Академический Документы

Профессиональный Документы

Культура Документы

Chap 4

Загружено:

nuke88againАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Chap 4

Загружено:

nuke88againАвторское право:

Доступные форматы

CHAPTER 4 Product and Service Design

Tata McGraw

Chapter 4

Product and Service Design

4-3

OBJECTIVES

Product Development Process Economic Analysis of Development Projects Designing for the Customer Design for Manufacturability Measuring Product Development Performance

4-4

Typical Phases of Product Development

Planning

Concept Development System-Level design Design Detail Testing and Refinement

Production Ramp-up

4-5

Economic Analysis of Project Development Costs

Using measurable factors to help determine:

Operational design and development decisions Go/no-go milestones

Building a Base-Case Financial Model

A financial model consisting of major cash flows Sensitivity Analysis for what if questions

4-6

Designing for the Customer

House of Quality

Quality Function Deployment

Ideal Customer Product

Value Analysis/ Value Engineering

4-7

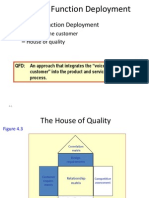

Designing for the Customer: Quality Function Deployment

Interfunctional teams from marketing, design engineering, and manufacturing Voice of the customer House of Quality

4-8

Designing for the Customer: The House of Quality

Correlation:

X X X X

Water resistance

Energy needed to close door Door seal resistance Check force on level needed Energy ground open door to Accoust. Trans. Window

Strong positive Positive Negative Strong negative

X = Us A = Comp. A B = Comp. B (5 is best) 1 2 3 4

Customer Requirement s Easy to close

Engineerin g Characteris tics

Competitive evaluation

X X AB

AB

Stays open on a hill 5

Customer requirements information forms the basis for this matrix, used to translate them into operating or engineering goals.

The McGraw-Hill Companies, Inc., 2004

Easy to open

XAB A XB X A B

Doesnt leak in rain 3 No road noise 2 Importance weighting Target values

5

Reduce energy level to 7.5 ft/lb Maintain current level

Reduce force to 9 lb. Reduce energy to 7.5 ft/lb. Maintain current level Maintain current level

10

Relationships:

Strong = 9 Medium = 3 Small = 1

Technical evaluation 4 3 (5 is best) 2

1

B A X

BA X

B A X

B X A

BXA

BA X

4-9

Designing for the Customer: Value Analysis/Value Engineering

Achieve equivalent or better performance at a lower cost while maintaining all functional requirements defined by the customer Does the item have any design features that are not necessary? Can two or more parts be combined into one? How can we cut down the weight? Are there nonstandard parts that can be eliminated?

4-10

Design for Manufacturability

Traditional Approach

We design it, you build it or Over the wall

Concurrent Engineering

Lets work together simultaneously

4-11

Design for Manufacturing and Assembly

1.

2.

3.

Greatest improvements related to DFMA arise from simplification of the product by reducing the number of separate parts: During the operation of the product, does the part move relative to all other parts already assembled? Must the part be of a different material or be isolated from other parts already assembled? Must the part be separate from all other parts to allow the disassembly of the product for adjustment or maintenance?

4-12

Measuring Product Development Performance

Performance Dimension

Time-to-market

Measures

Freq. Of new products introduced Time to market introduction Number stated and number completed Actual versus plan Percentage of sales from new products

Engineering hours per project Cost of materials and tooling per project Actual versus plan

Productivity

Quality

Conformance-reliability in use Design-performance and customer satisfaction Yield-factory and field

4-13

Question Bowl

Which of the following is the first phase of the typical phases of product development? a. Product/process engineering b. Product planning c. Concept development d. Planning e. Ramp-up Answer: d. Planning

4-14

Question Bowl

Which of the following is primarily focused on getting the voice of the customer into design specifications in product development? a. Concurrent engineering b. Value engineering c. DFMA d. Quality function deployment e. None of the above

