Академический Документы

Профессиональный Документы

Культура Документы

Orang-E-Nick: Fruity-Nergic Rue Des Caramboles Mapou Mauritius

Загружено:

Hudaa NeetooОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Orang-E-Nick: Fruity-Nergic Rue Des Caramboles Mapou Mauritius

Загружено:

Hudaa NeetooАвторское право:

Доступные форматы

Orang-e-nick

Fruity-Nergic

Rue des Caramboles

Mapou

Mauritius

SCOPE:

The HACCP Team have identified the scope of this process as being:

Processing of oranges for final production of heat-sterilized shelf-stable

orange juice. The HACCP team have determined to address the potential

of Microbiological, Chemical and Physical contamination through the

process of intake, handling, processing, storage until despatch to the

distributors facilities.

PURPOSE:

Compliance with FDAs current Good Manufacturing Practice Regulation

21 CFR Part 110 and FDAs Juice HACCP Regulation 21 CFR Part 120.

Product Description

Product Name Orang-i-Nick

Composition Orange juice concentrate, water,

preservatives

Product characeteristics pH of 3.5

Moisture content of 97%

Method of preservation Heat treatment, aseptic packaging

Packaging (inner) Tetra Brik cartons

Packaging (outer) Plastic crates/ pallets

Storage conditions Ambient temperature (20-25C),

refrigerate after opening

Distribution method Ambient temperature (20-25C)

truck/trailer

Shelf life 1 year

Specific labeling requirements Not suitable for people with sulfite

allergies

Not suitable for infants under 1 year

Customer preparation Ready-to-drink

Orang-e-

nick

O

r

a

n

g

-

e

-

n

i

c

k

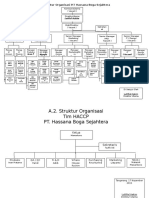

HACCP TEAM

Name Position Qualification/Experience

Harry Pillay HACCP team Leader HACCP Trainee Level 1,2,3,

Internal Audit Course, Trained in

GMPs, GHPs and ISO 9001 and ISO

22000, Juice HACCP regulations

Harry Pillay General Manager HACCP Trainee Level 1,2,3,

Internal Audit Course, Trained in

GMPs, GHPs, ISO 9001 and ISO

22000, Juice HACCP regulations

Selvina Kalleeperumal Production Manager HACCP Trainee Level 1,2,3, Trained

in GMPs, GHPs and Juice HACCP

regulations, ad-hoc training in

Process Control and equipment

calibration

Ashvin Khirodhur Quality Assurance Manager HACCP Trainee Level 1,2,3, trained

in Juice HACCP regulations, GMPs,

GHPs,

Enrico Chaitan Maintenance Manager HACCP Trainee Level 1,2,3, trained

in Preventative Maintenance,

HACCP Awareness

Hudaa Neetoo Procurement Manager HACCP Trainee Level 1,2,3,

Internal Audit Course

R

e

c

e

p

t

i

o

n

&

C

h

i

l

l

e

d

s

t

o

r

a

g

e

F

i

l

t

e

r

i

n

g

Washing

Selection

P

e

e

l

i

n

g

&

C

u

t

t

i

n

g

P

u

l

p

&

j

u

i

c

e

e

x

t

r

a

c

t

i

o

n

s

t

e

r

i

l

i

z

a

t

i

o

n

T

r

e

a

t

m

e

n

t

F

o

r

m

i

n

g

/

F

i

l

l

i

n

g

/

S

e

a

l

i

n

g

H

o

l

d

i

n

g

t

a

n

k

(

a

s

e

p

t

i

c

)

Bins Bins

Labeling/

Palletizing

Bins

B

i

n

s

Administrative Office

FRUITY-NERGIC ENTERPRISE FLOOR PLAN

Changing

room

T

a

n

k

Reception & storage

Washing, sanitizing, rinsing

Grading

Peeling &

Cutting

Pulp & juice

extraction

Filtering

C

o

n

t

i

n

u

o

u

s

s

t

e

r

i

l

i

z

a

t

i

o

n

T

r

e

a

t

m

e

n

t

a

t

8

0

C

f

o

r

3

0

s

C

o

o

l

i

n

g

&

H

o

l

d

i

n

g

(

a

s

e

p

t

i

c

)

f

o

r

3

0

m

i

n

u

n

t

i

l

p

r

o

d

u

c

t

t

e

m

p

e

r

a

t

u

r

e

r

e

a

c

h

e

s

<

3

5

C

F

o

r

m

i

n

g

/

F

i

l

l

i

n

g

2

5

0

m

l

/

S

e

a

l

i

n

g

P

a

c

k

a

g

e

L

a

b

e

l

l

i

n

g

/

P

a

l

l

e

t

i

z

i

n

g

PM

7-9 am

Lot, species, quantity

PM

Throughout shift (TS)

