Академический Документы

Профессиональный Документы

Культура Документы

Metals Extrusion and Drawing Processes Explained

Загружено:

Arvind Bhosale0 оценок0% нашли этот документ полезным (0 голосов)

118 просмотров26 страницThis document provides an overview of extrusion and drawing processes for metals. It discusses the key aspects of each process, including:

- Extrusion involves forcing a billet through a die to produce a part with constant cross-section, while drawing reduces the cross-section of solid rod/wire/tubing by pulling it through a die.

- The main types of extrusion are direct, indirect, and hydrostatic extrusion. Drawing force depends on factors like die angle, cross-section reduction, and material properties.

- Defects in both processes include surface cracking, internal cracking, and center cracking. Process parameters need to be optimized to reduce defects and residual stresses.

Исходное описание:

extrusion

Оригинальное название

Extrusion

Авторское право

© © All Rights Reserved

Доступные форматы

PPT, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документThis document provides an overview of extrusion and drawing processes for metals. It discusses the key aspects of each process, including:

- Extrusion involves forcing a billet through a die to produce a part with constant cross-section, while drawing reduces the cross-section of solid rod/wire/tubing by pulling it through a die.

- The main types of extrusion are direct, indirect, and hydrostatic extrusion. Drawing force depends on factors like die angle, cross-section reduction, and material properties.

- Defects in both processes include surface cracking, internal cracking, and center cracking. Process parameters need to be optimized to reduce defects and residual stresses.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PPT, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

118 просмотров26 страницMetals Extrusion and Drawing Processes Explained

Загружено:

Arvind BhosaleThis document provides an overview of extrusion and drawing processes for metals. It discusses the key aspects of each process, including:

- Extrusion involves forcing a billet through a die to produce a part with constant cross-section, while drawing reduces the cross-section of solid rod/wire/tubing by pulling it through a die.

- The main types of extrusion are direct, indirect, and hydrostatic extrusion. Drawing force depends on factors like die angle, cross-section reduction, and material properties.

- Defects in both processes include surface cracking, internal cracking, and center cracking. Process parameters need to be optimized to reduce defects and residual stresses.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PPT, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 26

Chapter 15

Extrusion and Drawing

of Metals

Topics

Introduction

The Extrusion Process

Extrusion Practice

Hot Extrusion

Cold Extrusion

Impact Extrusion

Hydrostatic Extrusion

Extrusion Defects

Extrusion Equipment

The Drawing Process

Drawing Practice

Defects and Residual

Stresses

Drawing Equipment

Introduction

Extrusion It is a process where a billet is forced

through a die.

Parts have constant cross-section

Typical Products of Extrusion Sliding Doors,

tubing having various cross-sections, structural and

architectural shapes and door and window frames.

Drawing It is a process where a cross-section of

solid rod, wire, or tubing is reduced or changed in

shape by pulling it through a die.

Extrusions

Fig : Extrusions and

examples of

products made by

sectioning off

extrusions.

The Extrusion Process

Types of Extrusion :

Direct Extrusion (or) Forward Extrusion Billet is placed in a

chamber and forced through a die opening by a hydraulically-driven ram or

pressing stem.

Indirect Extrusion Die moves towards the billet.

Hydrostatic Extrusion The billet is smaller in diameter that the

chamber, which is filled with a fluid, and the pressure is transmitted to the

billet by a ram.

Extrusion Ratio = A

o

/A

f

A

o

cross-sectional area of the billet

A

f

- cross-sectional area of extruded product

Direct Extrusion

Fig : Schematic illustration of direct extrusion process.

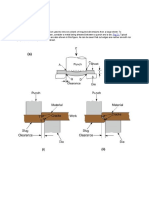

Types of Extrusion

Fig : Types of Extrusion (a) indirect

(b) hydrostatic (c) lateral

Process Variables in Direct Extrusion

Fig : Process variables in direct

extrusion. The die angle,

reduction in cross-section,

extrusion speed, billet

temperature, and lubrication

all affect the extrusion

pressure.

Fig : Method of determining the

circumscribing-circle

diameter (CCD) of an

extruded cross-section.

Extrusion Force :

F = A

o

kIn(A

o

/A

f

)

k-extrusion constant

A

o

, A

f

billet and extruded product areas

Fig : Extrusion constant k for various

metals at different temperatures

Types of Metal flow in extruding with square dies.

