Академический Документы

Профессиональный Документы

Культура Документы

Separator Fundamentals - Process Design

Загружено:

laleye_olumide100%(3)100% нашли этот документ полезным (3 голоса)

841 просмотров30 страницThis document provides an overview of separator fundamentals, including:

- The basic principles of separation using momentum, gravity, and coalescing

- The key components of separators like inlet piping, primary separation, demisters, and liquid collection

- Different types of separators including vertical and horizontal designs

- Specifications separators require like process data, inlet piping details, and performance guarantees

Исходное описание:

Separator Fundamentals - Process Design

Авторское право

© © All Rights Reserved

Доступные форматы

PPT, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документThis document provides an overview of separator fundamentals, including:

- The basic principles of separation using momentum, gravity, and coalescing

- The key components of separators like inlet piping, primary separation, demisters, and liquid collection

- Different types of separators including vertical and horizontal designs

- Specifications separators require like process data, inlet piping details, and performance guarantees

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PPT, PDF, TXT или читайте онлайн в Scribd

100%(3)100% нашли этот документ полезным (3 голоса)

841 просмотров30 страницSeparator Fundamentals - Process Design

Загружено:

laleye_olumideThis document provides an overview of separator fundamentals, including:

- The basic principles of separation using momentum, gravity, and coalescing

- The key components of separators like inlet piping, primary separation, demisters, and liquid collection

- Different types of separators including vertical and horizontal designs

- Specifications separators require like process data, inlet piping details, and performance guarantees

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PPT, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 30

Separator Fundamentals

Process Engineering Lunch and Learn Session (1 April 2008)

Overview

Safety Moment: Aerosol Cans in Cars

Basic Principles of Separation

Separator Components

Types of Separator

Separator Specifications

Separator Sizing will be discussed in another session

Safety Moment: Aerosol Cans in Cars

This information has been reprinted from a published

newsletter on August 12, 2003 for the San Antonio Works

EHS Department:

Do you keep WD-40, hair spray, etc. in your vehicle? If so,

you might want to reconsider.

The incident pictured happened at a refinery in Beaumont,

Texas.

A deodorant spray can was left in the back of the vehicle that

was parked in an open space in the middle of a hot, sunny

day.

Without warning, the can exploded inside the car.

Fortunately, no one was inside or near the car when it

happened.

Safety Moment: Aerosol Cans in Cars

Basic Principles of Separation

Three basic principles are used to achieve physical

separation of gas, liquids and solids:

Momentum

Gravity

Coalescing (a subset of momentum)

Any separator may employ one or more of these principles

to achieve separation.

Fluid phases must be immiscible and have different

densities for separation to occur.

Momentum

Fluid phases with different densities will have different

momentum.

If a two phase stream changes direction sharply, greater

momentum will not allow particles of the heavier phase to

turn as rapidly as the lighter fluid, so separation occurs.

Momentum is usually employed for bulk separation of the

two phases in a stream.

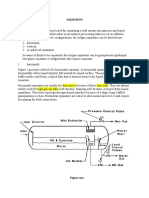

Gravity

Liquid droplets will settle out

if the gravitational force

acting on the droplet is

greater than the drag force

of the gas flowing around

the droplet.

Droplet attains terminal

velocity (Vt) when

gravitational force = drag

force

Vt is directly proportional to

Dp

Figure 7.2 GPSA Databook (11

th

Edition)

Coalescing

Very small droplets such as fog or mists cannot be

separated practically by gravity.

These droplets can be coalesced to form large droplets that

will settle by gravity.

Coalescing/demister devices in separator force droplets to

follow a tortuous path.

Droplets collide with other droplets on the coalescing device,

forming larger droplets which can then settle out by gravity.

