Академический Документы

Профессиональный Документы

Культура Документы

2 - HydroFORM - Mechanical Setup R2

Загружено:

carlos0 оценок0% нашли этот документ полезным (0 голосов)

203 просмотров17 страницHydroFORM phased array System is designed to perform corrosion mapping in two possible configurations. HydroFORM Mechanical Setup - Probe Installation Loosen the knob, apply light pressure on the probe to ensure the foam seal is secure against the inspection surface and tighten the knob. Minor differences in the water column due to the scanner "crabbing" will not affect beam angle at 0 degrees for corrosion mapping and thickness readings.

Исходное описание:

Оригинальное название

2_HydroFORM - Mechanical Setup R2

Авторское право

© Attribution Non-Commercial (BY-NC)

Доступные форматы

PPT, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документHydroFORM phased array System is designed to perform corrosion mapping in two possible configurations. HydroFORM Mechanical Setup - Probe Installation Loosen the knob, apply light pressure on the probe to ensure the foam seal is secure against the inspection surface and tighten the knob. Minor differences in the water column due to the scanner "crabbing" will not affect beam angle at 0 degrees for corrosion mapping and thickness readings.

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PPT, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

203 просмотров17 страниц2 - HydroFORM - Mechanical Setup R2

Загружено:

carlosHydroFORM phased array System is designed to perform corrosion mapping in two possible configurations. HydroFORM Mechanical Setup - Probe Installation Loosen the knob, apply light pressure on the probe to ensure the foam seal is secure against the inspection surface and tighten the knob. Minor differences in the water column due to the scanner "crabbing" will not affect beam angle at 0 degrees for corrosion mapping and thickness readings.

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PPT, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 17

HydroFORM Phased Array Corrosion Mapping System Part 2 Mechanical Setup

HydroFORM Corrosion Mapping System Mechanical Setup

The HydroFORM Phased Array System is designed to perform corrosion mapping in two possible configurations. Manual Encoded One Line Scans (1 axis)

Semi-Automated Encoded Multiple Line Scans (2 axis)

HydroFORM Mechanical Setup Probe Installation

Ensure that the probe is installed into the HydroFORM scanner where element number 1 is positioned correctly for the C-scan that will be created. The normal position for this is 1-64 left to right when scanning forward as pictured. When the Omniscan Start button is selected, the 0,0 position will set 2mm to the right of element number 1 as pictured. The Index axis will increment in the direction below indicated by the green arrow. (1mm focal law resolution and 61mm total width) The Scan axis will increment below in the direction indicated by the blue arrow at the resolution entered into the Omniscan.

HydroFORM Mechanical Setup Probe Installation

Loosen the knob (pictured at right), apply light pressure on the probe to ensure the foam seal is secure against the inspection surface and tighten the knob. The HydroFORM wedge used by the focal law calculator has a default height (Water column) of 12mm. This can be visualized on the Omniscan display prior to tightening the probe knob and adjusted by applying light pressure until the interface signal is at 0. It is also acceptable to modify the Hydro wedge parameters to the current position.

HydroFORM Mechanical Setup Probe Installation

The phased array probe will align parallel and level with the pipe when secured with the one-knob patent pending probe carriage. Minor differences in the water column due to the scanner Crabbing will not affect thickness readings when the interface gate (Yellow) is set to A-scan Syncro I/ To achieve the intended focal point, the real water column height must match the Hydro wedge height in the Omniscan database. Differences in the water column and calculator will not affect beam angle at 0 degrees for corrosion mapping and thickness readings.

