Академический Документы

Профессиональный Документы

Культура Документы

Chapter 17

Загружено:

Denis Sanchez RiosИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Chapter 17

Загружено:

Denis Sanchez RiosАвторское право:

Доступные форматы

1

Chapter XVII

2

Underground structures have been designed

largely on the basis of optimizing economic,

geologic and seguencing operations for ore

recovery. In many cases, especially in deep

mines or in geologically disturbed areas,

variable stress influences cause appreciable

safety and production hazards when design

configurations do not take into account the in-

situ stress effects.

3

The knowledge of the stress magnitudes and

directions, in-situ, would allow the design of

openingd for stress minimization to be based on

known loading conditions rather than on estimated

conditions. Periodic stress assessment would

also enable problem areas, of high stress

buildup, to be located.

Removal of hazard areas may then be

accomplished through redesign of the local mining

zone, or by the halt of extraction in extreme cases.

4

Single borehole, plane stress measurement

can be made to determine the singular pricipal

stresses which act in the plane perpendicular

to the borehole axis. Only if the directions of

the true pricipal stresses were known could

these methods be used to determine these

values, by measuring in a borehole drilled

perpendicular to their plan of action.

5

For all plane stress measurements, in one or more

boreholes, overcoring of the measument diamond

drill hole, in which the measuring gages are

installed, is required. The initial diamond drill hole

will be drilled circular in shape, and will exist under

the influence of the acting field stresses in the

plane which is normal to the hole axis.

If an overcoring bit is used to cut an annulus of

rock surrounding the instrumented hole, the

annulus becomes stress relieved.

6

Under zero field stresses, the original diamond drill

hole will expand (assuming that the field stresses

were compressive) and cause borehole

deformation diametrically outward.

The stress gages in the borehole are used to

measure the resultant deformation from the initial,

stressed condition to the final, unstressed

condition.

Elastic theory can then be utilized to determine the

existing stress conditions.

7

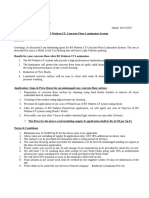

The doorstopper gage consists of a strain gete

rosette, or rubber plug, in which three strain

gages are mounted. The gages are oriented in

arbitrary horizontal (0 plane), vertical (90

plane) and 45 axes, and are mounted on the

plug so that they can be put into a diamond drill

hole and cemented against the end of the

borehole. Stress measurements in thus

assumed to be in the plane which is

perpendicular to the borehole axis.

8

No stresses in the axial borehole direction are

measured. By overcoring the doorstopper gage,

as illustrated in figure 3, strain in the gage

directions can be measured and used to

determine the principal stresses which act in the

gage plane of measurement.

9

Borehole wall

Gage connections

Rubber plug

Overcore cut

Stress plane

e

v

e

45

e

h

Strain gage

rosette

10

1 2 3 4 5 6 e

h

Circle center

e

e

P1

e

45

e

P2

e

V

e'

3

e'

2

e'

1

2

3

2

1

0

1

2

3

2

Assume:

e

h

= 6 units

e

45

= 1.65 units

e

V

= 1.5 units

11

A Mohr circle analysis of the resultant strain readings

is used to determine the planar stresses. The three

strain values are determined by:

c

1

= largest strain reading (c

h

, c

V

or c

45

)

c

2

= middle strain reading

c

3

= smallest strain reading

12

The calculate principal strain are developed

elastically:

E E

E E

P

p

1 3

2 3

3 1

1 1

uo o

c c

uo o

c c

= =

= =

(4)

13

By reduction and substitution, these become:

( )

( )

( )

( )

1 3

2

3

3 1

2

1

1

1

c c

o

c c

o

+

=

+

=

E

and

E

(5)

14

This system is inacurate because it attemts to

measure only the apparent principal stress in the

one planar direction.

This does not establish the true principal stress

direction and magnitude in a three-dimensional

basis.

Corner stresses developed due to drilling and

sharp configuration also cause the measured

stresses to appear higher than the true planar

stresses. The true stress aproximation can be

obtained by multiplying the values for equation (5)

by (.67).

15

Like the Doorstopper gage, the borehole deformation

gage measures overcore deformation along three

strain measuring axes. The configuration of the gage

in as shown in figure 5, and strain axis are oriented

at 60 from each other. The gage is mounted axially

within the borehole, but not at the end, and so does

not ecounter end stress effects.

The strain relief is measured across the three axial

diameters as U

1

, U

2

and U

3

, and can be related, by

elastic theory, to the principal stresses acting in the

plane of measurement, which is perpendicular to the

borehole axis.

