Академический Документы

Профессиональный Документы

Культура Документы

Operations Management: Mohanasundaram.k@alliance - Edu.in

Загружено:

Manish ShawОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Operations Management: Mohanasundaram.k@alliance - Edu.in

Загружено:

Manish ShawАвторское право:

Доступные форматы

OPERATIONS MANAGEMENT

K. Mohanasundaram

Mohanasundaram.k@alliance.edu.in

mohanstat@yahoo.com

OPERATIONS MANAGEMENT

William J. Stevenson, 9

th

Edition, Tata Mcgraw Hill

Reference books:

1. Operations Management, Theory and Practice - B.

Mahadevan

2. Operations Management for competitive advantage

Chase, Jacobs

3. Production and Operations Management

Paneerselvam

4. Operations Management

Russel & Taylor

5. Operations Management- Jay Heizer, Barry Render,

Jagadeesh Rajashekhar

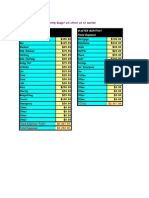

Assessment

INTERNAL (50)

MID TERM 20

ATTENDANCE 05

CASE STUDY (G) 10

PRESENTATION (G) 05

CLASS TEST 10

EXTERNAL (50) (Tentative/ subject to change)

SECTION A 5x2 = 10 All

SECTION B 4x5 = 20 Choice

SECTION C 5x10 =50 Choice

SECTION D 1x20 = 20 Compulsory

Syllabus

Introduction

Forecasting

Product and

service design

Capacity planning

Process selection

Facilities layout

Location analysis

Design of work

system

SCM

inventory

APP

MRP/ERP

JIT / LEAN

Network analysis

Quality

Acceptance

sampling

Maintenance

Scheduling

Productivity

Reliability

OBJECTIVES

Introduction

Definition

Management function

Organizations core function

Decision making

System perceptive

Transformational

Value added

Product /service difference / similarities

Goods and service continuum

Why to study OM

Importance of OM

Scope of OM

Performance Objectives

Evolution

Current trends in OM/ Challenges in OM

Introduction

Organization --> product tangible/intangible

Products are combination of both goods /services

Heart of every organization are the activities that makes

products. OPERATIONS

Operation describe what the organization does.

Eg: IBM make of computers

BA fly passengers

BBC radio/TV programmes

What is Operations Management?

Can be viewed as

1) Management function

2) Organizations core function

3) Decision Making

4) System

OM- Management function

Operations management (OM) is defined as

the design, operation, and improvement of

the systems that create and deliver the

firms primary products and services

The business function responsible for

planning, coordinating, and controlling the

resources needed to produce a companys

products and services

OM Across the Organization- core

function

Most businesses are supported by the

functions of operations, marketing, and

finance

The major functional areas must interact to

achieve the organization goals

OM Across the Organization -

continued

Marketing is not fully capable of meeting customer needs if

they do not understand what operations can produce

Finance cannot judge the need for capital investments if they

do not understand operations concepts and needs

Information systems enables the information flow throughout

the organization

Human resources must understand job requirements and

worker skills

Accounting needs to consider inventory management,

capacity information, and labor standards

OM- organization core function

Operations

Plant

Manager

Operations

Manager

Director

Manufacturing, Production control,

Quality assurance, Engineering,

Purchasing, Maintenance, etc

Finance Marketing

Functions - Airline

Operations

Finance/

Accounting

Marketing

Ground

Support

Flight

Operations

Facility

Maintenance

Catering

Airline

1984-1994 T/Maker Co.

Functions - Bank

Operations

Finance/

Accounting

Marketing

Check

Clearing

Teller

Scheduling

Transactions

Processing

Security

Commercial Bank

1984-1994

T/Maker Co.

