Академический Документы

Профессиональный Документы

Культура Документы

Chapter 2 Size Reduction 01

Загружено:

Azwin AhmadИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Chapter 2 Size Reduction 01

Загружено:

Azwin AhmadАвторское право:

Доступные форматы

PREPARED BY : AZWIN BT AHMAD

OBJECTIVE

Define size reduction process

State the important of size reduction process

Explain the forces involved in size reduction process, (compressive,

impact & shear)

Calculate the ratio for the size reduction operation

Estimate energy requirement for size reduction by using Rittingers,

Kicks & Bond law

Differentiate and explain the disintegration method of fibrous

materials

Identify and elaborate suitable equipment for different types of

food

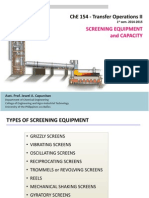

Understanding screening process and identify and elaborate

screening process

Pre-Test 2

State whether these statement are true(T) or false(F)

QUESTION ANSWER

1.Communition have the same meaning with size reduction

2.Shear force is used for fine grinding.

3.Energy use in size reduction process in unit horsepower,HP.

4. The force use in hammer mill is compressive force

5. The force use in crushing rolls is impact force

6. Reduction ratio , NP is the feed size over the final product size

7. Kicks law is used for fine grinding

8. A screen is a surface containing a number of equally size aperture

9. Screening is the unit operation in which a separated into two or

more fraction by passing over a tube

10. Small capacity plane screens are call fraction

DEFINITION OF SIZE REDUCTION

The size reduction or comminution is a

unit operation in which the average size of

solid pieces of food is reduced by

application of grading, compression or

impact forces

THE IMPORTANT OF SIZE REDUCTION

Size reduction may aid the extraction of a

desired constituent from a composition

structure

A decrease in particle size of a

material leads to an increase in

surface of solid. This increase in

surface is of assistance in many

rate processes

Intimate mixing or blending is usually

easier with smaller size range of

particles, an important consideration

in the production of formulated

Reduction to a definite size

range may be a specific

product requirement

FORCES INVOLVED IN SIZE REDUCTION

used for the coarse crushing of hard materials

Machine : Crushing rolls

COMPRESSIVE

can be regarded as general purpose forces and are used for

coarse, medium and fine grinding of a variety of food

materials

Machine : Hammer mill

IMPACT

for fine grinding

Machine : Disc attrition mill

SHEAR

DISINTEGRATION METHODS OF

FIBROUS MATERIALS

CUTTING/

SLICING

CUBING

SHREDING

PULPING

CUTTING / SLICING

Sliced fruits are much in demand as a desert dish.

They present an attractive appearance, the portions

produced being of convenient size for eating.

Rotary cutting knives are usually employed, the

knives being set to cut the material being presented

to them often on a vibrating belt into parallel slices or

of the desired thickness.

In other fruit slicing operations the fruit is forced

through a tube containing stationary knife edges

arranged radially along the length of the tube.

This type of assembly can produce decored, wedge

shaped sections from firmer fruits such as pineapple.

SLICING EQUIPMENT

CUBING

Cubing is the cutting of materials into cubes that

usually follows a preliminary slicing operation which

produces slices of the desired thickness.

These slices are then fed onto a conveyer belt

containing a series of studs which hold the slices in

position as the belt carries them against the rotary

knife assembly which cuts them into strips.

The strips then pass through a further cutting zone at

right to the stripping section. This produces the

required cube. Dicing Is a method of food preparation

in which the food item is cut into small blocks or dice.

CUBING EQUIPMENT

SHREDDING

Shredding is torn into small fragments, the

average size of the pieces depending on the

type of machine and on residence time in the

action zone.

Shredding often precedes dehydration, the

increase in surface aiding the rate process.

Hammer mills are commonly used as

shredders

PULPING

Pulping is widely used in the processing of lower grade fruits

separated during grading.

The fruit, which is edible but unacceptable for whole fruit

processing, may be used in jam manufacture.

A combination of pulping and sieving is used with many fruits and

vegetables.

A common equipment used for pulping consists of a cylindrical

perforated screen containing high speed rotating brushes.

Material is fed to the inside of the cylinder, the brushes forcing

pulped material through the perforations.

EQUIPMENT FOR SIZE REDUCTION

Hammer

mill

Crushing

rolls

Ball

miller

HAMMER MILL

A hammer mill is essentially a steel

drum containing a vertical or

horizontal rotating shaft or drum

on which hammers are mounted.

The hammers are free to swing on

the ends of the cross, or fixed to

the central rotor. The rotor is spin

at a high speed inside the drum

while material is fed into a feed

hopper.