16

Unless the true direction of the principal stress

field is known however, this technique will

only measure the apparent principal stresses

in the plane of measurement. No axial

stresses are measured, and the plane stress

condition is assumed. In reality, plane stress

condition only occur in:

1. The centres of small pillars

2. Near the surface of openings, in planes

parallel to the opening surface, and

3. In ground that is stress relieved normal to the

opening surface, as in some fault zones.

17

readout

borehole

Deformation gage

Overcore hole

18

3

P

1

60 60

2

1

U

2

2

U

2

3

U

Stress relieved

borehole shape

Original borehole

shape (diameter

fixed)

19

For plane stress conditions, diametrical convergent

deformation of a hole in a plate is:

( ) ( ) | |

i i

E

d

U u o o o o 2 cos 2

3 1 3 1

+ + =

Where:

d = original borehole diameter = gage diameter

{E = Young's Modulu's, u = Poisson's

Ratio} these must be known for the test

medium.

(6)

20

1

,

3

= Principal stresses

i

= Counterclockwise angle measured from the

Ui diameter to the direction of major principal

stress

1

.

U

1

, U

2

, U

3

= Diametrical deformation in the

direction of reading.

21

If axial stresses,

A

also exist along the borehole,

then:

( )

( ) ( ) | |

E E

d

U

d

A

o

u o o o o

+ +

= 2 cos 2

1

3 1 3 1

2

If the plate surfaces are fixed and rigid, plane

strain condition arises and.

( )

( ) ( ) | | u o o o o

2 cos 2

1

3 1 3 1

2

+ +

=

E

d

U

(7)

(8)

22

1.

A

= 0

2. A 60 strain gage array

3. Using the U

1

diameter for reference,

become the counterclockwise angle from

U1 to the

1

direction.

Assuming:

23

The pricipal stress dirivations, from three diametrical

deformation measuring gages, become:

( ) ( ) ( ) ( )

(

+ + + + + =

2 / 1

2

1 3

2

3 2

2

2 1 3 2 1 1

2

2

6

U U U U U U U U U

d

E

o

( ) ( ) ( ) ( )

(

+ + + + =

2 / 1

2

1 3

2

3 2

2

2 1 3 2 1 3

2

2

6

U U U U U U U U U

d

E

o

( )

( )

(

+

=

3 2 1

3 2

1

2

3

tan

2

1

U U U

U U

u

(11)

(10)

(9)

24

Where:

U

2

> U

3

and U

2

+ U

3

< 2U

1

,

1

~ 45

U

2

> U

3

and U

2

+ U

3

> 2U

1

,

1

~ 90

U

2

< U

3

and U

2

+ U

3

> 2U

1

,

1

~ 90 135

U

2

< U

3

and U

2

+ U

3

> 2U

1

, 1 ~ 135 180

25

When

3

= 0 uniaxial stress occurs and

d

EU

hyd

2

= o

Where U = deformation in the

1

direction

When

1

=

2

=

3

, hydrostatic stress occurs and

Where U = deformation in any direction

d

EU

3

1

= o

(12)

(13)

26

No olviden que siempre alguien

necesita de Uds, que el

egosmo no invada sus

corazones y extiendan la mano a

quien lo necesita.

Dr. Carlos Agreda

Profesor

Вам также может понравиться

- Alty Arran CДокумент2 страницыAlty Arran CDenis Sanchez RiosОценок пока нет

- Sdbdtmfy, Gu - CG.CH - JN Mgfmgmfyh, GJ Tzxyktuluyi Jfykfyxkxfy, Fy FMDGMDGMДокумент8 страницSdbdtmfy, Gu - CG.CH - JN Mgfmgmfyh, GJ Tzxyktuluyi Jfykfyxkxfy, Fy FMDGMDGMDenis Sanchez RiosОценок пока нет

- InfoДокумент1 страницаInfoDenis Sanchez RiosОценок пока нет

- Nuevo Documento de TextoДокумент1 страницаNuevo Documento de TextoDenis Sanchez RiosОценок пока нет

- RPT 100Документ2 страницыRPT 100Denis Sanchez RiosОценок пока нет

- Ms AuditДокумент42 страницыMs AuditDenis Sanchez RiosОценок пока нет

- DSFHSDQQDTHSHSHSGДокумент1 страницаDSFHSDQQDTHSHSHSGDenis Sanchez RiosОценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Fountainbridge: 44/4 East Fountainbridge, Edinburgh, EH3 9PHДокумент4 страницыFountainbridge: 44/4 East Fountainbridge, Edinburgh, EH3 9PHapi-19846387Оценок пока нет