Functions - Manufacturer

Operations

Finance/

Accounting

Marketing

Production

Control

Manufacturing

Quality

Control

Purchasing

Manufacturing

Typical role

1-17

Business Operations Overlap

Operations

Finance

Marketing

1-18

Operations Interfaces

Public

Relations

Accounting

Industrial

Engineering

Operations

Maintenance

Personnel

Purchasing

Distribution

MIS

Legal

OM Decisions

All organizations are based on decisions

Decisions follow a similar path

First decisions very broad Strategic decisions

Strategic Decisions set the direction for the entire

company; they are broad in scope and long-term in

nature

Following decisions focus on specifics - Tactical

decision and operational

OM Decisions

Tactical decisions focus on

Specific day-to-day issues

Resource needs, schedules, & quantities to produce

Tactical decisions are very frequent

Strategic decisions less frequent

Tactical decisions must align with strategic

decisions

OM- decision making perspective

Classification of operations management

decision/production management functions

Periodic/Continual Decision

Planning and designing of production systems/Operations and

control of production system

Planning, organising and control decisions

Strategic ( long term) and operational ( Short term) Decision

Productions management decision

Selection

Products

Processes

Equipment

Workforce

Location

Layout

Design

Products

Process Equipment

Jobs

Methods

Wage payment

Operating and

Control systems

System & Procedures

Updating

Involves

revision of

production

system in the

light of

changing

environment

Operating-

controlling

Setting targets

Scheduling

Sequencing

Inventory control

Quality control

Production control

Cost control

Maintenance

Long Term ( STRATEGIC)

Product selection and design

Process selection and planning

Facilities location ( minimize total delivered to customer

cost)

Facilities layout and material handling

Capacity planning

SHORT TERM (OPERATIONAL)

Production planning, Scheduling and control

Inventory planning and control

Quality Assurance

Work and Job Design

Maintenance and replacement

Cost reduction and control

OM Decisions

Operations Management system based

OM Transforms inputs to outputs

Inputs are resources such as

People, Material, and Money

Outputs are goods and services

OMs Transformation Process

Diagrammatical expression

INPUTS

PROCESS

OUTPUTS

Human

resources

(Workers, managers)

Capital

(Equipment, facilities)

Purchases

(Materials, services)

Land

Energy

Goods

Services

Transformation

depends on type

of

facility

1-30

OM system perspective

The operations function involves the conversion of

inputs into outputs

Inputs

Land

Labor

Capital

Transformation/

Conversion

process

Outputs

Goods

Services

Control

Feedback

Feedback Feedback

Value added

Food Processor

Inputs Processing Outputs

Raw Vegetables Cleaning Canned

vegetables

Metal Sheets Making cans

Water Cutting

Energy Cooking

Labor Packing

Building Labeling

Equipment

Hospital Process

Inputs Processing Outputs

Doctors, nurses Examination Healthy

patients

Hospital Surgery

Medical Supplies Monitoring

Equipment Medication

Laboratories Therapy

Operations

The process of changing input into output and

thereby adding value to some entity

Value added by performing

operation Function

Alter - change in the form or state of input:

physical manufacturing;

sensual/psychological feeling comfort or

satisfaction

Transport - located somewhere other than where it currently

is. Entity like people, garbage or goods.

Store - kept in a protected environment for some period

of time ( ware house)

Inspect - value of the entity may be enriched through an

inspection as we better understand its properties and then make

a decision ( repair, decision regarding purchase)

OMs Transformation Role

To add value

Increase product value at each stage

Value added is the net increase between output product value and

input material value

Provide an efficient transformation

Efficiency perform activities well at lowest possible cost

What is a Transformation Process?

Defined

A transformation process is defined as a

use of resources to transform inputs into

some desired outputs

Transformations

Physical--manufacturing

Locational--transportation

Exchange--retailing

Storage--warehousing

Physiological--health care

Informational--telecommunications

OM

Inputs Outputs

Conversion

Subsystem

Control

Subsystem

Product

Service

External

Legal, Economic, Social,

Technological

Market

Competition, Customer

Desires, Product Info.

Primary Resources

Materials, Personnel,

Capital, Utilities

Physical (Manufacturing)

Locational Services

(Transportation)

Exchange Services (Retailing)

Storage Services (Warehousing)

Other Private Services (Insurance)

Government Services

(Federal, State, Local)