Answer: d. Quality function deployment

4-15

Question Bowl

Which of the following is the first step in building a House of Quality in product development? a. Develop a list of customer requirements for the product b. Concept development c. Pilot production/Ramp-up d. Concurrent engineering e. None of the above

Answer: a. Develop a list of customer requirements for the product

4-16

Question Bowl

Of the following abbreviated concepts which derive the greatest product improvements as a result of simplification of the product by reducing the number of separate parts? a. CE Answer: b. DFMA b. DFMA c. QFD (Design for d. VA/VE Manufacturing and e. CAD Assembly)

4-17

End of Chapter 4

Вам также может понравиться

- Chap004 - Product and Service DesignДокумент51 страницаChap004 - Product and Service Designshivram2080% (10)

- Stevenson CH 04Документ41 страницаStevenson CH 04Karla Jenine Pacificador100% (1)

- Nirdosh Case StudyДокумент4 страницыNirdosh Case Studynuke88againОценок пока нет

- 6th Central Pay Commission Salary CalculatorДокумент15 страниц6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- CE Fundamentals Book-Volume 2Документ50 страницCE Fundamentals Book-Volume 2sinpackОценок пока нет

- Concurrent EngineeringДокумент238 страницConcurrent EngineeringBest ThingОценок пока нет

- 05 Swink Moas 4e Ch04Документ38 страниц05 Swink Moas 4e Ch04isfi23001Оценок пока нет

- Product and Service DesignДокумент17 страницProduct and Service DesignRahul KhannaОценок пока нет

- Product DesignДокумент12 страницProduct DesignAdrey LugoОценок пока нет

- Product Service Design Lesson 4Документ37 страницProduct Service Design Lesson 4Yash RangaОценок пока нет

- Product Design and Process SelectionДокумент25 страницProduct Design and Process Selectionira_mishra_3Оценок пока нет

- Designing Products & ServicesДокумент23 страницыDesigning Products & ServicesRitesh KumarОценок пока нет

- Product and Service DesignДокумент26 страницProduct and Service DesignBikaash SharmaОценок пока нет

- PRDCT and Srvce DesДокумент40 страницPRDCT and Srvce DesAli SyedОценок пока нет

- Student Slides Chapter 4Документ15 страницStudent Slides Chapter 4Anshuman LenkaОценок пока нет

- Product Design and Development - Design For ManufacturingДокумент114 страницProduct Design and Development - Design For ManufacturingfukusacoОценок пока нет

- Session Changed)Документ29 страницSession Changed)Avneesh BhattОценок пока нет

- 04 - Product and Service Design - V2Документ56 страниц04 - Product and Service Design - V2Yurt BianОценок пока нет

- Lecture 3 Product and Service DesignДокумент47 страницLecture 3 Product and Service DesignNickifah Alleyne100% (1)

- Manufacturing Systems: Concurrent EngineeringДокумент42 страницыManufacturing Systems: Concurrent EngineeringrudipramanaОценок пока нет

- 6 Product Specifications. Perancangan Produk. Teknik IndustriДокумент32 страницы6 Product Specifications. Perancangan Produk. Teknik IndustriAisah DirawidyaОценок пока нет

- Quality Function DeploymentДокумент6 страницQuality Function Deploymentsaurabhkaku0% (1)

- Product DesignДокумент25 страницProduct Designayushichaudhary72Оценок пока нет

- Concurrent EngineeringДокумент42 страницыConcurrent EngineeringAnonymous p8bHAAxОценок пока нет

- Concurrent Engineering and Traditional EngineeringДокумент42 страницыConcurrent Engineering and Traditional Engineeringkhizer2a67% (3)

- Chapter 4 ClassroomДокумент46 страницChapter 4 ClassroomBilly JaimeОценок пока нет

- ch-3 Part IДокумент37 страницch-3 Part IDesu mekonnenОценок пока нет

- Product and Service DesignДокумент46 страницProduct and Service DesignAchim BragancaОценок пока нет

- 6 Product SpecificationsДокумент32 страницы6 Product SpecificationszetseatОценок пока нет