Components of Separator

Inlet Piping (outside of

separator)

Primary Separation (A)

Gravity Settling (B)

Coalescing/Demister (C)

Liquid Collecting (D)

Figure 7.5 GPSA Databook (11

th

Edition)

Separator Inlet Piping

Minimises turbulence and velocity of fluid flowing into separator

Common specifications:

Straight length of pipe for 10 pipe diameters from separator

Avoid horizontal bends, elbows and control valves on inlet line immediately

upstream of separator (source of shear, turbulence and causes small

droplets)

Larger size of pipe to match separator inlet nozzle size for 10 pipe diameters

from separator

If inlet piping size cannot be modified (e.g. retrofit, space restriction):

Install guiding vanes or cyclone in inlet piping

Above specifications can minimise the amount of entrained liquid (mist)

therefore assisting separation

By providing piping data and process data, vendor can quantify amount

of bulk liquid, entrained liquid (mist) and particle size distribution to

greatly improve separator design

Primary Separation

Separates bulk liquid from gas

Uses inlet device to break the momentum and distribute the

flow

Figure 11.5 Campbells Volume 2

Half Pipe Inlet Device

Half Pipe Inlet Device

Gas shoots towards the back of the wall

Maldistribution of gas

Sends both gas and liquid downwards

Liquid entrainment in vapour flowing onto demister

www.cdsengineering.com

Vane Inlet Device

Distributes the fluid along the

vanes

Fluid (gas and liquid)

changes direction

Liquid follows the vane wall

and drops off

Gas follows the vane wall

and flows up

www.prosep.com

www.prosep.com

Cyclone Inlet Device

Fluid is directed by a swirl

element to spin along the

cyclone wall

Liquid flows downwards

along the cyclone wall

Gas flows downwards

together with liquid then

upwards

Liquid outlet can be

submerged in liquid phase

to minimise foaming

www.prosep.com

www.prosep.com

Gravity Settling

Utilises the force of gravity to enhance the separation of

entrained droplets.

Gas moves through the barrel at low velocity

D

L

h

L

g

V

gas

F

gravity

D

V

ga

s

F

gravity

Gravity Settling

Vertical vessel: specify diameter so that Vgas < Vterminal

Horizontal vessel: specify length of vessel to allow droplet to

settle

Straightening vanes are sometimes used to reduce

turbulence

Demister Section

Removes small droplets by coalescing small droplets to form

larger droplets so they can settle by gravity

Figure 11.5 Campbells Volume 2

Vane Pack and Wire Mesh

Vane Pack

Gas and liquid droplets forced

to change direction

Droplets absorbed by wet

surface and collected in

pockets

Can handle higher flow than

wire mesh

Mist Mat/Wire Mesh

Gas and liquid droplets

forced to change direction

Droplets strike surface

then flow downwards

More effective at

separating smaller

particles than vane pack

Figure 7-13 GPSA Databook 11

th

Edition

www.natcogroup.com

Cyclone Demister Device

Uses centrifugal forces to separate

liquid droplets from a gas stream.

Gas and liquid enter the cyclone tube

and is set into rotation by vanes

mounted on a central body.

Gas flows axially along the tube.

The heavier liquid droplets are

thrown to the wall due to the

centrifugal action.

The liquid is then transported through

slits at the cyclone wall into a liquid

collecting chamber and drained back

to the vessel through downcomers.

Not effective below certain velocity.

www.prosep.com

Liquid Collection

Provides enough residence time:

to allow vapour to be released from the liquid.

to allow 2 liquid phase to separate

Contains volume to handle sudden surge in inlet liquid flow.

One of liquid collection issues is foaming.

Presence of chemicals such as corrosion inhibitor and glycol can

increase the likelihood of foaming.

Foaming can be minimised by reducing shearing, turbulence and

velocity of fluids into separator.

Foaming can be dealt with by increasing the height of the separator to

allow foams to settle.