The material is impacted by the

hammer bars and is thereby

shredded and expelled through

screens in the drum of a selected

size.

Hammer mill apple shredder for

juicing.

CRUSHING ROLLS

Two or more heavy steel

cylinders revolve towards

each other.

Particles of feed are nipped

and pulled through the

rolls, experiencing a

compressive force with

crushes them.

In some machines a

differential speed is

maintained between rolls

and shearing force also

arise.

BALL MILLER

A ball mill, a type of grinder, is a cylindrical

device used in grinding (or mixing) materials

like ores, chemicals, ceramic raw materials

and paints.

Ball mills rotate around a horizontal axis,

partially filled with the material to be ground

plus the grinding medium.

Different materials are used as media,

including ceramic balls, flint pebbles and

stainless steel balls. An internal cascading

effect reduces the material to a fine powder.

Industrial ball mills can operate continuously,

fed at one end and discharged at the other

end. Large to medium-sized ball mills are

mechanically rotated on their axis, but small

ones normally consist of a cylindrical capped

container that sits on two drive shafts .

The grinding works on the principle of critical

speed. The critical speed can be understood

as that speed after which the steel balls

(which are responsible for the grinding of

particles) start rotating along the direction of

the cylindrical device; thus causing no further

grinding.

To be continue

Вам также может понравиться

- Unit 3 Size ReductionДокумент33 страницыUnit 3 Size ReductionM.sathishkumarОценок пока нет

- Rice Milling Process ExplainedДокумент4 страницыRice Milling Process ExplainedAhmed zia tahir100% (1)

- Sri Lankan Organic Waste RecyclingДокумент22 страницыSri Lankan Organic Waste Recyclingmnajeli100% (1)

- Theory 4-2 ClarificationДокумент22 страницыTheory 4-2 ClarificationRaikaОценок пока нет

- PT - 241properties and Characteristics of ParticlesДокумент49 страницPT - 241properties and Characteristics of ParticlesAli HasSsan100% (1)

- Food TechnologyДокумент41 страницаFood Technologydynav100% (2)

- Che 154 Lecture 3b Screening EquipmentДокумент34 страницыChe 154 Lecture 3b Screening EquipmentAiza CabolesОценок пока нет

- Particle Size ReductionДокумент23 страницыParticle Size Reductionverygoodbrother100% (1)

- Design and Development of Turmeric Polishing MachineДокумент4 страницыDesign and Development of Turmeric Polishing MachineIJMERОценок пока нет

- 426 ScreeningДокумент53 страницы426 ScreeningmseaОценок пока нет

- The DIRK PFA Classification Products: The Design of DIRK POZZOCRETE Air ClassifiersДокумент15 страницThe DIRK PFA Classification Products: The Design of DIRK POZZOCRETE Air ClassifiersAnkit DwivediОценок пока нет

- Puddlers-1 Tillage ImplementДокумент21 страницаPuddlers-1 Tillage Implementmanikandan.v0% (1)

- Group 2 analyzes size reduction equipment used in processing materialsДокумент2 страницыGroup 2 analyzes size reduction equipment used in processing materialsOvianti SiTompulОценок пока нет

- Rice Milling Systems ExplainedДокумент6 страницRice Milling Systems ExplainedTheresa CostalesОценок пока нет

- vVIBRAX - SIEBTECHNIK GMBH PDFДокумент32 страницыvVIBRAX - SIEBTECHNIK GMBH PDFzamburittiОценок пока нет

- 07 Mixing - Food Process Engineering TechnologyДокумент25 страниц07 Mixing - Food Process Engineering Technologyecky_moury6742Оценок пока нет

- Energy Conservation Analysis in Biscuit IndustryДокумент7 страницEnergy Conservation Analysis in Biscuit IndustryijaertОценок пока нет

- Paddy Rice MillingДокумент14 страницPaddy Rice Millingnavdeepjindal680% (1)

- Reason For Processing Farm ProduceДокумент2 страницыReason For Processing Farm ProduceIsraelОценок пока нет

- Sensory Evaluation Training at CFTRIДокумент2 страницыSensory Evaluation Training at CFTRIAida DadkhahОценок пока нет

- Basics of Die and Press Tool AssemblyДокумент6 страницBasics of Die and Press Tool Assemblyshakthimuthu narayananОценок пока нет

- Surface Tension in Food Analysis - 17FET113Документ15 страницSurface Tension in Food Analysis - 17FET113Sagar BadnakheОценок пока нет

- PACKAGED DRINKING WATERДокумент9 страницPACKAGED DRINKING WATERAditya GhatgeОценок пока нет

- HARVESTING AND THRESHING MACHINERYДокумент48 страницHARVESTING AND THRESHING MACHINERYAnalinda SurilОценок пока нет

