Академический Документы

Профессиональный Документы

Культура Документы

Stairs and Staircases STAIRS AND STAIRCASES TYPES

Загружено:

civilaskarОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Stairs and Staircases STAIRS AND STAIRCASES TYPES

Загружено:

civilaskarАвторское право:

Доступные форматы

By

ANMOL GARG (Lect. Govt. Polytechnic College, Bathinda) 9914410599 garganmol2@rediffmail.com

STAIRS AND STAIRCASES -In every building, some arrangement should be made to provide access to its different floors and roof. -These levels are connected for communication by any of the following methods: 1> Ladders 2> Steps-stair 3> Escalators 4> Lifts 5> Ramps and chutes 6> Trolley-rope ways

Stairs and Stair case: A series of steps which provides access from one floor to another is called a stair, and the part of the building accommodating the stair is known as Stair Case. > A Stair may be constructed with steps either rising continuously or with a break in the form of landing in between. > All the steps should be so designed and constructed that up and down movement can be made with ease, comfort, quickness and safety. > The Stairs can be of any suitable material.

> Classification of stairs acc. to material used > WOODEN STAIRS > STONE STAIRS > METAL STAIRS > R.C.C. STAIRS > BRICK STAIRS

Wooden Stairs: It consists of wooden members! > It also consists of various members such as: Strings or Stringers, Treads, Risers and Nosing. > Treads and Risers are jointed by tongued and grooved joints, which are further housed in or fixed to the strings to form steps of a flight

> Nosing projection should be 15 mm and not more than the thickness of the tread in any case > The Scota or other ornamental mouldings can be provided under the projection of nosing

Stone Stairs: The Stairs constructed of specially dressed Stone Blocks or Slabs are called Stone Stairs

> These are more Durable, Hard, Fire-Resistant and Simple in construction > They are not liable to Decay > They are commonly used as External Stairs leading from the Ground level to the Entrance of a building at Ground floor > They are also used as approaches to Basement, Heating Chambers etc. > They are formally used in Commercial and Public buildings

Metal Stairs: The Stairs having different members made of Steel or Cast Iron are known as Metal Stairs > In these Stairs, The Strings are usually in the form of Steel Channels or Plates > The Treads consist of Checkered or Steel Plate, Concrete or Stone Slabs, fixed at their ends to the Strings by means of Angle Iron by Rivets or Welding > These Steps are suitable where rough Wear and Tear and Fire-proof qualities are required like Factories, Godowns etc.

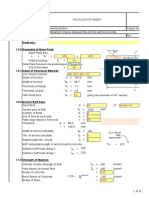

The Treads of Metal Stair can be constructed of: 1) Metal Stair with Checkered Plate or Conc. Slab: > It consists of Steel Strings of Channels or Troughs with Checkered Plate Treads as shown:

2) Metal Stair with Steel Plate & Stone Slab Treads > In this, the Treads are of Steel Plates > The Stone and Marble Treads can also be used as shown:

3) Metal Stair with Concrete Steps: In this Stair, the Stringers are of Steel and Steps constructed of Concrete as shown: > The Steps are finished with Metal Nosing

4) Spiral Stair: The Metal Stair consisting of a central pipe Newel fixed with C.I. Steps around it in a Spiral form is known as Spiral Stair as shown:

> The Treads are of Checkered Plate Treads for safety and can be of Precast or Cast-in-situ Treads > Used on Terraces, small Space and Lesser Traffic

Concrete Stairs: The Stairs constructed of Cement Concrete, Plain or Reinforced, are called Concrete Stairs Concrete Stairs are of two following types 1) Plain Concrete Stairs 2) R.C.C. Stairs

1) Plain Concrete Stairs: The Concrete Stairs constructed of Precast Concrete blocks or Cast-in-situ Cement Concrete without using Reinforcement are known as Plain Concrete Stairs > The Steps are mostly of Spandril type and are supported as in case of Stone Stairs > These Stairs are constructed in place of Stone Stairs and are mainly used at entrances to the buildings these days

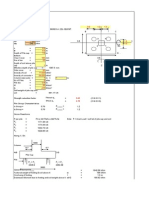

2) R.C.C. Stairs: The Stairs constructed of Reinforced Cement Concrete are known as R.C.C. Stairs > The Steps are usually finished with Non-slippery material as Tiles, Terrazzo, Marble or other finish for pleasing appearance > For this, checkered grooves may be provided on it > The nosing is prevented to damage by fixing Brass, Iron castings or by embedding G.I. pipe at the nosing or paving the treads with Flag Stones as shown:

> Balusters are fixed into holes in treads by embedding them in Rich Cement Mortar

The Advantages of R.C.C. Stairs are: > Easy to construct into any geometrical shape > More durable, Fire-resistant and less noisy > Require comparatively thin sections > With suitable finish, provides pleasing appearance > Easy to wash and clean so provide better sanitation > They can be built of any complicated design The R.C.C. Stairs are further of Three types: 1) R.C.C. Slab and Beam type Stair 2) R.C.C. cantilever type Stair 3) R.C.C. Slab type Stair

1) R.C.C. Slab and Beam Type Stair: The R.C.C. Stair in which Steps are designed to act as slab between the Wall and a Stringer or between two Stringers is known as R.C.C. Slab and Beam Type Stair as shown:

2) R.C.C. Cantilever Type Stair: The R.C.C. Stair in which steps are cantilevered from the wall is known as R.C.C. Cantilever Type Stair

3) R.C.C. Slab Type Stair: The R.C.C. Stair in which each flight is designed and constructed as Inclined Slab is known as R.C.C. Slab Type Stair

Brick Stairs: The Stairs constructed of brick masonry are called Brick Stairs > This type of Stair can be made either Solid or provided with Arches to reduce the quantity of brickwork as shown: > The Treads of such Stairs are generally kept 1-1/2 brick in width and rise= two layers of bricks

THANK YOU

?? ??