Liquid Levels Definition

NLL Normal Liquid Level

Liquid level maintained by controls during operation

HLL High Liquid Level

First liquid level above NLL to trigger an alarm

HHLL High High Liquid Level

Second liquid level above NLL to trigger a shutdown

LLL Low Liquid Level

First liquid level below NLL to trigger an alarm

LLLL Low Low Liquid Level

Second liquid level below NLL to trigger a shutdown

Hold-up time

(Residence Time)

Time to fill separator from empty to NLL at design

liquid feed rate.

Surge Time Time to fill separator from NLL to HLL at design

liquid feed rate.

Liquid Collection Devices

Calming baffle reduces turbulence, creates uniform velocity.

Coalescing pack causes discontinuous phase to form larger droplets.

Weir separates different liquid phases.

Liquid Collection Devices

Vortex breaker prevents vortex formation and gas

carryunder.

Figure 11.10 Campbells 7

th

Edition Volume 2.

Separator Types

Basic types: Vertical Separator and Horizontal Separator

Vertical Separator Horizontal Separator

Gas flows vertically upwards against liquid

settling. Therefore, gas velocity must be less

than the liquid droplet terminal velocity for

effective separation.

Gas flows horizontally and hence

perpendicular to droplet setting.

Therefore, the gas velocity can be

larger than the liquid droplet velocity

For the same application, vertical separator is

generally less efficient than horizontal

separator.

Horizontal separator is generally more

effective in separating vapour and liquid

due to a larger surface area for vapour

to be released from liquid.

Vapour flow area is constant therefore

performance of separator is not sensitive to

changing liquid level.

Vapour flow area depends on liquid

level therefore the performance of

horizontal separator can deteriorate as

liquid level rises.

Separator Types

Basic types: Vertical Separator and Horizontal Separator

Vertical Separator Horizontal Separator

For the same application, vertical separator

generally takes less plot space.

For the same application, horizontal

separator generally takes more plot

space but less height.

Vertical separator is generally used when gas

is the dominant phase.

Horizontal separator is generally used

when gas and liquids are of equal

proportions or liquid is the dominant

phase.

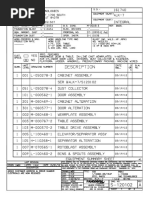

Separator Specifications

What separator vendor requires:

Process data:

Max. liquid, max vapour and max Rho V (momentum) cases

Inlet flow rate, density and viscosity

Liquid surface tension

Presence of solids

Presence of corrosive materials

Required separation efficiency carryover, particle size removed

Separator Specifications

What separator vendor requires:

Inlet piping data (optional):

Length of straight run into vessel

Pipe size

Presence of bends, elbows, control valves

Specifications:

Applicable industry standards

Applicable client standards

Separator Specifications

What performance guarantee is required from vendor:

Vapour and liquid flow capacity

Liquid carryover:

total liquid carryover (e.g. 0.1 US gallon liquid carryover/MMSCF gas)

particle size carryover (e.g. 99.9% of 30 microns and above removed)

Beware of particle size carryover, this does not reflect the total

amount of liquid carryover.

On some separators, particle size carryover is important (e.g. flare

scrubber, compressor scrubber and filter coalescer).

On some separators, particle size carryover is not important (e.g.

production separators). In this case, total liquid carryover is more

important.

Future Topic: Separator Sizing

Some of the topics which can be covered:

Separator Sizing Formula (K-Factor)

Cautions about using K-Factor (GPSA extract)

Nozzle sizing

WorleyParsons Standard Spreadsheet

Design Guides and Standards

Case Study

Question Time

Questions?

