Академический Документы

Профессиональный Документы

Культура Документы

Lesson 9 - Layout and Flow

Загружено:

Derrick Maatla MoadiАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Lesson 9 - Layout and Flow

Загружено:

Derrick Maatla MoadiАвторское право:

Доступные форматы

71

Chapter 7 Layout and flow

Pearson Education Ltd. Rob Judges

71

Slack, Chambers and Johnston, Operations Management, 6th Edition, Nigel Slack, Stuart Chambers, and Robert Johnston 2010

72

Layout and flow

,"erations strateg# !rocess design

Su""l# net$ork design %a#out %a#out &lo$ and .lo$ !eo"le, 'obs and organi(ation !roduct)ser*ice design

+esign !lanning and control

-m"ro*ement

!rocess technolog#

72

Slack, Chambers and Johnston, Operations Management, 6th Edition, Nigel Slack, Stuart Chambers, and Robert Johnston 2010

7/

Key Teaching Ob ecti!es

0 1o introduce the t$o conce"ts o. "rocess t#"e and la#out t#"e and the relationshi" bet$een them 0 1o describe the basic la#out t#"es in terms o. the nature o. the .lo$ o. trans.ormed resources through the "rocess 0 1o stress that most real la#outs are h#brids o. the "ure t#"es 0 1o identi.# some o. the sim"le a""roaches that can be used to determine the e2act nature o. a la#out

7/

Slack, Chambers and Johnston, Operations Management, 6th Edition, Nigel Slack, Stuart Chambers, and Robert Johnston 2010

73

Key operations "uestions

-n Cha"ter 7 4 %a#out and .lo$4 Slack et al identi.# the .ollo$ing ke# 5uestions6 07hat is la#out8 07hat are the basic la#out t#"es used in o"erations8 07hat t#"e o. la#out should an o"eration choose8 09o$ should each basic la#out t#"e be designed in detail8

73

Slack, Chambers and Johnston, Operations Management, 6th Edition, Nigel Slack, Stuart Chambers, and Robert Johnston 2010

7:

Layout in!ol!es the relati!e positioning of transfor#ed resources within operations and the allocation of tas$s% which together dictate the flow of transfor#ed resources

1he relati*e "ositioning o. trans.orming resources

;i e deciding $here to "ut all the .acilities, machines, e5ui"ment and sta.. in the o"eration<

1he allocation o. tasks to trans.orming resources

1he .lo$ o. trans.ormed resources

;i e the materials, in.ormation and customers

7:

Slack, Chambers and Johnston, Operations Management, 6th Edition, Nigel Slack, Stuart Chambers, and Robert Johnston 2010

76

Tesco store&s flow process

'hat layout type is a con!entional super#ar$et and how does it differ fro# a #anufacturing operation using the sa#e layout type(

Essentiall#, a su"ermarket uses a .unctional la#out Each area o. the su"ermarket can be seen as being e5ui*alent to a $orkstation or machine in a manu.acturing o"eration 1he trans.ormed resource ;customers< .lo$s bet$een *arious areas de"ending on their indi*idual needs So each customer $ill take a ;sometimes marginall#< di..erent route through the o"eration 1he biggest di..erence bet$een the su"ermarket and an e5ui*alent manu.acturing o"eration concerns the ob'ecti*es o. the la#out -n con*entional manu.acturing o"erations, the ob'ecti*e is usuall# to minimi(e the distance tra*elled in ;or time taken to get through< the o"eration =# contrast, a su"ermarket>s la#out is intended to ma2imi(e sales 1his is not al$a#s the same as ma2imi(ing the distance tra*elled ;or time taken to get through< the o"eration, but it $ill certainl# in*ol*e a greater time s"ent looking at, and ho"e.ull# bu#ing, "roducts

Slack, Chambers and Johnston, Operations Management, 6th Edition, Nigel Slack, Stuart Chambers, and Robert Johnston 2010

76

77

'hat is a layout(

0 1he ?la#out> o. an o"eration or "rocess means ho$ its trans.ormed resources are "ositioned relati*e to each other and ho$ its *arious tasks are allocated to these trans.orming resources 0 1ogether these t$o decisions $ill dictate the "attern o. .lo$ .or trans.ormed resources as the# "rogress through the o"eration or "rocess

'hy is layout decisions i#portant

0 %a#out is an im"ortant decision because, i. the la#out "ro*es $rong, it can lead to o*er@long or con.used .lo$ "atterns, customer 5ueues, long "rocess times, in.le2ible o"erations, un"redictable .lo$ and high cost 0 Also, re@la#ing out an e2isting o"eration can cause disru"tion, leading to customer dissatis.action or lost o"erating time

Slack, Chambers and Johnston, Operations Management, 6th Edition, Nigel Slack, Stuart Chambers, and Robert Johnston 2010

77

7B

'hat #a$es a good layout(

C Inherent safety All "rocesses $hich might constitute a danger to either sta.. or customers should not be accessible to the unauthori(ed C Length of flow 1he .lo$ o. materials, in.ormation or customers should be a""ro"riate .or the o"eration 1his usuall# means minimi(ing the distance tra*elled b# trans.ormed resources C Clarity of flow All .lo$ o. materials and customers should be $ell sign"osted, clear and e*ident to sta.. and customers alike C Staff conditions Sta.. should be located a$a# .rom nois# or un"leasant "arts o. the o"eration C Management coordination Su"er*ision and communication should be assisted b# the location o. sta.. and communication de*ices C Accessibility. All machines and .acilities should be accessible .or "ro"er cleaning and maintenance C Use of space All la#outs should use s"ace a""ro"riatel# 1his usuall# means minimi(ing the s"ace used, but sometimes can mean achie*ing an im"ression o. s"acious lu2ur#, as in the entrance lobb# o. a high@class hotel C Long-term flexibility. %a#outs need to be changed "eriodicall# A good la#out $ill ha*e been de*ised $ith the "ossible .uture needs o. the o"eration in mind