Quality, species

PM/QAM

Time/temperature

Every process

PM/QC

Labels/quantity/

packing

Every pallet

PM/QC

Dispensed volume

Every 30 mins

PM/QC

Product temperature

Every process

W

a

r

e

h

o

u

s

e

PM/QAM

Time/temperature

Every process

PM

TS

[Chlorine], water temperature

PM

TS

[detergent

],

[sanitizer]

PM

TS

GHPs, [detergent], [sanitizer]

TetraPak

cartons

Hydrogen

peroxide

bathing

UV

treatment

Processing

Step

Potential

Hazards

Likely? Severe

?

S/N Preventive measures CCP/C

P

Limit

s

Receiving Pathogenic

vegetative

bacteria &

spore-forming

bacteria (B)

Worms (B/Q)

Pesticides (C)

Stones/sand/s

oil/ metals (P)

Colorants/pig

ments (Q)

L

L

L

L

L

H

L

H

H

L

S

NS

S

S

NS

Control source. Letter of warranty.

Approved suppliers list. No harvest of

drops. Storage at 7C in chiller to

prevent bacterial and fungal

multiplication. Sterilization as final

killing step

Removed at grading stage

Random sampling to test for

pesticide residues. Spray programs

submitted by suppliers, Traceability

between raw material supplier and

end product

Removed at grading stage.

Metal detector after filtration

Removed at washing stage

CP

CP

CCP

CP

QP

-

-

< 10

ppb

-

-

Grading Pathogens

multiplication

(B)

L

H

S

Wash and sanitize hands using hand

dip. Cull out decayed and infected

products.

CP

-

Processing

Step

Potential Hazards

Likel

y?

Severe?

S/N Preventive measures CCP/

CP

Limits

Washing/

sanitizing/

rinsing

Pathogen

multiplication,

infiltration or

survival

Pesticide

infiltration (C)

L

L

H

H

S

S

Using chlorinated wash at

effective concentration,

dosage regularly monitored.

Sterilization as eventual heat

killing step

Temperature of water 7C

higher than core orange

temperature

CP

CP

-

-

Peeling &

Cutting

Pathogen

transference

and

multiplication

(B)

Pesticides

transference (C)

Metal/Blades (P)

L

L

L

H

H

H

S

S

S

High acidity prevents

multiplication. Destruction by

heat-killing step

Washing of knives at every

break

Metal detector after filtering

CP

CP

CP

-

Processing

Step

Potential Hazards

Likel

y?

Severe?

S/N Preventive measures CCP/C

P

Limits

Extraction

and

Filtering

Pathogen

survival and

multiplication

(B)

Spoilage

bacteria/molds

(B/Q)

Metal/Blades

(P)

L

L

L

H

M

H

S

NS

S

Destruction by sterilization -

heat killing step

Metal detector

CP

CP

CCP

-

-

< 2.5

mm

Sterilization Vegetative

pathogens

Pathogenic

sporeformers

Ascospores and

mycotoxin

formation

L

L

L

H

H

H

S

S

NS

Heat treatment at 85C for

30s. pH prevents outgrowth of

bacterial spores

pH prevents outgrowth of

spores and toxin formation

Anti-fungal preservatives

CCP

CP

CP

T:85C

t: 30s

Processing

Step

Potential Hazards

Likel

y?

Severe?

S/N Preventive measures CCP/C

P

Limits

Cooling &

holding

Pathogenic and

Spoilage

thermophilic

sporeformers

(B/Q)

Metal, rust

L

L

H

H

S

S

Product temperature to reach

< 35C. pH prevents

outgrowth of spores. Limited

oxygen availability prevents

outgrowth of aerobic spore-

formers.

