Академический Документы

Профессиональный Документы

Культура Документы

Porcelains Used in Metal Ceramics / Orthodontic Courses by Indian Dental Academy

Загружено:

indian dental academyОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Porcelains Used in Metal Ceramics / Orthodontic Courses by Indian Dental Academy

Загружено:

indian dental academyАвторское право:

Доступные форматы

PORCELAINS USED IN METAL

CERAMICS.

INDIAN DENTAL ACADEMY

Leader in continuing dental education

www.indiandentalacademy.com

www.indiandentalacademy.com

INTRODUCTION

Metal ceramic restorations

combine the strength and

accuracy of cast metal with the

esthetics of porcelain.

Indian dental academy

www.indiandentalacademy.com

Metal ceramic restoration:

"a fixed restoration that

employs a metal substructure

on which a ceramic veneer is

fused" (Glossary of

Prosthodontic Terms, 1987).

Indian dental academy

www.indiandentalacademy.com

A 13- unit metal-ceramic

restoration.

www.indiandentalacademy.com

HISTORY/ DEVELOPMENT OF

CERAMICS.

PROPERTIES OF FUSED

PORCELAIN.

TERMINOLOGY

CHEMISTRY & COMPOSITION

CLASSIFICATION OF DENTAL

CERAMICS.

www.indiandentalacademy.com

METAL CERAMIC SUBSTRUCTURE

BONDING BETWEEN THE METAL

DESIGN & PORCELAIN

PORCELAIN APPLICATION

METHOD

FIRING PROCEDURES

FINISHING & ADJUSTMENTS

Metal ceramic technology.

www.indiandentalacademy.com

The word Ceramics is derived

from Greek word keramos

which means pottery or burnt

stuff.

Porcelain in English means

china.

www.indiandentalacademy.com

Ceramics

Compounds of one or more metals

with a non metallic element,

usually oxygen. They are formed

of chemical and biochemical

stable substances that are strong,

hard , brittle, and inert non

conductors of thermal and

electrical energy(GPT-7).

www.indiandentalacademy.com

Porcelain is defined as

A ceramic material formed of

infusible elements joined by lower

fusing materials. Most dental

porcelain are glasses and are

used in the fabrication of teeth for

dentures, pontics and facings,

metal ceramic restorations,

crowns, inlays, onlays, and other

restorations.

www.indiandentalacademy.com

Other designations of metal

ceramics

Porcelain-fused to metal.

Ceramo-metal crown.

Porcelain veneer crown.

Porcelain bonded to metal

crown.

www.indiandentalacademy.com

Structure of ceramics

Their atomic structure and resultant

properties depend, not only on

composition, but also on thermal history.

Dental porcelain are glassy materials

Glasses may be regarded as a super cooled

liquids or as non crystalline solids

www.indiandentalacademy.com

History

CHINESE ARE CREDITED WITH

THE DEVELOPMENT OF

PORCELAIN AS EARLY AS 1000

AD.

DENTRECOLLES, INGRATIED

HIMSELF WITH CHINESE

POTTERS AROUND 1717 IN

ORDER TO LEARN THE COVETED

PORCELAIN MANUFACTURING

PROCESS

www.indiandentalacademy.com

IN 1760 FAUCHARD AND OTHERS

HAD REPORTED USING BAKED

ENAMEL.

IN 1774 ALEXIS DUCHATEAU &

NICOLAS DUBOIUS

CONSTRUCTED COMPLETE

DENTURES FROM A MATERIAL

THEY REFERRED TO AS MINERAL

PASTE.

www.indiandentalacademy.com

IN 1808 GIUSSEPPANGELO FONZI

DEVISED A METHOD TO MASS

PRODUCE INDIVIDUAL

PORCELAIN DENTURE TEETH

www.indiandentalacademy.com

1850 Samuel Stockton was the first to

mass produce these teeth first in

America

Claudius Ash created a artificial tooth

that could be placed over a post on

either a complete denture of FPD. It

was known as tube tooth.

www.indiandentalacademy.com

1889 Dr Charles H. Land gave the

idea of fusing porcelain to a thin

platinum foil. he developed low

fusing porcelain in 1898. 1903 he

introduced the porcelain jacket crown

to dentistry

www.indiandentalacademy.com

1907 Stockton developed dental

porcelain.

1962 M. Weinstein, S.Katz, and

A.B.Weinstein patented a method to

fabricate the first metal ceramic

crown.

www.indiandentalacademy.com

Two of the most important breakthroughs

responsible for the long-standing superb

aesthetic performance and clinical

survivability of metal-ceramic restorations

are the patents of Weinstein and

Weinstein (1962) and Weinstein et al

(1962).

One of these patents described the

formulations of feldspathic porcelain that

allowed systematic control of the sintering

temperature and thermal expansion

coefficient.

www.indiandentalacademy.com

The other patent described the

components that could be

used to produce alloys that

bonded chemically to and

were thermally compatible with

feldspathic porcelains

www.indiandentalacademy.com

What are ceramics?

Dental ceramics may consist

primarily of glasses ,porcelains,

glass-ceramics.

The properties of ceramics are

customized for dental application

by precise control of the type &

amount of the components used

in their production.

www.indiandentalacademy.com

Ceramics are more resistant to

corrosion. Ceramics generally do

not react with most liquids, gases,

alkalies & acids. And they remain

stable over long time.

Dental ceramics exhibit far to

excellent flexure strength & fracture

toughness.

www.indiandentalacademy.com

Although ceramics are strong,

temperature-resistant & resilient

these materials are brittle and may

fracture when quickly heated and

cooled.

Dental ceramics are non-metallic

inorganic structures,primarily

containing components of oxygen

with one or more metallic or semi

metallic elements.

www.indiandentalacademy.com

Most ceramics are

characterized by their refractory

nature, high hardness,

(relatively low tensile strength

and essentially zero percent

elongation), and chemical

inertness.

Properties of ceramics.

www.indiandentalacademy.com

For dental applications a

hardness of a ceramic less than

that of enamel and an easily

polishable surface are desirable

to minimize the wear damage that

can be produced on enamel by

the ceramic surface.

www.indiandentalacademy.com

1) Strength.

Porcelain is a material having good

strength. However, it is brittle and

tends to fracture.

The strength of porcelain is usually

measured in terms of its flexure

strength or modulus of rupture.

www.indiandentalacademy.com

a) Flexure strength:

It is a combination of compressive,

tensile, as well as shear strength.

Glazed porcelain is stronger than

ground porcelain.

Ground-75.8 Mpa (11,000 psi)

Glazed-141.1 Mpa (20,465 psi)

www.indiandentalacademy.com

b) Compressive strength:

Porcelains have good compressive

strength.

331 Mpa (48,000psi)

www.indiandentalacademy.com

c) Tensile strength:

Is low

34 MPa (5000psi).

www.indiandentalacademy.com

d) Shear strength:

It is low and is due to the ductility

caused by the complex structure of

dental porcelain.

110 Mpa (16000psi).

www.indiandentalacademy.com

Factors affecting strength.

1) Composition.

2) Surface integrity: Surface imperfections

like microscopic cracks and porosities

reduce the strength.

3) Firing procedure: Inadequate firing

weakens the structure as vitrification is not

complete. Overfiring also decrease

strength as more of the core gets

dissolved in the fluxes, thereby weakening

the core network. www.indiandentalacademy.com

2) Modulus of elasticity:

Porcelain as high modulus of

elasticity.

69 GPa .

www.indiandentalacademy.com

3) Surface hardness:

Porcelain is much harder than natural

teeth.

460 KHN

www.indiandentalacademy.com

4) Wear resistance:

Porcelain is more resistant to wear

than natural teeth. Thus, it should not

be placed opposite to natural teeth.

www.indiandentalacademy.com

5) Specific gravity:

Is 2.242.