Slack, Chambers and Johnston, Operations Management, 6th Edition, Nigel Slack, Stuart Chambers, and Robert Johnston 2010

7B

7D

The four basic layout types

Eost "ractical la#outs are deri*ed .rom onl# .our basic layout types6

1 &i2ed@"osition la#out

0 -n .i2ed@"osition la#out the trans.ormed resources do not mo*e bet$een the trans.orming resources -nstead o. materials, in.ormation or customers .lo$ing through an o"eration, the reci"ient o. the "rocessing is stationar# and the e5ui"ment, machiner#, "lant and "eo"le $ho do the "rocessing mo*e as necessar# 0 1his could be because the "roduct or the reci"ient o. the ser*ice is too large to be mo*ed con*enientl#, or it might be too delicate to mo*e, or "erha"s it could ob'ect to being mo*edF .or e2am"le6

Motorway construction the "roduct is too large to mo*e. Open-heart surgery "atients are too delicate to mo*e. High-class service restaurant customers $ould ob'ect to being mo*ed to $here .ood is "re"ared Shipbuilding the "roduct is too large to mo*e. Mainframe computer maintenance the "roduct is too big and "robabl# also too delicate to mo*e, and the customer might ob'ect to bringing it in .or re"air

Slack, Chambers and Johnston, Operations Management, 6th Edition, Nigel Slack, Stuart Chambers, and Robert Johnston 2010

7D

7 10

The four basic layout types

2 &unctional la#out

0 &unctional la#out is so called because it con.orms to the needs and con*enience o. the .unctions "er.ormed b# the trans.orming resources $ithin the "rocesses 0 -n .unctional la#out, similar resources or "rocesses are located together 1his ma# be because it is con*enient to grou" them together, or that the utili(ation o. trans.orming resources is im"ro*ed -t means that $hen materials, in.ormation or customers .lo$ through the o"eration, their route is determined according to their needs +i..erent "roducts or customers $ill ha*e di..erent needs and there.ore take di..erent routes E2am"les o. .unctional la#outs include6

C Hospital some processes (e.g. X-ray machines and laboratories are re!uired by several t#"es o. "atientF some "rocesses ;e g general $ards< can achie*e high sta..@ and bed@utili(ation C Machining the parts which go into aircraft engines some processes (e.g. heat treatment need s"ecialist su""ort ;heat and .ume e2traction<F some "rocesses ;e g machining centres< re5uire the same technical su""ort .rom s"ecialist setter4o"eratorsF some "rocesses ;e g grinding machines< get high machine utili(ation as all "arts $hich need grinding "ass through a single grinding section C Supermar"et some products# such as tinned goods# are convenient to restoc" if grouped together Some areas, such as those holding .ro(en *egetables, need the common technolog# o. .ree(er cabinets ,thers, such as the areas holding .resh *egetables, might be together because that $a# the# can be made to look attracti*e to customers

Slack, Chambers and Johnston, Operations Management, 6th Edition, Nigel Slack, Stuart Chambers, and Robert Johnston 2010

7 10

7 11

)unctional layout in a library * the path of one custo#er

%oan books in sub'ect order ,n@line and C+@R,E access room

Stud# desks

Com"an# re"orts En5uiries

1o 'ournal stack

Current 'ournal s Reser*e collection

Re.erence section

Store room Counter sta..

Co"#ing area

Entrance

7 11

E2it

Slack, Chambers and Johnston, Operations Management, 6th Edition, Nigel Slack, Stuart Chambers, and Robert Johnston 2010

7 12

The four basic layout types

/ Cell la#out

0 A cell la#out is one $here the trans.ormed resources entering the o"eration are "re@selected ;or "re@select themsel*es< to mo*e to one "art o. the o"eration ;or cell< in $hich all the trans.orming resources, to meet their immediate "rocessing needs, are located 0 Cell la#out is an attem"t to bring some order to the com"le2it# o. .lo$ $hich characteri(es .unctional la#out E2am"les o. cell la#outs include6

C Some laptop assembly within a contract manufacturer$s factory# the assembly of different la"to" brands ma# be done in a s"ecial area dedicated to that one brand that has s"ecial re5uirements such as "articularl# high 5ualit# le*els C %&unch$ products area in a supermar"et some customers use the supermar"et 'ust to "urchase sand$iches, sa*our# snacks, etc .or their lunch 1hese "roducts ma# be located together so that these customers do not ha*e to search around the store C Maternity unit in a hospital customers needing maternity attention are a well-defined grou" $ho can be treated together and $ho are unlikel# to need the other .acilities o. the hos"ital at the same time that the# need the maternit# unit

7 12

Slack, Chambers and Johnston, Operations Management, 6th Edition, Nigel Slack, Stuart Chambers, and Robert Johnston 2010

7 1/

+epart#ent store with sports goods ,shop-within-a-shop&

=ooks and *ideo s

&oot$e ar !er.ume and 'e$eller#

S"orts sho"

Eens$ear

Entrance

Con.ectioner #, ne$s"a"er, maga(ines and stationer#

Ele*ators 7omen>s clothes

Entrance

%uggag e and gi.ts

7 1/

Slack, Chambers and Johnston, Operations Management, 6th Edition, Nigel Slack, Stuart Chambers, and Robert Johnston 2010

7 13

The four basic layout types

3 !roduct la#out

0 !roduct la#out in*ol*es locating the trans.orming resources entirel# .or the con*enience o. the trans.ormed resources 0 Each "roduct, "iece o. in.ormation or customer .ollo$s a "rearranged route in $hich the se5uence o. acti*ities that are re5uired matches the se5uence in $hich the "rocesses ha*e been located 0 1he trans.ormed resources ?.lo$> as in a ?line> through the "rocess 1his is $h# this t#"e o. la#out is sometimes called .lo$ or line layout 0 &lo$ is "redictable and there.ore relati*el# eas# to control E2am"les o. "roduct la#out include6