Вам также может понравиться

- 2008 Seadoo Shop ManualДокумент555 страниц2008 Seadoo Shop Manualanon_846090969100% (3)

- Oil and Gas ProcessingДокумент3 страницыOil and Gas ProcessingRaghav AgrawalОценок пока нет

- Welder Qualification Test Certificate: Weld Test Details Range of ApprovalДокумент1 страницаWelder Qualification Test Certificate: Weld Test Details Range of ApprovalRamkunwar YadavОценок пока нет

- Distillation Calculation FormulasДокумент21 страницаDistillation Calculation FormulasVaibhav Mishra100% (2)

- MIDAS ChecklistДокумент27 страницMIDAS ChecklistBhagirath JoshiОценок пока нет

- Oil and Gas SeparatorsДокумент23 страницыOil and Gas SeparatorsSofea Hanom NordinОценок пока нет

- GPSA 13 Ed. SeparationДокумент48 страницGPSA 13 Ed. Separationjz9080% (5)

- ThessaloniansДокумент89 страницThessalonianslaleye_olumideОценок пока нет

- Gas-Liquid Separators PDFДокумент9 страницGas-Liquid Separators PDFMubarik AliОценок пока нет

- Separator Design GuideДокумент36 страницSeparator Design Guidelaleye_olumide100% (16)

- Separador BifásicoДокумент42 страницыSeparador BifásicoAldoDeLaCerda100% (1)

- 2 3 Phase Separation SystemДокумент14 страниц2 3 Phase Separation SystemDodiya Nikunj100% (1)

- Two Phase SeparatorДокумент67 страницTwo Phase SeparatorRaden MasОценок пока нет

- Separator VesselДокумент15 страницSeparator VesselShaho Abdulqader Mohamedali67% (3)

- Three Phase Separator DesignДокумент5 страницThree Phase Separator DesignAymen KhlifiОценок пока нет

- Separator & Production FacilitiesДокумент11 страницSeparator & Production FacilitiestumiОценок пока нет

- Dive Scubapro - Mk2+, Mk2 - Maintenance ProcedureДокумент4 страницыDive Scubapro - Mk2+, Mk2 - Maintenance ProceduremanonpomОценок пока нет

- UOP Engineering Design - Fractionation PDFДокумент263 страницыUOP Engineering Design - Fractionation PDFThienthan10095% (20)

- Gas-Liquid Vertical Separator PDFДокумент2 страницыGas-Liquid Vertical Separator PDFRathish RagooОценок пока нет

- Thermosyphon Reboiler HydraulicsДокумент2 страницыThermosyphon Reboiler HydraulicskaramullahrasheedОценок пока нет

- Oil Water Separator TheoryДокумент3 страницыOil Water Separator Theoryjlcheefei9258Оценок пока нет

- Specifying SeparatorsДокумент33 страницыSpecifying Separatorsdinesh_hsenid100% (1)

- Quantifying Oil - Water Separation Performance in Three-Phase Separators-Part 1.PDF - ImportantДокумент12 страницQuantifying Oil - Water Separation Performance in Three-Phase Separators-Part 1.PDF - ImportantmofiyinfoluОценок пока нет

- Three Phase SeparatorsДокумент12 страницThree Phase SeparatorsSergio Diaz100% (1)

- Liquid Liquid Separation TechnologyДокумент16 страницLiquid Liquid Separation TechnologyMurrali Raj JeyagapalОценок пока нет

- GasLiquid Separators-Design RulesДокумент21 страницаGasLiquid Separators-Design Ruleswahyuriansyah100% (1)

- Windlass Brake TestДокумент44 страницыWindlass Brake TestHasancan YavaşОценок пока нет

- Scenarios in PSV Sizing During Gas BlowbyДокумент94 страницыScenarios in PSV Sizing During Gas BlowbyMiquel Àngel Artiol FerroОценок пока нет

- Pressure Vessel PresentationДокумент18 страницPressure Vessel Presentationlaleye_olumide0% (1)

- 02 110 BPS Foam Pump Skid With Foam Pump and RC ControllerДокумент8 страниц02 110 BPS Foam Pump Skid With Foam Pump and RC Controllerarachman297988Оценок пока нет

- Separator SizingДокумент11 страницSeparator Sizingmusaveer50% (2)

- Chapter 4 (A) General Theory & Two Phase SeparatorsДокумент139 страницChapter 4 (A) General Theory & Two Phase Separatorsdinesh_hsenid100% (2)

