Академический Документы

Профессиональный Документы

Культура Документы

Final Turbine Meet

Загружено:

VIBHAVАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Final Turbine Meet

Загружено:

VIBHAVАвторское право:

Доступные форматы

10th STEAM TURBINE PROFESSIONAL MEET

HIGHER HPT FIRST STAGE PRESSURE & RECTIFICATION AT SITE NTPC TANDA TPS

Presented by: Brijesh Kumar (AGM/TMD)

Shahnawaz A Khan (Asst. Mgr/TMD)

Brief detail of U#1 HP Higher Pressure Problem

st 1

Stage

Tanda TPS: 4X110 MW Units

TG : Skoda Power, Czech Make

R&M of U#1 was carried out in Nov'2008 during which following major jobs were carried out HPT:

New HPT rotor placed.

Refurbishent of HP nozzle segments done.

Refurbishent of new HP diaphragms.

Brief detail of U#1 HP Higher Pressure Problem

Replacement of HP diaphragm#3.

st 1

Stage

After R&M, higher 1st stage pressure of HPT was observed in the range of 107 ksc. Higher 1st stage pressure is leads to Lower turbine efficiency. Excessive force on turbine casing parting plane fasteners causing life reduction.

Higher drum pressure & MS piping pressure.

Brief detail of U#1 HP Higher Pressure Problem

st 1

Stage

Potential causes of high 1st stage pressure:

Restricted nozzle.

Deposition on the blades of HP rotor & diaphragms.

Checks during O/H of U#1

Following checks were carried out to find the cause of the problem:

Steam flowpath

HP nozzle segment condition HP diaphragms for scaling/deposition HP rotor scaling/deposition

Findings

Flowpath readings & blade surfaces of rotor & diaphragms were found satisfactory.

No significant deposition was found on HP rotor blades as well as diaphragm blades.

After opening the HPT, condition of HP nozzles were found very healthy. So, it was further analysed & throat of the nozzles found to be very less that designed value.

Findings

Values found:

HP Top Nozzle HP Bottom Nozzle Before O/H Design

Average Value(mm)

Before O/H

Design

Throat

14.7

16.10

14.56

16.10

Width

22.5

22.5

22.5

22.5

HP Nozzle

OUR APPROACH

In view of the above findings, the matter was discussed with Ex-BHEL expert & was decided to increase the throat of the nozzle segments while refurbishing it in-situ. HP nozzle refurbishment job done by sandblasting, grinding, polishing & final finishing.

Readings after Nozzle repair at site:

Average Value(mm) HP Top Nozzle After O/H Design HP Bottom Nozzle After O/H Design

Throat

16.04

16.00

16.00

16.00

Width

22.5

22.5

22.5

22.5

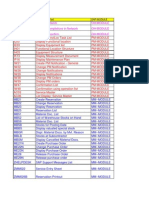

EEMG DATACHART DEPICTING 1st STAGE PR. WITH VARIOUS PARAMETERS

Readings after EEMG efficiency test.

U#1 Load (MW) Main Steam Pressure before ESV (ksc) Main Steam Temp before ESV (oC) First Stage Pressure HPT Efficiency Before O/H 110.10 133.05 After O/H 113.12 131.10

534.87

534.0

107.5 72.90

103.6 74.31

THANK YOU

Вам также может понравиться

- Maintain turbine plant feed systemsДокумент21 страницаMaintain turbine plant feed systemsVIBHAV100% (1)

- Ogn Ops Perf 002Документ12 страницOgn Ops Perf 002VIBHAVОценок пока нет

- 15 YearsДокумент14 страниц15 YearsVIBHAVОценок пока нет

- Od Ops Syst 001Документ5 страницOd Ops Syst 001VIBHAVОценок пока нет

- Ogn Ops Mech 017Документ4 страницыOgn Ops Mech 017VIBHAVОценок пока нет

- Ogn Ops Mech 023Документ6 страницOgn Ops Mech 023VIBHAVОценок пока нет

- Ogn Ops Mech 026Документ12 страницOgn Ops Mech 026VIBHAVОценок пока нет

- Ogn Ops Mech 014Документ5 страницOgn Ops Mech 014VIBHAVОценок пока нет

- Sim MMSD 19.04.14Документ24 страницыSim MMSD 19.04.14VIBHAVОценок пока нет

- Od Ops Mech 007Документ14 страницOd Ops Mech 007VIBHAVОценок пока нет

- Od Ops Mech 004Документ6 страницOd Ops Mech 004VIBHAVОценок пока нет

- OH matrix analysis and scoringДокумент3 страницыOH matrix analysis and scoringVIBHAVОценок пока нет

- OH matrix analysis and scoringДокумент3 страницыOH matrix analysis and scoringVIBHAVОценок пока нет

- Od Ops Mech 007Документ14 страницOd Ops Mech 007VIBHAVОценок пока нет

- Ogn Ops Mech 003Документ40 страницOgn Ops Mech 003VIBHAV100% (2)

- Report - DF - DT Relay Setting With AnnexДокумент37 страницReport - DF - DT Relay Setting With AnnexVIBHAVОценок пока нет

- List of TCodes in SAPДокумент15 страницList of TCodes in SAPVIBHAV67% (3)

- A 144Документ2 страницыA 144VIBHAVОценок пока нет

- Sap Kws GT 1b R&M Oh Report 10jul13Документ3 страницыSap Kws GT 1b R&M Oh Report 10jul13VIBHAVОценок пока нет