HydroFORM Mechanical Setup Probe Installation - Foam

Pressure applied to the probe during installation is directly related to the foam insert position and will affect the ability to maintain the water column. Care should be taken to ensure that the probe is not installed with too much or too little tension on the foam. To optimize both the position of the probe and tension of the foam the interface echo between the water and component surface should appear at 12mm. This is the default height of the Hydro wedge in the Omniscan database and when positioned correctly will result in the interface signal appearing at zero mm using the default set up file. (With gate I Syncro on Pulse, not \ I)

HydroFORM System Manual Encoded One Line Scans

In the manual encoded one line scan configuration, the position of the data is maintained and recorded using the encoder integrated in the HydroFORM carriage. The integrated encoder has a resolution of 8 steps\mm that is entered into the Omniscan MXU software in the Scan-Encoder-Resolution for Encoder #1. In this configuration with the default aperture of 4 elements (4mm per A-scan), the HydroFORM will provide a one line scan of 61 A-scans (61mm) up to the limit of either the 160 megabyte file size (Standard) or 300 megabyte file size (Optional). For the 160 megabyte standard Omniscan, the limit would be a C-scan of 61mm X 7680mm at a resolution of 1mm in both axis. For the 300 megabyte optional Omniscan, the limit would be a C-scan of 61mm X 14,400mm at a resolution of 1mm in both axis. To piece multiple one line scans together in one data file, the probe can be indexed manually in the Omniscan software or indexed by use of a clicker (Olympus P/N: OPTX674) and index of the C-scan entered manual.

HydroFORM System Manual Encoded One Line Scans

For manual encoded one line scans, plug the Mini-Wheel encoder cable to the Lemo-DE15 encoder cable extension. The DE15 connector will connect to the OmniScan.

HydroFORM System Semi-Auto Raster Scanning (2 Axis)

Use of the HydroFORM system in the 2 axis semi-automated mode requires the Olympus CHAIN Scanner (Chainscan-XY38) or similar. The HydroFORM adaptation kit includes all of the required hardware to adapt the HydroFORM HD Mapper to a standard Olympus CHAIN Scanner XY38. Included in the adaptation kit is the crank handle, encoder junction with Lemo connector, reversed spring loaded arm for HydroFORM scanner attachment, four plastic wheels and parts to allow the CHAIN Scanner to inspect Flat surfaces.

HydroFORM System Semi-Auto CHAIN Scanner

In the CHAIN Scanner manual, locate the required number of short links and long links for the diameter of pipe to be inspected and connect them in accordance with the manual. Insure the adjustment screw is set so that when clamped on the pipe the scanner is snug to the pipe and does not move freely. Make sure you use a small link with dovetail on it for installation of the umbilical attachment device.

10

HydroFORM System Semi-Auto CHAIN Scanner

Install the HydroFORM on the index arm as pictured below. The probe knob should be on the far side of the HD Mapper from the CHAIN Scanner wheels. The probe should be installed with element 1 closest to the CHAIN Scanner wheels. The umbilical should be configured with slack to allow a full range of movement on the index arm. Index Axis

Scan Axis

64

1

11

HydroFORM System Semi-Auto CHAIN Scanner

The HydroFORM assembly is connected to the CHAIN Scanner by a spring loaded arm that has 3 possible positions. 1. Locked up (for HydroFORM manipulation) 2. Locked down 3. Free moving When acquiring data and manipulating the scanner the arm should be in the free moving position. Acquiring data when the arm is in a locked position results in poor data quality and scanner operation.

12

HydroFORM System Semi-Auto CHAIN Scanner

Position the scanner so that 0,0 (XY position) on the probe is in the intended position on the pipe. Using the default aperture of 4 elements, this puts 0,0 (Focal law 1) 2mm from the element 1 position line.

0,0

13

Semi-Auto Chain Scanner Position of 0,0 for C-scan

To assist in positioning the HydroFORM at the correct 0,0 position a magnetic template is provided. Place the magnetic template on the component with the 0,0 position of the Cscan under the window below indicated by the red arrow. After the magnetic template is in place the HydroFORM can be put in place prior to locking down the chain scanner.