Monitoring and feedback control

Establish standards of performing or outputs

Measures actual performance

Compare the difference between the actual and planned

Take appropriate remedial actions by changing inputs revising

plans, Changing priorities, Expediting the progress etc.,

Hybrid organizations

Some organizations are a blend of

service/manufacturing/quasi-

manufacturing (QM) organizations

QM characteristics include

Low customer contact & Capital Intensive

1-41

Types of Operations

Operations Examples

Goods Producing Farming, mining, construction ,

manufacturing, power generation

Storage/Transportation Warehousing, trucking, mail

service, moving, taxis, buses,

hotels, airlines

Exchange Retailing, wholesaling, banking,

renting, leasing, library, loans

Entertainment Films, radio and television,

concerts, recording

Communication Newspapers, radio and television

newscasts, telephone, satellites

Goods & Services

Services

Intangible product

Product cannot be

inventoried

High customer contact

Short response time

Labor intensive

Manufacturing

Tangible product

Product can be

inventoried

Low customer contact

Longer response time

Capital intensive

1-43

Goods vs Service

Characteristic Goods Service

Customer contact Low High

Uniformity of input High Low

Labor content Low High

Uniformity of output High Low

Output Tangible Intangible

Measurement of productivity Easy Difficult

Opportunity to correct problems High Low

Inventory Much Little

Evaluation Easier Difficult

Patentable Usually Not usual

Comparison: Continuum

Physical

nature of

product

Inventories

Customer

contact

Customer

response time

Quality

Resource

Size

Location

CATEGORIES

Comparison: Continuum

Intangible, Perishable

(ideas, concepts,

information)

Physical, durable

PHYSICAL NATURE OF PRODUCTS

TOWARDS SERVICES TOWARDS MANUFACTURING

Output less able to be

inventoried

Output can be inventoried

INVENTORY - ABLE

Comparison: Continuum

CUSTOMER CONTACT WITH PRODUCTION

Low or no contact

Customer contacts with

distributor / retailer

High contact

Customer as special

inputs

TOWARDS MANUFACTURING TOWARDS SERVICES

Services industries with low

customer contact ?

CUSTOMER RESPONSE TIME

Long Short

Difficulty matching

capacity with demand

demands fluctuate.

TOWARDS MANUFACTURING TOWARDS SERVICES

Comparison: Continuum

Comparison: Continuum

LOCATION

Regional, national or

international markets

Local markets (near the

customer)

TOWARDS MANUFACTURING TOWARDS SERVICES

SIZE

Large facilities Small facilities

RESOURCES

Capital intensive (more

automation)

Labour intensive

Comparison: Continuum

MEASUREMENT OF QUALITY

Easy to measure

Quantitative nature

Harder to measure

subjective assessments

TOWARDS MANUFACTURING TOWARDS SERVICES

1-50

Automobile assembly, steel making

Home remodeling, retail sales

Automobile Repair, fast food

Goods-service Continuum

Computer repair, restaurant meal

Song writing, software development

Goods Service

Surgery, teaching

Similarities

Process and the use of technology

Concern for quality, productivity and

customer

Choices capacity, location, layout of

facilities

Package offered - goods and services

On the other hand

Both use technology

Both have quality, productivity, & response issues

Both must forecast demand

Both will have capacity, layout, and location issues

Both have customers, suppliers, scheduling and staffing

issues

Manufacturing often provides services

Services often provides tangible goods

Core services are basic things

that customers want from

products they purchase

Core Services

Defined

Core Services Performance Objectives

Operations

Managemen

t

Flexibility

Quality

Speed

Price (or cost

Reduction)

Value-added services

differentiate the organization

from competitors and build

relationships that bind

customers to the firm in a

positive way

Value-Added Services

Defined

Value-Added Service Categories

Operations

Management

Information

Problem Solving

Sales Support

Field Support

Definition : OM

57

Operations management is an area of business that is

concerned with the production of goods and services, and

involves the responsibility of ensuring that business operations

are efficient and effective.

APICS The Association for Operations Management defines operations

management as "the field of study that focuses on the effective

planning, scheduling, use, and control of a manufacturing or service

organization through the study of concepts from design engineering,

industrial engineering, management information systems, quality

management, production management, inventory management,

accounting, and other functions as they affect the organization"

Operations refers to the production of goods and services, the set

of value-added activities that transform inputs into many outputs

MANUFACTURING AND SERVICES

Manufacturing Organizations

Use operations management in the

transformation process of turning raw

materials into physical goods.

Service Organizations

Use operations management in creating

nonphysical outputs in the form of

services (the activities of employees

interacting with customers).