Metal detector after packaging

CP/Q

P

CCP

-

-

Processing

Step

Potential Hazards

Likely

?

Severe?

S/N Preventive measures CCP/CP Limits

Forming/

filling/seali

ng

Pathogen

multiplication

(B)

Pathogen

cross-

contamination

(B)

Metals (P)

Underfilling

(Q)

L

L

L

L

H

M

M

H

S

NS

S

S

100% seal inspection

on-line , verification

of sealer bar,

random sampling for

seal strength and

integrity

Metal detector after

packaging

Calibration of

dispenser

CCP

CCP

Seal

strength:

5kg/100mm

Seal width:

10 mm

0 seal

defects

< 2.5 mm

Packaging/l

abeling/pall

etizing

Pests, rodents

(B/Q)

Wrong label

(Q)

L

L

M

L/M

NS

NS

Pallets placed at 18

cm from wall

Cling film wrapping

Package inspection

QP

QP

-

-

Вам также может понравиться

- HACCPДокумент64 страницыHACCPvalsvalsaraj50% (2)

- Haz Waste MNGMNTДокумент53 страницыHaz Waste MNGMNTajeetjdmОценок пока нет

- Cocoa Butter HACCPДокумент5 страницCocoa Butter HACCPmamasita25100% (1)

- Sample HACCP PlanДокумент1 страницаSample HACCP PlanBRIGHT DZAHОценок пока нет

- GROUP 4-Frozen FoodДокумент20 страницGROUP 4-Frozen FoodThanh VânОценок пока нет

- Reverse Osmosis System FaridДокумент30 страницReverse Osmosis System FaridAchFaridWadjdiОценок пока нет

- Material Safety Data Sheet: Identification of The Substance / Preparation, Revision Number and DateДокумент3 страницыMaterial Safety Data Sheet: Identification of The Substance / Preparation, Revision Number and Dateمحمود سلحشورОценок пока нет

- Water Criteria STD N Pollution 03Документ35 страницWater Criteria STD N Pollution 03Harshal SabaneОценок пока нет

- 2.5 FletchersHACCPanalysisДокумент4 страницы2.5 FletchersHACCPanalysisDenina Annisa100% (2)

- ACI Final Report SaraДокумент44 страницыACI Final Report SaraNishuti DeyОценок пока нет

- Fineamin Finealga 25Документ6 страницFineamin Finealga 25Irina AlexandraОценок пока нет

- Example HACCP StudyДокумент9 страницExample HACCP Studycassilda_carvalho@hotmail.comОценок пока нет

- Student Works: HACCP ANALYSIS Case 3: Canned Sardine in Tomato Sauce Group 1Документ11 страницStudent Works: HACCP ANALYSIS Case 3: Canned Sardine in Tomato Sauce Group 1nasonex91Оценок пока нет

- 241 MSDSДокумент7 страниц241 MSDSPete DechaОценок пока нет

- General Procedure For Analysis of PCB and Ocp PDFДокумент19 страницGeneral Procedure For Analysis of PCB and Ocp PDFSenkatuuka LukeОценок пока нет

- Assignment Food Safety Regulation: Topic: Potato ChipsДокумент8 страницAssignment Food Safety Regulation: Topic: Potato Chipsinfo tamilОценок пока нет

- UHT Theory LTHДокумент36 страницUHT Theory LTHthanhtl_hugolata100% (4)

- Product Catalogue 2011 12Документ184 страницыProduct Catalogue 2011 12Jagesh RanjanОценок пока нет

- SM 6630 Organochlorine Pesticides 185.6kbДокумент16 страницSM 6630 Organochlorine Pesticides 185.6kbDavid AmayaОценок пока нет

- Chocolate Liquor HACCPДокумент5 страницChocolate Liquor HACCPKSXОценок пока нет

- Chocolate Liquor HACCPДокумент5 страницChocolate Liquor HACCPanon_437804943Оценок пока нет

- English's Exposition VinoДокумент27 страницEnglish's Exposition VinoAnnel Lucero CarhuallanquiОценок пока нет

- Hazard Analysis Worksheet For Glass ContainersДокумент6 страницHazard Analysis Worksheet For Glass ContainersAdare Oluwafemi Thomas100% (1)