The specific gravity of fired porcelain

is usually less, because of the

presence of air voids. It varies from

2.2 to 2.3.

www.indiandentalacademy.com

6) Dimensional stability:

Porcelain is dimensionally stable after

firing.

www.indiandentalacademy.com

7) Chemical stability:

It is insoluble and impermeable to oral

fluids. Also it is resistant to most

solvents. However, contact with

hydrofluoric acid causes etching of

the porcelain surface.

www.indiandentalacademy.com

8) Esthetic properties:

Are excellent. It is able to match

adjacent tooth structure in

translucence, color and intensity.

www.indiandentalacademy.com

9) Biocompatibility.

It is compatible with the oral tissue.

www.indiandentalacademy.com

Refers to the ability of a metal

and its veneering porcelain to

contract at similar rates.

The coefficient of thermal

expansion by definition is the

change in length per unit of

original length of a material when

its temperature is raised by 1o K

.

10) Thermal compatibility

www.indiandentalacademy.com

Thermal compatibility (contd.)

When the co efficient of thermal

expansion of metal and porcelain

are compatible the tensile stress

that develop during cooling are

insufficient to cause immediate

cracking of porcelain or delayed

cracking after cooling at room

temperature.

www.indiandentalacademy.com

Porcelains have coefficient of thermal

expansion between 13.0 and 14.0 X

10-6 and metal between 13.5 and

14.5 X 10-6.

The difference of 0.5 X10-6 in thermal

expansion between metal and

porcelain causes the metal to contract

slightly more than does the ceramic

during cooling after firing the

porcelain.

www.indiandentalacademy.com

This puts the ceramic under

slight residual compression

which makes it less sensitive

to applied tensile forces.

www.indiandentalacademy.com

Methods of strengthening ceramics

Strengthening occurs through two

mechanism,

1) development of residual

compressive stresses.

2) interruption of crack propagation.

www.indiandentalacademy.com

Development of residual compressive

stresses.

1) Ion exchange: (chemical

tempering)

exchange of potassium ions (which is

35% larger) for sodium ions. thus

there is squeezing of the potassium

ion into smaller spaces. This creates

a residual compressive stresses on

the surface of the glass.

www.indiandentalacademy.com

Thermal tempering.

By rapidly cooling the surface of the

object while it is hot and in the molten

state. This rapid cooling produces a

layer of rigid glass surrounding a soft

core. As the molten core solidifies ,it

tends to shrink, creates a residual

tensile stress in the core thus leaving

the outer layer in residual

compressive stress.

www.indiandentalacademy.com

THERMAL EXPANSION COEFFICIENT

MISMATCH:

Ceramic in combination with metal are

heated together .The metal which is

veneered with ceramic has a higher

coefficient of thermal expansion than the

ceramic. Hence on cooling, the metal

contracts more than the ceramics thus

leaving the outer layer, of ceramic in

residual compressive stress.

www.indiandentalacademy.com

Interruption of crack propagation.

Two different types of dispersions used to

interrupt crack propagation are:

1) By absorption of energy by the

dispersed tough particle from the crack

and thus depleting its driving force for

propagation.

2) By change of crystal structure under

stress to absorb energy from the crack.

www.indiandentalacademy.com

1) Dispersion of a crystalline

phase.

A tough crystalline material like alumina is

added in particulate form. The glass is

toughened and strengthened because the

crack cannot penetrate the alumina

particles as easily as it can propagate in

the glass. Thus the aluminous porcelains

were developed for Porcelain Jacket

Crown. (PJC)

www.indiandentalacademy.com

Transformation toughening.

A crystalline material is incorporated that

is capable of undergoing a change in

crystal structure when placed under

stress. The crystalline material used is

termed as partially stabilized zirconia

(PSZ).The refractive index of PSZ is

higher than glass matrix. Thus the PSZ

scatters the light producing an opacifying

effect.

www.indiandentalacademy.com

Terminology.

Porcelain-fused-to-metal (PFM): a

popular alternative designation

for the metal ceramic restoration.

www.indiandentalacademy.com

Porcelain bonding: a term used to

explain the mechanisms by which

dental porcelain fuses or adheres to a

metal substructure

Coping: the word coping can be used to

identify the metal substructure of single-

unit crowns designed for bonding to

dental porcelain. Copings are made on

a single tooth preparation, which may

be a single unit or attached to pontics

for a fixed partial denture.

www.indiandentalacademy.com

Framework: this term is often applied

to fixed partial dentures and identifies

a one-piece substructure composed

on either several copings attached to

a pontic or multiple single units that

are joined together as a single

structure.

www.indiandentalacademy.com

Degassing: the process of heat-treating

a cast metal substructure in a porcelain

furnace as one of the preparatory steps

to applying an opaque porcelain.

Subjecting the finished metal to

elevated temperatures (980 to

1,050C) in a reduced atmosphere

(vacuum) or in air reportedly burns off

organic surface impurities and

eliminates entrapped gaseous

contaminants. A newer and perhaps

more appropriate termoxidizinghas

emerged in the literature to describe this

procedure.

www.indiandentalacademy.com

Oxidation (or oxidizing): the

process by which a metal

substructure is heated in a

porcelain furnace to produce an

oxide layer for porcelain bonding

as well as to cleanse the

porcelain-bearing surfaces of

contaminants

www.indiandentalacademy.com

ADVANTAGES OF DENTAL

PORCELAIN

Dental ceramics are attractive

because of their biocompatibility,

long-term color stability, wear

resistance, and their ability to be

formed into precise shapes.

www.indiandentalacademy.com

Disadvantages.

They require costly processing

equipment and specialized

training.

Susceptibility to brittle fracture

at relatively low stresses

www.indiandentalacademy.com

The chemical components of dental

porcelain.

Feldspar (K2O Al 2O3-6SiO2 & Na2o

Al2o3-6SiO2)

Quartz (SiO2)

Alumina (Al2O3)

Kaolin (Al2O3 -2SiO2 2H2O)

www.indiandentalacademy.com

Feldspar

Found as a mix of two substances .

It does not occur in pure form in

nature

Mineral is crystalline and opaque

Color is indefinite and between gray

and pink.

www.indiandentalacademy.com

Type of

feldspar

Chemical

formula

Other

names

Properties uses

Potassiu

m

aluminiu

m

silicate.

(K

2

O.Al

2

O

3

.6Si

O

2

)

orthocla

se or

potash

feldspar

1.Reduces the

fluidity of the molten

materials

2.helps to maintain

the form of the

porcelain buildup

3.adds translucent

qualities to fired

restorations.

Found in

majority

of the

porcelain

systems

Sodium

aluminu

m

silicate

(Na

2

O.

Al

2

O

3

.

6SiO

2

)

albite or

sodium

feldspar

.

1.Lowers fusion

temperature of the

porcelain.

Less

preferred

Lime

feldspar

CaO.2

Al

2

O

3

.2

SiO

2

www.indiandentalacademy.com

On heating it becomes glassy and

fuses at 1290 C, on overheating it

may loose its shape .

Impurities : Mica

Iron it is important to

remove it as its oxides act as strong

coloring agents.

www.indiandentalacademy.com

Removal of impurities

Iron-

manually only light colored pieces of

feldspar are selected

Feldspar is grounded into fine powder

and vibrated down inclined planes

surrounded by induction magnets

www.indiandentalacademy.com

Primarily responsible for forming

glass matrix

Functions

www.indiandentalacademy.com

Glass modifiers such as the oxides of

potassium, sodium, and calcium acts

as fluxes to increase a porcelains

coefficient of thermal expansion.