- Zohflashrepc GT1BДокумент3 страницыZohflashrepc GT1BVIBHAVОценок пока нет

- The Maharaja Sayajirao University of Baroda: The Annual Quality Assurance Report of Internal Quality Assurance CellДокумент11 страницThe Maharaja Sayajirao University of Baroda: The Annual Quality Assurance Report of Internal Quality Assurance CellVIBHAVОценок пока нет

- Outage Manager Training DgpsДокумент1 страницаOutage Manager Training DgpsVIBHAVОценок пока нет

- Starting Oil Pump in Service Problem at NTPC, Ttps Unit #5, 110 MW UnitДокумент5 страницStarting Oil Pump in Service Problem at NTPC, Ttps Unit #5, 110 MW UnitVIBHAVОценок пока нет

- Abb Vs Cost Sheet ExceptionДокумент4 страницыAbb Vs Cost Sheet ExceptionVIBHAVОценок пока нет

- Overhauling Flash Report: Kawas Overhaul For Fy 2013-14Документ2 страницыOverhauling Flash Report: Kawas Overhaul For Fy 2013-14VIBHAVОценок пока нет

- Detailed Report From FranceДокумент17 страницDetailed Report From FranceVIBHAVОценок пока нет

- A 149 High Ecc ChecklistДокумент3 страницыA 149 High Ecc ChecklistVIBHAVОценок пока нет

- A 148Документ2 страницыA 148VIBHAVОценок пока нет

- Performance of Mill Xrp-803Документ4 страницыPerformance of Mill Xrp-803VIBHAVОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- 006GB99140A - Rapidec LmonoДокумент2 страницы006GB99140A - Rapidec Lmonopdl5775Оценок пока нет

- Chungbuk Product Show & Trade Fair 2014: Myanmar Business MatchingДокумент11 страницChungbuk Product Show & Trade Fair 2014: Myanmar Business Matchingapi-241660673Оценок пока нет

- Cat C80Документ2 страницыCat C80Imola MovidaОценок пока нет

- Environment of HRMДокумент12 страницEnvironment of HRMmycreation18Оценок пока нет

- Service DM Kalibrierung Tab Dienstleistungen enДокумент2 страницыService DM Kalibrierung Tab Dienstleistungen enrcnexyОценок пока нет

- Barrel PonicsДокумент101 страницаBarrel Ponicsmogaemil100% (1)

- AAIB Money Market Fund (Juman) : Fact Sheet JuneДокумент1 страницаAAIB Money Market Fund (Juman) : Fact Sheet Juneapi-237717884Оценок пока нет

- Durometro TBH100Документ2 страницыDurometro TBH100magicianchemist100% (1)

- IELTS PhrasesДокумент4 страницыIELTS PhrasesSaphira42100% (1)

- b2b MarketingДокумент14 страницb2b Marketingkrantiuv3Оценок пока нет

- Chapter Practice Problems (PDS) : FiitjeeДокумент2 страницыChapter Practice Problems (PDS) : Fiitjeesampath741150% (2)

- Human Resource PPT of InfosysДокумент15 страницHuman Resource PPT of InfosysRohit Padalkar0% (1)

- Reddit Protein ExperimentДокумент1 страницаReddit Protein ExperimentPete PuzaОценок пока нет

- The Siege of LeningradДокумент1 страницаThe Siege of Leningradapi-266244169Оценок пока нет

- Metrology & Measurement: Anand K Bewoor & Vinay A KulkarniДокумент9 страницMetrology & Measurement: Anand K Bewoor & Vinay A KulkarniKuwer ThakurОценок пока нет

- MBA Course Structure: Foundation Courses (Sem1)Документ2 страницыMBA Course Structure: Foundation Courses (Sem1)Ali ArnaoutiОценок пока нет

- Friction IntroductionДокумент2 страницыFriction IntroductionRica MarquezОценок пока нет

- FEDEX 10 and 25 KG Box RateДокумент1 страницаFEDEX 10 and 25 KG Box RateLinhОценок пока нет

- Domestic Oil Tanks - 2500 LitreДокумент2 страницыDomestic Oil Tanks - 2500 LitreTitanEnvОценок пока нет

- Physics 101 Practice Exam 3Документ3 страницыPhysics 101 Practice Exam 3Katherine McLarneyОценок пока нет

- 9th Stucture of Atom Test Paper-2Документ2 страницы9th Stucture of Atom Test Paper-2Sabu VincentОценок пока нет

- New Equate Style GuideДокумент3 страницыNew Equate Style GuideKristin B Fielding0% (1)

- Antenna L InEДокумент2 страницыAntenna L InERasheed Yaser RabahОценок пока нет

- Zodiac: EclipticДокумент5 страницZodiac: EclipticsicavelicuОценок пока нет

- Hdca-5 TVДокумент2 страницыHdca-5 TVDaniel ManoleОценок пока нет

- File Ap en 7Документ2 страницыFile Ap en 7Rakib HossainОценок пока нет

- Shopstar Electric Chain Hoist: WarningДокумент2 страницыShopstar Electric Chain Hoist: WarningFelipe GonzalezОценок пока нет

- Worksheet Living Nonliving ThingsДокумент0 страницWorksheet Living Nonliving ThingsHusna Hafiza Razami100% (1)

- Chapter 4 - VDC BoylestadДокумент10 страницChapter 4 - VDC BoylestadAbril de VeraОценок пока нет

- Laptop Acceptance/Issue FormДокумент3 страницыLaptop Acceptance/Issue FormJeremy NashОценок пока нет