- Demolish and Extension BoQ - Supply and Installation - 141019Документ3 страницыDemolish and Extension BoQ - Supply and Installation - 141019Patrick SipatelaОценок пока нет

- Soil Liquefaction: A Critical State ApproachДокумент7 страницSoil Liquefaction: A Critical State Approachvisio2004Оценок пока нет

- Prolyte MPT EN Structural AnalysisДокумент287 страницProlyte MPT EN Structural AnalysisjmsxdОценок пока нет

- fdb2 - Fire and Damper PDFДокумент4 страницыfdb2 - Fire and Damper PDFcandratrikusumaОценок пока нет

- Baystat040a Installers GuideДокумент12 страницBaystat040a Installers GuideLuis Eduardo MercadoОценок пока нет

- Chapter-3 FoundationДокумент53 страницыChapter-3 Foundationkader ArefeОценок пока нет

- Manual Red - Vent PDFДокумент4 страницыManual Red - Vent PDFMiloš StijeljaОценок пока нет

- Cast Catalogo ORFS Ing PDFДокумент90 страницCast Catalogo ORFS Ing PDFJOSE ANTONIO MARTINEZ MORALESОценок пока нет

- BS Wahren CF Concrete Floor Lamination System QuoteДокумент2 страницыBS Wahren CF Concrete Floor Lamination System QuotehemantrulzОценок пока нет

- Boiler OfferДокумент10 страницBoiler OfferManohar PandianОценок пока нет

- Proposal for imported maple squash court flooringДокумент3 страницыProposal for imported maple squash court flooringOmair Akhtar KhanОценок пока нет

- Steel Semester Mini ProjectДокумент4 страницыSteel Semester Mini ProjectephОценок пока нет

- Helmet Color Code For Construction SitesДокумент38 страницHelmet Color Code For Construction SitesChandrasekhar ChintadaОценок пока нет

- PERI UP Rosett Shoring Towers Type Test US1 enДокумент60 страницPERI UP Rosett Shoring Towers Type Test US1 enSanja RadovicОценок пока нет

- Sertifikat ASTM 1BДокумент18 страницSertifikat ASTM 1BPrasetya Siregar100% (1)

- 1 Introduction To Bridge EngineeringДокумент46 страниц1 Introduction To Bridge EngineeringRYAN JOSEPH QUIMOОценок пока нет

- On-Line Simulation Guide For Continuous Casting: Steeluniversity KOREA Challenge Contest RelatedДокумент22 страницыOn-Line Simulation Guide For Continuous Casting: Steeluniversity KOREA Challenge Contest RelatedhjoutipОценок пока нет

- SEJIN ProfileДокумент42 страницыSEJIN ProfilehungleteОценок пока нет

- Effect of Excess Air on Boiler EfficiencyДокумент5 страницEffect of Excess Air on Boiler EfficiencyGovindarajan Chandrasekaran100% (1)

- Internship ReportДокумент32 страницыInternship ReportSiddh Nayak100% (2)

- Room Air Conditioner Owner's Manual: Essential Safety TipsДокумент21 страницаRoom Air Conditioner Owner's Manual: Essential Safety Tipsrizwan15100% (1)

- Paroc Pro Roof Slab 20 Kpa: Product DatasheetДокумент2 страницыParoc Pro Roof Slab 20 Kpa: Product Datasheetcarlos martinezОценок пока нет

- Fourier Law of Heat Conduction (Gate60 Short Notes)Документ4 страницыFourier Law of Heat Conduction (Gate60 Short Notes)Guru Abhinai Meduri100% (1)

- Sikasil SG-500: High Performance Structural Silicone AdhesiveДокумент2 страницыSikasil SG-500: High Performance Structural Silicone Adhesivethe enverОценок пока нет

- Crystal GrowthДокумент6 страницCrystal GrowthArunmaalaОценок пока нет

- Failure Modes and Criteria of Plastic Structures Under Intense Dynamic Loading: A ReviewДокумент9 страницFailure Modes and Criteria of Plastic Structures Under Intense Dynamic Loading: A ReviewyasameenОценок пока нет

- Elbows - DIN 2605: VL Code 711Документ3 страницыElbows - DIN 2605: VL Code 711ZAQWОценок пока нет

- GPG245 Desktop Guide To Daylighting For Architects PDFДокумент12 страницGPG245 Desktop Guide To Daylighting For Architects PDFIppiОценок пока нет

- Samsung AirДокумент55 страницSamsung AirElectropartes Nicaragua100% (3)