The fluxes increase the porcelains

coefficient of thermal expansion by

breaking up oxygen crosslinking.

www.indiandentalacademy.com

Primarily responsible for

forming glass matrix

Has a fusion temperature

Silica (Quartz or Flint) SiO

2

www.indiandentalacademy.com

SiO

2

www.indiandentalacademy.com

Silica contributes stability to the

mass of porcelain during heating

by providing a framework for the

other ingredients.

Also acts to strengthen the

porcelain.

Functions

www.indiandentalacademy.com

KAOLIN (Al2 o3-2sio22H2o)

It is deposited along the banks and at the

bottom of streams in the form of clay.

Only purest form of clay are used for

dental porcelain.

www.indiandentalacademy.com

Preparation of clay

Repeated washing until all foreign

materials are separated.

Allowed to settle.

Dried and screened.

Nearly white powder is obtained.

www.indiandentalacademy.com

Properties of clay

I. Its gives OPAQUENESS to porcelain

II. MOULDABLE :On mixing with water it

becomes sticky and aids in forming a

workable mass of the porcelain during

molding.

III. Clay-water suspension maintains its

shape during firing in a furnace.

IV. On subjecting to high heat it adheres to

the framework of Quartz particles and

shrinks considerably.

www.indiandentalacademy.com

Little or no kaolin is found is

modern day low fusing

porcelain.

Kaolin is not used in enamel

powder as it will decrease its

translucency.

www.indiandentalacademy.com

Alumina.(Al2o3)

The hardest and perhaps the

strongest oxide.

Its CTE is similar to the low fusing

porcelains.

It also strengthens the porcelain.

www.indiandentalacademy.com

Manufacturing of ceramics

powder

www.indiandentalacademy.com

Fritting.

The process of blending, melting and

quenching the glass components is

termed fritting.

All the raw mineral powders are mixed

together in a refractory crucible and

heated till a molten mass is formed.

It is then quenched in water.

It immediately breaks into fragments and

this is termed the frit.

www.indiandentalacademy.com

Frits are ground to the specific particle

size established by individual

manufacturers for their particular brand of

porcelain.

www.indiandentalacademy.com

TOOTH PREPARATION FOR

THE METAL CERAMIC

RESTORATION

www.indiandentalacademy.com

Depth

orientation

grooves flat

end tapered

diamond.

www.indiandentalacademy.com

www.indiandentalacademy.com

Make at least

two vertical

cuts in the

incisal portion

of the facial

surface.

www.indiandentalacademy.com

Next align the

flat end tapered

diamond with

the gingival

portion of the

facial surface.

www.indiandentalacademy.com

Sink the side of

the diamond into

the mesiodistal

center of the

facial

surface,maintain

the instrument

alignment parallel

to the gingival

surface of the

facial segment.

www.indiandentalacademy.com

Make two incisal

orientation grooves

that are 2mm

deep.The diamond

should be parallel to

the incisal edge

faciolingally.

www.indiandentalacademy.com

Incisal

reduction is

done with the

flat end tapered

diamond.

www.indiandentalacademy.com

www.indiandentalacademy.com

Facial

reduction;

incisal half,flat

end tapered

diamond.

www.indiandentalacademy.com

If there sound

tooth structure

inter proximally,

wing

preparation is

done.

www.indiandentalacademy.com

Begin the lingual

reduction with the

small round

diamond with

diameter of

1.4mm. Sink this

instrument into

the lingual tooth

structure up to

0.7mm.

www.indiandentalacademy.com

Lingual axial reduction

torpedo diamond and carbide

finishing bur.

www.indiandentalacademy.com

Lingual

reduction is

done with the

small wheel

diamond.

www.indiandentalacademy.com

Smooth the entire

facial surface with

no.171 bur .Round

over the any sharp

angles on the incisal

angle or along the

edges of the incisal

notches with no.171

bur.

www.indiandentalacademy.com

Components of the metal

ceramic restoration

Two major components:

a metal substructure and a porcelain

veneer.

The surface oxide layer that lies

between the metal and the porcelain

veneer could be considered a

separate component, but it is an

integral part of the casting alloy

substructure.

www.indiandentalacademy.com

www.indiandentalacademy.com

The basic components of a traditional

porcelain kit include

1.opaque porcelain.

2.dentin porcelains

3.enamel porcelains

Modifiers, stains & glazes.

Newest products has high fusing

shoulder porcelains.

www.indiandentalacademy.com

The metal substructure

Conventional low-fusing dental

porcelain lacks the strength

required of an all-porcelain

restoration, so a metal substructure

is added to support the porcelain

veneer.

The thickness of the metal coping

can vary, depending on the type of

casting alloy used and the amount

of tooth structure reduced by the

dentist.

www.indiandentalacademy.com

The oxide layer

Most metal ceramic alloys are

oxidized after the porcelain-

bearing area of the restoration has

been properly finished and

cleaned.

www.indiandentalacademy.com

The metal oxides that form on the

alloy's surface during this heat-

treatment procedure play a key role

in bonding the dental porcelain to

the underlying metal substructure.

Because noble elements do not

oxidize, an alloy's base metal

constituents are principally

responsible for forming this oxide

layer.

www.indiandentalacademy.com

Differences in alloy composition

require that oxidation techniques be

alloy specific

Ideally this oxidation should be no

more than a discrete, monomolecular

film on the alloy's surface for all metal

ceramic alloys, irrespective of

compositional differences.

www.indiandentalacademy.com

Opaque porcelain layer

These porcelains are made opaque by the

addition of insoluble oxides, such as

tin oxide (SnO2),

titanium oxide (TiO2),

zirconium oxide (ZrO2),

cerium oxide (CeO2),

www.indiandentalacademy.com

Opaque porcelain layer contd.

oxide, and

rubidium oxide,

barium zinc oxide.

Such oxides have high refractive

indices, so they scatter light.

www.indiandentalacademy.com

Composition on chemical

analysis

www.indiandentalacademy.com

Between 8% and 15% of an opaque

powder is composed of metallic

oxides, and some particles may be

less than 5 um in size.

Even small differences in particle size

distribution are thought to influence

the ability of opaques to mask the

color of a metal substructure.

www.indiandentalacademy.com

The opaque porcelains three major

functions:

(1) to establish the porcelain-metal

bond,

(2) to mask the dark color of the

metal substructure, and

(3) to initiate the development of

the selected shade of porcelain.

www.indiandentalacademy.com

A uniform thickness of 0.2 to 0.3

mm generally is regarded as ideal.

That masking power is influenced

by the amount and the color of the

oxidized (degassed) metal casting

(Naylor, 1986)

www.indiandentalacademy.com

A casting alloy of a different

composition might generate a thick,

dark oxide layer (Naylor, 1986) and

require a thicker opaque covering.

The thickness of the opaque layer

needed to veneer the metal and

mask the surface oxides differs

among brands of porcelain and

even varies for different shades

within the same porcelain system

www.indiandentalacademy.com

www.indiandentalacademy.com

Body porcelains

Body porcelain collectively describes

four principal types of porcelain

powders used to recreate the "body" of

a restoration: dentin (body or gingival),

enamel (or incisal), translucent, and

modifier.

These body porcelains are mixed with

either distilled water or a special liquid

(provided with the porcelain kit) that

helps to prevent the buildup from drying

out rapidly. www.indiandentalacademy.com

They are applied directly over the fired

opaque layer .

The dentin, enamel, translucent, and

modifier powders all have the same

chemical and physical properties, they

may be intermixed freely if custom

shading is desired.

They differ in appearance in the fired

state because of variations in the

amount and type of metallic oxide

pigments each contains.

www.indiandentalacademy.com

The dentin porcelain veneer

The major color contribution is derived

from the pigmented metal oxides in the

dentin body porcelain

It is this initial layer of dental porcelain

that imparts the dentin shade

associated with, but not confined to, the

gingival two thirds of a tooth.

