Академический Документы

Профессиональный Документы

Культура Документы

Water Circulation System

Загружено:

AkashKishoreОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Water Circulation System

Загружено:

AkashKishoreАвторское право:

Доступные форматы

Water Circulation

System

Contents of Presentation

Theory of circulation

Types of circulation

Economizer

Water walls

Drum and its internals

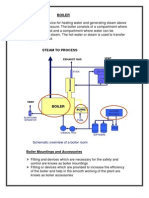

Circulation in Boiler

The steam generator has to produce steam at highest

purity, and at high pressure and temperature required for the

turbine.

.Water must flow through the heat absorption surface of the

boiler in order that it may be evaporated into steam .

Natural circulation is the ability of water to circulate

continuously, with gravity and changes in temperature being

the only driving force known as "thermal head.

Because the density of the cold water is greater, it descends in the 'downcomer'

towards the lower bottom ring header, displacing the warmer water up into the

front tubes.

The ratio of the weight of water to the weight of steam in the

mixture is called Circulation Ratio.

Criticality of Drum Level control

Boiler drum level control is critical for both plant protection

and equipment safety and applies equally to high and low

levels of water within the boiler drum.

The purpose of the drum level controller is to bring the drum

up to level at boiler start-up and maintain the level at constant

steam load.

A dramatic decrease in this level may uncover boiler tubes,

allowing them to become overheated and damaged.

An increase in this level may interfere with the process of

separating moisture from steam within the drum,

Forced Circulation

However, when the pressure in the

water-tube boiler is increased, the

difference between the densities of the

water and saturated steam falls,

consequently less circulation occurs.

To keep the same level of steam

output at higher design pressures, the

distance between the Bottom ring

header and the steam drum must be

increased, or some means of forced

circulation must be introduced.

Therefore natural circulation is limited

to boiler with drum operating pressure

around 175 Kg/cm2.

Natural Circulation & Forced

Circulation

Natural Circulation

The downcomer contain relatively

cold water, whereas the riser tube

contain steam water mixture ,whose

density is comparitively less .this

density difference is the driving force

,for the mixture. (thermo-siphon

principle)

Circulation takes place at such a high

rate that the driving force and

frictional resisitance in water wall are

balanced.

Natural Circulation Forced Circulation

Forced Circulation

Beyond 180 Kg/cm2 of pressure, circulation is to be assisted with

mechanical pumps, to overcome frictional losses. To regulate the flow

through various tubes, orifice plates are used. This system is applicable in

the high sub-critical regions (say 200 Kg/cm2).

Economizer

Boiler Economizer are feed-water heaters in which the heat

from waste gases is recovered to raise the temperature of

feed-water supplied to the boiler.

Economizer

The economizer preheats the feed water by utilizing the residual heat of the flue gas.

It reduces the exhaust gas temperature and saves the fuel.

Modern power plants use steel-tube-type economizers.

Design Configuration: divided into several sections : 0.6 0.8 m gap

Finned Economizers

Advantages of Economizer

6

o

C raise in feed water

temperature, by economizers

corresponds to a

1% saving in fuel consumption

22

0

C reduction in flue gas

temperature increases boiler

efficiency by 1%

Boiler Drum

It is an enclosed Pressure

Vessel

Heat generated by

Combustion of Fuel is

transferred to water to

become steam

Process: Evaporation

Steam volume increases to 1,600

times from water and produces

tremendous force

DRUM Lifting in progress

DRUM SERVES TWO MAIN

FUNCTIONS

SEPERATING STEAM FROM THE

MIXTURE OF WATER AND STEAM

IT HOUSES ALL EQUIPMENTS USED FOR

PURIFICATION OF THE STEAM AFTER

BEING SEPERATED FROM THE WATER

Downcomers

There are six down comers which carry

water from boiler drum to the ring header.

They are installed from outside the furnace to

keep density difference for natural circulation

of water & steam.

WATER

WALLS

Heating and evaporating the feed water supplied to the boiler from the

economisers.

These are vertical tubes connected at the top and bottom to the

headers.

These tubes receive water from the boiler drum by means of

downcomers connected between drum and water walls lower header.

Approximately 50% of the heat released by the combustion of the fuel in

the furnace is absorbed by the water walls.