IMPORTANCE OF OM

- It encompasses both services and manufacturing.

- It is important in effectively and efficiently managing

productivity.

- It plays a strategic role in an organizations

competitive success.

- Synergies must exist with other functional areas of the

organization

Operations account for 60-80% of the direct expenses that

burden a firms profit.

Objective of OM

Produces the goods/service in required quantity and of quality as

per schedule at a minimum cost that determine the extent of

customer satisfaction.

Performing objective

Efficiency doing things right

Effectiveness doing the right things

Quality conform to quality specification

Lead time time elapsed in the conversion

process (minimize) - Q, Inventory

Capacity Utilization manpower/ machines etc.

Flexibility flexibility of producing a

combination of o/p, satisfy the

customers needs

objective of Production Management

to produce the desired product or specified product by

specified methods so that the optimal utilization of

available resources is met with.

production management is responsible to produce the

desired product, which has marketability at the

cheapest price by proper planning, the manpower,

material and processes.

Production management must see that it will deliver

right goods of right quantity at right place and at right

price.

Why to Study Operations

Management?

Business Education

Systematic Approach

to Org. Processes

Career Opportunities

Cross-Functional

Applications

Operations

Management

1-63

Operations Management includes:

Forecasting

Capacity planning

Scheduling

Managing inventories

Assuring quality

Motivating employees

Deciding where to locate facilities

Supply chain management

And more . . .

Scope of Operations Management

HIGHLIGHTS

Management technology

Ethical issues

OM in practice

Evolution/ History

1-66

Management Technology

Technology: The application of scientific

discoveries to the development and

improvement of goods and services

Product and service technology

Process technology

Information technology

1-67

Ethical Issues

Financial statements

Worker safety

Product safety

Quality

Environment

Community

Hiring/firing workers

Closing facilities

Workers rights

POM

Marketing

MIS

Engineering

HRM

QA

Accounting

Sales

Finance

OM in Practice

OM has the most diverse organizational function

Manages the transformation process

OM has many faces and names such as;

V. P. operations, Director of supply chains, Manufacturing

manager

Plant manger, Quality specialists, etc.

All business functions need information from OM in

order to perform their tasks

OM is the business function that is responsible for managing

and coordinating the resources needed to produce a

companys products and services.

Its role of OM is to transform organizational inputs into

companys products or services outputs

OM is responsible for a wide range of decisions, ranging from

strategic to tactical.

Organizations can be divided into manufacturing and service

organizations, which differ in the tangibility of the product or

service

A number of historical milestones have shaped OM. Some of

the more significant of these are the Industrial Revolution,

scientific management, the human relations movement,

management science, and the computer age

OM is highly important function in todays dynamic business

environment. Among the trends with significant impact are

just-in-time, TQM, reengineering, flexibility, time-based

competition, SCM, global marketplace, and environmental

issues

OM works closely with all other business functions

Business Information Flow

Introduction to POM - The Origins

Sakichi Toyoda receives a patent for

a wooden loom

philosophy of KAIZEN is born out of

the need to compete.

Henry Ford invents

the moving

assembly line

Toyoda Motor Company Ltd.

is created.

Kiichiro Toyoda builds a

plant at Koromo and through

the imbalance caused by

piece work, hangs a sign in

his new production shop that

reads JUST IN TIME.

Taichi Ohno moves to

the Toyota Motor

Company Ltd.

Ohno begins to perfect

the Just-in-Time

concepts introduced by

Kiichiro

Toyota brings the

Toyota Production

System to the

United States in

collaboration with

GM

Womack and Jones

publish The Machine

that Changed the

World

1890 Late 1890s

Central figures who originated the

idea of "Eliminating Waste",

Lillian Gilbreth brings psychology into the

mix by studying the motivations of workers

and how attitudes affected the outcome of

a process.

Frank Gilbreth develops Motion Study and

invented Process Charting.

Frederick W. Taylor develops the principles

of Time Study and standardized work.

1937 1943 1908 1980 1990

Before: cars were built in one

spot and the workers moved

from car to car. This was called

the gypsy production system.