The dentinal layer is overbuilt slightly,

cut back, and overlaid with enamel

porcelain in those sections of the

restoration where greater translucency

is desired.

www.indiandentalacademy.com

For more accurate shade

duplication, estimates of the

combined thickness of fired dentin

and enamel porcelains range from

a minimum of 0.5 to 1.0 mm to a

maximum thickness of 1.5 to 2.0

mm

www.indiandentalacademy.com

For uniformity of shade and maximum

strength, it is desirable to have an even

thickness of porcelain covering the

metal substructure.

The minimum total thickness of

porcelain may be between 1.2 to 1.3

mm at the middle one third of the

restoration and 1.5 to 1.6 mm at the

incisal edge (Yamamoto, 1985).

www.indiandentalacademy.com

ENAMEL PORCELAIN VENEER

Enamel porcelains are more

translucent than dentin porcelains.

The enamel porcelains are usually in

the violet to grayish range & impart a

combination of true translucency &

the illusion of the translucency by

virtue of their grayish or some times

bluish appearance.

www.indiandentalacademy.com

When fired, enamel porcelains are more

translucent than dentin porcelains

(McLean, 1979).

They also have a more restricted range

of shades. A typical porcelain system

may provide only four or five bottles of

enamel powders to cover the entire

range of shades in the kit.

www.indiandentalacademy.com

Translucent porcelains

Translucent porcelains are not

transparent, they do not allow the

transmission of all light.

They are applied as a veneer over nearly

the entire surface of a typical porcelain

buildup.

This veneer imparts depth and a natural

enamel-like translucency without

substantially altering the body shade that

is overlaid.

www.indiandentalacademy.com

These porcelains are more color concentrated &

were designed to aid in the achieving internal

color modifications.

They are used to distinguish the dentin, enamel

& translucent porcelains, because they have the

same basic physical & chemical properties.

All these powders are basically same materials,

they do differ in the appearance because of the

modifiers.

BODY MODIFIERS

www.indiandentalacademy.com

www.indiandentalacademy.com

Stain powders contain less silica or

alumina & more sodium & potassium

oxides.

They contain high concentration of

metallic oxides.

They are created by mixing the

metallic oxides with lower fusion point

glasses

STAINS

www.indiandentalacademy.com

GLAZES

Glazes are generally colorless, low fusing

porcelains.

They possess considerable fluidity at high

temperatures.

They fill small surface porosities &

irregularities. when fired helps to recreate

the external glazy appearance of the

natural tooth

www.indiandentalacademy.com

www.indiandentalacademy.com

GLAZE (Contd.)

A glazed ceramic surface is

generally considered beneficial by

increasing the fracture resistance

and reducing the potential

abrasiveness of ceramic surfaces

www.indiandentalacademy.com

Color coding

By convention dentin powders are pink

and enamel powders are blue.

These organic colors burn off during firing

procedure and do not affect the shade of

the fired restoration in any way.

Some manufacturers color code the

distilled water instead of the powder.e.g.

pencraft porcelain

www.indiandentalacademy.com

CLASSIFICATION OF DENTAL

CERAMICS

Different types of dental ceramics are

available These include core ceramic,

liner ceramic, margin ceramic,

opaque dentin (also, body or gingival)

ceramic, dentin ceramic, enamel

(incisal) ceramic, stain ceramic, glaze

ceramic, and addition ceramic

www.indiandentalacademy.com

These products can be

classified in several possible

ways according to their: (1) use

or indications (anterior,

posterior, crowns, veneers, post

and cores, FPDs, stain ceramic,

and glaze ceramic);

www.indiandentalacademy.com

(2) composition (pure alumina,

pure zirconia, silica glass, leucite-

based glass-ceramic, and lithia-

based glass-ceramic

(3) processing method (sintering,

partial sintering and glass infiltration

,CAD-CAM, and copy-milling);

www.indiandentalacademy.com

Microstructure (glass, crystalline,

and crystal-containing glass);

Translucency (opaque,

translucent, and transparent);

Fracture resistance; or

Abrasiveness

www.indiandentalacademy.com

Based on the method of fabrication

1. Condensation porcelains using

condensation and sintering

2. Castable ceramics Dicor-Dentsply

3. Pressable ceramics

4. Machinable ceramics

5. Infiltrated ceramics

6. Injection molded ceramics Cerestore

www.indiandentalacademy.com

1) Regular feldspathic porcelain

2) Aluminous porcelain

3) Metal bonding porcelain.

Classification (Mclean)

www.indiandentalacademy.com

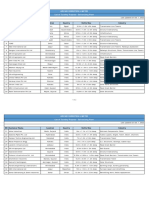

Based on their fusion temperature (Phillips,1982)

type Fusing

temperature

range

uses

High fusing

porcelains-

1288 to 1371

C

1200-1400

used for

manufacturing

denture teeth .

Both are

similar in

composition

and

microstructure.

Medium fusing

Porcelains-

1093 to 1260

C

1050-1200

for all ceramic

restorations

and

prefabricated

pontics.

Low fusing

porcelains-

871 to 1066 C

800-1050

for metal

ceramic and all

ceramic.

www.indiandentalacademy.com

METAL SUB STRUCTURE

DESIGN.

Majority of the porcelain-to-metal bond

failures occur as a direct result of improper

substructure design

Errors in the preparation of the metal

ceramic substructure frequently go

unnoticed until the brittle porcelain veneer

fails in service.

www.indiandentalacademy.com

TYPES

FUNCTIONS.

DESIGN.

METAL SUB STRUCTURE

DESIGN.

www.indiandentalacademy.com

Types of metal ceramic system.

A. Cast metal ceramic alloys:

1.Noble-metal alloy systems:

High gold - a) Gold platinum palladium.

Low gold - b) Gold palladium silver.

Gold free - c) Palladium silver.

2.Base metal alloys systems:

Nickel chromium alloy.

Cobalt chromium alloys ( rarely used in

ceramic bonding).

www.indiandentalacademy.com

B. Foil copings:

a) Bonded platinum foil coping.

b) Swaged gold alloy foil coping.

www.indiandentalacademy.com

a) Bonded platinum foil coping:

Another method of bonding porcelain to

metal is the use of tin oxide coatings on

platinum foil.

The method consists of bonding

aluminous porcelain to platinum foil

copings.

Attachment of the porcelain is secured by

electroplating the foil with a thin layer of tin

and then oxidizing it in a furnace.

www.indiandentalacademy.com

The objective of this type of

restoration is to improve esthetics.

The thicker cast metal coping that is

normally used is replaced by a thinner

platinum foil, thus allowing more

space for the porcelain.

www.indiandentalacademy.com

b) Swaged Gold Alloy Foil Coping:

A laminated gold alloy supplied in fluted

shape is also used as an alternative to the

cast metal coping.

The foil is swaged onto the die and flame

sintered to form a coping.

An interfacial alloy powder is applied

and fired and the coping is then veneered

with porcelain.

www.indiandentalacademy.com

Primary functions:-

The casting provides fit of the

restoration to the prepared tooth.

The metal forms oxides that bond

chemically to the dental porcelain.

www.indiandentalacademy.com

The coping serves as a rigid

foundation to which the brittle

porcelain can be attached for

increased strength & support.

The sub structure restores the

tooth's proper emergence profile.

www.indiandentalacademy.com

Secondary functions.

Metal occlusal & lingual articulating

surfaces generally less destructive to

the enamel of the opposing natural

tooth.

Fabrication of the restoration with

minimal occlusal clearance has more

potential for the success with metal

substructure than all ceramic alloys.

www.indiandentalacademy.com

Occlusal surfaces can be easily

adjusted & repolished intraorally.