ANMOL GARG 9914410599 garganmol2@rediffmail.com

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Specification For Aluminum DoorsДокумент6 страницSpecification For Aluminum DoorscivilaskarОценок пока нет

- Premix Carpet For TankДокумент1 страницаPremix Carpet For TankcivilaskarОценок пока нет

- Safegard Septic TanksДокумент6 страницSafegard Septic TankscivilaskarОценок пока нет

- Design of Anchor Bolt - Rev.AДокумент8 страницDesign of Anchor Bolt - Rev.AcivilaskarОценок пока нет

- Design of Anchor Bolt - Rev.AДокумент8 страницDesign of Anchor Bolt - Rev.AcivilaskarОценок пока нет

- Design of Pile CapДокумент120 страницDesign of Pile Capcivilaskar100% (3)

- Piperack Design ExampleДокумент42 страницыPiperack Design ExampleSushant Bijam67% (6)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- English Vs Romanian SyntaxДокумент7 страницEnglish Vs Romanian SyntaxAna Maria Chirea-Stoica100% (1)

- Prudence and FrugalityДокумент17 страницPrudence and FrugalitySolaiman III SaripОценок пока нет

- 40rua 40rusДокумент68 страниц40rua 40rusfua2011live.comОценок пока нет

- Socio Economic Conditions of Migrant LabourДокумент7 страницSocio Economic Conditions of Migrant LabourDR SEKHARОценок пока нет

- Oakite 61B - TIДокумент2 страницыOakite 61B - TI顏煥杰Оценок пока нет

- MUMBAI ConsultantsДокумент43 страницыMUMBAI ConsultantsER RaviОценок пока нет

- Prima Magistra:: Wulan Rahayu Syachtiyani, Novi TrisnawatiДокумент12 страницPrima Magistra:: Wulan Rahayu Syachtiyani, Novi TrisnawatiGita GloriaОценок пока нет

- ABC Press Release and AllocationДокумент28 страницABC Press Release and AllocationAndrew Finn KlauberОценок пока нет

- Art & Science: Meeting The Needs of Patients' Families in Intensive Care UnitsДокумент8 страницArt & Science: Meeting The Needs of Patients' Families in Intensive Care UnitsRiaОценок пока нет

- Vocabulary Placement TestДокумент3 страницыVocabulary Placement TestMonica Vergara MejiaОценок пока нет

- 10th Syllbus PDFДокумент104 страницы10th Syllbus PDFGagandeep KaurОценок пока нет

- HYSYS Basis PDFДокумент306 страницHYSYS Basis PDFsalman hussainОценок пока нет

- 09-Hispec DespecДокумент51 страница09-Hispec DespecHyungon KimОценок пока нет

- How To Query Asham Tele Points (Telebirr)Документ13 страницHow To Query Asham Tele Points (Telebirr)Fayisa ETОценок пока нет

- Introduction EthicsДокумент26 страницIntroduction EthicsLawrence MarquezОценок пока нет

- Inventory Counting in Inventory ManagementДокумент15 страницInventory Counting in Inventory ManagementDinesh GuptaОценок пока нет

- Segway v1 04 Eng Segway Atv Snarler Manual t3b L7eДокумент192 страницыSegway v1 04 Eng Segway Atv Snarler Manual t3b L7eMarouane LASRYОценок пока нет

- Indian Standard: Methods of Test For Aggregates For ConcreteДокумент22 страницыIndian Standard: Methods of Test For Aggregates For ConcreteAnuradhaPatraОценок пока нет

- Risk Management Q1Документ8 страницRisk Management Q1Parth MuniОценок пока нет

- Java ProgrammingДокумент134 страницыJava ProgrammingArt LookОценок пока нет

- Guidelines For The Oral Presentation Bands Singers e MusicДокумент2 страницыGuidelines For The Oral Presentation Bands Singers e Musicjuliusdelazare100% (1)

- Tutorial Probability and Statistics: SolutionsДокумент3 страницыTutorial Probability and Statistics: SolutionsAdnanОценок пока нет

- What Is A RubricДокумент2 страницыWhat Is A Rubricjasmina2869Оценок пока нет

- UK TV StreamingДокумент22 страницыUK TV StreamingSuhanto KastaredjaОценок пока нет

- Chapter 1 To7 With Course OutlineДокумент34 страницыChapter 1 To7 With Course Outlinerk_kamatchi3483Оценок пока нет

- Artikel Jurnal Siti Tsuwaibatul AДокумент11 страницArtikel Jurnal Siti Tsuwaibatul Aaslamiyah1024Оценок пока нет

- Control System Engineering: Topic Block Diagram RepresentationДокумент24 страницыControl System Engineering: Topic Block Diagram RepresentationWaqas AfzalОценок пока нет

- 3838-Article Text-7786-1-10-20230403Документ8 страниц3838-Article Text-7786-1-10-20230403Ramona Elena SpiridonОценок пока нет

- Aircraft Tyre Maintenance - SKYbrary Aviation SafetyДокумент8 страницAircraft Tyre Maintenance - SKYbrary Aviation Safetynosh1983Оценок пока нет

- Culture & CivilizationДокумент21 страницаCulture & CivilizationMadhuree Perumalla100% (1)