C (utomobile assembly almost all variants of the same model re!uire the same se!uence of "rocesses C &oan application processing all applications re!uire the same se!uence of clerical and decision@making acti*ities C Self-service cafeteria generally the se!uence of customer re!uirements (starter# main course, dessert, drink< is common to all customers, but la#out also hel"s control customer .lo$

7 13

Slack, Chambers and Johnston, Operations Management, 6th Edition, Nigel Slack, Stuart Chambers, and Robert Johnston 2010

7 1:

Product flow in Cadbury&s

&lo$ o. chocolate in Cadbur#>s .actor# &lo$ o. customers in Cadbur# 7orld

=oth Cadbur#>s chocolate .actor# and its ?Cadbur# 7orld> *isitor attraction use ?"roduct> la#out =ut $hat $ill be di..erent about the la#outs and $h#8

7 1:

Slack, Chambers and Johnston, Operations Management, 6th Edition, Nigel Slack, Stuart Chambers, and Robert Johnston 2010

7 16

.n ar#y induction centre which uses product layout

%ecture theatre

7aiting area

7aiting area

+octor Gni.orm issuing area +octor

+octor

=lood test H@ra# =lood test H@ra# =lood test H@ra# Records6 "ersonal histor# and medical details

+octor

Gni.orm store

+octor

+octor

7 16

Slack, Chambers and Johnston, Operations Management, 6th Edition, Nigel Slack, Stuart Chambers, and Robert Johnston 2010

7 17

. product layout in a paper #anufacturing operation

7 17

Slack, Chambers and Johnston, Operations Management, 6th Edition, Nigel Slack, Stuart Chambers, and Robert Johnston 2010

7 1B

.n inno!ati!e layout in a surgery i#pro!es its efficiency

7 1B

Slack, Chambers and Johnston, Operations Management, 6th Edition, Nigel Slack, Stuart Chambers, and Robert Johnston 2010

7 1D

)actory flow helps surgery producti!ity

'hat do you thin$ are the ad!antages and disad!antages of this arrange#ent when co#pared with the con!entional layout of one surgeon re#aining in one operating theatre( 1he .irst "oint to make here is that, essentiall#, the la#out has not changed as such =oth a con*entional o"erating theatre and the arrangement described in the short case are ?.i2ed "osition> la#outs 7hat has changed is that, t$o "atients are mo*ed in and out o. their o"erating theatres ;the .i2ed "ositions< in order .or "re"aration $ork that does not in*ol*e the surgeon to be carried out $hilst the surgeon is o"erating on the other "atient 1his has the ad*antage o. utili(ing $hat "resumabl# is the scarce resource ;the surgeon< e*en though t$o o"erating theatres are no$ needed 1o some e2tent, it is mo*ing to$ards the "rinci"les o. .lo$ "rocesses because, although the "atient does not mo*e as such, the# do mo*e relati*e to the surgeon

7 1D

Slack, Chambers and Johnston, Operations Management, 6th Edition, Nigel Slack, Stuart Chambers, and Robert Johnston 2010

7 20

/i0ed layout1 . restaurant co#ple0 with all four basic layout types

Cell la#out bu..et &i2ed@"osition la#out ser*ice restaurant

+essert bu..et Starter bu..et

%ine la#out ca.eteria

Ser*ice line ,*en !re"aration

Eain course bu..et

&unctional la#out kitchen

Cool room &ree(er Iegetable "re" Jrill

7 20

Slack, Chambers and Johnston, Operations Management, 6th Edition, Nigel Slack, Stuart Chambers, and Robert Johnston 2010

7 21

2electing a layout

0 1he im"ortance o. .lo$ to an o"eration $ill de"end on its !olu#e and !ariety characteristics. 0 7hen *olume is *er# lo$ and *ariet# is relati*el# high, ?.lo$> is not a ma'or issue and a .i2ed@"osition man# be suitable 0 7ith higher *olume and lo$er *ariet#, .lo$ becomes an issue 0 -. the *ariet# is still high, ho$e*er, an entirel# .lo$@dominated arrangement is di..icult because there $ill be di..erent .lo$ "atterns 0 7hen the *ariet# o. "roducts or ser*ices reduces to the "oint $here a distinct ?categor#> $ith similar re5uirements becomes e*ident but *ariet# is still not small, cell la#out could become a""ro"riate 0 7hen *ariet# is relati*el# small and *olume is high, .lo$ can become regulari(ed and a "roduct@based la#out is likel# to be a""ro"riate, as in an assembl# "lant 0 1he *olume4*ariet# characteristics o. the o"eration $ill, to a large e2tent, narro$ the choice do$n to one or t$o la#out o"tions 0 1he decision as to $hich la#out t#"e to ado"t $ill be in.luenced b# an understanding o. their relati*e ad*antages and disad*antages

Slack, Chambers and Johnston, Operations Management, 6th Edition, Nigel Slack, Stuart Chambers, and Robert Johnston 2010

7 21

7 22

3olu#e and !ariety characteristics of layout types

9igh &lo$ is intermittent %o$ &i2ed@"osition la#out &unctional la#out Cell la#out Iariet# Iolume %o$ 9igh

!roduct la#out

Regular .lo$ more im"ortant

7 22

&lo$ becomes continuous

Slack, Chambers and Johnston, Operations Management, 6th Edition, Nigel Slack, Stuart Chambers, and Robert Johnston 2010

Regular .lo$ more .easible

7 2/

.d!antages and disad!antages of fi0ed position layout

&i2ed@"osition la#out

Ier# high "roduct and mi2 .le2ibilit#

Ad*antages

!roduct)customer not mo*ed 9igh *ariet# o. tasks .or sta.. Ier# high unit costs Scheduling s"ace and acti*ities can be di..icult

+isad*antages

7 2/

Slack, Chambers and Johnston, Operations Management, 6th Edition, Nigel Slack, Stuart Chambers, and Robert Johnston 2010

7 23

.d!antages and disad!antages of functional layout

&unctional la#out

9igh "roduct and mi2 .le2ibilit#

Ad*antages

Relati*el# robust in the case o. disru"tions Eas# to su"er*ise %o$ utili(ation

+isad*antages Can ha*e *er# high 7-!