- Product and Service DesignДокумент66 страницProduct and Service DesignantehenОценок пока нет

- POM Presentation Chapter #4 Ahmed Javed (FA18-BBA-024)Документ45 страницPOM Presentation Chapter #4 Ahmed Javed (FA18-BBA-024)ahmed javedОценок пока нет

- Product and Service Design: LessonДокумент44 страницыProduct and Service Design: LessonAngelica Mae CavalidaОценок пока нет

- Om Unit - Ii MbaДокумент60 страницOm Unit - Ii MbaPrerana eclubОценок пока нет

- Cbme ReportДокумент38 страницCbme ReportNessa VillaralboОценок пока нет

- Operation ManagementДокумент11 страницOperation ManagementrabiaumarОценок пока нет

- Chapter Six (Product Specifications)Документ32 страницыChapter Six (Product Specifications)DsgSyedNasRulОценок пока нет

- New Products Management: Merle Crawford Anthony Di Benedetto 10 EditionДокумент19 страницNew Products Management: Merle Crawford Anthony Di Benedetto 10 EditionmzumziОценок пока нет

- 3 - Product and Service DesignДокумент38 страниц3 - Product and Service DesignJulie Pearl GuarinОценок пока нет

- Module-4 Product and Service DesignДокумент30 страницModule-4 Product and Service DesignJi YuОценок пока нет

- Lecture 4 Product and Service DesignДокумент42 страницыLecture 4 Product and Service DesignsanaullahbndgОценок пока нет

- MBA IInd SEM POM Chapter 12 Product Design, Manufacturing TechnologyДокумент75 страницMBA IInd SEM POM Chapter 12 Product Design, Manufacturing TechnologyPravie92% (12)

- Session New Product Development ProcessДокумент36 страницSession New Product Development ProcessMr. Priyanshu Gupta Student, Jaipuria LucknowОценок пока нет

- Student Stevenson Chapter-03 Product-DesignДокумент65 страницStudent Stevenson Chapter-03 Product-Designk60.2112280077Оценок пока нет

- Chapter 1 Introduction To Mechanical Design ProcessДокумент28 страницChapter 1 Introduction To Mechanical Design ProcessAloha NamiОценок пока нет

- Presentation OM Chap 05Документ52 страницыPresentation OM Chap 05Muhammad Muzamil HussainОценок пока нет

- WK 4 B Product&ServicedesignДокумент45 страницWK 4 B Product&Servicedesignapi-3726594Оценок пока нет

- Unit 2Документ30 страницUnit 2rgnyawaliОценок пока нет

- Chapter 7 FinaceДокумент43 страницыChapter 7 FinaceMiakeresuTsukamitoОценок пока нет

- Product and Service DesignДокумент40 страницProduct and Service DesignSapari VelОценок пока нет

- Concurrent Engineering Product Innovation Tools Process Innovation Tools Innovation ManagementДокумент71 страницаConcurrent Engineering Product Innovation Tools Process Innovation Tools Innovation ManagementAnkit RastogiОценок пока нет

- Chapter 4 - Product and Service DesignДокумент60 страницChapter 4 - Product and Service DesignGio Mintu100% (2)

- Product and Service Design: Mcgraw-Hill/IrwinДокумент58 страницProduct and Service Design: Mcgraw-Hill/IrwinTamoor BaigОценок пока нет

- ME3013 Chap 5Документ7 страницME3013 Chap 5pavetran raviОценок пока нет

- Product and Service Design: Mcgraw-Hill/IrwinДокумент59 страницProduct and Service Design: Mcgraw-Hill/IrwinMarryRose Dela Torre FerrancoОценок пока нет

- Chap004 - Product and Service DesignДокумент52 страницыChap004 - Product and Service Designjhaeus enajОценок пока нет

- 2-Development Processes and OrganizationsДокумент28 страниц2-Development Processes and OrganizationsJane ReyesОценок пока нет

- Product and Service DesignДокумент61 страницаProduct and Service Designaprian0% (1)