THANK YOU

Вам также может понравиться

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesОт EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesОценок пока нет

- Nurrohman - ProjectДокумент32 страницыNurrohman - ProjectNurrohman NurrohmanОценок пока нет

- Oil and Gas Artificial Fluid Lifting TechniquesОт EverandOil and Gas Artificial Fluid Lifting TechniquesРейтинг: 5 из 5 звезд5/5 (1)

- ME 310a Steam Turbines: Cooling TowersДокумент33 страницыME 310a Steam Turbines: Cooling Towersshivkumar shindeОценок пока нет

- Progressive Development of Power Generation Through Steam GenerationДокумент8 страницProgressive Development of Power Generation Through Steam GenerationAshish GauravОценок пока нет

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingОт EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingРейтинг: 5 из 5 звезд5/5 (3)

- Steam CondensersДокумент32 страницыSteam CondensersaadhithyarajasekaranОценок пока нет

- 1 STДокумент34 страницы1 STDeepak JangidОценок пока нет

- 1st VDFДокумент35 страниц1st VDFDeepak JangidОценок пока нет

- Power Plant BoilersДокумент24 страницыPower Plant BoilerstabishkhanaligОценок пока нет

- Water Circulation SystemДокумент31 страницаWater Circulation SystemSaurav Kumar0% (1)

- High Pressure Boilers PDFДокумент38 страницHigh Pressure Boilers PDFgokul viratОценок пока нет

- High Pressure Boilers PDFДокумент38 страницHigh Pressure Boilers PDFgokul virat100% (2)

- Steam GeneratorДокумент55 страницSteam GeneratorSumeet SinghОценок пока нет

- Steam Generation PDFДокумент8 страницSteam Generation PDFKhairatun NisaОценок пока нет

- High Pressure BoliersДокумент40 страницHigh Pressure Boliersjojo pantherОценок пока нет

- Chapter 3 SteamGeneratorsДокумент156 страницChapter 3 SteamGeneratorssam afiОценок пока нет

- Steam Drum Systems As Well As Once-Through Steam Generators (OTSG) SystemsДокумент8 страницSteam Drum Systems As Well As Once-Through Steam Generators (OTSG) SystemsGobardhana swainОценок пока нет

- Theory of Steam GenerationДокумент8 страницTheory of Steam Generationraudatul22Оценок пока нет

- Steam Generators 2Документ33 страницыSteam Generators 2gbharathreddysОценок пока нет

- Boiler Maintenance and OperationsДокумент30 страницBoiler Maintenance and OperationsSuresh SenanayakeОценок пока нет

- Boiler PerformanceДокумент30 страницBoiler PerformanceJoeb DsouzaОценок пока нет

- Steam DrumДокумент9 страницSteam DrumMECHANICAL KRCEОценок пока нет

- Power Plant Systems Operation: Steam Turbine Operation Overview and Water and Steam Cycle (Part 2)Документ28 страницPower Plant Systems Operation: Steam Turbine Operation Overview and Water and Steam Cycle (Part 2)نهاد نهادОценок пока нет

- Condenser & BoilerДокумент33 страницыCondenser & BoilerShaun Patrick Albao100% (1)

- Velox, Babcock and Wilocox, La-Mont andДокумент26 страницVelox, Babcock and Wilocox, La-Mont andDhushyanth KumarОценок пока нет

- High Pressure Boilers 1238Документ41 страницаHigh Pressure Boilers 1238rajushamla9927Оценок пока нет

- Water Circulation SystemДокумент37 страницWater Circulation SystemSam50% (2)

- Chapter 4 - Part 1-BoilersДокумент56 страницChapter 4 - Part 1-BoilersRaj GandhiОценок пока нет

- Heat Recovery Steam GeneratorДокумент26 страницHeat Recovery Steam GeneratorHitesh Singla100% (1)

- BoilersДокумент8 страницBoilersSanjana ReddyОценок пока нет

- Boiler Circulation SystemДокумент32 страницыBoiler Circulation SystemRitik Dewangan100% (1)

- BoilerДокумент14 страницBoileravv456Оценок пока нет

- Module 3Документ62 страницыModule 3AshishОценок пока нет

- Power SystemДокумент16 страницPower SystemJeet SarkarОценок пока нет

- Heat ExchangerДокумент16 страницHeat Exchangeratulbhogare7100% (1)