Com"le2 .lo$

7 23

Slack, Chambers and Johnston, Operations Management, 6th Edition, Nigel Slack, Stuart Chambers, and Robert Johnston 2010

7 2:

.d!antages and disad!antages of cell layout

Cell la#out

Can gi*e good com"romise

Ad*antages

&ast through"ut Jrou" $ork can result in good moti*ation Can be costl# to rearrange e2isting la#out Can need more "lant

+isad*antages

7 2:

Slack, Chambers and Johnston, Operations Management, 6th Edition, Nigel Slack, Stuart Chambers, and Robert Johnston 2010

7 26

.d!antages and disad!antages of product layout

!roduct la#out

%o$ unit costs .or high *olume

Ad*antages

,""ortunities .or s"eciali(ation o. e5ui"ment Can ha*e lo$ mi2 .le2ibilit#

+isad*antages Not *er# robust in the case o.

disru"tions 7ork can be *er# re"etiti*e

7 26

Slack, Chambers and Johnston, Operations Management, 6th Edition, Nigel Slack, Stuart Chambers, and Robert Johnston 2010

7 27

The relationship between process types and layout types

Eanu.acturing .unctional t#"es

!ro'ect "rocesses Jobbing "rocesses &unctional la#out =atch "rocesses Cell la#out Eass "rocesses Continuous "rocesses

Slack, Chambers and Johnston, Operations Management, 6th Edition, Nigel Slack, Stuart Chambers, and Robert Johnston 2010

=asic la#out t#"es

&i2ed@"osition la#out

Ser*ice .unctional t#"es

!ro.essional ser*ices

Ser*ice sho"s

Eass ser*ices !roduct la#out

7 27

7 2B

4asic layout types ha!e different fi0ed and !ariable costs that see# to deter#ine which one to use

Costs

&i2ed@ "osition &unctional

Cell !roduct

Gse Gse .i2ed@ .unctional "osition

Gse cell

Gse "roduct

Iolume

7 2B

Slack, Chambers and Johnston, Operations Management, 6th Edition, Nigel Slack, Stuart Chambers, and Robert Johnston 2010

7 2D

4ut uncertainty about e0act fi0ed and !ariable costs #eans the decision can rarely be #ade on cost alone

Costs

&i2ed@"osition &unctional Cell !roduct

( Gse "roduct

Gse .i2ed@"osition Gse .i2ed@"osition or .unctional Gse .unctional

Iolume

Gse .unctional or cell or "roduct Gse .unctional or cell

7 2D

Slack, Chambers and Johnston, Operations Management, 6th Edition, Nigel Slack, Stuart Chambers, and Robert Johnston 2010

7 /0

+etailed design techni"ues

,nce the basic la#out t#"e has been decided, the ne2t ste" is to decide the detailed design o. the la#out

&i2ed "osition 4 resource location anal#sis

0 1he ob'ecti*e o. the detailed design o. .i2ed@"osition la#outs is to achie*e a la#out .or the o"eration $hich allo$s all the trans.orming resources to ma2imi(e their contribution to the trans.ormation "rocess b# allo$ing them to "ro*ide an e..ecti*e ?ser*ice> to the trans.ormed sources

&unctional la#out 4 .lo$ charts and relationshi" charts Cell la#out 4 "roduct .lo$ anal#sis !roduct la#out 4 assembl# line balancing techni5ues

7 /0

Slack, Chambers and Johnston, Operations Management, 6th Edition, Nigel Slack, Stuart Chambers, and Robert Johnston 2010

7 /1

+etailed design of functional layout

0 1he detailed design o. .unctional la#outs is com"le2, as is .lo$ in this t#"e o. la#out 0 Chie. among the .actors $hich lead to this com"le2it# is the *er# large number o. di..erent o"tions 0 &or ) centres there are .actorial ) ()* different ways of arranging the centres 0 1his co#binatorial co#ple0ity of functional layouts #a$es o"timal solutions di..icult to achie*e in "ractice 0 Eost .unctional la#outs are designed b# a combination o. intuition, common sense and s#stematic trial and error 5nfor#ation re"uired before detailed design of functional layouts C 1he area re5uired b# each $ork centreF C 1he constraints on the sha"e o. the area allocated to each $ork centreF C 1he degree and direction o. .lo$ bet$een each $ork centre ;.or e2am"le, number o. 'ourne#s, number o. loads or cost o. .lo$ "er distance tra*elled<F C 1he desirabilit# o. $ork centres being close together or close to some .i2ed "oint in the la#out

7 /1

Slack, Chambers and Johnston, Operations Management, 6th Edition, Nigel Slack, Stuart Chambers, and Robert Johnston 2010

7 /2

Collecting infor#ation in functional layout

;a<

1o &rom

%,A+S)+AK

;b<

%,A+S)+AK

= 17

E A =

-. direction is not im"ortant, colla"ses to

= /0

A = C + E /0 1/

20

/0 10 20

/0

60 20

10

70 /0

C + E

/0 B0 30

- -

10 10 10 10

7 /2

Slack, Chambers and Johnston, Operations Management, 6th Edition, Nigel Slack, Stuart Chambers, and Robert Johnston 2010

7 //

Collecting infor#ation in functional layout 6Continued7

;b<

%,A+S)+AK

A A = C + E

= /0

;c< . 4 ,r, alternati*el# C + E

%,A+S)+AK

/0

60 20

/0

/0 B0 30

@ /0 60 @ 20 @ /0 B0 30

7 //

Slack, Chambers and Johnston, Operations Management, 6th Edition, Nigel Slack, Stuart Chambers, and Robert Johnston 2010