The metal axial walls can support

the removable partial denture.

www.indiandentalacademy.com

Metal sub structure design

Majority of the porcelain-to-metal

bond failures occur as a direct result

of improper substructure design

Errors in the preparation of the metal

ceramic substructure frequently go

unnoticed until the brittle porcelain

veneer fails in service.

www.indiandentalacademy.com

Sub structure design (contd)

Hence necessary to understand

the essentials of proper

substructure design, since it will

help to ensure the longevity of the

final prosthesis.

www.indiandentalacademy.com

Principles of substructure

design.

Are the occlusal contacts to be

in metal or porcelain?

www.indiandentalacademy.com

Occlusion in metal requires less tooth

reduction (1 to 1.5 mm).

Approximately 2 mm of occlusal

reduction is necessary for posterior

teeth and 1 to 1.5 mm for anterior

teeth requiring porcelain on occluding

surfaces.

www.indiandentalacademy.com

Metal surfaces can be more easily

adjusted and repolished at chair side

without adversely affecting the

restoration.

On the other hand, removing the

glaze of a metal ceramic restoration

during intraoral adjustments weakens

the porcelain greatly

www.indiandentalacademy.com

2. Are the centric occlusal

contacts 1.5 to 2mm from the

porcelain-metal junction?

www.indiandentalacademy.com

occlusal contacts when placed

directly on or close to the porcelain-

metal junction, there is an increased

likelihood the porcelain will chip or

fracture at that point of contact .

Porcelain is strongest under

compression and weakest under

tension, so situations that induce

tensile stresses in the ceramic during

function are more apt to promote

bond failures

www.indiandentalacademy.com

A substructure should be designed so

the functional incisal or occlusal

contacts are located at least 1 .5 mm

and perhaps as much as 2 mm from

the metalporcelain junction.

www.indiandentalacademy.com

When the

anterior teeth

contact in the

incisal region,it is

often necessary

to consider a

design with

lingual surface in

porcelain to avoid

functioning on or

over the

porcelain metal

junction.

www.indiandentalacademy.com

Do not

design the

sub structure

so contact

occurs at the

porcelain

metal

junction.

www.indiandentalacademy.com

When the anterior

teeth occlude in the

gingival half of the

maxillary teeth or

when the lingual

tooth reduction is

less than 1mm it is

best to design the

sub structure with

occlusion in the

metal.

www.indiandentalacademy.com

3.Are the interproximal contacts

to be restored in metal or

porcelain?

www.indiandentalacademy.com

The inter proximal contact areas of

anterior teeth, and at least the mesial

contacts of posterior teeth, are

frequently restored in porcelain

with porcelain inter proximal contact

areas would be more esthetic,

particularly with anterior teeth.

www.indiandentalacademy.com

It is important to provide proper metal

support to a porcelain marginal ridge

in the substructure design to prevent

possible fracture

However, the distal inter proximal

contacts of posterior teeth may be

restored in either metal or porcelain

because these areas are not as

critical esthetically.

www.indiandentalacademy.com

4.Are the cusp tips (or incisal

edges )adequately supported by

the metal substructure with no

more than 2mm of unsupported

porcelain?

www.indiandentalacademy.com

The ultimate goal of any substructure

is to support an even thickness (1mm

minimum, 2 mm maximum) of the

porcelain veneer.

If this maximum thickness is

exceeded, the ceramic layer may no

longer be properly supported,

resulting in a catastrophic failure at

the cusp tip or incisal edge

www.indiandentalacademy.com

5. Is the substructure thick

enough to provide a rigid

foundation for the porcelain

veneer?

www.indiandentalacademy.com

Areas to be veneered with

porcelain must be at least 0.3 mm

thick.

with base metal alloys, the

coping can be reduced to 0.2 mm

or less and still be strong enough

to support the porcelain

www.indiandentalacademy.com

How does dental porcelain bond to

metal?

(1) van der Waals forces (Lacy, 1977),

(2) mechanical retention,

(3) compression bonding, and

(4) direct chemical bonding (Lacy,

1977; McLean, 1980;

www.indiandentalacademy.com

van der Waals forces

The attraction between charged

atoms that are in intimate contact yet

do not actually exchange electrons is

derived from van der Waals forces.

These secondary forces are

generated more by a physical

attraction between charged particles

Van der Waalsforces are generally

weak.

www.indiandentalacademy.com

www.indiandentalacademy.com

The better the wetting of the

metal surface, the greater the van

der Waals forces.

porcelain's adhesion to metal can

be diminished or enhanced by

alterations in the surface

character (texture) of the

porcelain-bearing surface on the

substructure

www.indiandentalacademy.com

van der Waals forces are only

minor contributors to the overall

attachment process.

www.indiandentalacademy.com

The porcelain-bearing area of a metal

casting contains many microscopic

irregularities into which opaque

porcelain may flow when fired.

Air abrading the metal with aluminum

oxide is believed to enhance

mechanical retention further by

eliminating surface irregularities

(stress concentrations)

Mechanical retention

www.indiandentalacademy.com

Mechanical retention's

contribution to bonding may be

relatively limited.

Dental porcelain does not require

a roughened area to bond to

metal but some surface

roughness is effective in

increasing bonding forces

www.indiandentalacademy.com

www.indiandentalacademy.com

www.indiandentalacademy.com

Compression bonding

Dental porcelain is strongest under

compression and weakest under

tension; hence, if the coefficient of

thermal expansion of the metal

substrate is greater than that of the

porcelain placed over it, the porcelain

should be placed under compression

on cooling

www.indiandentalacademy.com

the metal contracts faster than the

porcelain but is resisted by the

porcelain's lower coefficient of

thermal expansion.

This difference in contraction

rates creates tensile forces on the

metal and corresponding

compressive forces on the

porcelain.

www.indiandentalacademy.com

Chemical bonding

The single most significant

mechanism of porcelain-metal

attachment is a chemical bond

between dental porcelain and the

oxides on the surface of the metal

substructure

www.indiandentalacademy.com

The two hypothesis that explains

chemical bonding are

1, The sandwich theory

the oxide layer is permanently

bonded to the metal substructure on

one side while the dental porcelain

remains on the other

www.indiandentalacademy.com

The oxide layer itself is

sandwiched in between the metal

substructure and the opaque

porcelain. This "sandwich" theory

is undesirable in that a thick oxide

layer might exist that would

weaken the attachment of metal

to porcelain

www.indiandentalacademy.com

The second, and more likely, theory

suggests that the surface oxides

dissolve, or are dissolved by, the

opaque layer. The porcelain is then

brought into atomic contact with the

metal surface for enhanced wetting

and direct chemical bonding so metal

and porcelain share electrons.

(McLean, 1980; Yamamoto, 1985)

www.indiandentalacademy.com

Chemical "bonding" is generally

accepted as the primary

mechanism in the porcelain-metal

attachment process

www.indiandentalacademy.com

www.indiandentalacademy.com

www.indiandentalacademy.com

The oxidation (degassing) process

After the cast metal ceramic

castings have been properly

finished with uncontaminated

carbide burs or ceramic abrasives

the castings are heat-treated in a

porcelain furnace (in air or a

vacuum) to a designated

temperature for a specified period

of time (Naylor, 1986).

www.indiandentalacademy.com

The heat-treatment process

allows specific oxides to form on

the metal surface. These oxides

are responsible for the chemical

porcelain- metal "bond."

www.indiandentalacademy.com

A high-gold-content alloy contains

oxidizable trace elements such as tin,

indium, and iron to produce an

adherent oxide layer. Because

elements like gold and the other noble

metals do not oxidize, it is often

necessary to hold these castings at

temperature for several minutes to

permit the non noble trace elements

to form the oxide layer

www.indiandentalacademy.com

The base metal alloys readily

oxidize, but trace elements are

still added in an effort to form a

particular type of oxide for a

stable bond .