- Bio Rad WaterДокумент28 страницBio Rad Waterjluisreino3386Оценок пока нет

- CCP and OprpДокумент5 страницCCP and OprpGorack ShirsathОценок пока нет

- Determinacion NitratoДокумент43 страницыDeterminacion NitratoalvaritodgОценок пока нет

- Wastewater Treatment StepsДокумент21 страницаWastewater Treatment StepsMohammad Abu ShattalОценок пока нет

- Material Safety Data Sheet: Identification of The Substance / Preparation, Revision Number and DateДокумент3 страницыMaterial Safety Data Sheet: Identification of The Substance / Preparation, Revision Number and Dateمحمود سلحشورОценок пока нет

- BGQYNДокумент3 страницыBGQYNdalton2003Оценок пока нет

- C N (OH) MW: 129.08 CAS: 108-80-5 RTECS: XZ1800000: Cyanuric Acid 5030Документ4 страницыC N (OH) MW: 129.08 CAS: 108-80-5 RTECS: XZ1800000: Cyanuric Acid 5030Dian IryantiОценок пока нет

- FS Slides PRP Sept 2015 Compatibility ModeДокумент51 страницаFS Slides PRP Sept 2015 Compatibility Modealias brownОценок пока нет

- Marco RoqueДокумент8 страницMarco Roquemiguel angel luque gutiérrezОценок пока нет

- Petruci 2018Документ29 страницPetruci 2018Ngọc Ánh LêОценок пока нет

- 02 Packhouse Risk Assessments 2014Документ38 страниц02 Packhouse Risk Assessments 2014Johnson Gitonga Nderi80% (5)

- Haccp & Its Implementation in Food Industry: Dr. H. K. SharmaДокумент58 страницHaccp & Its Implementation in Food Industry: Dr. H. K. Sharmaankita pathaniaОценок пока нет

- SDS 3DT180Документ10 страницSDS 3DT180Rahadiyan100% (1)

- Waterpollution11807Документ52 страницыWaterpollution11807Mridula SaranОценок пока нет

- Hot Smoking Fish HACCP ReportДокумент16 страницHot Smoking Fish HACCP ReportSevim ArslanОценок пока нет

- Jitmm A15 Ramasoota TuberculosisДокумент29 страницJitmm A15 Ramasoota Tuberculosisblack2laminОценок пока нет

- API, Pharmacopoeia Impurities - Olympus Impurities Standard SuppliersДокумент13 страницAPI, Pharmacopoeia Impurities - Olympus Impurities Standard SuppliersOlympus Chemicals & FertilizersОценок пока нет

- MTLBE Report. Pueblo JADДокумент49 страницMTLBE Report. Pueblo JADJohn Alfrey Dondiego PuebloОценок пока нет

- The Hong Kong Polytechnic UniversityДокумент18 страницThe Hong Kong Polytechnic UniversityJasmine TsoОценок пока нет

- Tank Farm ConsiderationsДокумент102 страницыTank Farm ConsiderationsRakesh ShindeОценок пока нет

- 1746 Pharma Biotech Water Requirements GBДокумент2 страницы1746 Pharma Biotech Water Requirements GBnavas1972Оценок пока нет

- ff5 - Haccp Frying (2004)Документ22 страницыff5 - Haccp Frying (2004)Banuraspati100% (1)

- Disinfection: Jae K. (Jim) Park, Professor Dept. of Civil and Environmental Engineering University of Wisconsin-MadisonДокумент70 страницDisinfection: Jae K. (Jim) Park, Professor Dept. of Civil and Environmental Engineering University of Wisconsin-MadisonChanel100% (1)

- Hot Smoked Fish Company HACCP PlanДокумент11 страницHot Smoked Fish Company HACCP PlanRam Eman OsorioОценок пока нет

- STPP Technical - MsdsДокумент7 страницSTPP Technical - MsdskusmanОценок пока нет

- HACCP ImplementationДокумент25 страницHACCP ImplementationAronn SiamОценок пока нет

- Hazard AnalysisДокумент5 страницHazard AnalysisArun GuptaОценок пока нет

- 518 MSDSДокумент9 страниц518 MSDSPete DechaОценок пока нет

- Apb 2021-12-14Документ3 страницыApb 2021-12-14katiОценок пока нет

- Soy Sauce Production FinalДокумент40 страницSoy Sauce Production Finalafidah99Оценок пока нет

