОценок пока нет

- Zener DataДокумент2 страницыZener Dataapi-27149887Оценок пока нет

- INTERCOMP Pt300 Users Manual Rev GДокумент44 страницыINTERCOMP Pt300 Users Manual Rev GCTN2010Оценок пока нет

- Easygen-3000 Series (Package P1) Genset Control: InterfaceДокумент102 страницыEasygen-3000 Series (Package P1) Genset Control: InterfacejinameОценок пока нет

- كتاب الهيدروديناميكا-4 The HydrodynamicДокумент25 страницكتاب الهيدروديناميكا-4 The HydrodynamicHocine Gherbi FaycelОценок пока нет

- 1855OME - Instruction Manual - Kinney Oil Mist EliminatorsДокумент15 страниц1855OME - Instruction Manual - Kinney Oil Mist EliminatorsahmedОценок пока нет

- InverterДокумент8 страницInverterrajinipre-1Оценок пока нет

- 83 - Detection of Bearing Fault Using Vibration Analysis and Controlling The VibrationsДокумент12 страниц83 - Detection of Bearing Fault Using Vibration Analysis and Controlling The VibrationsmaulikgadaraОценок пока нет

- ITU ISUP Release Cause CodesДокумент5 страницITU ISUP Release Cause Codesdelgado08Оценок пока нет

- BPCL Kochi Refinery MS BLOCK PROJECT Piping Material SpecificationДокумент1 страницаBPCL Kochi Refinery MS BLOCK PROJECT Piping Material SpecificationDeepak DayalОценок пока нет

- 2009 Energy Storage-U.S. Department of EnergyДокумент380 страниц2009 Energy Storage-U.S. Department of EnergydiwhiteОценок пока нет

- IEC CsODESДокумент2 страницыIEC CsODESArun KumarОценок пока нет

- Sodium Citrate AUДокумент3 страницыSodium Citrate AUKrishna OgotОценок пока нет

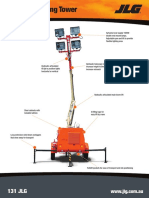

- JLG Lighting Tower 6308AN Series II 20150907Документ2 страницыJLG Lighting Tower 6308AN Series II 20150907DwiSulistyo09Оценок пока нет

- Siemens-Relee de Timp PDFДокумент2 страницыSiemens-Relee de Timp PDFChioibasNicolaeОценок пока нет

- Supercharging: Superchargers & TurbochargersДокумент11 страницSupercharging: Superchargers & TurbochargersAkhil Here100% (1)

- The Tallest Buildings in The WorldДокумент2 страницыThe Tallest Buildings in The WorldW4G8989Оценок пока нет

- Vehicle Air Conditioning (VAC) : System Operation and The Refrigerant CycleДокумент49 страницVehicle Air Conditioning (VAC) : System Operation and The Refrigerant CycleVarun RaizadaОценок пока нет

- Carimin Acacia Stability-Onhire Loading JerunДокумент6 страницCarimin Acacia Stability-Onhire Loading Jerunh2sbnj86b4Оценок пока нет