14

Semi-Auto Chain Scanner Position of 0,0 for C-scan

The chain scanner has a arm length (Index or Y axis) that will allow the probe five revolutions or Strokes around the pipe. Using the default set up this results in a C-scan acquisition of 305mm X pipe circumference. (61mm X 5 strokes) For multiple acquisitions, the chain scanner must be repositioned every 305mm. The magnetic template is used to set the original 0,0 position and to maintain the correct position for successive scanner positions every 305mm. See Omniscan Setup Power Point for encoder preset position and C-scan area creation for consecutive repositioning of the chain scanner for inspections larger than five strokes (305mm)

15

HydroFORM System Semi-Auto CHAIN Scanner

Move the scanner to the side slightly and open the water control valve until the water chamber is flooded and all bubbles have disappeared from the S-scan display. After initially flooding the water chamber and clearing the bubbles, the water pressure can be reduced to a light flow during scanning. The surface condition of the pipe will determine how much water is required. Best results and fastest scan speed will be achieved with an electric pump due to constant consistent pressure. Be sure to move the scanner back to 0,0 prior to starting the acquisition.

16

Вам также может понравиться

- ACUREN Thickness Measurement ProcedureДокумент15 страницACUREN Thickness Measurement ProcedureAhmed Ben Nouma0% (1)

- Phased Array Sectorial Scanning OverviewДокумент72 страницыPhased Array Sectorial Scanning OverviewLG Milton LuisОценок пока нет

- Asme NM.2-2018Документ126 страницAsme NM.2-2018aneeshjokay75% (4)

- Build Size and Aesthetics with the 6-Week Hype Gains Hypertrophy ProgramДокумент21 страницаBuild Size and Aesthetics with the 6-Week Hype Gains Hypertrophy ProgramDanCurtis100% (1)

- DUAL MATRIX ARRAY OverviewДокумент37 страницDUAL MATRIX ARRAY OverviewLe Anh Duy100% (1)

- Part 3 Omni SetupДокумент19 страницPart 3 Omni SetupReem AwwadОценок пока нет

- NDT SetupBuilder - OverviewДокумент32 страницыNDT SetupBuilder - OverviewgueridiОценок пока нет

- ADA Design Guide 2010Документ7 страницADA Design Guide 2010Jack BarkerОценок пока нет

- Customer Advisory For Fire Suppression Systems - V4 - ENДокумент18 страницCustomer Advisory For Fire Suppression Systems - V4 - ENsak100% (1)

- Appendix F Phased Array Ultrasonic Testing: 1.0 PurposeДокумент17 страницAppendix F Phased Array Ultrasonic Testing: 1.0 PurposeThananon Chomcherd100% (2)

- Tofd PCNДокумент22 страницыTofd PCNmarforall5205Оценок пока нет

- Astm e 1001Документ9 страницAstm e 1001KEN KОценок пока нет

- QUSE PA Crack Sizing Test Procedure API UT 11 May 2017Документ12 страницQUSE PA Crack Sizing Test Procedure API UT 11 May 2017solrac4371100% (2)

- Small Diameter Tube and Pipe Inspection With Phased Array PDFДокумент7 страницSmall Diameter Tube and Pipe Inspection With Phased Array PDFAlanka PrasadОценок пока нет

- Evaluation of Flaw Acceptance Ratios According to ASME Section VIII CodeДокумент3 страницыEvaluation of Flaw Acceptance Ratios According to ASME Section VIII CodeWoodrow FoxОценок пока нет

- Performance and Mechanical Running Tests of Centrifugal CompressorsДокумент5 страницPerformance and Mechanical Running Tests of Centrifugal CompressorsVicky KumarОценок пока нет

- M-107/M-208 Wheel SpecificationДокумент40 страницM-107/M-208 Wheel SpecificationKristian Marchena100% (3)

- PAUT Application for Boiler Tube InspectionДокумент10 страницPAUT Application for Boiler Tube InspectionmuhdmsohОценок пока нет

- Full Matrix Capture and Total Focusing MethodДокумент7 страницFull Matrix Capture and Total Focusing MethodMuhammad UmairОценок пока нет