- BKM High Pressure Boiler Micro Project IIESTSДокумент12 страницBKM High Pressure Boiler Micro Project IIESTSBrajesh Kumar0% (1)

- Meg 5-LF-35-36 Aux Steam SystemДокумент23 страницыMeg 5-LF-35-36 Aux Steam SystemAkash KandwalОценок пока нет

- Power Plant Steam Generators: Introduction: A Two in One - Combustor and Heat ExchangerДокумент42 страницыPower Plant Steam Generators: Introduction: A Two in One - Combustor and Heat ExchangerABCDОценок пока нет

- Dcb20053 - Topic 2Документ51 страницаDcb20053 - Topic 2Margerath TiongОценок пока нет

- PowerДокумент26 страницPowersenaОценок пока нет

- Maintenance Procedure and Working of Lamont and Benson BoilerДокумент14 страницMaintenance Procedure and Working of Lamont and Benson Boileromkar digamabar sononeОценок пока нет

- Steam BoilersДокумент35 страницSteam BoilersMohammedAminShaikhОценок пока нет

- Boilers: - Fire Tube - Water Tube - Scotch Gerald Q. Campañano Bridging Batch 8Документ12 страницBoilers: - Fire Tube - Water Tube - Scotch Gerald Q. Campañano Bridging Batch 8Gerald CampañanoОценок пока нет

- BoilerДокумент23 страницыBoilerfaizan_3i6300Оценок пока нет

- Meg 5-LF-29-30 Types of Aux BoilersДокумент54 страницыMeg 5-LF-29-30 Types of Aux BoilersAkash KandwalОценок пока нет

- Introduction To Boilers: Submitted To: Dr. Vivekananda Vivekananda Submitted By: Archee Gupta Kartik SinoliyaДокумент23 страницыIntroduction To Boilers: Submitted To: Dr. Vivekananda Vivekananda Submitted By: Archee Gupta Kartik SinoliyaKARTIK SINOLIYAОценок пока нет

- Steam Cycle and Steam Power Plant: Ermo/property - tables/H2O/H2O - Su Per3.htmlДокумент18 страницSteam Cycle and Steam Power Plant: Ermo/property - tables/H2O/H2O - Su Per3.htmlMark Joseph Nambio NievaОценок пока нет

- Boiler Water & Steam CycleДокумент50 страницBoiler Water & Steam CycleRaviKushwahaОценок пока нет

- Indian BoilersДокумент10 страницIndian Boilerslavpandey8719Оценок пока нет

- Boiloers and Its Mountings 4Документ53 страницыBoiloers and Its Mountings 4Kummitha ObulareddyОценок пока нет

- BKLT DeaeratorДокумент24 страницыBKLT Deaeratormalikgaurav01Оценок пока нет

- High Pressure BoilerДокумент8 страницHigh Pressure BoilerAnand KalaniОценок пока нет

- Steam Jet Refrigeration SystemДокумент9 страницSteam Jet Refrigeration SystemHenok GhidayОценок пока нет

- Report in Steam Generators: Schematic Diagram of A Boiler SystemДокумент18 страницReport in Steam Generators: Schematic Diagram of A Boiler SystemZa YonОценок пока нет

- SeminarДокумент20 страницSeminarPrajwal Chavan100% (1)

- Reboiler: Altitude Training InstituteДокумент36 страницReboiler: Altitude Training InstituteShrutika TelangeОценок пока нет

- Natural Circulation in BoilerДокумент9 страницNatural Circulation in BoilerSajjad AhmedОценок пока нет

- BS 65-1981Документ27 страницBS 65-1981jasonОценок пока нет

- Paterno Report: Dr. Fred S. Berlin, M.D., PH.D Final Report 2-7-2013Документ45 страницPaterno Report: Dr. Fred S. Berlin, M.D., PH.D Final Report 2-7-2013The Morning CallОценок пока нет

- Unknown Facts About Physicians Email List - AverickMediaДокумент13 страницUnknown Facts About Physicians Email List - AverickMediaJames AndersonОценок пока нет