- Chapter 4 SeparatorsДокумент109 страницChapter 4 Separatorsdinesh_hsenid100% (1)

- Tray Distillation ColumnsДокумент27 страницTray Distillation ColumnsRajeshkumar Elango0% (1)

- Design Manual Mist Eliminator - NewДокумент16 страницDesign Manual Mist Eliminator - Newashif100% (2)

- Sulfur Plant Design ManualДокумент367 страницSulfur Plant Design ManualLuispajuelo73100% (8)

- Mist EliminatorsДокумент6 страницMist EliminatorspskarthikОценок пока нет

- Liquid-Vapor Separation Efficiency (Envp0102)Документ24 страницыLiquid-Vapor Separation Efficiency (Envp0102)jbl_Оценок пока нет

- 02 The Wind Turbine-0001Документ16 страниц02 The Wind Turbine-0001vodasanket100% (1)

- C 5 Vacuum DistillationДокумент20 страницC 5 Vacuum DistillationAhmed Mohamed KhalilОценок пока нет

- P10 Natural Gas - Removal of Acid GasesДокумент73 страницыP10 Natural Gas - Removal of Acid GasesWalid Ben Husein100% (2)

- Guide For Vessel Sizing PDFДокумент24 страницыGuide For Vessel Sizing PDFManish542Оценок пока нет

- Design and Simulation of Continuous Distillation Columns PDFДокумент33 страницыDesign and Simulation of Continuous Distillation Columns PDFnghiemta18Оценок пока нет

- Design Two-Phase Separators Within The Right LimitsДокумент8 страницDesign Two-Phase Separators Within The Right Limitschipiloo100% (1)

- FRI Internal Design Vol4Документ55 страницFRI Internal Design Vol4syamsudin2006Оценок пока нет

- WB140 2N PDFДокумент12 страницWB140 2N PDFLuisAlbertoVerdejoTapiaОценок пока нет

- WRC 302-1985Документ38 страницWRC 302-1985CarlosОценок пока нет

- Separator SizingДокумент21 страницаSeparator SizingEkundayo JohnОценок пока нет

- Manual Drum Vessel Size LummusДокумент66 страницManual Drum Vessel Size Lummusdglightbue100% (6)

- Gas - Liquid SeparatorДокумент25 страницGas - Liquid SeparatorDeep MehtaОценок пока нет

- Turbine RepairДокумент67 страницTurbine RepairFrancisco Novoa Rodriguez50% (2)

- Process Design: Vessel Sizing (Liquid & Vapour Separators)Документ36 страницProcess Design: Vessel Sizing (Liquid & Vapour Separators)Krishanu SahaОценок пока нет

- AD2000 (31barg) CalculationДокумент10 страницAD2000 (31barg) CalculationMagdaline Matabang100% (1)

- Select The Right ReboilerДокумент2 страницыSelect The Right ReboilerSteven A McMurray100% (2)

- Debottlenecking OptionsДокумент16 страницDebottlenecking OptionsAhmad DeyabОценок пока нет

- Numerical Cave Propagation SimulationsДокумент14 страницNumerical Cave Propagation SimulationswalterloliОценок пока нет

- RFQ Cs Fiittings2Документ21 страницаRFQ Cs Fiittings2laleye_olumideОценок пока нет

- Flare SystemsДокумент10 страницFlare SystemsMahboob Ur-RahmanОценок пока нет

- Epf Crude Oil TreatmentДокумент1 страницаEpf Crude Oil Treatmentafroznishat100% (2)

- Caustic Scrubber Designs For h2s Removal From Refinery Gas Streams Afpm 2014Документ26 страницCaustic Scrubber Designs For h2s Removal From Refinery Gas Streams Afpm 2014Widya Isti AriantiОценок пока нет