After: Ford used a big rope

and winch to pull the cars

along the assembly line and

kept the workers stationary

1990

Historical Events in

Operations Management

Era Events/Concepts Dates Originator

Industrial

Revolution

Steam engine 1769

James Watt

Division of labor 1776

Adam Smith

Interchangeable parts 1790

Eli Whitney

Scientific

Management

Principles of scientific

management

1911

Frederick W. Taylor

Time and motion studies 1911

Frank and Lillian

Gilbreth

Activity scheduling chart 1912

Henry Gantt

Moving assembly line 1913

Henry Ford

Historical Events in Operations

Management (cont.)

Era Events/Concepts Dates Originator

Human

Relations

Hawthorne studies 1930 Elton Mayo

Motivation theories

1940s Abraham Maslow

1950s Frederick Herzberg

1960s Douglas McGregor

Operations

Research

Linear programming 1947 George Dantzig

Digital computer 1951 Remington Rand

Simulation, waiting

line theory, decision

theory, PERT/CPM

1950s

Operations research

groups

MRP, EDI, EFT, CIM

1960s,

1970s

Joseph Orlicky, IBM

and others

Historical Events in Operations

Management (cont.)

Era Events/Concepts Dates Originator

Quality

Revolution

JIT (just-in-time) 1970s Taiichi Ohno (Toyota)

TQM (total quality

management)

1980s

W. Edwards Deming,

Joseph Juran

Strategy and

operations

1980s

Wickham Skinner,

Robert Hayes

Business process

reengineering

1990s

Michael Hammer,

James Champy

Six Sigma 1990s GE, Motorola

Historical Events in Operations

Management (cont.)

Era Events/Concepts Dates Originator

Internet

Revolution

Internet, WWW, ERP,

supply chain management

1990s ARPANET, Tim

Berners-Lee SAP,

i2 Technologies,

ORACLE

E-commerce 2000s Amazon, Yahoo,

eBay, Google, and

others

Globalization WTO, European Union,

and other trade

agreements, global supply

chains, outsourcing, BPO,

Services Science

1990s

2000s

Numerous countries

and companies

Business Operations: Definition

Early Concepts : 1776 1880

Scientific Management Era : 1880-1910

Mass Production Era: 1910-1980

Lean Production Era: 1980-1995

Mass Customization Era: 1995- present

Cost Focus

Quality Focus

Customization

Focus

Significant Events in OM

Division of labor (Smith, 1776)

Standardized parts (Whitney, 1800)

Scientific Management (Taylor, 1881)

Coordinated assembly line (Ford 1913)

Gantt charts (Gantt, 1916)

Motion Study (the Gilbreths, 1922)

Quality control (Shewhart, 1924)

CPM/PERT (DuPont, 1957)

MRP (Orlicky, 1960)

CAD

Flexible manufacturing systems (FMS)

Manufacturing Automation Protocol (MAP)

Computer Integrated Manufacturing (CIM)

Current Issues in OM

Coordinate the relationships between

mutually supportive but separate

organizations.

Optimizing global supplier, production, and

distribution networks.

Increased co-production of goods and

services

Current Issues in OM (contd)

Managing the customers experience

during the service encounter

Raising the awareness of operations as a

significant competitive weapon

POM in Global economy

82

Product Architecture

Service Design Current Vs Future

Industry Verticals

Centers of Excellence

1-83

Challenges of Managing Services

Service jobs are often less structured than

manufacturing jobs

Customer contact is higher

Worker skill levels are lower

Services hire many low-skill, entry-level workers

Employee turnover is higher

Input variability is higher

Service performance can be affected by workers

personal factors

1-84

Trends in Business

Major trends

The Internet, e-commerce, e-business

Management technology

Globalization

Management of supply chains

Outsourcing

Agility

Ethical behavior

Discussion

With regard to the type of businesses below,

detail the:

Input, processes, output

Extent of client/customer participation

Nature and source of information

Types of business:

Educational institution

Factory manufacturing iron pipes

Jewellery store

ASSIGNMENT

TRENDS IN OM

CHALLENGES OF OM

SUMMARY

Components of POM

Planning

Organizing

Controlling

Models and Behaviour

Summary

It is a management function

Organizations core function

Every organization has OM function

Service or Manufacturing

For profit or Not for profit

Вам также может понравиться

- Basics Of Operations Management In 40 CharactersДокумент32 страницыBasics Of Operations Management In 40 Charactersravi_nyseОценок пока нет