7 /3

Collecting infor#ation in functional layout 6Continued7

;a<

1o &rom

%,A+S)+AK

;d<

GN-1 C,S1)+-S1ANCE 1RAIE%%E+

1o

= 17

&rom

= 2

C 2 /

+ 2 / 2

E 2 3 2 10

A = C + E /0 1/

20

/0 10 20

A =

-. cost o. .lo$ di..ers bet$een $ork centres, combine $ith

/ 2 2

10

70 /0

C + E

- -

10 10 10 2 2 2 2

10 10 10 10

7 /3

Slack, Chambers and Johnston, Operations Management, 6th Edition, Nigel Slack, Stuart Chambers, and Robert Johnston 2010

7 /:

Collecting infor#ation in functional layout 6Continued7

;d< GN-1 C,S1)+-S1ANCE 1RAIE%%E+

1o &rom

;e< +A-%K C,S1)+-S1RANCE 1RAIE%%E+

1o &rom

= 2

C 2 /

+ 2 / 2

E 2 3 2 10

1o gi*e

= /3

A = C + E / 2

A = /D C + /00

60 20 60 60 130 /00

20

10 10 10 2 2 2 2

E 20 20 20 20

7 /:

Slack, Chambers and Johnston, Operations Management, 6th Edition, Nigel Slack, Stuart Chambers, and Robert Johnston 2010

7 /6

Collecting infor#ation in functional layout 6Continued7

;e< +A-%K C,S1)+-S1ANCE 1RAIE%%E+

1o &rom

;.< +A-%K C,S1)+-S1RANCE 1RAIE%%E+

= /3

E A =

im"ortant, colla"ses to

= 7/

A = /D C + /00

60 20 60 60 130 -. direction is not /00

B0

/60 30 B0

20

C + E

160 /20

E 20 20 20 20

7 /6

Slack, Chambers and Johnston, Operations Management, 6th Edition, Nigel Slack, Stuart Chambers, and Robert Johnston 2010

7 /7

)unctional layout design* #ini#i8ing distance tra!elled

0 -n .unctional la#out, the "rime ob'ecti*e is to minimi(e the costs to the o"eration $hich are associated $ith .lo$ through the o"eration 0 1his means minimi(ing the total distance tra*elled in the o"eration 0 1he e..ecti*eness o. the la#out can thus be calculated .rom6 E..ecti*eness o. la#out L M+i' ,i' for all i - ' 7here6 0 +i' . the flow in loads or 'ourneys per period of time from wor" centre i to wor" centre ' 0 ,i' . the distance between wor" centre i and wor" centre '. 0 1he lo$er the e..ecti*eness score, the better the la#out

7 /7

Slack, Chambers and Johnston, Operations Management, 6th Edition, Nigel Slack, Stuart Chambers, and Robert Johnston 2010

7 /B

. relationship chart

C,+E A E , G H C%,SENESS Absolutel# necessar# Es"eciall# im"ortant -m"ortant ,rdinar# closeness Gnim"ortant Gndesirable

+E!AR1EEN1

Eetrolog# Electronic testing Anal#sis Gltrasonic testing &atigue testing -m"act testing

E E

A G , ,

, G G

H G

7 /B

Slack, Chambers and Johnston, Operations Management, 6th Edition, Nigel Slack, Stuart Chambers, and Robert Johnston 2010

7 /D

+etailed design in cell layout

-n cell la#out design a .unctional la#out is di*ided into cells, each o. $hich has the resources to "rocess a ?.amil#> o. "arts

;a< 1 1 2 9 / 3 : 6 7 B 9 9 9 9 9 9 9 9 9 9 9 9 9 9 9 Com"onent .amilies 2 / 3 : 6 7 9 9 Eachines 9 9 ;a< B 9 1 69 / B 2 : 7 / 39 Com"onent .amilies 6 B : 2 3 1 9 9 9 9 9 9 9 9 9 9 9 9 9 9 9 9 9 9 9 B

Eachines

!roduction .lo$ anal#sis to allocate machines to cells

Slack, Chambers and Johnston, Operations Management, 6th Edition, Nigel Slack, Stuart Chambers, and Robert Johnston 2010

7 /D

7 30

+etailed design of product layout 0 Rather than ?$here to "lace $hat>, "roduct la#out is concerned more $ith ?$hat to "lace $here> 0 %ocations are .re5uentl# decided u"on and then $ork tasks are allocated to each location 0 &or e2am"le, it ma# ha*e been decided that .our stations are needed to make com"uter cases 0 1he decision then is $hich o. the tasks that go into making the cases should be allocated to each station 0 1he main "roduct la#out decisions are as .ollo$s6

C 7hat c#cle time is needed8 C 9o$ man# stages are needed ;number o. $orkstations<8 C 9o$ should the task@time *ariation be dealt $ith8 C 9o$ should the la#out be balanced8

Slack, Chambers and Johnston, Operations Management, 6th Edition, Nigel Slack, Stuart Chambers, and Robert Johnston 2010

7 30

7 31

The cycle ti#e of product layouts

0 Cycle ti#e is the ti#e between co#pleted products% "ieces o. in.ormation or customers emerging .rom the "rocess 0 -t is calculated b# considering the likel# demand .or the "roducts or ser*ices o*er a "eriod and the amount o. "roduction time a*ailable in that "eriod

'or$ed E0a#ple

Su""ose the regional back@o..ice o"eration o. a large bank is designing an o"eration $hich $ill "rocess its mortgage a""lications 1he number o. a""lications to be "rocessed is 160 "er $eek and the time a*ailable to "rocess the a""lications is 30 hours "er $eek

C#cle time .or the la#out L 1ime A*ailable L No 1o be "rocessed 30 L 160 1 3 L 1: minutes