- IRIS Inspection Accurately Measures Tube Wall Thickness (39Документ3 страницыIRIS Inspection Accurately Measures Tube Wall Thickness (39Jacques SauОценок пока нет

- Ultrasonic Testing Procedure SampleДокумент10 страницUltrasonic Testing Procedure SamplePrashant PuriОценок пока нет

- Qualification Process For Phased Array UT Using DNV RP-F118Документ12 страницQualification Process For Phased Array UT Using DNV RP-F118aztec20100% (1)

- Measure Pipe Wall Thickness Using Tangential RadiographyДокумент7 страницMeasure Pipe Wall Thickness Using Tangential Radiographykirubha_karan2000Оценок пока нет

- Profile Radiography IAEAДокумент14 страницProfile Radiography IAEAPaolo Ng100% (1)

- MX2 Training Program - Setup Encoded InspectionsДокумент22 страницыMX2 Training Program - Setup Encoded InspectionsVictor Antonio Diaz Faundez100% (1)

- MFL Tank Floor InspectionДокумент18 страницMFL Tank Floor Inspectionshaban100% (4)

- Standard Guide For Evaluating Performance Phased Array UnitДокумент20 страницStandard Guide For Evaluating Performance Phased Array UnitAnonymous m43RBxOVZ2Оценок пока нет

- Omniscan Setup - Basic SetupДокумент29 страницOmniscan Setup - Basic SetupcarlosОценок пока нет

- Eddy Current ProbesДокумент20 страницEddy Current Probesedapo7950% (2)

- Ultrasonic Testing of ASTM A‐182 Gr. 321 BarsДокумент14 страницUltrasonic Testing of ASTM A‐182 Gr. 321 BarsAbhayОценок пока нет

- OmniScan MX2 Wedge Delay CalibrationДокумент18 страницOmniScan MX2 Wedge Delay CalibrationVictor Antonio Diaz Faundez100% (1)

- 2011 PipeWizard Training Part 01Документ62 страницы2011 PipeWizard Training Part 01rajeev jegadeesan100% (1)

- PAUT Ultrasonic Testing Procedure ASME - SVDN Rev 01EДокумент29 страницPAUT Ultrasonic Testing Procedure ASME - SVDN Rev 01ETrung Tinh Ho100% (2)

- OmniSX MX2 Training 4A PA Calculator OverviewДокумент10 страницOmniSX MX2 Training 4A PA Calculator OverviewcarlosОценок пока нет

- Eddyfi CorporatePresentation Feb2015Документ37 страницEddyfi CorporatePresentation Feb2015Anonymous CD0suI9Оценок пока нет

- ASTM E2700 09 Standard Practice For Contact Ultrasonic Testing of Welds Using Phased ArraysДокумент9 страницASTM E2700 09 Standard Practice For Contact Ultrasonic Testing of Welds Using Phased ArraysDairo Damian MelendezОценок пока нет

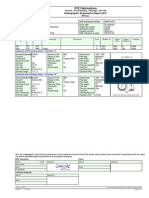

- Ndtspec Radiographic Nde ReportДокумент1 страницаNdtspec Radiographic Nde ReportcarlosОценок пока нет

- FLOORMAP3Di-R High Speed MFL Floor Scanner with STARS Top & Bottom Defect DiscriminationДокумент6 страницFLOORMAP3Di-R High Speed MFL Floor Scanner with STARS Top & Bottom Defect Discriminationjose ocanaОценок пока нет

- Aws Application of Phased Array UltrasonicДокумент7 страницAws Application of Phased Array UltrasonicDileep KumarОценок пока нет

- OmniScan SX \ MX2 Training - Phased Array Wedge OverviewДокумент37 страницOmniScan SX \ MX2 Training - Phased Array Wedge OverviewcarlosОценок пока нет