- Om 1Документ32 страницыOm 1kushagrakaushik61Оценок пока нет

- Chapter1 - Intro OMДокумент13 страницChapter1 - Intro OMCOCONUTОценок пока нет

- O M Concepts, Systems & Emerging TrendsДокумент62 страницыO M Concepts, Systems & Emerging TrendsShveta HastirОценок пока нет

- Operations Management: Mohanasundaram.k@alliance - Edu.inДокумент88 страницOperations Management: Mohanasundaram.k@alliance - Edu.inAlem Abebe AryoОценок пока нет

- Operations Management: Course Instructor: Mansoor QureshiДокумент25 страницOperations Management: Course Instructor: Mansoor QureshiPrince ZiaОценок пока нет

- Operations Management B 28Документ311 страницOperations Management B 28Nikhil ChandranОценок пока нет

- Operation Management Chapter 1Документ72 страницыOperation Management Chapter 1Prasansha TamangОценок пока нет

- Operations Management IntroductionДокумент33 страницыOperations Management IntroductionHem GhimireОценок пока нет

- Chap01 Operation MGMT & StrategyДокумент43 страницыChap01 Operation MGMT & StrategyAlicia NgОценок пока нет

- Introduction To Operations ManagementДокумент40 страницIntroduction To Operations ManagementAchim BragancaОценок пока нет

- Introduction To Production & Operations ManagementДокумент24 страницыIntroduction To Production & Operations ManagementAhsan AnikОценок пока нет

- Lesson Operations Management and Operations Function: ObjectivesДокумент8 страницLesson Operations Management and Operations Function: ObjectivesHayna Marie AguilarОценок пока нет

- Operations Management NotesДокумент251 страницаOperations Management Notesfatsoe1100% (1)

- Opm-Bba-Wk 1-2013Документ29 страницOpm-Bba-Wk 1-2013afzaalkhnОценок пока нет

- Lecture 1 Introduction To Operations ManagementДокумент36 страницLecture 1 Introduction To Operations ManagementsanaullahbndgОценок пока нет

- Operation Management: by Mahr Irfan Ahmad Tahir B.SC., ACFMA (Pak) MIPA (Aus) AFA (UK)Документ12 страницOperation Management: by Mahr Irfan Ahmad Tahir B.SC., ACFMA (Pak) MIPA (Aus) AFA (UK)Rehan AhmadОценок пока нет

- Introduction To Operations Management: Compiled byДокумент15 страницIntroduction To Operations Management: Compiled byjorgeОценок пока нет

- Introduction to Operations Management and ResearchДокумент37 страницIntroduction to Operations Management and ResearchRohan KaranОценок пока нет

- Operations ManagementДокумент132 страницыOperations ManagementECОценок пока нет

- Operations ManagementДокумент37 страницOperations Managementponnu483Оценок пока нет

- Operations Management IntroductionДокумент29 страницOperations Management IntroductionRishabh SarawagiОценок пока нет

- Introduction To OMДокумент30 страницIntroduction To OMtafere99Оценок пока нет

- MFE M5 PPT - For Series 2Документ33 страницыMFE M5 PPT - For Series 2Akhil SankarОценок пока нет

- Om-1 1Документ29 страницOm-1 1Prabin ChaudharyОценок пока нет

- Manop 1 Intro Sep 2011Документ23 страницыManop 1 Intro Sep 2011Astrini Wulandari DewanthiОценок пока нет

- ch-1 Part IДокумент32 страницыch-1 Part IDesu MekonnenОценок пока нет

- Operations Management Chapter 1Документ35 страницOperations Management Chapter 1Randyl ServanoОценок пока нет

- A SummaryДокумент125 страницA SummarySushil PokhrelОценок пока нет

- Course Details and Introduction to Operations ManagementДокумент125 страницCourse Details and Introduction to Operations ManagementSarita BhandariОценок пока нет

- Chapter No.1 Introduction To Product & Operation Management: Bba 7 MorningДокумент15 страницChapter No.1 Introduction To Product & Operation Management: Bba 7 MorningBabar IjazОценок пока нет

- Operations Management (Mic)Документ20 страницOperations Management (Mic)Michelle GoОценок пока нет