- RKJM 2Документ12 страницRKJM 2Muchamad MungfaridОценок пока нет

- HACCP Principles and Applications: Introduction To Food Safety HazardsДокумент6 страницHACCP Principles and Applications: Introduction To Food Safety HazardsSujit ShandilyaОценок пока нет

- R3000 - Rhodamine B - MSDSДокумент8 страницR3000 - Rhodamine B - MSDSSilva CondoeiraОценок пока нет

- Haccp Potatoes PDFДокумент22 страницыHaccp Potatoes PDFRoberto Carlos Marin Perez50% (2)

- PPL MSDS Material Data Safety SheetДокумент6 страницPPL MSDS Material Data Safety SheetvyompvОценок пока нет

- Breakfast Booster Marketing Plan I. Executive SummaryДокумент7 страницBreakfast Booster Marketing Plan I. Executive SummaryJasmine GabianaОценок пока нет

- Top Notch 1 Assessment Answer KeyДокумент5 страницTop Notch 1 Assessment Answer Keybe hatem66% (32)

- Uranium Chef o A World of Adventure For Fate Core (10889644)Документ76 страницUranium Chef o A World of Adventure For Fate Core (10889644)Alahel100% (2)

- The Pittston Dispatch 11-11-2012Документ70 страницThe Pittston Dispatch 11-11-2012The Times LeaderОценок пока нет

- Effect of Sales Promotion On Consumers With Reference To FMCG Companies in IndiaДокумент11 страницEffect of Sales Promotion On Consumers With Reference To FMCG Companies in IndiaBikram beheraОценок пока нет

- Tips and Recipes CookingДокумент100 страницTips and Recipes CookingNikola Arsovski100% (1)

- Hydroponics SWOT AnalysisДокумент21 страницаHydroponics SWOT AnalysisDОценок пока нет

- Alcoholic and Non-Alcoholic BeveragesДокумент30 страницAlcoholic and Non-Alcoholic BeveragesFrank BookhardtОценок пока нет

- Nidhishree Part2 (3) PDFДокумент51 страницаNidhishree Part2 (3) PDFDeepti NayakОценок пока нет

- Unit 3 Agricultural Systems Management Reliability of Agricultural SystemsДокумент22 страницыUnit 3 Agricultural Systems Management Reliability of Agricultural Systemsthirumangai6Оценок пока нет

- Behind The Brands: Food Justice and The 'Big 10' Food and Beverage CompaniesДокумент52 страницыBehind The Brands: Food Justice and The 'Big 10' Food and Beverage CompaniesOxfamОценок пока нет

- Chapter 1-6Документ35 страницChapter 1-6caironsalamОценок пока нет

- Lecture PPT of Alligation and Mixture (2) SolutionsДокумент40 страницLecture PPT of Alligation and Mixture (2) SolutionsVicky Guleria100% (2)

- Divi's Laboratories (DIVLAB) : Well Poised To Capture Revival in CRAMSДокумент20 страницDivi's Laboratories (DIVLAB) : Well Poised To Capture Revival in CRAMSspatel1972Оценок пока нет

- Pan Malayan InsuranceДокумент4 страницыPan Malayan InsuranceRegina AsejoОценок пока нет

- FINAL Questionnaire For Lack of Brand Loyalty of KFCДокумент3 страницыFINAL Questionnaire For Lack of Brand Loyalty of KFCmarayam112Оценок пока нет

- Final Report Based On 60 Days Market Work As A Nilons' Army Soldier in Mumbai MarketДокумент54 страницыFinal Report Based On 60 Days Market Work As A Nilons' Army Soldier in Mumbai MarketKabir SinghОценок пока нет

- Aspic and GeleeДокумент5 страницAspic and GeleeShailendra Kumar SinghОценок пока нет

- On VerkaДокумент17 страницOn VerkaDeepshikha Suri60% (5)

- This Post Describes About The Top 10 Best Ayurvedic Companies in IndiaДокумент7 страницThis Post Describes About The Top 10 Best Ayurvedic Companies in IndiaSiddhendu BhattacharjeeОценок пока нет

- RAJPUT - Gokul IndustryДокумент76 страницRAJPUT - Gokul IndustryrajputvjОценок пока нет