- OmniScan SX \ MX2 Training - Phased Array Wedge OverviewДокумент37 страницOmniScan SX \ MX2 Training - Phased Array Wedge OverviewcarlosОценок пока нет

- MX2 Training Program 13 Multiprobe InspectionДокумент8 страницMX2 Training Program 13 Multiprobe InspectionVictor Antonio Diaz FaundezОценок пока нет

- BS EN 12668-3 - Combind EquipmentДокумент14 страницBS EN 12668-3 - Combind EquipmentRenier KoenОценок пока нет

- Corrosion - Mapping Usign Phased Array - Olympus NDTДокумент3 страницыCorrosion - Mapping Usign Phased Array - Olympus NDTpokeboy19Оценок пока нет

- Guide Wave Ultrasonic Pipe Test ProcedureДокумент10 страницGuide Wave Ultrasonic Pipe Test ProcedurejeswinОценок пока нет

- MX2 Training Program 10A Sensitivity Cal Wizard All LawsДокумент18 страницMX2 Training Program 10A Sensitivity Cal Wizard All LawsVictor Antonio Diaz FaundezОценок пока нет

- OmniSX MX2 Training 4B Phased Array ProbesДокумент49 страницOmniSX MX2 Training 4B Phased Array Probescarlos100% (2)

- ASTM 2491 - 08 PhaseArray PDFДокумент18 страницASTM 2491 - 08 PhaseArray PDFOmero MeraОценок пока нет

- E 2261 - e 2261M - 12Документ15 страницE 2261 - e 2261M - 12ruben carcamo100% (1)

- Ultrasonic Testing Procedure For Corrosion Mapping: AstronДокумент7 страницUltrasonic Testing Procedure For Corrosion Mapping: AstronKuppan Srinivasan100% (3)

- Eddyliner PX User ManualДокумент146 страницEddyliner PX User ManualcarlosОценок пока нет

- MFL Compendium - 001Документ26 страницMFL Compendium - 001kingston100% (2)

- Diploma Pharmacy First Year - Hap - MCQSДокумент13 страницDiploma Pharmacy First Year - Hap - MCQSAnitha Mary Dambale91% (33)

- Eddy Current Array TutorialДокумент13 страницEddy Current Array TutorialsameerОценок пока нет

- 2.a.omniscan Setup - Calibration For Sectorial ScanДокумент34 страницы2.a.omniscan Setup - Calibration For Sectorial Scancarlos0% (1)

- 2.a.omniscan Setup - Calibration For Sectorial ScanДокумент34 страницы2.a.omniscan Setup - Calibration For Sectorial Scancarlos0% (1)

- 2.a.omniscan Setup - Calibration For Sectorial ScanДокумент34 страницы2.a.omniscan Setup - Calibration For Sectorial Scancarlos0% (1)

- Corrosion MappingДокумент17 страницCorrosion MappingJuliog100% (1)

- Egg Pasteurization Manual 1969Документ54 страницыEgg Pasteurization Manual 1969Tomas MuzzioОценок пока нет

- NDT MarketplaceДокумент1 страницаNDT MarketplacecarlosОценок пока нет

- Conder Separator Brochure NewДокумент8 страницConder Separator Brochure Newednavilod100% (1)

- Measuring Ultrasonic Velocity in Materials by Comparative Pulse-Echo MethodДокумент14 страницMeasuring Ultrasonic Velocity in Materials by Comparative Pulse-Echo MethodRoman D100% (1)

- Ultrasonic Exam RequirementsДокумент2 страницыUltrasonic Exam RequirementsAngelTinocoОценок пока нет

- PAUT Procedure EEISДокумент13 страницPAUT Procedure EEISZakirUllahОценок пока нет

- Astm e 1158Документ5 страницAstm e 1158KEN KОценок пока нет

- Silverwing B Scan ReportДокумент46 страницSilverwing B Scan ReportpjhollowОценок пока нет