Fig : Types of metal flow in extruding with square dies. (a) Flow pattern obtained at low friction, or in indirect

extrusion. (b) Pattern obtained with high friction at the billet-chamber interfaces, (c) Pattern obtained at

high friction, or with cooling of the outer regions of the billet in the chamber. This type of pattern, observed

in metals whose strength increases rapidly with decreasing temperature, leads to defect known as pipe, or

extrusion defect.

Hot Extrusion

Extrusion is carried out at elevated temperatures for metals and

alloys that do not have sufficient ductility at room temperature, or

in order to reduce the forces required.

Die Design and Die Materials

Fig : (a) An extruded 6063-T6 aluminum ladder lock for aluminum extension ladders. This parts is 8mm thick and

is sawed from the extrusion, (b)-(d) Components of various dies for extruding intricate hollow shapes.

Cross-sections to be extruded

Fig : Poor and good examples of cross-sections to be extruded. Note the importance of eliminating sharp

corners and of keeping section thickness uniform.

Cold Extrusion

Combination of operations, such as direct and indirect extrusion and forging.

Advantages :

Improved mechanical properties

Good control of dimensional tolerances

Improved surface finish

Elimination of the need for billet heating;

Fig : Two examples of cold

extrusion. Thin arrows

indicate the direction

of metal flow during

extrusion.

Impact Extrusion

Similar to indirect extrusion

Punch descends rapidly on the blank, which is extruded backward

Fig : Schematic illustration of the impact-extrusion process. The extruded parts are

stripped by the use of a stripper plate, because they tend to stick to the punch.

Examples of Impact Extrusion

Fig : (a) Two examples of products made by impact extrusion. These parts may also be made by casting, by forging,

or by machining; the choice of process depends on the dimensions and the materials involved and on the

properties desires. Economic considerations are also important in final process selection. (b) and (c) Impact

extrusion of a collapsible tube by the Hooker process.

Hydrostatic Extrusion

The pressure required for extrusion is supplied through and incompressible fluid medium

surrounding the billet

Usually carried at room temperature, typically using vegetable oils as the fluid

Brittle materials are extruded generally by this method

It increases ductility of the material

It has complex nature of the tooling

Fig : General view of a 9-

MN (1000-ton) hydraulic-

extrusion press.

Extrusion Defects

1. Surface cracking.

2. Pipe.

3. Internal Cracking

Fig : (a) Chevron cracking (central burst) in extruded round steel bars. Unless the products are inspected, such internal

defects may remain undetected, and later cause failure of the part in service. This defect can also develop in the

drawing of rod, of wire, and of tubes. (b) Schematic illustration of rigid and plastic zones in extrusion. The

tendency toward chevron cracking increases if the two plastic zones do not meet. Note that the plastic zone can be

made larger either by decreasing the die angel or by increasing the reduction in cross-section (or both).

Drawing Process

In this process the cross section of a round rod or wire is typically reduced or

changed by pulling it through a die

Die angle has great influence on the drawing force and the quality of the drawn

product

Drawing FORCE :

F = Y

avg

Af In (Ao/Af) ; Y

avg

average true stress of the material in the die gap

Fig : Process variables in wire

drawing. The die angle, the

reduction in cross-sectional

area per pass, the speed of

drawing, the temperature,

and the lubrication all affect

the drawing force, F.

Tube Drawing Operations

Fig : Examples of tube-drawing operations, with and without internal mandrel. Note that a variety of

diameters and wall thickness can be produced from the same initial tube stock (which had been made

by other processes).

Die Design

Characteristic features of a typical die design for drawing

Fig : Terminology of a typical

die used for drawing

round rod or wire.

Fig : Tungsten-carbide die insert in a

steel casing. Diamond dies, used in

drawing thin wire, are encased in a

similar manner.

Die Materials

Commonly used materials are Tool Steels and Carbides

Diamond dies are used for fine wire.

For improved wear resistance, steel dies may be chromium

plated, and carbide dies may be coated with titanium nitride

For Hot drawing, cast-steel dies are used

Lubrication

Proper lubrication is essential in drawing, in order to improve

die life, reduce drawing forces and temperature, and

improve surface finish.