- Hubungan Body Image Dengan Pola Konsumsi Dan Status Gizi Remaja Putri Di SMPN 12 SemarangДокумент7 страницHubungan Body Image Dengan Pola Konsumsi Dan Status Gizi Remaja Putri Di SMPN 12 SemarangNanda MaisyuriОценок пока нет

- He 3 Basic Types of Descriptive Research MethodsДокумент2 страницыHe 3 Basic Types of Descriptive Research MethodsRahul SarinОценок пока нет

- Test On QuantifiersДокумент1 страницаTest On Quantifiersvassoula35Оценок пока нет

- What To Do Following A Workplace AccidentДокумент5 страницWhat To Do Following A Workplace AccidentMona DeldarОценок пока нет

- Index Medicus PDFДокумент284 страницыIndex Medicus PDFVania Sitorus100% (1)

- Business PlanДокумент17 страницBusiness PlanChester Cortez50% (2)

- Lecture 8 - ThermodynamicsДокумент65 страницLecture 8 - ThermodynamicsHasmaye PintoОценок пока нет

- Flores V PinedaДокумент10 страницFlores V Pinedacha chaОценок пока нет

- Rajivgandhi University of Health Sciences Bangalore, KarnatakaДокумент19 страницRajivgandhi University of Health Sciences Bangalore, KarnatakaHUSSAINA BANOОценок пока нет

- Key ScientificДокумент4 страницыKey ScientificGarrettОценок пока нет

- Aakanksha ProjectДокумент32 страницыAakanksha ProjectAakash murarkaОценок пока нет

- Complement Fixation Test: Process Testing For Antigen Semi-Quantitative Testing References External LinksДокумент2 страницыComplement Fixation Test: Process Testing For Antigen Semi-Quantitative Testing References External LinksYASMINAОценок пока нет

- General Session Two - Work Life BalanceДокумент35 страницGeneral Session Two - Work Life BalanceHiba AfandiОценок пока нет

- Adult Module 1 - Five Healthy Habits Handout (English) PDFДокумент2 страницыAdult Module 1 - Five Healthy Habits Handout (English) PDFKennedy FadriquelanОценок пока нет

- Havehas Affirm Neg Interrogwith Aliens - 19229Документ3 страницыHavehas Affirm Neg Interrogwith Aliens - 19229Ana Victoria Cuevas BeltránОценок пока нет

- L Addison Diehl-IT Training ModelДокумент1 страницаL Addison Diehl-IT Training ModelL_Addison_DiehlОценок пока нет

- Emerging Re-Emerging Infectious Disease 2022Документ57 страницEmerging Re-Emerging Infectious Disease 2022marioОценок пока нет

- PV2R Series Single PumpДокумент14 страницPV2R Series Single PumpBagus setiawanОценок пока нет

- Overall Summary:: SAP MM Certified Associate & SAP Certification ID: 0019350978Документ6 страницOverall Summary:: SAP MM Certified Associate & SAP Certification ID: 0019350978Ganapathi RajОценок пока нет

- Me3391-Engineering Thermodynamics-805217166-Important Question For Engineering ThermodynamicsДокумент10 страницMe3391-Engineering Thermodynamics-805217166-Important Question For Engineering ThermodynamicsRamakrishnan NОценок пока нет

- Plumbing Breakup M 01Документ29 страницPlumbing Breakup M 01Nicholas SmithОценок пока нет

- Remote Control Unit Manual BookДокумент21 страницаRemote Control Unit Manual BookIgor Ungur100% (1)

- User Manual: 3603807 CONTACT US - 09501447202,8070690001Документ1 страницаUser Manual: 3603807 CONTACT US - 09501447202,8070690001Arokiaraj RajОценок пока нет

- BUERGER's Inavasc IV Bandung 8 Nov 2013Документ37 страницBUERGER's Inavasc IV Bandung 8 Nov 2013Deviruchi GamingОценок пока нет

- FSSC 22000 V6 Guidance Document Environmental MonitoringДокумент10 страницFSSC 22000 V6 Guidance Document Environmental Monitoringjessica.ramirezОценок пока нет

- STR Mpa-MpmДокумент8 страницSTR Mpa-MpmBANGGAОценок пока нет

- Family Stress TheoryДокумент10 страницFamily Stress TheoryKarina Megasari WinahyuОценок пока нет