- 340 INSPECTION (PG 112 - 121) : Para. 302.3.3Документ3 страницы340 INSPECTION (PG 112 - 121) : Para. 302.3.3r_ramiresОценок пока нет

- HTHA - Relatório SGS PDFДокумент231 страницаHTHA - Relatório SGS PDFlgustavocoelhoОценок пока нет

- IACS Rec-69-Rev2-Oct-2020-Ul (NDT)Документ21 страницаIACS Rec-69-Rev2-Oct-2020-Ul (NDT)Al aminОценок пока нет

- Se 273Документ4 страницыSe 273solrac4371Оценок пока нет

- CMAP Reporting - Operating ManualДокумент46 страницCMAP Reporting - Operating ManualJesus E ContrerasОценок пока нет

- Paut Paper PDFДокумент7 страницPaut Paper PDFAyesha GeОценок пока нет

- TCG Sectorial 2 - 0Документ11 страницTCG Sectorial 2 - 0Gelson André BarbosaОценок пока нет

- Hydroform Phased Array Corrosion Mapping System Part 1 - Equipment OverviewДокумент13 страницHydroform Phased Array Corrosion Mapping System Part 1 - Equipment OverviewGhaithОценок пока нет

- RollerFORM PT1 Omni SetupДокумент33 страницыRollerFORM PT1 Omni SetupOussama KhelilОценок пока нет

- Weld ProcedureДокумент2 страницыWeld ProcedurecarlosОценок пока нет

- 1463520118Документ2 страницы1463520118carlosОценок пока нет

- Winter 2018 Registration FormДокумент1 страницаWinter 2018 Registration FormcarlosОценок пока нет

- Aerofab NDT Rotary Probes CatalogДокумент23 страницыAerofab NDT Rotary Probes CatalogcarlosОценок пока нет

- Zetec Ultravision EC DatasheetДокумент2 страницыZetec Ultravision EC Datasheetcarlos0% (1)

- RotoUTscan v8Документ2 страницыRotoUTscan v8carlosОценок пока нет

- Safety Data Sheet: SIR Chem® Dry Powder 63 RedДокумент6 страницSafety Data Sheet: SIR Chem® Dry Powder 63 RedcarlosОценок пока нет

- HDV Accessories: Videoscope Camera Probes & AccessoriesДокумент1 страницаHDV Accessories: Videoscope Camera Probes & AccessoriescarlosОценок пока нет

- Cygnus 1 Manual V617AДокумент42 страницыCygnus 1 Manual V617AMichael JordanОценок пока нет

- 811 2800 - PFINDER 280 - Flyer - GB - v2Документ1 страница811 2800 - PFINDER 280 - Flyer - GB - v2carlosОценок пока нет

- Setup Guide No 4 Weld Inspection WeldcheckДокумент7 страницSetup Guide No 4 Weld Inspection WeldcheckcarlosОценок пока нет

- VM Products Gain Test Box2Документ16 страницVM Products Gain Test Box2carlos100% (1)

- 30mm CalibrationДокумент10 страниц30mm CalibrationcarlosОценок пока нет

- 4.omniscan Setup - Min-Wheel Encoder SetupДокумент13 страниц4.omniscan Setup - Min-Wheel Encoder SetupcarlosОценок пока нет

- 3dii BrochureДокумент6 страниц3dii BrochurecarlosОценок пока нет

- OmniSX MX2 Training 5A Weld and Part Wizard UseДокумент15 страницOmniSX MX2 Training 5A Weld and Part Wizard Usecarlos100% (1)

- 1 OmniSX GettingStarted Touchscreen UseДокумент25 страниц1 OmniSX GettingStarted Touchscreen UsecarlosОценок пока нет

- 3 OmniSX GettingStarted PA Weld AnalysisДокумент16 страниц3 OmniSX GettingStarted PA Weld AnalysiscarlosОценок пока нет

- Stepan Formulation 943Документ2 страницыStepan Formulation 943Mohamed AdelОценок пока нет