Types of Lubrication

a) Wet drawing : Dies and Rods are completely immersed in

lubricant

b) Dry drawing : Surface of the rod to be drawn is coated

with a lubricant

c) Coating : Rod or Wire is coated with a soft metal that acts

as a solid lubricant

d) Ultrasonic Vibration of the dies and mandrels.

Defects and Residual Stresses

Typical defects are

center cracking

seams

Fig : Schematic illustration of roll straightening of a drawn round rod.

DRAWING EQUIPMENT

Fig : Two views of multistage wire-drawing machine that is typically

used in the making of copper wire for electrical wiring.

THE END

Вам также может понравиться

- Casting Processes: DR Ajay BatishДокумент46 страницCasting Processes: DR Ajay BatishAlisha GuptaОценок пока нет

- The T6 Heat Treatment of Semi-Solid Metal Processed Alloy A356Документ5 страницThe T6 Heat Treatment of Semi-Solid Metal Processed Alloy A356tumoyeОценок пока нет

- Unit-V Design of Moulds Molding PartsДокумент8 страницUnit-V Design of Moulds Molding Partsyuvaraj4509Оценок пока нет

- Aluminum Die Casting Process FlowДокумент13 страницAluminum Die Casting Process FlowPrabish KumarОценок пока нет

- Casting Technology: DC School Text BookДокумент23 страницыCasting Technology: DC School Text BookmikeОценок пока нет

- Calculating Plastic Component Shrinkage and DistortionДокумент4 страницыCalculating Plastic Component Shrinkage and DistortionRajendra Kumar SharmaОценок пока нет

- MP-I - Unit 5 - Sheet Metal WorkingДокумент60 страницMP-I - Unit 5 - Sheet Metal WorkingTirumala Height Phase-IОценок пока нет

- Die Casting GuidelinesДокумент12 страницDie Casting GuidelinesMichael Arvin GabineteОценок пока нет

- Interview QuestionДокумент22 страницыInterview QuestionsugeshОценок пока нет

- Design For InjectionДокумент38 страницDesign For Injectionnurwinantoindra100% (1)

- Design For Mouldability-UK092010Документ16 страницDesign For Mouldability-UK092010mjobson100% (1)

- Sheet Metal ShopДокумент43 страницыSheet Metal ShopBhaskar KandpalОценок пока нет

- Troubleshooting Guide 1Документ4 страницыTroubleshooting Guide 1Cindy GallosОценок пока нет

- BME Unit IV Machine ToolsДокумент41 страницаBME Unit IV Machine ToolsArvind BhosaleОценок пока нет

- Injection Moulding Defects GuideДокумент10 страницInjection Moulding Defects GuideAmith S KaratkarОценок пока нет

- Plastics Processing TechniquesДокумент59 страницPlastics Processing TechniquesSusmit NimjeОценок пока нет

- 2.17. Design Procedure For Progressive DiesДокумент2 страницы2.17. Design Procedure For Progressive DiesAnand Prajapati100% (1)

- Die Casting Heat Treatment Process To Increase Strength Part 2Документ6 страницDie Casting Heat Treatment Process To Increase Strength Part 2itslowОценок пока нет

- CSM 1Документ119 страницCSM 1Chris LumyОценок пока нет

- Injection molding machine schematics and process guideДокумент29 страницInjection molding machine schematics and process guideTamirat NemomsaОценок пока нет

- Astm B308 - B308M 10Документ6 страницAstm B308 - B308M 10Harold NaiborhuОценок пока нет

- What Are Bend Allowance, Bend Deduction and K-FactorДокумент11 страницWhat Are Bend Allowance, Bend Deduction and K-Factoritsme5616Оценок пока нет

- Engineering Metrology and MeasurementsДокумент128 страницEngineering Metrology and MeasurementsArvind Bhosale100% (7)

- Squeeze CastingДокумент38 страницSqueeze Castingjishnus100% (1)

- SHEARINGДокумент6 страницSHEARINGanmol6237Оценок пока нет

- How Voids Form in Thick Plastic PartsДокумент4 страницыHow Voids Form in Thick Plastic PartsRavindra ErabattiОценок пока нет