- Operations Management: William J. StevensonДокумент28 страницOperations Management: William J. StevensonHarsimar NarulaОценок пока нет

- Product and Service DesignДокумент48 страницProduct and Service Designbugzmio0% (1)

- Topic 5 - Product and Process DesignДокумент49 страницTopic 5 - Product and Process DesignCОценок пока нет

- Product DesignДокумент27 страницProduct DesignrubensОценок пока нет

- Scanner Darkly Good Night and Good Luck Gone Baby Gone King of Comedy Amistad The Constant Gardener The NegotiatorДокумент1 страницаScanner Darkly Good Night and Good Luck Gone Baby Gone King of Comedy Amistad The Constant Gardener The Negotiatornuke88againОценок пока нет

- 46 Brilliant Short Novels You Can Read in A DayДокумент25 страниц46 Brilliant Short Novels You Can Read in A Daynuke88again67% (6)

- The Induction Quiz FinalsДокумент65 страницThe Induction Quiz Finalsnuke88againОценок пока нет

- Charting in ExcelДокумент221 страницаCharting in Excelnuke88againОценок пока нет

- AP ContactДокумент1 страницаAP Contactnuke88againОценок пока нет

- Ancient Pueblo PeoplesДокумент14 страницAncient Pueblo Peoplesnuke88againОценок пока нет

- Chap 6Документ26 страницChap 6nuke88againОценок пока нет

- Chap011 - Inventory ManagementДокумент37 страницChap011 - Inventory Managementnuke88againОценок пока нет

- Debt Servicing HandbookДокумент81 страницаDebt Servicing Handbooknuke88againОценок пока нет

- Chap 11Документ21 страницаChap 11nuke88againОценок пока нет

- Chap 17Документ43 страницыChap 17nuke88againОценок пока нет

- What Is EnlightenmentДокумент6 страницWhat Is EnlightenmentCiceroFilosofiaОценок пока нет

- Chap 6AДокумент26 страницChap 6Anuke88againОценок пока нет

- Consulting-Ten Commandments of Small Business (Lesson)Документ1 страницаConsulting-Ten Commandments of Small Business (Lesson)nenu_100Оценок пока нет

- Chap 5Документ37 страницChap 5Satyajit HatiОценок пока нет

- Chap 5AДокумент14 страницChap 5Anuke88againОценок пока нет

- Management) Handbook For Small BusinessДокумент48 страницManagement) Handbook For Small BusinesskayusiОценок пока нет

- Inside The Guru Mind - Peter Drucker PDFДокумент15 страницInside The Guru Mind - Peter Drucker PDFKhiet PhamОценок пока нет

- 5 04 FinancialFitness PDFДокумент9 страниц5 04 FinancialFitness PDFbook2mindОценок пока нет

- (Ebook - English) Nietzsche, Friedrich - Philosophy and TruthДокумент8 страниц(Ebook - English) Nietzsche, Friedrich - Philosophy and TruthpraetorОценок пока нет

- Donald Trump - Fortune Without Fear Real Estate RichesДокумент94 страницыDonald Trump - Fortune Without Fear Real Estate RichesreaderОценок пока нет

- Just 1% The Power of Microtrends PDFДокумент19 страницJust 1% The Power of Microtrends PDFMina DefontanОценок пока нет

- CircumciДокумент1 страницаCircumciParvez AhamedОценок пока нет

- CromwellДокумент1 страницаCromwellParvez AhamedОценок пока нет

- H VaneДокумент1 страницаH VaneParvez AhamedОценок пока нет

- Milton, John - Sonnets (Poetry)Документ5 страницMilton, John - Sonnets (Poetry)nuke88againОценок пока нет

- Milton, John - To MR Cyriack Skinner Upon His Blindness (PoemДокумент1 страницаMilton, John - To MR Cyriack Skinner Upon His Blindness (Poemnuke88againОценок пока нет