- Health Programs Activities Timeframe Expected Output Child CareДокумент3 страницыHealth Programs Activities Timeframe Expected Output Child CareC SamОценок пока нет

- Risk Management in Educational InstitutionsДокумент8 страницRisk Management in Educational InstitutionsBhoxszKurtjusticePascualОценок пока нет

- Undas Deployment PadsДокумент15 страницUndas Deployment PadsVic NairaОценок пока нет

- Coal Workers' Pneumoconiosis (Black Lung Disease) Treatment & Management - Approach Considerations, Medical Care, Surgical CareДокумент2 страницыCoal Workers' Pneumoconiosis (Black Lung Disease) Treatment & Management - Approach Considerations, Medical Care, Surgical CareامينОценок пока нет

- Biosafety FH Guidance Guide Good Manufacturing Practice enДокумент40 страницBiosafety FH Guidance Guide Good Manufacturing Practice enMaritsa PerHerОценок пока нет

- Training and Supervision of Health Care WorkersДокумент12 страницTraining and Supervision of Health Care WorkerspriyankaОценок пока нет

- Edinburgh Postnatal Depression Scale. Detection of Postnatal Depression. Development of The 10-ItemДокумент6 страницEdinburgh Postnatal Depression Scale. Detection of Postnatal Depression. Development of The 10-ItemKyze LQОценок пока нет

- Refresher 2 (Pipe)Документ12 страницRefresher 2 (Pipe)Kira YagamiОценок пока нет

- Lab 9-Measurement of Filtrate Loss and Mud Cake Thickness of Drilling Mud Sample Using Dead Weight Hydraulic Filter Press Considering API Standard.Документ17 страницLab 9-Measurement of Filtrate Loss and Mud Cake Thickness of Drilling Mud Sample Using Dead Weight Hydraulic Filter Press Considering API Standard.Sunny BbaОценок пока нет

- Ficha Tecnica Emeral 8C PDFДокумент11 страницFicha Tecnica Emeral 8C PDFLeticia KoerichОценок пока нет

- Notes Lecture No 3 Cell Injury and MechanismДокумент5 страницNotes Lecture No 3 Cell Injury and MechanismDr-Rukhshanda RamzanОценок пока нет

- The Bresle Method: Improving Accuracy of Soluble Salt MeasurementsДокумент4 страницыThe Bresle Method: Improving Accuracy of Soluble Salt MeasurementsMuthuKumarОценок пока нет

- Electrolyte AE 11 - MSDSДокумент8 страницElectrolyte AE 11 - MSDSShinta Nugraha MughniОценок пока нет

- Class9. CVD and PVDДокумент30 страницClass9. CVD and PVDiraОценок пока нет

- 6V Plush Ride-On: Owner'S ManualДокумент26 страниц6V Plush Ride-On: Owner'S ManualVisas LaredoОценок пока нет

- Preferensi Konsumen &strategi Pemasaran Produk Bayem Organik Di CVДокумент8 страницPreferensi Konsumen &strategi Pemasaran Produk Bayem Organik Di CVsendang mОценок пока нет

- Final TLE9 Nail Care9 Q1 Module 3Документ20 страницFinal TLE9 Nail Care9 Q1 Module 3Ma. Andrea LagmanОценок пока нет

- Radiol 2020201473Документ37 страницRadiol 2020201473M Victoria SalazarОценок пока нет

- Vastra Grah .Pvt. LTD: In-House Manufacturing FacaltyДокумент2 страницыVastra Grah .Pvt. LTD: In-House Manufacturing FacaltySaurabh JainОценок пока нет

- Bespoke Fabrication Systems for Unique Site SolutionsДокумент13 страницBespoke Fabrication Systems for Unique Site Solutionswish uОценок пока нет

- 1324 1624 1824 Owners Manual 6 4 08Документ64 страницы1324 1624 1824 Owners Manual 6 4 08Miguel LopОценок пока нет