- Intro to Operations Management Chapter SummaryДокумент30 страницIntro to Operations Management Chapter SummaryFahad ChowdhuryОценок пока нет

- Production and Operations ManagementДокумент28 страницProduction and Operations Managementwelcome2jungleОценок пока нет

- Introduction of OMДокумент17 страницIntroduction of OMDhruvit Pravin Ravatka (PGDM 18-20)Оценок пока нет

- Operations Management: Week 01Документ19 страницOperations Management: Week 01chris layОценок пока нет

- Lecture 2 UNIT 1 IntroductionДокумент21 страницаLecture 2 UNIT 1 IntroductionPriya GuptaОценок пока нет

- Lecture 01-20141129Документ36 страницLecture 01-20141129maria saleemОценок пока нет

- BOOOOMДокумент221 страницаBOOOOMScrappy WellОценок пока нет

- Introduction To OmДокумент23 страницыIntroduction To OmNitin KarnkaleОценок пока нет

- 5th Semester Operation Management BBMДокумент125 страниц5th Semester Operation Management BBMNeha TimsinaОценок пока нет

- OMДокумент35 страницOMNikhila PinnintiОценок пока нет

- Operations Management OverviewДокумент17 страницOperations Management OverviewShaОценок пока нет

- Operations Management: Samyr J. BДокумент14 страницOperations Management: Samyr J. BSameer Jan BhatОценок пока нет

- Nature of Operation MGTДокумент56 страницNature of Operation MGTAhmed HonestОценок пока нет

- Operations and Production ManagementДокумент37 страницOperations and Production ManagementpreetiОценок пока нет

- Operations ManagementДокумент64 страницыOperations ManagementVictor Boateng100% (1)

- Introduction To Operations ManagementДокумент32 страницыIntroduction To Operations ManagementPrajna Shirsho ShomeОценок пока нет

- Operations Management: Hassaan TariqДокумент17 страницOperations Management: Hassaan TariqThe CrimiОценок пока нет

- Malabar Cements Project ReportДокумент59 страницMalabar Cements Project ReportRomiОценок пока нет

- Lecture 1 Introduction To Operations ManagementДокумент20 страницLecture 1 Introduction To Operations ManagementCleo de ChicoОценок пока нет

- TQMCH1Документ44 страницыTQMCH1Neko MidoriОценок пока нет

- Production & Operation Management: Bba 7 Semester University of TurbatДокумент29 страницProduction & Operation Management: Bba 7 Semester University of TurbatAman UllahОценок пока нет

- 21 Operations Management Module 1Документ136 страниц21 Operations Management Module 1RISHAV RAJ GUPTAОценок пока нет

- Operations and Supply Chain ManagementДокумент61 страницаOperations and Supply Chain ManagementSandeep SonawaneОценок пока нет

- Hindustaan DuduuuДокумент29 страницHindustaan Duduuusantoshmishra5510Оценок пока нет

- Production and Operations: ManagementДокумент56 страницProduction and Operations: ManagementBhargav KanjariyaОценок пока нет

- OM - Operations ManagementДокумент30 страницOM - Operations ManagementNiranjan PatilОценок пока нет

- American Airlines Rainbow TeAAM and Its Strategy To Target The LGBT SegmentДокумент25 страницAmerican Airlines Rainbow TeAAM and Its Strategy To Target The LGBT SegmentManish ShawОценок пока нет

- New Microsoft Word DocumentДокумент17 страницNew Microsoft Word DocumentManish ShawОценок пока нет

- Pepsi ProjectДокумент126 страницPepsi ProjectManish ShawОценок пока нет

- Service-Management: Submitted By, Manish KumarДокумент13 страницService-Management: Submitted By, Manish KumarManish ShawОценок пока нет

- Front Page of Pepsi ProjectДокумент10 страницFront Page of Pepsi ProjectManish ShawОценок пока нет

- Business Plan of Electronic BicycleДокумент9 страницBusiness Plan of Electronic BicycleSabdi AhmedОценок пока нет

- FNCE 101: DR Chiraphol New Chiyachantana Problem Set # 6 (Chapter 14)Документ2 страницыFNCE 101: DR Chiraphol New Chiyachantana Problem Set # 6 (Chapter 14)Vicky HongОценок пока нет