- CAE DS – High Pressure Die Casting Design Parting LineДокумент9 страницCAE DS – High Pressure Die Casting Design Parting LineGanesan ThangasamyОценок пока нет

- Ejector PinsДокумент21 страницаEjector PinssyazwanmahadzirОценок пока нет

- Powder Metallurgy: Basics & Applications Powder MetallurgyДокумент11 страницPowder Metallurgy: Basics & Applications Powder MetallurgyVivek BajpaiОценок пока нет

- A RUNNER-GATE DESIGN SYSTEM FOR DIE CASTING DIESДокумент9 страницA RUNNER-GATE DESIGN SYSTEM FOR DIE CASTING DIESKetan ChhedaОценок пока нет

- Aker Solutions LNGДокумент27 страницAker Solutions LNGruov100% (1)

- Datasheet EFPE 1003ANДокумент1 страницаDatasheet EFPE 1003ANAhyoria ZapataОценок пока нет

- Casting ProcessesДокумент20 страницCasting ProcessesVv4HОценок пока нет

- VacuumДокумент6 страницVacuum03sri03Оценок пока нет

- Creo EnglishДокумент83 страницыCreo EnglishTruonglanaОценок пока нет

- Ahmedabad and Gujarat Sample DataДокумент20 страницAhmedabad and Gujarat Sample DataPriya Shinde100% (1)

- Feed Is The Path, Which Plastic Melt From Nozzle Traverses To Reach The Impressions Without Much Loss of andДокумент26 страницFeed Is The Path, Which Plastic Melt From Nozzle Traverses To Reach The Impressions Without Much Loss of andS Karthick KeyanОценок пока нет

- MOLD PLASTIC SETДокумент98 страницMOLD PLASTIC SETSenthil KumarОценок пока нет

- 11 KV 120 SQMM AAA Covered Conductor TSДокумент7 страниц11 KV 120 SQMM AAA Covered Conductor TSabhishekОценок пока нет

- MoldДокумент44 страницыMoldrohitОценок пока нет

- Difference Between Forging and CastingДокумент2 страницыDifference Between Forging and CastingMOHAMMAD ALIОценок пока нет

- CH03. Sheet Metal ProcessesДокумент73 страницыCH03. Sheet Metal ProcesseshizanorhudaОценок пока нет

- Chapter 5-Sheet MetalworkingДокумент82 страницыChapter 5-Sheet MetalworkingSeab PisethОценок пока нет

- Plastic Fasteners Welding BondingДокумент28 страницPlastic Fasteners Welding BondingcfcshakerОценок пока нет

- Advantages of LPDCДокумент2 страницыAdvantages of LPDCSuhas KrishnaОценок пока нет

- Squeeze Casting - An Overview PDFДокумент9 страницSqueeze Casting - An Overview PDFDian Try SaputriОценок пока нет

- Extrusion Design GuideДокумент12 страницExtrusion Design GuideL.A. AlumíniosОценок пока нет

- Plastic Metal Forming of Metals and PowdersДокумент20 страницPlastic Metal Forming of Metals and Powdersيوسف عادل حسانينОценок пока нет

- Metal Casting Design: Mold and Gating System Design, Directional Solidification, and TroubleshootingДокумент7 страницMetal Casting Design: Mold and Gating System Design, Directional Solidification, and TroubleshootingzidaaanОценок пока нет

- Multi-Component Injection Molding PDFДокумент40 страницMulti-Component Injection Molding PDFkfaravОценок пока нет

- Principle of Spot WeldingДокумент2 страницыPrinciple of Spot Weldingkgggani100% (1)

- rr321803 Foundry TechnologyДокумент6 страницrr321803 Foundry TechnologySRINIVASA RAO GANTAОценок пока нет

- Sheet MetalДокумент11 страницSheet Metalshah_faizan123Оценок пока нет

- MFG Tooling - 09 Progressive Dies PDFДокумент16 страницMFG Tooling - 09 Progressive Dies PDFNhan LeОценок пока нет

- Metal-Casting Process and EquipmentДокумент18 страницMetal-Casting Process and EquipmentZulfikarUdenОценок пока нет

- Module 1 - Design Considerations DMEДокумент59 страницModule 1 - Design Considerations DMEsreeramhariharanОценок пока нет

- MD Design ConsiderationДокумент18 страницMD Design ConsiderationjhpatelОценок пока нет