- Particle Technology: Size Reduction EquipmentsДокумент7 страницParticle Technology: Size Reduction EquipmentsMubarak AhmadОценок пока нет

- Static Fluid Bed Dryers, Vibrating Fluid Bed Dryers and Exhaust TechnologyДокумент8 страницStatic Fluid Bed Dryers, Vibrating Fluid Bed Dryers and Exhaust TechnologyOscar Alvitez DominguezОценок пока нет

- # Unit Operations in Food Processing NotesДокумент90 страниц# Unit Operations in Food Processing NotesManmath SontakkeОценок пока нет

- Wheat Milling and Baking Technology Foodkida-1Документ8 страницWheat Milling and Baking Technology Foodkida-1Sumit KumarОценок пока нет

- The Basics of ScreeningДокумент41 страницаThe Basics of Screeningالمشري بدوОценок пока нет

- Foam Mat Drying TechniqueДокумент22 страницыFoam Mat Drying TechniqueMariah SadafОценок пока нет

- Sugar Mill HiДокумент46 страницSugar Mill HiSaravanapriya KarthikОценок пока нет

- Food ProcessingДокумент51 страницаFood Processingpradip_kumarОценок пока нет

- Food AdulterationДокумент14 страницFood AdulterationAnmol YadavОценок пока нет

- Size Reduction Equipment Types: Crushers, Grinders, Ultrafine Grinders & Cutting MachinesДокумент2 страницыSize Reduction Equipment Types: Crushers, Grinders, Ultrafine Grinders & Cutting MachinesGaurav Sharma100% (1)

- Mechanical OPerationДокумент10 страницMechanical OPerationAnshika RajputОценок пока нет

- Course Syllabus in LEA 212Документ6 страницCourse Syllabus in LEA 212Jose Richard GirayОценок пока нет

- Unit Operations in Food ProcessingДокумент19 страницUnit Operations in Food ProcessingGup Rat0% (1)

- Design Optimization For Grey Water TreatmentДокумент21 страницаDesign Optimization For Grey Water TreatmentIJRASETPublicationsОценок пока нет

- Seed Cleaning MachineДокумент2 страницыSeed Cleaning MachineDidier SanonОценок пока нет

- Design Hammer MillsДокумент12 страницDesign Hammer MillsSaqib ChandОценок пока нет

- Process Equipment Design Materials Selection 7-02-13Документ91 страницаProcess Equipment Design Materials Selection 7-02-13May TampusОценок пока нет

- Size Reduction and Screening of SolidsДокумент11 страницSize Reduction and Screening of SolidsLeah Cunningham100% (1)

- Blanching CoconutДокумент1 страницаBlanching CoconutAndriyana Miyano SantiОценок пока нет

- Manufacturing Process of A Cricket BatДокумент2 страницыManufacturing Process of A Cricket Batarjun_niroulaОценок пока нет

- Elcan Vibratory Screeners and Separators Brochure PDFДокумент8 страницElcan Vibratory Screeners and Separators Brochure PDFJitendra Kadam0% (1)

- Lecture - 4 Mixing PDFДокумент36 страницLecture - 4 Mixing PDFKazi Nafis UllahОценок пока нет

- Non Thermal Food ProcessingДокумент33 страницыNon Thermal Food ProcessingsantoshОценок пока нет

- Rice MachinesДокумент3 страницыRice MachinesitsataurОценок пока нет

- Factors affecting food deterioration and shelf lifeДокумент74 страницыFactors affecting food deterioration and shelf lifeSweta Priyadarshini100% (1)

- FAO Report On GROUNDNUT OIL PDFДокумент16 страницFAO Report On GROUNDNUT OIL PDFVIRTU 8 HR & IT LLPОценок пока нет

- Rice Mill-2 PDFДокумент7 страницRice Mill-2 PDFPriyal Savla100% (1)

- Buffalo Milk Vs Cow MilkДокумент3 страницыBuffalo Milk Vs Cow MilktrajrajОценок пока нет

- BeveragesДокумент105 страницBeveragesShubham MannaОценок пока нет

- Powder 2 (Lec 11)Документ23 страницыPowder 2 (Lec 11)سلام شاكر حميد جميل 6506Оценок пока нет

- Lab 4 - Parboiling Rice MillingДокумент4 страницыLab 4 - Parboiling Rice MillingKishoree Krishna Kumaree100% (1)

- Unit 11 Softy and Novelties - Definition, Composition, Legal Standards and Method of ManufactureДокумент15 страницUnit 11 Softy and Novelties - Definition, Composition, Legal Standards and Method of ManufactureRonak RawatОценок пока нет