- 40221390-Dehydrated-Onion - MarketДокумент13 страниц40221390-Dehydrated-Onion - MarketGourav TailorОценок пока нет

- Full Text Lamb To SlaughterДокумент10 страницFull Text Lamb To SlaughterFakhrurrazi OppaОценок пока нет

- Activity Proposal 2021 - OFFERING ALA CARTE MENUДокумент3 страницыActivity Proposal 2021 - OFFERING ALA CARTE MENUsamcoronel925Оценок пока нет

- Garrett Greninger Resume PDFДокумент1 страницаGarrett Greninger Resume PDFapi-347363422Оценок пока нет

- Housekeeping Department and Other Department CoordinationДокумент8 страницHousekeeping Department and Other Department CoordinationDzeiy Euhm Tan Angeles0% (1)

- The Food Lab's Complete Guide To Pan-Seared SteaksДокумент13 страницThe Food Lab's Complete Guide To Pan-Seared SteaksMichael RyanОценок пока нет

- Yeast Production Industry: Global Market Is Expected To Grow at CAGR of 8.9% Over The Period 2016-2021Документ71 страницаYeast Production Industry: Global Market Is Expected To Grow at CAGR of 8.9% Over The Period 2016-2021Mohammed HammoudehОценок пока нет

- Amul Final ReportДокумент47 страницAmul Final Reportavinash tripathi100% (5)

- VCCI - Research On NTMs of The EU On VNese Fruit Exports EN-3.2019 PDFДокумент80 страницVCCI - Research On NTMs of The EU On VNese Fruit Exports EN-3.2019 PDFtien nguyenОценок пока нет

- The Beck Diet Solution Weight Loss Workbook: The 6-Week Plan to Train Your Brain to Think Like a Thin PersonОт EverandThe Beck Diet Solution Weight Loss Workbook: The 6-Week Plan to Train Your Brain to Think Like a Thin PersonРейтинг: 3.5 из 5 звезд3.5/5 (33)

- The Obesity Code: Unlocking the Secrets of Weight LossОт EverandThe Obesity Code: Unlocking the Secrets of Weight LossРейтинг: 4 из 5 звезд4/5 (6)

- Gut: The Inside Story of Our Body's Most Underrated Organ (Revised Edition)От EverandGut: The Inside Story of Our Body's Most Underrated Organ (Revised Edition)Рейтинг: 4 из 5 звезд4/5 (378)

- Summary of Mary Claire Haver's The Galveston DietОт EverandSummary of Mary Claire Haver's The Galveston DietРейтинг: 5 из 5 звезд5/5 (1)

- Love Yourself, Heal Your Life Workbook (Insight Guide)От EverandLove Yourself, Heal Your Life Workbook (Insight Guide)Рейтинг: 5 из 5 звезд5/5 (40)

- The Food Lover's Cleanse: 140 Delicious, Nourishing Recipes That Will Tempt You Back into Healthful EatingОт EverandThe Food Lover's Cleanse: 140 Delicious, Nourishing Recipes That Will Tempt You Back into Healthful EatingРейтинг: 4 из 5 звезд4/5 (3)

- Instant Loss On a Budget: Super-Affordable Recipes for the Health-Conscious CookОт EverandInstant Loss On a Budget: Super-Affordable Recipes for the Health-Conscious CookРейтинг: 3.5 из 5 звезд3.5/5 (2)

- Metabolism Revolution: Lose 14 Pounds in 14 Days and Keep It Off for LifeОт EverandMetabolism Revolution: Lose 14 Pounds in 14 Days and Keep It Off for LifeОценок пока нет

- Summary: Fast Like a Girl: A Woman’s Guide to Using the Healing Power of Fasting to Burn Fat, Boost Energy, and Balance Hormones: Key Takeaways, Summary and AnalysisОт EverandSummary: Fast Like a Girl: A Woman’s Guide to Using the Healing Power of Fasting to Burn Fat, Boost Energy, and Balance Hormones: Key Takeaways, Summary and AnalysisРейтинг: 3 из 5 звезд3/5 (2)

- Glucose Revolution: The Life-Changing Power of Balancing Your Blood SugarОт EverandGlucose Revolution: The Life-Changing Power of Balancing Your Blood SugarРейтинг: 5 из 5 звезд5/5 (351)