- SPI Mold Finish - Practical Approach: ShareДокумент2 страницыSPI Mold Finish - Practical Approach: ShareDavid Lay IIОценок пока нет

- Sheet Metal WorkingДокумент23 страницыSheet Metal WorkingSujit MishraОценок пока нет

- METAL WORKING EXTRUSION PROCESSДокумент94 страницыMETAL WORKING EXTRUSION PROCESSSajjad0% (1)

- Advances in Casting TechnologiesДокумент34 страницыAdvances in Casting Technologiesvijaykumarn100% (1)

- Casting Process Overview: Sand Mould Preparation and Pattern MakingДокумент31 страницаCasting Process Overview: Sand Mould Preparation and Pattern MakingChirag TaterОценок пока нет

- Fundamentals of Metal CastingДокумент45 страницFundamentals of Metal CastingsuntharОценок пока нет

- Sheet MetalДокумент60 страницSheet MetalAnonymous tQhtrPbОценок пока нет

- Sheet MATALДокумент9 страницSheet MATALSunil KumarОценок пока нет

- Disb Ebc 2010 11Документ7 страницDisb Ebc 2010 11Arvind BhosaleОценок пока нет

- Experiment 4Документ3 страницыExperiment 4Arvind BhosaleОценок пока нет

- ZolotoIndustries BallValvesДокумент7 страницZolotoIndustries BallValvesabasakОценок пока нет

- Rangat Concept PlanДокумент10 страницRangat Concept Planmoses14Оценок пока нет

- Introduction To MeasurementДокумент48 страницIntroduction To MeasurementArvind BhosaleОценок пока нет

- Cyclic Elastoplastic Large Displacement Analysis and Stability Evaluation of Steel Tubular BracesДокумент16 страницCyclic Elastoplastic Large Displacement Analysis and Stability Evaluation of Steel Tubular BracesBoonsap WitchayangkoonОценок пока нет

- Experiment No 8Документ6 страницExperiment No 8Arvind BhosaleОценок пока нет

- Dial IndicatorsДокумент1 страницаDial IndicatorsArvind BhosaleОценок пока нет

- 02 KljuceviДокумент26 страниц02 KljuceviEkwere Wilfred UdohОценок пока нет

- Development of TQM in Steel Manufacturers' Production: KeywordsДокумент8 страницDevelopment of TQM in Steel Manufacturers' Production: Keywordsdede_xОценок пока нет

- Experiment 4Документ3 страницыExperiment 4Arvind BhosaleОценок пока нет

- Principios de MetrologiaДокумент4 страницыPrincipios de MetrologiaJonatan BuitragoОценок пока нет

- Experiment No 7-MQCДокумент7 страницExperiment No 7-MQCArvind Bhosale100% (1)

- Calibration of Measuring Instrument: Experiment No: 3 DateДокумент4 страницыCalibration of Measuring Instrument: Experiment No: 3 DateArvind BhosaleОценок пока нет

- TQM Excellence at Tata SteelДокумент6 страницTQM Excellence at Tata SteelSanthosh RMОценок пока нет

- Calibration of Measuring Instrument: Experiment No: 3 DateДокумент4 страницыCalibration of Measuring Instrument: Experiment No: 3 DateArvind BhosaleОценок пока нет

- 1) Introduction To ManufacturingДокумент15 страниц1) Introduction To ManufacturingShaleen ChhabraОценок пока нет

- Unit 4 Surface Texture: ObjectivesДокумент23 страницыUnit 4 Surface Texture: ObjectivesApechRangerОценок пока нет

- Principios de MetrologiaДокумент4 страницыPrincipios de MetrologiaJonatan BuitragoОценок пока нет

- Metrology AssignmentДокумент31 страницаMetrology AssignmentKailas Sree Chandran100% (1)

- Pune University Metrology Quality CourseДокумент3 страницыPune University Metrology Quality CourseArvind BhosaleОценок пока нет

- Uploadfolder 3808 Workshop PracticeДокумент26 страницUploadfolder 3808 Workshop PracticeChrise RajОценок пока нет

- Metrologyandgeometricdimensioningandtolerancing 140519071212 Phpapp02Документ105 страницMetrologyandgeometricdimensioningandtolerancing 140519071212 Phpapp02Arvind BhosaleОценок пока нет