The oxidation procedure may be

carried out in a vacuum to

minimize the amount of oxidation,

and the hold time is often reduced

or omitted.

www.indiandentalacademy.com

Allowing certain base metal alloys

to oxidize in air, or to remain at

temperature, could lead to over

oxidation. An excessively thick

and non-adherent oxide layer is

often responsible for porcelain

bond failures

www.indiandentalacademy.com

www.indiandentalacademy.com

A properly oxidized casting often

has a distinctive appearance in

terms of color and character

(texture, thickness, etc).

That appearance of a properly

oxidized metal substructure differs

among alloy systems and may

also differ among alloys within the

same system.

www.indiandentalacademy.com

www.indiandentalacademy.com

Some manufacturers do not

recommend an oxidation/

degassing step; instead, they

advocate minimizing the number

of firings to which the casting is

subjected.

www.indiandentalacademy.com

Removing the oxide layer

Two principal methods for

removing oxides are

Acid treatment (chemical method)

Nonacid treatment (mechanical

method).

www.indiandentalacademy.com

Acid treatment

(chemical method)

Different types of acids are used to reduce

or eliminate surface oxides, including

hydrofluoric, hydrochloric, and dilute

sulfuric acid.

The potential hazards of these acids

require that they be stored and used in

clearly marked, resealable plastics bottles.

It is advisable to wear protective rubber

gloves and eye protection during all

handling procedures.

www.indiandentalacademy.com

A rubber-tipped instrument should be

used to place oxidized castings into

the acid appropriate for the alloy.

Place the covered container in an

ultrasonic unit for the time

recommended by the alloy

manufacturer.

Remove the casting and thoroughly

rinse it under tap water. For the final

cleaning step, put the coping in a

container of distilled water and clean

it ultrasonically for 10 to 15 minutes.

www.indiandentalacademy.com

Nonacid treatment

(Mechanical method)

Castings can be air-abraded with pure, 50-

um aluminum oxide (Al2o3) that is non-

recycled.

Steam clean or ultrasonically clean the

casting in distilled water for 10 to 15

minutes before applying the opaque

porcelain.

www.indiandentalacademy.com

Porcelain-metal bond failures

Metal ceramic alloys, whether noble

or base metals, all oxidize differently

because of variations in their

composition.

If the oxidation process is not

performed properly, the subsequent

porcelain-metal bond may be weak

and may lead to bond failure.

www.indiandentalacademy.com

www.indiandentalacademy.com

Porcelain delamination

With base metal alloys, the

separation of the porcelain veneer

from the metal substrate can be

more a loss of the "attachment" of

the oxide layer that is either too

thick or is poorly adherent to the

metal substructure.

www.indiandentalacademy.com

www.indiandentalacademy.com

Porcelain delamination contd

Overoxidation has been a particular

problem with the heavily oxidizing

base metal alloys and has been

linked to their increased tendency for

bond failures .

www.indiandentalacademy.com

Bond failures are not caused by a loss

of the chemical bond between the

ceramic and the oxide layer

on the contrary, the porcelain might

remain visibly attached to the oxides

but the oxide layer may be so thick that

the bond is lost through it .

This particular problem is caused by

the formation of a thick and poorly

adherent oxide layer.

www.indiandentalacademy.com

www.indiandentalacademy.com

www.indiandentalacademy.com

Classification of bond failures in

metal-ceramics.

(Given by O Brien (1977).

1) Metal Porcelain:

Fracture leaves a clean surface of

metal. Seen when metal surface is devoid

of oxides. May also be due to

contaminated or porous metal surface.

Usually occurs in high gold alloys.

www.indiandentalacademy.com

2) Metal oxide Porcelain:

Porcelain fractures at metal oxide

surface, leaving oxide firmly attached to

metal .Seen more often in base metal alloy

systems.

3) Metal Metal Oxide:

Metal oxide breaks away from the

metal and is left attached to the porcelain.

Seen commonly in base metal alloy

systems due to over production of

chromium and nickel oxides.

www.indiandentalacademy.com

4) Metal Oxide Metal Oxide:

Fracture occurs through the metal

oxide. Results from overproduction of

oxide causing sandwich effect between

metal and porcelain. Occurs during the

usage of nickel-chromium alloys.

5) Cohesive within Metal:

More common in bridges where the

joint area breaks. Rarely seen in single

crowns.

www.indiandentalacademy.com

6) Cohesive within Porcelain:

Tensile failure within porcelain. Bond

strength exceeds strength of porcelain.

Seen in high gold content alloys.

www.indiandentalacademy.com

Excessive

absorption of

oxides by the

porcelain can lower

the porcelain's

coefficient of

thermal expansion,

alter the final

shade (cause a

graying or bluing),

or do both (Naylor,

1986

www.indiandentalacademy.com

Changes in the

shade of the

porcelain may

not be noticeable

with posterior

restorations,

particularly if a

greater thickness

of porcelain

masks the dark

oxides

www.indiandentalacademy.com

Incompatible materials

Further more, bond failures are not always

attributable to improper oxidation but may

actually be caused by a physical

incompatibility between the porcelain and

the metal substructure. The difference in

the coefficient of thermal expansion of the

veneering porcelain and the metal ceramic

alloy may be slight yet sufficient to be

responsible for cracking of the ceramic

veneer or substantial enough to result in

porcelain debonding.

www.indiandentalacademy.com

www.indiandentalacademy.com

Overoxidation/underoxidation

The oxidation procedure varies for alloys

of different compositions.

Careful processing followed by an

assessment of the postoxidation

appearance of each casting will ensure

that the procedure was accomplished

correctly.

Castings that are either overoxidized or

underoxidized should be reprocessed

accordingly until a uniform oxide of the

desired color and thickness recommended

for the alloy involved has formed.

www.indiandentalacademy.com

Contamination

castings that demonstrate some form

of contamination may not have to be

remade but by simply refinishing a

substructure's porcelain-bearing

surface may be all that is necessary

when surface debonding becomes

evident. Uncontaminated finishing

materials are used to prevent this.

www.indiandentalacademy.com

www.indiandentalacademy.com

Simply

refinishing this

casting removed

the surface and

subsurface

contamination

and resulted in

an appropriate

porcelain-metal

bond.

www.indiandentalacademy.com

Applying Porcelain to the Metal

Substructure

The application of dental porcelain to

the metal substructure is the single

most demanding procedure in the

fabrication of a metal ceramic

restoration.

As a rule, the skills needed for this

particular process require the most

effort to perfect.

www.indiandentalacademy.com

Instruments and equipment

Brushes

A variety of brush sizes and styles are

available in porcelain instrument kits, the

most important of which are the brushes

used for building or stacking porcelain.

. The size range varies from a no. 4 to a no. 8.

Sable brushes are the standard because

they permit easy manipulation of the

porcelain.

www.indiandentalacademy.com

Another frequently used instrument is a

large no.10 brush, often referred to as a

whipping brush

A basic instrument kit should also include

flat brushes with relatively stiff bristles.

These large- and small-sized brushes

should be kept dry because they are used

exclusively to remove porcelain particles

from non porcelain-bearing areas and from

inside the substructure prior to firing.

www.indiandentalacademy.com

Very small no. 0 to no. 000 sable

brushes are required for the

placement of stains or small

increments of porcelain. These

brushes are useful anywhere

maximum control is necessary

www.indiandentalacademy.com

Carving Instruments

Porcelain carving instruments, designed for

shaping and carving porcelain buildups.

Carving instruments serve two principal

functions.

1.Those with a serrated handle can be

used to condense wet porcelain.

2.Instruments with blades, as well as the

small discoid carver, can be used to build

(stack) porcelain, shape the buildup, and

carve the porcelain.

www.indiandentalacademy.com

Spatula

Small, flexible, metal spatula is used

to dispense and mix porcelain.