So the bank>s la#out must be ca"able o. "rocessing a com"leted a""lication once e*er# 1: minutes

Slack, Chambers and Johnston, Operations Management, 6th Edition, Nigel Slack, Stuart Chambers, and Robert Johnston 2010

7 31

7 32

:u#ber of stages ; wor$stations ; :o. of wor$ers

0 1he ne2t decision concerns the number o. stages in the la#out and de"ends on the c#cle time re5uired and the total 5uantit# o. $ork in*ol*ed ;total wor$ content7 in "roducing the "roduct or ser*ice 0 The larger the total wor$ content and the smaller the re5uired c#cle time, the more stages $ill be necessar# 'or$ed E0a#ple

Su""ose the bank in the "re*ious e2am"le calculated that the a*erage total $ork content o. "rocessing a mortgage a""lication is 60 minutes 1he number o. stages needed to "roduce a "rocessed a""lication e*er# 1: minutes can be calculated as .ollo$s6

Number o. stages L total $ork content re5uired c#cle time L 60 minutes L 1: minutes 3 stages

7 32

Slack, Chambers and Johnston, Operations Management, 6th Edition, Nigel Slack, Stuart Chambers, and Robert Johnston 2010

7 3/

4alancing wor$-ti#e allocation

0 ,ne o. the most im"ortant design decisions in "roduct la#out is that o. line balancing. 0 5n the mortgage@"rocessing e2am"le $e ha*e assumed that the 1: minutes o. $ork content are allocated e5uall# to the .our stations 0 1his is nearl# al$a#s im"ossible to achie*e in "ractice and some imbalance in the $ork allocation results

'or$ed E0a#ple

-n &igure o*erlea. the $ork allocations in a .our@stage line are illustrated 1he total amount o. time in*ested in "roducing each "roduct or ser*ice is .our times the c#cle time because, .or e*er# unit "roduced, all .our stages ha*e been $orking .or the c#cle time 7hen the $ork is e5uall# allocated bet$een the stages, the total time in*ested in each "roduct or ser*ice "roduced is 3 N 2 : L 10 minutes 9o$e*er, $hen $ork is une5uall# allocated, as illustrated, the time in*ested is / 0 N 3 L 12 minutes, i e 2 0 minutes o. time, 16 67 "er cent o. the total, is $asted

Slack, Chambers and Johnston, Operations Management, 6th Edition, Nigel Slack, Stuart Chambers, and Robert Johnston 2010

7 3/

7 33

4alancing loss is that proportion of the ti#e in!ested in processing the product or ser!ice which is not used producti!ely

An ideal ?balance> $here $ork is allocated e5uall# bet$een the stages

/ 2: 2 %oad 1: 1 0: 0 1 2 / 3 C#cle time L 2 : mins 7ork allocated to stage

Stage

7 33

Slack, Chambers and Johnston, Operations Management, 6th Edition, Nigel Slack, Stuart Chambers, and Robert Johnston 2010

7 3:

4alancing loss is that proportion of the ti#e in!ested in processing the product or ser!ice which is not used producti!ely 6Continued7

=ut i. $ork is not e5uall# allocated, the c#cle time $ill increase and ?balancing losses> $ill occur

/: / 2: 2 %oad 1: 1 0: 0

C#cle time L / 0 mins

7ork allocated to stage

-dle time

6 2 2< s s 4 o l 0 O ;/ ncing < a : l a 2 b ting /04 ; a l u O c < l Ca 42/ 0 / ; L e m i t e l mins -d 0 2 e l L c#c 20 e*er# /0 L g N n i 3 c =alan 67 6 1 0 L loss 67P 6 1 L

3

Slack, Chambers and Johnston, Operations Management, 6th Edition, Nigel Slack, Stuart Chambers, and Robert Johnston 2010

Stage

7 3:

7 36

4alancing techni"ues

0 . precedence diagra# is used to assist in balancing wor$ti#e allocation. 0 This is a representation of the ordering of the elements which compose the total $ork content o. the "roduct or ser*ice 0 1his general a""roach is to allocate elements .rom the "recedence diagram to the .irst stage, starting .rom the le.t, in order o. the columns until the $ork allocated to the stage is as close to, but less than, the c#cle time 7hen that stage is as .ull o. $ork as is "ossible $ithout e2ceeding the c#cle time, mo*e on to the ne2t stage, and so on, until all the $ork elements are allocated, taking into account "recedence re5uirements 0 9euristic rules are used to decide $hich task to select .or allocation6

C Sim"l# choose the largest that $ill ?.it> into the time remaining at the stage C Choose the element $ith the most ?.ollo$ers>6 that is the highest number o. elements $hich can onl# be allocated $hen that element has been allocated

Slack, Chambers and Johnston, Operations Management, 6th Edition, Nigel Slack, Stuart Chambers, and Robert Johnston 2010

7 36

7 37

4alancing techni"ues

'or$ed E0a#ple Qarlstad Qakes ;QQ< is a manu.acturer o. s"ecialit# cakes, $hich has recentl# obtained a contract to su""l# a ma'or su"ermarket chain $ith a s"ecialit# cake in the sha"e o. a s"ace rocket -t has been decided that the *olumes re5uired b# the su"ermarket $arrant a s"ecial "roduction line to "er.orm the .inishing, decorating and "acking o. the cake 1his line $ould ha*e to carr# out the elements sho$n in .igure o*erlea., $hich also sho$s the "recedence diagram .or the total 'ob 1he initial order .rom the su"ermarket is .or :,000 cakes a $eek and the number o. hours $orked b# the .actor# is 30 "er $eek &rom this6

1he re5uired c#cle time L 30 hrs N 60 mins :,000 L 0 3B minutes

1he re5uired number o. stages L 1 6B min ;the total $ork content< L / : stages 0 3B min ;the re5uired c#cle time<

1his means .our stages are re5uired

7 37

Slack, Chambers and Johnston, Operations Management, 6th Edition, Nigel Slack, Stuart Chambers, and Robert Johnston 2010