- Pangborn ManualДокумент19 страницPangborn Manuallucas_martin_3Оценок пока нет

- Gas Liquid Separators Bothamley JM CampbellДокумент9 страницGas Liquid Separators Bothamley JM CampbellLTORRESMОценок пока нет

- Separator Fundamentals - Process DesignДокумент30 страницSeparator Fundamentals - Process Designlaleye_olumide100% (3)

- Syllabus Mechanical Qaqc Course Sdlinc 9600162099Документ3 страницыSyllabus Mechanical Qaqc Course Sdlinc 9600162099Sridurgha Lakshmi Inc SDLINC NDT QA QC INSTITUTE100% (3)

- 3 Phase SeparatorsДокумент12 страниц3 Phase Separatorsnkhamidy100% (1)

- Strida Folding Bike - Personal Tips and Facts From The CreatorДокумент8 страницStrida Folding Bike - Personal Tips and Facts From The CreatorGeorg100% (2)

- Demister Sizing Using Normal Flow Conversion:: Customer: Enquiry No: Item No: DateДокумент3 страницыDemister Sizing Using Normal Flow Conversion:: Customer: Enquiry No: Item No: Daterakesh3487100% (2)

- EquipmentRatingSizing PartIV SeparatorSizingДокумент47 страницEquipmentRatingSizing PartIV SeparatorSizingMubarik AliОценок пока нет

- Vertical SeparatorДокумент38 страницVertical SeparatorSaidFerdjallahОценок пока нет

- Selecting The Proper TEMA TypeДокумент3 страницыSelecting The Proper TEMA TypeMubarik AliОценок пока нет

- Sequestering CO in The Built Environment: Calera CorporationДокумент48 страницSequestering CO in The Built Environment: Calera CorporationPassmore DubeОценок пока нет

- Separator DesignДокумент38 страницSeparator DesignDela Quarme100% (1)

- Htfs ManualsДокумент151 страницаHtfs Manualsgion_ro401100% (4)

- BN-EG-UE109 Guide For Vessel SizingДокумент36 страницBN-EG-UE109 Guide For Vessel SizingAjith KumarОценок пока нет

- Sizing Separators and Accumulators PDFДокумент4 страницыSizing Separators and Accumulators PDFjt_breakdanceОценок пока нет

- 4 SPE-77495-Increasing Separation Capacity With New and Proven TechnologiesДокумент6 страниц4 SPE-77495-Increasing Separation Capacity With New and Proven TechnologiesDavid VMОценок пока нет

- Lec#09 PHT - (04 Mar 2013 - Monday) - Design of Shell & Tube Heat ExchangerДокумент30 страницLec#09 PHT - (04 Mar 2013 - Monday) - Design of Shell & Tube Heat ExchangerQamar AbbasОценок пока нет

- Tower Tray Oil and Gas IndustryДокумент11 страницTower Tray Oil and Gas IndustryHeet PatelОценок пока нет

- KIRK KSME Axial Cyclone Swirl Mist Eliminators PDFДокумент4 страницыKIRK KSME Axial Cyclone Swirl Mist Eliminators PDFสิทธิไชย อรุณวํฒนชัยОценок пока нет

- Principles of Separation: Incoming Stream Spin Around Reaction Force From The Separator WallДокумент10 страницPrinciples of Separation: Incoming Stream Spin Around Reaction Force From The Separator Wallmohamad alamehОценок пока нет

- Separation Lecture 2Документ21 страницаSeparation Lecture 2Mohamed S Helmy100% (1)

- Separators: Figure OneДокумент8 страницSeparators: Figure OneMohamed Moder100% (1)

- Position Description: (Financial, Operational, Etc)Документ4 страницыPosition Description: (Financial, Operational, Etc)laleye_olumideОценок пока нет

- Offshore & Structural Plate SizeДокумент4 страницыOffshore & Structural Plate Sizelaleye_olumideОценок пока нет