- Concurrent Engineering: Tools and Technologies For Mechanical System DesignДокумент986 страницConcurrent Engineering: Tools and Technologies For Mechanical System DesignOm Parkash SharmaОценок пока нет

- Chapter 4-Product and Service Design NewДокумент104 страницыChapter 4-Product and Service Design Newsp914132Оценок пока нет

- Concurrent EngineeringДокумент17 страницConcurrent EngineeringKudzie Maphy MasaireОценок пока нет

- Cost Reduction-Life Cycle CostingДокумент25 страницCost Reduction-Life Cycle CostingParamjit Sharma100% (3)

- Concurrent Engineering and TeamworkДокумент5 страницConcurrent Engineering and TeamworkAnonymous Om94erWpaAОценок пока нет

- PDPP - Presentation.3.Concurrent. Engineering - January.2021Документ17 страницPDPP - Presentation.3.Concurrent. Engineering - January.2021Ashish KumarОценок пока нет

- Operations Management ReportДокумент54 страницыOperations Management ReportMj GutierrezОценок пока нет

- Concurrent Engineering NotesДокумент41 страницаConcurrent Engineering NotesDominicОценок пока нет

- Use of Artificial Intelligence in Concurrent EngineeringДокумент16 страницUse of Artificial Intelligence in Concurrent EngineeringAMAR SAIОценок пока нет

- Dourado, João Paulo Silva, Rui Silva, Ângela Maria Esteves DaДокумент14 страницDourado, João Paulo Silva, Rui Silva, Ângela Maria Esteves DaDiego SilvaОценок пока нет

- Aiaa Mdo TC 1998 White Paper On MdoДокумент426 страницAiaa Mdo TC 1998 White Paper On MdoFlávio CoutinhoОценок пока нет

- Mtic NotesДокумент50 страницMtic NotesAnshita GargОценок пока нет

- Groover Fundamentos Manual SolucionesДокумент3 страницыGroover Fundamentos Manual SolucionesCADTDDОценок пока нет

- Implementation of Mechatronics System Design Strategy: Case Studies at Taif University - Saudi ArabiaДокумент22 страницыImplementation of Mechatronics System Design Strategy: Case Studies at Taif University - Saudi ArabiaVinod KumarОценок пока нет

- #2. C2-Product DesignДокумент14 страниц#2. C2-Product DesignHashane PereraОценок пока нет

- Automation and Computer Integrated Manufacturing SyllabusДокумент2 страницыAutomation and Computer Integrated Manufacturing SyllabusMulu GirmayОценок пока нет

- 2019 - 09 - 10 Product, Process and Schedule DesignДокумент35 страниц2019 - 09 - 10 Product, Process and Schedule Designvinthya vayaperieОценок пока нет

- Capitulo 2Документ32 страницыCapitulo 2ukalОценок пока нет

- PLCM MODULE 2 Dr. S B MALUR. 2021Документ52 страницыPLCM MODULE 2 Dr. S B MALUR. 2021HiОценок пока нет

- Mechatronics 2 Vdi Model Example PDFДокумент40 страницMechatronics 2 Vdi Model Example PDFRenzo Arredondo PradaОценок пока нет

- Concurrent Engineering Design SyllabusДокумент19 страницConcurrent Engineering Design Syllabusalexcittadini01Оценок пока нет

- 1 Introduction PDFДокумент60 страниц1 Introduction PDFAnmolОценок пока нет

- Concurrent EngineeringДокумент15 страницConcurrent EngineeringTushar Ballabh BMLОценок пока нет

- Concurrent EngineeringДокумент9 страницConcurrent Engineering19990SANDОценок пока нет

- Design Manufacturing: Computer-IntegratedДокумент667 страницDesign Manufacturing: Computer-IntegratedAlexander CasallasОценок пока нет

- Rohini 54883195730Документ13 страницRohini 54883195730Abd AОценок пока нет

- Concurrent Engineering and Traditional EngineeringДокумент42 страницыConcurrent Engineering and Traditional Engineeringkhizer2a67% (3)