- Metrology AssignmentДокумент31 страницаMetrology AssignmentKailas Sree Chandran100% (1)

- Pune University Metrology Quality CourseДокумент3 страницыPune University Metrology Quality CourseArvind BhosaleОценок пока нет

- LatheДокумент74 страницыLatheArvind BhosaleОценок пока нет

- BME Unit V ThermodynamicsДокумент22 страницыBME Unit V ThermodynamicsArvind Bhosale100% (3)

- Analysis of Tool Geometry for Screw Extrusion MachinesДокумент12 страницAnalysis of Tool Geometry for Screw Extrusion MachinesdjklikaОценок пока нет

- Training ReportsДокумент12 страницTraining ReportsSahil Garg100% (1)

- Co-rotating Twin-screw Extruders: Advancements for Higher Productivity and EfficiencyДокумент5 страницCo-rotating Twin-screw Extruders: Advancements for Higher Productivity and EfficiencySalem GarrabОценок пока нет

- Thematic Proceedings 2010Документ201 страницаThematic Proceedings 2010Walter montes hoyosОценок пока нет

- Internship Report CEATДокумент51 страницаInternship Report CEATrogerОценок пока нет

- Solidworks Manual (1) 1Документ45 страницSolidworks Manual (1) 1Daniel HerreraОценок пока нет

- MET-TECH - Product Data Sheet - EXTRUSION PRESS LINE - 2200 MT - 8"Документ2 страницыMET-TECH - Product Data Sheet - EXTRUSION PRESS LINE - 2200 MT - 8"Ângelo PereiraОценок пока нет

- Road Markings - Product Application Chart: HIGHWAY MARKINGS LTD - Kilshanroe, Enfield, Co. Meath & Charlestown, Co. MayoДокумент1 страницаRoad Markings - Product Application Chart: HIGHWAY MARKINGS LTD - Kilshanroe, Enfield, Co. Meath & Charlestown, Co. MayoShams KhattakОценок пока нет

- Nitriding SteelДокумент40 страницNitriding SteelkaoblekstenaОценок пока нет

- To PM Technology: A Guide For Designers and EngineersДокумент30 страницTo PM Technology: A Guide For Designers and EngineersBasliu DoinaОценок пока нет

- Living Hinge DesignДокумент9 страницLiving Hinge Designom.mauryaОценок пока нет

- Ocean Yc Ycb Ycb-Sc Catalogue 2012.04.24 PДокумент12 страницOcean Yc Ycb Ycb-Sc Catalogue 2012.04.24 Ppramithbuddhikaisi100% (1)

- Tosaf Polycarbonate Brochure FinalДокумент9 страницTosaf Polycarbonate Brochure FinalEsthikar khan0% (1)

- TC5CSZ (CS Series) : DatasheetДокумент4 страницыTC5CSZ (CS Series) : DatasheetankitОценок пока нет

- Volume 1 - General - V1-CH03-Basis of DesignДокумент32 страницыVolume 1 - General - V1-CH03-Basis of DesignMohamed100% (2)

- Pro-E Wildfire 5.0Документ10 страницPro-E Wildfire 5.0rolwin0% (1)

- CW March 2020 PDF For Download PDFДокумент68 страницCW March 2020 PDF For Download PDFАлексей СюкринОценок пока нет

- 3D Design and Modeling GuideДокумент111 страниц3D Design and Modeling GuideCad NoviceОценок пока нет

- DEFORM News Spring Summer 2023Документ2 страницыDEFORM News Spring Summer 2023Hossein VahediОценок пока нет

- Metals From Ores: 2. Scope of Extractive MetallurgyДокумент48 страницMetals From Ores: 2. Scope of Extractive MetallurgyAdetiyo Burhanudin HakimОценок пока нет

- Taizhou Zhuoxin Plastics Co., LTD.: PPR Raw Material Analysis ReportДокумент3 страницыTaizhou Zhuoxin Plastics Co., LTD.: PPR Raw Material Analysis ReportFabiola Sugey Gonzales CcamaОценок пока нет

- 1 Effect of MicrospheresДокумент8 страниц1 Effect of MicrospheresRehan SharmaОценок пока нет