- Feed MixerДокумент7 страницFeed MixerEijay ReyesОценок пока нет

- ParboilingДокумент7 страницParboilingAmrish rajОценок пока нет

- VinitaДокумент20 страницVinitayogesh kumarОценок пока нет

- A Presentation On Size Reduction ProcessДокумент19 страницA Presentation On Size Reduction Processyogesh kumarОценок пока нет

- Cover Page: CMS Analyzers & Chips PAC Single Gas Monitors Draeger-Tubes & Accuro PumpsДокумент8 страницCover Page: CMS Analyzers & Chips PAC Single Gas Monitors Draeger-Tubes & Accuro PumpsChetanОценок пока нет

- APTESДокумент8 страницAPTESmarianaОценок пока нет

- 3 Alkyne Problem Set MOCДокумент13 страниц3 Alkyne Problem Set MOCMuhammad barakatОценок пока нет

- Chemical Bonding and Molecular Structure - Lecture NotesДокумент51 страницаChemical Bonding and Molecular Structure - Lecture NotesEdith EatonОценок пока нет

- The Periodic LawДокумент33 страницыThe Periodic Lawviolaplayer09Оценок пока нет

- Fundamental Understanding of Carbon Black Feedstock (CBFS)Документ31 страницаFundamental Understanding of Carbon Black Feedstock (CBFS)SDawОценок пока нет

- Chemical EquilibriaДокумент5 страницChemical Equilibriaroku shinОценок пока нет

- Alcohol, Ether & Phenol: Chapter Practice ProblemsДокумент6 страницAlcohol, Ether & Phenol: Chapter Practice ProblemsAtharva GanjuОценок пока нет

- Physical Science Lesson 7Документ17 страницPhysical Science Lesson 7GLADYS SARAELОценок пока нет

- Baking SodaДокумент1 страницаBaking SodaSevenОценок пока нет

- Water's Unique PropertiesДокумент5 страницWater's Unique PropertiesMuhamad Izzuddin Abd HalimОценок пока нет

- Corrosion Control Che 311Документ43 страницыCorrosion Control Che 311Jaison JoseОценок пока нет

- SAMICAL - Unit Process and Unit OperationsДокумент7 страницSAMICAL - Unit Process and Unit OperationsSameer DiwanОценок пока нет

- FSX 414 Weld Wire PDFДокумент1 страницаFSX 414 Weld Wire PDFJ. BangjakОценок пока нет

- Le Chatelier's PrincipleSTДокумент4 страницыLe Chatelier's PrincipleSTDerek JohnsonОценок пока нет

- Ceravalve - Ceramic Lined Ball ValvesДокумент6 страницCeravalve - Ceramic Lined Ball Valvesprihartono_diasОценок пока нет

- Graphing Gas Collection RatesДокумент8 страницGraphing Gas Collection RatesMike GarryОценок пока нет

- 05chemicalДокумент2 страницы05chemicaldalton2004Оценок пока нет

- G10 Chemistry BookletДокумент41 страницаG10 Chemistry BookletMemory SitambuliОценок пока нет

- CH 603 - Coordination Chemistry: Bonding, Spectra and ReactionsДокумент6 страницCH 603 - Coordination Chemistry: Bonding, Spectra and ReactionsbudhladaОценок пока нет

- CH 16Документ2 страницыCH 16onlydlonlyОценок пока нет

- Orange Book Approved Drug Products With Therapeutic Equivalence EvaluationsДокумент280 страницOrange Book Approved Drug Products With Therapeutic Equivalence EvaluationspruthvishОценок пока нет

- Uses of Urea: PrillsДокумент14 страницUses of Urea: PrillsRegita FebriantiОценок пока нет

- 11 HW ChemistryДокумент6 страниц11 HW ChemistryJ BalanОценок пока нет

- Rigid-Rod b-Barrels as Lipocalin ModelsДокумент11 страницRigid-Rod b-Barrels as Lipocalin ModelsThina Tina StaОценок пока нет

- Achem ProblemsДокумент2 страницыAchem Problemsmichsantos100% (1)

- Research Paper in PH IndicatorДокумент11 страницResearch Paper in PH IndicatorKhristine Khate Odiaman MendezОценок пока нет

- Ammonium Chloride Corrossion in RefineryДокумент12 страницAmmonium Chloride Corrossion in RefinerySudarshan GopalОценок пока нет

- 2023 CHEM P6 ID TableДокумент2 страницы2023 CHEM P6 ID TableHendry RaoОценок пока нет

- Compactrol Rev. 02Документ2 страницыCompactrol Rev. 02abdelaziz_ismail685662Оценок пока нет