- Eni in NigeriaДокумент4 страницыEni in Nigerialaleye_olumideОценок пока нет

- PV Elite 2008Документ3 страницыPV Elite 2008laleye_olumideОценок пока нет

- SSETP 02 00 Agenda 5th EdДокумент1 страницаSSETP 02 00 Agenda 5th Edlaleye_olumideОценок пока нет

- Remotely Operated Vehicles Market ReportДокумент23 страницыRemotely Operated Vehicles Market Reportlaleye_olumideОценок пока нет

- 2012-09-01 Brun ROV AUVtrends MarineTechnologyReporterДокумент4 страницы2012-09-01 Brun ROV AUVtrends MarineTechnologyReporterlaleye_olumideОценок пока нет

- Amount/Sq Metre (Dollars) @142naira Per UsdollarДокумент6 страницAmount/Sq Metre (Dollars) @142naira Per Usdollarlaleye_olumideОценок пока нет

- Total Cost Total Space Cost/sq MT Annual Cost/sq MTR $/SQ MTR Rent 395,799,446.00 4,099.00 96,560.00 24,140.00 178.81 Service ChargesДокумент1 страницаTotal Cost Total Space Cost/sq MT Annual Cost/sq MTR $/SQ MTR Rent 395,799,446.00 4,099.00 96,560.00 24,140.00 178.81 Service Chargeslaleye_olumideОценок пока нет

- Authorization Form For ApplicationsДокумент1 страницаAuthorization Form For Applicationslaleye_olumideОценок пока нет

- Remember To Leave Enough Time To Walk To Your Stop and To Your DestinationДокумент2 страницыRemember To Leave Enough Time To Walk To Your Stop and To Your Destinationlaleye_olumideОценок пока нет

- Hydrostatic Test ProcedureДокумент7 страницHydrostatic Test Procedurelaleye_olumideОценок пока нет

- Fluids and LubricantsДокумент2 страницыFluids and LubricantsRUN GOОценок пока нет

- Industrial Attachment ReportДокумент20 страницIndustrial Attachment ReportAlbert OjiamboОценок пока нет

- Volvo TAD1641VEДокумент7 страницVolvo TAD1641VEJokoОценок пока нет

- 04 AdamsParts 71-98Документ30 страниц04 AdamsParts 71-98apuhapuh_153349Оценок пока нет

- Air Standard CycleДокумент93 страницыAir Standard CycleJonathan CerdanОценок пока нет

- Welding Symbols and NomenclatureДокумент17 страницWelding Symbols and Nomenclaturesa saОценок пока нет

- ROHR2fesu FeaturelistДокумент20 страницROHR2fesu FeaturelistJohan ConradieОценок пока нет

- Volvo (Dem) and Haldex: History, Function, Diagnosis and RepairsДокумент6 страницVolvo (Dem) and Haldex: History, Function, Diagnosis and RepairsNecsaszNorbertОценок пока нет

- College of Engineering Process Control Lab.: Basrah UniversityДокумент11 страницCollege of Engineering Process Control Lab.: Basrah UniversityhanaОценок пока нет

- I.S. Code - 456 Recommendation:: 1. For ConcreteДокумент4 страницыI.S. Code - 456 Recommendation:: 1. For ConcreteSonu PanwarОценок пока нет

- Overall DimensionДокумент1 страницаOverall DimensionjanetОценок пока нет

- Physics Cun It PacketsДокумент226 страницPhysics Cun It PacketsRana MukherjeeОценок пока нет

- Thermo Dyanmics 2Документ2 страницыThermo Dyanmics 2xcalliber404Оценок пока нет

- Chain Wheels ChainconveyorДокумент9 страницChain Wheels ChainconveyorPedro RBОценок пока нет

- NES 339 Requirements For Steering and Stabilizer Systems For HM Surface Ships and Royal Fleet Auxiliaries - Category 1Документ66 страницNES 339 Requirements For Steering and Stabilizer Systems For HM Surface Ships and Royal Fleet Auxiliaries - Category 1JEORJEОценок пока нет