Any small metal fragments generated

during mixing can then be introduced

into the wet porcelain as

contaminants.

www.indiandentalacademy.com

This metal debris can dramatically discolor

the mix as well as the fired porcelain

restoration. With careful use, however, the

metal mixing spatula need not be abraded.

But for added safety, a glass mixing rod is

often substituted for the metal spatula to

avoid this problem altogether.

www.indiandentalacademy.com

Razor knives

Another necessity in the basic set of

instruments is some type of razor knife,

equipped with a thin, flexible blade for

carving the porcelain buildup.

www.indiandentalacademy.com

Hemostat

A small, straight or curved hemostat is

needed to hold the work during the

opaquing process and during porcelain

additions and condensation.

Hemostats can be modified to hold the

metal substructure securely without

damaging the metal margins. However, an

18-gauge handle added to the lingual collar

provides a convenient, safe, yet secure grip

for removing the restoration from the

working cast and holding it during

condensation

www.indiandentalacademy.com

Glass or ceramic mixing slab

Finally, either a glass slab, ceramic tile, or

ceramic tray can serve as a plate for

mixing and storing the porcelain during the

buildup procedure. Initially, a small mixing

slab will suffice (Fig 8-9a).

www.indiandentalacademy.com

As modifiers are added and more

complex buildups are attempted,a larger

working surface will be required to

accommodate all the different porcelain

mixtures

www.indiandentalacademy.com

PORCELAIN CONDENSATION.

Condensing dental porcelain actually

refers to any procedure that results in the

unfired porcelain particles being tightly

packed on to themselves.

As the particles moves closer together, the

air and moisture previously occupying the

space between the individual particles

move to the surface of the buildup.

www.indiandentalacademy.com

Any liquid or air that remains trapped in

the unfired porcelain will form voids in the

unfired ceramic.

The presence of porosity in fired porcelain

weakens the restoration and impairs its

esthetic qualities.

www.indiandentalacademy.com

In well-condensed porcelain there is

reduction in the amount of firing shrinkage.

Methods of porcelain condensation.

1) capillary action.

2) vibration

3) spatulation

4) whipping

5) dry powder addition.

www.indiandentalacademy.com

Capillary action.

The technique of blotting a wet

built up with absorbent paper

uses surface tension.

www.indiandentalacademy.com

Vibration.

Is created by passing a serrated

instrument over the neck of a

hemostat in which the restoration is

held.

Vibration is a means to mechanically

draw additional moisture to the

surface where it can then be removed

by blotting paper.

www.indiandentalacademy.com

Spatulation.

A spatula is used to apply ,

then rub the porcelain built up

to force the liquid to the

surface.

www.indiandentalacademy.com

Whipping.

A no. 10 sable brush is rapidly

moved over the porcelain surface

with a whipping motion. The

whipping motion brings the liquid

to the outer surface for blotting.

www.indiandentalacademy.com

Dry powder addition.

Requires dry porcelain powder be

sprinkled on an area of wet

porcelain, using the existing liquid

to moisten the powder addition.

www.indiandentalacademy.com

Opaquing the metal

substructure

The areas of the substructure that will

be veneered with porcelain must not

be touched and should be protected

from dust, oils from the skin, and any

other forms of contamination

www.indiandentalacademy.com

www.indiandentalacademy.com

Applying opaque porcelain

glass rod technique

First wet the oxidized metal substructure

to be veneered with distilled water and

gently vibrate the casting to thoroughly wet

the surface.

A wet surface makes porcelain application

easier and reduces the possibility of

trapping air between the porcelain and the

metal. The thin film of water also will draw

the opaque particles onto the metal

surface.

www.indiandentalacademy.com

www.indiandentalacademy.com

Use the pointed end of the glass rod to

apply the opaque porcelain. Begin by

opaquing the most convex portion of the

coping Move the opaque toward the

porcelain-metal junction from one

interproximal area to the other and

cover the incisal edge.

Glass rod technique.

www.indiandentalacademy.com

www.indiandentalacademy.com

Then move the opaque over the incisal

edge to cover the porcelain-bearing

surface on the lingual aspect. Once the

porcelain-bearing areas are completely

covered, lightly tap the hemostat and the

porcelain will settle into any concavities

www.indiandentalacademy.com

www.indiandentalacademy.com

If, during the opaque application,

areas of opaque appear rough and

irregular, lightly tap the hemostat

handle or move the serrations on a

carver across the hemostat in a

sawing motion.

The vibrations created by either of

these procedures will act to

condense the wet porcelain into a

more uniform layer.

www.indiandentalacademy.com

www.indiandentalacademy.com

Excess moisture should be removed

before the opaque is applied to the metal.

Gently blend the opaque at the porcelain-

metal junction.

Lightly tap the hemostat and dry the

opaque by placing it in front of an open

porcelain furnace muffle.

www.indiandentalacademy.com

www.indiandentalacademy.com

Dry the opaque layer

by exposing it to the

heat radiating from

the porcelain muffle.

www.indiandentalacademy.com

www.indiandentalacademy.com

A properly fired

(sintered)

opaque layer

should have a

sheen or

eggshell glisten.

www.indiandentalacademy.com

If a second application of opaque

porcelain is required, lightly wet the

opaqued surface with opaque liquid.

Apply the second opaque porcelain

layer in the same manner as the first.

Keep this second layer as thin and

uniform as possible.

www.indiandentalacademy.com

www.indiandentalacademy.com

www.indiandentalacademy.com

Applying opaque porcelain

brush technique

Simply mix the

opaque porcelain

.Use the tip of

porcelain brush to lift

a portion of the mixed

opaque

www.indiandentalacademy.com

Apply the porcelain on the most

convex part of the oxidized coping.

Repeat the process several times

until the porcelain-bearing area is

completely covered with porcelain.

www.indiandentalacademy.com

www.indiandentalacademy.com

www.indiandentalacademy.com

Mixing dentin porcelains

The technique for mixing body

porcelains is same as that used

to mix opaque porcelains in that a

glass rod is preferred to a metal

spatula and the liquid is carefully

added to the powder to prevent

the entrapment of air.

www.indiandentalacademy.com

Mix the body

powders (dentin

and enamel) with

the

recommended

liquid (Vita VMK

68 porcelain and

modeling liquid )

www.indiandentalacademy.com

When properly

mixed, dentin

porcelain should

have a

smooth,cream

consistency.

www.indiandentalacademy.com

If too much liquid is

added to the mix,

use a tissue or

blotting paper to

remove excess

liquid until the

proper consistency

is achieved.

www.indiandentalacademy.com

Appling dentin porcelain.

The dentin porcelain buildup

procedure is to apply and condense

enough porcelain to create a

restoration that is 10% to 15% large

than normal.

www.indiandentalacademy.com

This overbuilding will accommodate

the enamel veneer that will be placed

over the dentin layer and help to

compensate for shrinkage of the

porcelain. A high quality sable brush

is preferred to create the porcelain

buildup

www.indiandentalacademy.com

The dentin built up technique.