- Practical Project Execution Alloy Wheels Manufacturing PlantДокумент5 страницPractical Project Execution Alloy Wheels Manufacturing PlantSanjay KumarОценок пока нет

- Axial DCF Business Valuation Calculator GuideДокумент4 страницыAxial DCF Business Valuation Calculator GuideUdit AgrawalОценок пока нет

- Journal entries for lamp production costs and inventoryДокумент2 страницыJournal entries for lamp production costs and inventoryLucy HeartfiliaОценок пока нет

- SWOT of Coca ColaДокумент4 страницыSWOT of Coca ColaYoongingОценок пока нет

- Department of Labor: DekalbДокумент58 страницDepartment of Labor: DekalbUSA_DepartmentOfLabor50% (2)

- Commodity Trading: An OverviewДокумент15 страницCommodity Trading: An OverviewvijayxkumarОценок пока нет

- Accounting for Legal FirmsДокумент23 страницыAccounting for Legal FirmsARVIN RAJОценок пока нет

- Books On Africa and Related Issues Published by The UNU: Library@hq - Unu.eduДокумент29 страницBooks On Africa and Related Issues Published by The UNU: Library@hq - Unu.eduPawar SachinОценок пока нет

- What Dubai Silicon Oasis DSO Free Zone OffersДокумент3 страницыWhat Dubai Silicon Oasis DSO Free Zone OffersKommu RohithОценок пока нет

- Table of Contents Answers: Pre-TestДокумент67 страницTable of Contents Answers: Pre-TestLachlanОценок пока нет

- Dan Loeb Sony LetterДокумент4 страницыDan Loeb Sony LetterZerohedge100% (1)

- Exercise 2Документ2 страницыExercise 2Michael DiputadoОценок пока нет

- Vietnamese Restaurant Business PlanДокумент6 страницVietnamese Restaurant Business PlanShamsudeen Abubakar SodangiОценок пока нет

- Conference Report JG16Документ16 страницConference Report JG16LoloaОценок пока нет

- TB 14Документ67 страницTB 14Dang ThanhОценок пока нет

- Impacts of The COVID-19 Pandemic On Food Trade in The CommonwealthДокумент32 страницыImpacts of The COVID-19 Pandemic On Food Trade in The CommonwealthTú NguyễnОценок пока нет

- GST ChallanДокумент1 страницаGST ChallannavneetОценок пока нет

- Cannibalization: This Module Covers The Concepts of Cannibalization and Fair Share DrawДокумент12 страницCannibalization: This Module Covers The Concepts of Cannibalization and Fair Share DrawVishal GargОценок пока нет

- Modify Monthly Budget TemplateДокумент32 страницыModify Monthly Budget TemplateMohammed TetteyОценок пока нет

- Pow Rs Duties Under RT IДокумент18 страницPow Rs Duties Under RT IVamshi Krishna BoorlaОценок пока нет

- 10 LBT ChallanДокумент2 страницы10 LBT ChallanPrateik ParakhОценок пока нет

- Subject: Fundamentals of Abm 1 Grade Level: Eleven Quarter: Three (2) Week: Two I. OBJECTIVES: at The End of The Lesson, Students Are Expected ToДокумент7 страницSubject: Fundamentals of Abm 1 Grade Level: Eleven Quarter: Three (2) Week: Two I. OBJECTIVES: at The End of The Lesson, Students Are Expected ToRoz AdaОценок пока нет

- Columbus Custom Carpentry HR IssuesДокумент5 страницColumbus Custom Carpentry HR IssuesWendy Aden SaputraОценок пока нет

- Roland Gareis Happy ProjectsДокумент88 страницRoland Gareis Happy ProjectsStefana RondakОценок пока нет

- Question Bank1Документ357 страницQuestion Bank1xerxesОценок пока нет

- Piyush TahkitДокумент44 страницыPiyush TahkitPankaj VishwakarmaОценок пока нет

- Aadfi Rates BDC Amongst The Best Performing African Development Finance Institutions in AfricaДокумент1 страницаAadfi Rates BDC Amongst The Best Performing African Development Finance Institutions in AfricaLesego MoabiОценок пока нет

- Lesson 4 Final Income Taxation PDFДокумент4 страницыLesson 4 Final Income Taxation PDFErika ApitaОценок пока нет