7 3B

Precedence diagra# for Karlstad Ca$es

0 17 mins

0 /0 mins

0 2: mins

0 0: mins

0 2: mins

a

0 12 mins

c

0 /6 mins

g

0 10 mins

h

0 0B mins

7 3B

Slack, Chambers and Johnston, Operations Management, 6th Edition, Nigel Slack, Stuart Chambers, and Robert Johnston 2010

7 3D

Ele#ent listing for Karlstad Ca$es - e0a#ple

Element Element Element Element Element Element Element Element Element

a b c d e . g h i

+e@tin and trim Resha"e $ith o..@cuts Clad in almond .ondant Clad in $hite .ondant +ecorate, red icing +ecorate, green icing +ecorate, blue icing A..i2 trans.ers 1rans.er to base and "ack

0 12 mins 0 /0 mins 0 /6 mins 0 2: mins 0 17 mins 0 0: mins 0 10 mins 0 0B mins 0 2: mins

1otal $ork content L 1 6B mins

7 3D

Slack, Chambers and Johnston, Operations Management, 6th Edition, Nigel Slack, Stuart Chambers, and Robert Johnston 2010

7 :0

.llocation of ele#ents and balancing for Karlstad Ca$es

Stage 1 0 /0 mins a 0 12 mins b c 0 /6 mins Stage 2 Stage / 0 17 mins e 0 2: mins d 0 0: mins . g 0 10 mins h 0 0B mins 0 2: mins i Stage 3

<.B <.A C#cle time L 0 3B mins <.@ <.? <.> <.= < = > ? @

-dle time L ;0 3B 4 0 32< O ;0 3B 4 0 /6< O ;0 3B 4 0 32< e*er# L 0 23 mins c#cle !ro"ortion o. 0 23 idle time "er L 3 N 0 3B c#cle

L 12 :P

7 :0

Slack, Chambers and Johnston, Operations Management, 6th Edition, Nigel Slack, Stuart Chambers, and Robert Johnston 2010

7 :1

,Long and thin& !ersus ,short and fat& layouts

A 60 minute task $ith a re5uired c#cle time o. 1: minutes

cess o r " hin t @ g n o

=A =A =A =A

1 e*er# 1: minutes

60 ?< ?<

1 e*er# 1: minutes

60

?<

?<

1 e*er# 1: minutes

60

60

at . @ t r Sho

es c o r "

7 :1

Slack, Chambers and Johnston, Operations Management, 6th Edition, Nigel Slack, Stuart Chambers, and Robert Johnston 2010

7 :2

Long and thin !ersus short and fat

0%ong and short describes the number o. stages 0&at and thin describes the amount o. $ork at each stage

Ad*antages o. long@thin "rocesses controlled .lo$ sim"le materials handling lo$er ca"ital re5uirement ;no du"lication< greater e..icienc# higher s"ace utili(ation

Ad*antages o. short@.at "rocesses higher mi2 .le2ibilit# higher *olume .le2ibilit# greater robustness less monotonous higher o$nershi"

7 :2

Slack, Chambers and Johnston, Operations Management, 6th Edition, Nigel Slack, Stuart Chambers, and Robert Johnston 2010

7 :/

Calculating the re"uired cycle ti#e

=<< @C< #ins @.C #ins

+eciding how #any staff 6or stages7 are needed

&orecast +emands +uring the !eriod ;A< A*ailabilit# o. !roducti*e 1ime ;=< C#cle 1ime ;CL=)A<

7ork Content o. the 1ask ;+< C#cle 1ime Re5uired ;C< Number o. Sta.. ;+)C<

AA #ins @.C #ins ==.@B 6=>7

7 :/

Slack, Chambers and Johnston, Operations Management, 6th Edition, Nigel Slack, Stuart Chambers, and Robert Johnston 2010

7 :3

5ndi!idual .ssign#ent >

0 7eldon Case Stud#, Cha"ter 7 "age 20/ +ue B A"ril 2013 1he assignment should be handed in as a hard co"#

7 :3

Slack, Chambers and Johnston, Operations Management, 6th Edition, Nigel Slack, Stuart Chambers, and Robert Johnston 2010

Вам также может понравиться

- Lecture 1. Workshop ManagementДокумент44 страницыLecture 1. Workshop ManagementDerrick Maatla MoadiОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- Introduction To Pneumatics and Hydraulics: Mr. M.MoadiДокумент65 страницIntroduction To Pneumatics and Hydraulics: Mr. M.MoadiDerrick Maatla MoadiОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Gaborone Institute of Professional StudiesДокумент2 страницыGaborone Institute of Professional StudiesDerrick Maatla MoadiОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Asset Management Training 03-08-19Документ32 страницыAsset Management Training 03-08-19Derrick Maatla MoadiОценок пока нет

- Maths Mid Year Exam First YearsДокумент2 страницыMaths Mid Year Exam First YearsDerrick Maatla MoadiОценок пока нет

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Physics I Class 12: Uniform Circular MotionДокумент20 страницPhysics I Class 12: Uniform Circular MotionDerrick Maatla MoadiОценок пока нет

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Introduction To Pneumatics: Mr. MoadiДокумент38 страницIntroduction To Pneumatics: Mr. MoadiDerrick Maatla MoadiОценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Systems and ControlДокумент16 страницSystems and ControlDerrick Maatla MoadiОценок пока нет

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Statics: ES 113 Mr. MoadiДокумент49 страницStatics: ES 113 Mr. MoadiDerrick Maatla MoadiОценок пока нет

- Business StructuresДокумент22 страницыBusiness StructuresDerrick Maatla MoadiОценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Costing and Pricing of Goods and Services: Mr. M. MoadiДокумент28 страницCosting and Pricing of Goods and Services: Mr. M. MoadiDerrick Maatla MoadiОценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Physics Double (Bgcse) February TestДокумент9 страницPhysics Double (Bgcse) February TestDerrick Maatla MoadiОценок пока нет