Return the

cleaned,

opaqued coping

to the master

cast.

www.indiandentalacademy.com

To minimize the

entrapment of air in

the porcelain,

move the tip of the

pointed brush

through the mixed

dentin porcelain

and remove the

brush with the

dentin porcelain

captured on the

brush

www.indiandentalacademy.com

Apply the

porcelain to the

most convex

surface (midfacial

area) on the

restoration.

www.indiandentalacademy.com

Coax the porcelain

toward the

interproximal and

incisal areas. Add

more porcelain to

the facial surface

and use a light

tapping motion to

move the porcelain

along the

porcelain-metal

junction.

www.indiandentalacademy.com

Move the porcelain

down to the incisal

edge and lightly blot

the buildup to

condense the

porcelain on the

substructure. place

the additional dentin

porcelain in the incisal

region and move it

from one

interproximal area to

the other.

www.indiandentalacademy.com

Control the flow of

the material and

condense the

buildup by

periodically blotting

the wet porcelain

with the tissue. use

light gingival-to-

incisal strokes on

the facial surface

to create the

desired facial

contour.

www.indiandentalacademy.com

Add additional

porcelain to the

incisal aspect of

the incisal edge.

www.indiandentalacademy.com

Add additional

porcelain to

complete the

mesial and distal

corners.

www.indiandentalacademy.com

Cutting back the dentin buildup

With the buildup complete, dentin

porcelain as to be removed from those

areas of the crown where you would like to

have enamel porcelain. The procedure of

removing dentin porcelain for enamel

placement is referred to as the "dentin

cutback."

www.indiandentalacademy.com

If dentin porcelain is overbuilt(A), the amount of

dentin remaining after the cutback may also be

incorrect.

www.indiandentalacademy.com

When the restoration has the correct

anatomical contours and is slightly

overbuilt(A) by 10% to 15%, the dentin

cutback will also be correct.

www.indiandentalacademy.com

With a razor

knife cut back

the incisal edge

from between 1

to 1.5 mm.

Dentin cut back technique

www.indiandentalacademy.com

Remove dentin

porcelain at the

mesial

interproximal line

angle. Extend the

cut to the junction

of the middle and

gingival one thirds

for younger

patients.

www.indiandentalacademy.com

Cut across the

middle one third.

Stop the cut

back at the distal

interproximal

area.

www.indiandentalacademy.com

At the distal

interproximal line

angle, make a cut

from the incisal edge

toward the gingival

one third as far as

required for the

esthetics .Then cut

back the middle one

third of the facial

surface as necessary.

www.indiandentalacademy.com

Examine the

restoration from

an incisal view

for symmetry

and adequacy of

the cutback.

www.indiandentalacademy.com

Smooth the

cutback areas

with the

porcelain brush

so the transitions

from dentin to

enamel porcelain

are gradual.

www.indiandentalacademy.com

For younger

patients ,develop

mamelons.With a

pointed brush

,create two

depressions on the

facial surface with

vertical strokes

from incisal to

gingival.

www.indiandentalacademy.com

Mixing the enamel

porcelain.

www.indiandentalacademy.com

Glass rod is used

to mix the powder

and liquid .The

enamel mix is

slightly wetter than

the dentin mix to

facilitate its

addition to a

previously applied

and condensed

dentin layer.

www.indiandentalacademy.com

The mixed enamel

porcelain should have

a consistency that

permits it to be readily

picked up by a

properly pointed

porcelain brush.

www.indiandentalacademy.com

With a pointed

brush, apply

enamel porcelain

to one corner of

the cutback.

www.indiandentalacademy.com

Add more enamel

porcelain and

move it across the

facial surface in the

incisal one third.

Push the wet mix

toward the middle

one third of the

crown and work it

into the opposite

interproximal line

angle.

www.indiandentalacademy.com

Blend the enamel

porcelain at the

junction of the

middle and gingival

one thirds and

begin to establish

the incisal edge

and condense the

porcelain by

blotting

periodically.

www.indiandentalacademy.com

With additional

enamel porcelain,

complete the

incisal edge length

and the mesial-

incisal line angle.

Work your way

along the incisal

edge to create

more of a distal-

incisal line angle.

www.indiandentalacademy.com

Blend the enamel

porcelain into the

gingival one third

on the facial

surface. Re-create

the interproximal

contours and line

angles.

www.indiandentalacademy.com

Shape the mesial-

incisal corner as

required for each

case. Examine the

builtup from an

incisal view and

evaluate the

overall shape.

Make certain the

restoration is

slightly over built.

www.indiandentalacademy.com

Condense the built

up.

www.indiandentalacademy.com

Use your thin razor

knife to cut and

shape the mesial

and distal

interproximal

areas. This

procedure also

removes any

unwanted

porcelain below the

interproximal

contact areas.

www.indiandentalacademy.com

Carefully remove

the crown from the

master cast. Add

enamel porcelain

to the small

dimples in each

interproximal

contact area.

www.indiandentalacademy.com

Remove excess

porcelain from the

porcelain-metal

junction and clean the

facial metal collar of

any porcelain with a

small brush or your

pointed porcelain

buildup brush.

www.indiandentalacademy.com

Firing procedure.

The large bulk need more time to dry and

pre-heat.

Adhere to manufacturers recommended

drying time.

A properly fired porcelain body bake

should have a pebbly or orange peel

appearance.

www.indiandentalacademy.com

Adjusting and finishing the metal

ceramic restoration.

Applying and firing the porcelain veneer to

a metal substructure only approximates

the shape, contour, occlusion, and surface

finish restoration.

The porcelain application process requires

slight overbuild of the ceramic, this results

in a bulky restoration.

www.indiandentalacademy.com

Consequently, the fired porcelain requires

additional adjustments to reduce any

overcontouring and recreate a lifelike

ceramic surface finish before the

characterizing (staining) and glazing

stages.

Adjusting , contouring, and finishing

procedures for metal ceramic restorations

play a critical role in achieving both proper

function and optimal esthetics.

www.indiandentalacademy.com

Armamentarium.

1. Equipment Handpiece with speeds of

50,000 rpm or below.

2. Instruments Iwanson metal caliper.

3. Materials Diamond abrasives,

Prepolish wheels, diamond disks.

www.indiandentalacademy.com

The iwanson

metal calipers

can be used for

thickness

measurements

of metal or metal

and porcelain.

www.indiandentalacademy.com

Diamond abrasive

instruments.

www.indiandentalacademy.com

Porcelain

prepolish wheel

.Designed for

smoothening and

polishing

ceramic

surfaces.

www.indiandentalacademy.com

Diamond disks

For adjusting

and contouring

interproximal

areas.

www.indiandentalacademy.com

Procedures in adjusting and

finishing the metal ceramic

restoration.

1. To ensure the

casting

completely seats

on the die.

www.indiandentalacademy.com

2.Adjusting the interproximal contacts.

a) Mark the

mesial

interproximal

contact using

thin double

sided marking

film.

www.indiandentalacademy.com

b) Marking

identifies the

location and

intensity of

contact.

www.indiandentalacademy.com

Adjustments in

the contact area

with pre-polish

wheel.

www.indiandentalacademy.com

The thickness of

the restoration is

periodically

checked to

ensure that it is

not over

contoured.

www.indiandentalacademy.com

The desired

characterization

is marked and

with an

abrasive the

appropriate

shape is

created with

desired effect.

www.indiandentalacademy.com

Staining and glazing.

After a restoration has been adjusted and

finished, it is necessary to make color

corrections or additions and create a

lifelike surface luster.

www.indiandentalacademy.com

Surface stains

should be

applied with a

small sable

brush.

www.indiandentalacademy.com

Stain is placed

in area where

the

characterization

is intended.

Blend or dilute

the effect of the

stain

www.indiandentalacademy.com

The glaze is

picked up with

a staining

brush and

applied to the

ceramic

surface where

desired.

www.indiandentalacademy.com

Dry the

restoration in the

porcelain

furnace.

www.indiandentalacademy.com

The restoration is

fired according to the

porcelain

manufacturers

direction.

www.indiandentalacademy.com

Typically

glazed

restoration.

www.indiandentalacademy.com

Mechanical polishing.

Mechanical polishing of the

restoration after glazing gives the

restoration a natural life like

appearance.

www.indiandentalacademy.com

A diamond polishing

paste.

Pumice flour

www.indiandentalacademy.com

After

mechanical

polishing. A

life like luster

is created in

the ceramic

yet the surface