- The Body Book: The Law of Hunger, the Science of Strength, and Other Ways to Love Your Amazing BodyОт EverandThe Body Book: The Law of Hunger, the Science of Strength, and Other Ways to Love Your Amazing BodyОценок пока нет

- The Diabetes Code: Prevent and Reverse Type 2 Diabetes NaturallyОт EverandThe Diabetes Code: Prevent and Reverse Type 2 Diabetes NaturallyРейтинг: 4.5 из 5 звезд4.5/5 (2)

- Eat to Lose, Eat to Win: Your Grab-n-Go Action Plan for a Slimmer, Healthier YouОт EverandEat to Lose, Eat to Win: Your Grab-n-Go Action Plan for a Slimmer, Healthier YouОценок пока нет

- Sugar Crush: How to Reduce Inflammation, Reverse Nerve Damage, and Reclaim Good HealthОт EverandSugar Crush: How to Reduce Inflammation, Reverse Nerve Damage, and Reclaim Good HealthРейтинг: 4 из 5 звезд4/5 (6)

- How Not to Die by Michael Greger MD, Gene Stone - Book Summary: Discover the Foods Scientifically Proven to Prevent and Reverse DiseaseОт EverandHow Not to Die by Michael Greger MD, Gene Stone - Book Summary: Discover the Foods Scientifically Proven to Prevent and Reverse DiseaseРейтинг: 4.5 из 5 звезд4.5/5 (83)

- Secrets From the Eating Lab: The Science of Weight Loss, the Myth of Willpower, and Why You Should Never Diet AgainОт EverandSecrets From the Eating Lab: The Science of Weight Loss, the Myth of Willpower, and Why You Should Never Diet AgainРейтинг: 3.5 из 5 звезд3.5/5 (38)

- Find Your Path: Honor Your Body, Fuel Your Soul, and Get Strong with the Fit52 LifeОт EverandFind Your Path: Honor Your Body, Fuel Your Soul, and Get Strong with the Fit52 LifeРейтинг: 4 из 5 звезд4/5 (3)

- The Diet Trap Solution: Train Your Brain to Lose Weight and Keep It Off for GoodОт EverandThe Diet Trap Solution: Train Your Brain to Lose Weight and Keep It Off for GoodОценок пока нет

- How to Be Well: The 6 Keys to a Happy and Healthy LifeОт EverandHow to Be Well: The 6 Keys to a Happy and Healthy LifeРейтинг: 5 из 5 звезд5/5 (1)

- The Stark Naked 21-Day Metabolic Reset: Effortless Weight Loss, Rejuvenating Sleep, Limitless Energy, More MojoОт EverandThe Stark Naked 21-Day Metabolic Reset: Effortless Weight Loss, Rejuvenating Sleep, Limitless Energy, More MojoОценок пока нет

- The Arm: Inside the Billion-Dollar Mystery of the Most Valuable Commodity in SportsОт EverandThe Arm: Inside the Billion-Dollar Mystery of the Most Valuable Commodity in SportsРейтинг: 4 из 5 звезд4/5 (49)

- Eat Complete: The 21 Nutrients That Fuel Brainpower, Boost Weight Loss, and Transform Your HealthОт EverandEat Complete: The 21 Nutrients That Fuel Brainpower, Boost Weight Loss, and Transform Your HealthРейтинг: 2 из 5 звезд2/5 (1)

- Body Love Every Day: Choose Your Life-Changing 21-Day Path to Food FreedomОт EverandBody Love Every Day: Choose Your Life-Changing 21-Day Path to Food FreedomРейтинг: 4 из 5 звезд4/5 (1)

- The Volumetrics Eating Plan: Techniques and Recipes for Feeling Full on Fewer CaloriesОт EverandThe Volumetrics Eating Plan: Techniques and Recipes for Feeling Full on Fewer CaloriesОценок пока нет

- The Candida Cure: The 90-Day Program to Balance Your Gut, Beat Candida, and Restore Vibrant HealthОт EverandThe Candida Cure: The 90-Day Program to Balance Your Gut, Beat Candida, and Restore Vibrant HealthОценок пока нет

- Grit & Grace: Train the Mind, Train the Body, Own Your LifeОт EverandGrit & Grace: Train the Mind, Train the Body, Own Your LifeРейтинг: 4 из 5 звезд4/5 (3)