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- July Form4 Physics Test Fixed PDFДокумент16 страницJuly Form4 Physics Test Fixed PDFDerrick Maatla MoadiОценок пока нет

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- What Is A RadicalДокумент2 страницыWhat Is A RadicalDerrick Maatla MoadiОценок пока нет

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Laplace TransformДокумент11 страницLaplace TransformDerrick Maatla MoadiОценок пока нет

- IntercoolingДокумент13 страницIntercoolingDerrick Maatla MoadiОценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Compression With IntercoolingДокумент8 страницCompression With IntercoolingDerrick Maatla MoadiОценок пока нет

- Test Signal Unit F (T) (T 0) F(S) General Comments Advantages DisadvantagesДокумент1 страницаTest Signal Unit F (T) (T 0) F(S) General Comments Advantages DisadvantagesDerrick Maatla MoadiОценок пока нет

- Lecture 9-10 - Frequency Response MethodsДокумент68 страницLecture 9-10 - Frequency Response MethodsDerrick Maatla Moadi100% (1)

- Solution Manual For Labor Relations Development Structure Process 12th Edition Fossum 0077862473 9780077862473Документ16 страницSolution Manual For Labor Relations Development Structure Process 12th Edition Fossum 0077862473 9780077862473savannahzavalaxodtfznisq100% (27)

- PDS Air CompressorДокумент1 страницаPDS Air Compressordhavalesh1Оценок пока нет

- Goal of The Firm PDFДокумент4 страницыGoal of The Firm PDFSandyОценок пока нет

- Forecasting and Demand Management PDFДокумент39 страницForecasting and Demand Management PDFKazi Ajwad AhmedОценок пока нет

- MAYA1010 EnglishДокумент30 страницMAYA1010 EnglishjailsondelimaОценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Technical BidДокумент64 страницыTechnical Bidjhon smithОценок пока нет

- 1849 1862 Statutes at Large 601-779Документ200 страниц1849 1862 Statutes at Large 601-779ncwazzyОценок пока нет

- Calio Z: Type Series BookletДокумент24 страницыCalio Z: Type Series BookletDan PopescuОценок пока нет

- Event Management (MAX FIT)Документ12 страницEvent Management (MAX FIT)vkrish6Оценок пока нет

- Cma Inter GR 1 Financial Accounting Ebook June 2021 OnwardsДокумент358 страницCma Inter GR 1 Financial Accounting Ebook June 2021 OnwardsSarath KumarОценок пока нет

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- 9MFY18 MylanДокумент94 страницы9MFY18 MylanRahul GautamОценок пока нет

- SC Circular Re BP 22 Docket FeeДокумент2 страницыSC Circular Re BP 22 Docket FeeBenjamin HaysОценок пока нет

- FLIPKART MayankДокумент65 страницFLIPKART MayankNeeraj DwivediОценок пока нет

- 173089Документ22 страницы173089aiabbasi9615100% (1)

- Bank Soal LettersДокумент17 страницBank Soal Lettersderoo_wahidahОценок пока нет

- Analyzing Sri Lankan Ceramic IndustryДокумент18 страницAnalyzing Sri Lankan Ceramic Industryrasithapradeep50% (4)

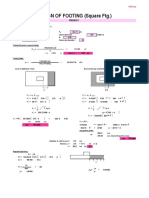

- Design of Footing (Square FTG.) : M Say, L 3.75Документ2 страницыDesign of Footing (Square FTG.) : M Say, L 3.75victoriaОценок пока нет

- AMC Mining Brochure (A4 LR)Документ2 страницыAMC Mining Brochure (A4 LR)Bandung WestОценок пока нет

- Objectives in DraftingДокумент1 страницаObjectives in Draftingshannejanoras03Оценок пока нет

- The Space Planning Data Cycle With Dynamo - Dynamo BIM PDFДокумент6 страницThe Space Planning Data Cycle With Dynamo - Dynamo BIM PDFLuiz PessôaОценок пока нет

- Mosaic Charter School TIS Update 12202019Документ73 страницыMosaic Charter School TIS Update 12202019Brandon AtchleyОценок пока нет

- Response LTR 13 330 VielmettiДокумент2 страницыResponse LTR 13 330 VielmettiAnn Arbor Government DocumentsОценок пока нет

- Account Statement From 1 Oct 2018 To 15 Mar 2019: TXN Date Value Date Description Ref No./Cheque No. Debit Credit BalanceДокумент8 страницAccount Statement From 1 Oct 2018 To 15 Mar 2019: TXN Date Value Date Description Ref No./Cheque No. Debit Credit BalancerohantОценок пока нет

- Wind Turbines Fundamentals Technologies Application Economics 2nd EditionДокумент3 страницыWind Turbines Fundamentals Technologies Application Economics 2nd Editionhafidztampan0% (1)

- Course Outline ReviewerДокумент12 страницCourse Outline Reviewerjmd.besanaОценок пока нет

- Why Is Inventory Turnover Important?: ... It Measures How Hard Your Inventory Investment Is WorkingДокумент6 страницWhy Is Inventory Turnover Important?: ... It Measures How Hard Your Inventory Investment Is WorkingabhiОценок пока нет

- Report - Summary - Group 3 - MKT201Документ4 страницыReport - Summary - Group 3 - MKT201Long Nguyễn HảiОценок пока нет

- Borang Pengesahan PembetulanДокумент7 страницBorang Pengesahan PembetulanARMIZAWANI BINTI MOHAMED BUANG (KMPH)Оценок пока нет

- Orange Stripe # 57 EnglishДокумент2 страницыOrange Stripe # 57 EnglishShahid RazaОценок пока нет

- ITMC (International Transmission Maintenance Center)Документ8 страницITMC (International Transmission Maintenance Center)akilaamaОценок пока нет