Академический Документы

Профессиональный Документы

Культура Документы

ME150P ELecture 1 (04 January 2011)

Загружено:

engrjayasis20Исходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

ME150P ELecture 1 (04 January 2011)

Загружено:

engrjayasis20Авторское право:

Доступные форматы

3

rd

Term S.Y. 2010-2011

Group 1

04 January 2011

I. Psychrometry

II. Air Conditioning System

III. Heat Load Estimation

IV. Practical Air Conditioning System

V. Air Distribution System

VI. Piping System

VII. Equipment Selection

VIII. Refrigerated Load

IX. Ice Manufacturing

I. Heat Load

II. Air Distribution

III. Equipment Selection

Refrigeration and Air Conditioning (Chapters

14 & 15) by C.P. Arora

Carrier System Design Manual Part I, II, & III

Mechanical Engineering Tables and Charts

Latest Edition by MRII

Refrigeration (Chapter X: Cooling Load

Calculation) by Dossat (SI Edition)

Kent Handbook Power Volume (Section 11:

Ice Manufacturing)

08 January 2011

Chapter 14: Properties of Moist Air; Refrigeration and Air

Conditioning by C.P. Arora

Dry air and water vapor form a binary

mixture. The properties of moist air are called

psychrometric properties and the subject

which deals with the behavior of moist air is

known as psychrometry.

Specific or absolute humidity or humidity

ratio or moisture content as it is variously

called denoted by the symbol is defined as

the ratio of the mass of water vapor (w.v.) to

the mass of dry air (d.a.) in a given volume of

the mixture. Thus

Where the subscripts a and v refer to dry air

and water vapor respectively.

v a

a v

m

m

v

e

v

= =

Since p denotes the actual total atmospheric

pressure, then from Daltons Law

So that,

a v

p p p = +

0.622

v

v

p

p p

e =

The concept of specific humidity is that if we take

1 kg of dry air

Then the mass of water vapor associated with

this dry air, in the same volume is

so that the total mass of this volume of moist air

is

.

1

a

m kg =

v

m kg e =

(1 ) m kg e = +

The temperature is called the dew point

temperature (DPT). It is the temperature to

which moist air must be cooled at constant

pressure before condensation of moisture

takes place.

The DPT can be found by knowing, from the

steam tables, the saturation temperature

at the partial pressure of the water vapor.

d

t

d

t

v

p

PROBLEM

In a dew point apparatus a metal beaker is

cooled by gradually adding ice water to the

water initially at room temperature. The

moisture from the room air begins to

condense on the beaker when its temperature

is 12.8C. If the room temperature is 21C

and the barometric pressure is 1.01325 bar,

find the partial pressure of water vapor in the

room air and parts by mass of water vapor in

the room air.

SOLUTION

Partial pressure of water vapor at DPT 12.8C

Partial pressure of dry air

Specific humidity

2

1.479 kN/m

v

p =

2

101325 1479 99846 N/m

a v

a

p p p

p

=

= =

1479

0.622 0.622

99846

v v

a a

m p

m p

e = = =

SOLUTION

Specific humidity

Parts by mass of water vapor

w.v.

0.009214

d.a.

kg

kg

e =

0.009214 w.v.

0.00913

1 1.009214 mixture

v

m kg

m kg

e

e

= = =

+

The degree of saturation is a measure of the

capacity of air to absorb moisture.

It is denoted by the symbol

1

1

v s

s s v

p p p

p p p

e

e

(

= =

(

Relative humidity denoted by the symbol or

RH is defined as the ratio of the mass of

water vapor in a certain volume of moist air at

a given temperature to the mass of water

vapor in the same volume of saturated air at

the same temperature.

v s

s v

p

RH

p

v

|

v

= = =

The enthalpy of moist air is obtained by the

summation of the enthalpies of the

constituents. Thus, the enthalpy of moist air

h is equal to the sum of the enthalpies of dry

air and associated water vapor, i.e.,

per kg of dry air, where subscripts a are for

dry air and v are for the water vapor part.

a v

h h h e = +

Where t is in C

Where t is in C

1.005 (2500 1.88 ) kJ/kg d.a. h t t e = + +

0.24 (1061 0.444 ) Btu/lbm d.a. h t t e = + +

PROBLEM: A mixture of dry air and water

vapor is at a temperature of 21C under a

total pressure of 736 mmHg. The dew point

temperature is 15C. Find:

i. Partial pressure of water vapor

ii. Relative humidity

iii. Specific humidity

iv. Specific enthalpy of water vapor by the three

methods of Fig. 14.5

v. Enthalpy of air per kg of dry air

vi. Specific volume of air per kg of dry air

SOLUTION:

i. From steam tables, the partial pressure of

water vapor at 15C DPT is

ii. Saturation pressure of water vapor at 21C DBT

Relative humidity

.

2

12.79 mmHg = 12.79 (133.5) = 1707.5 N/m

v

p =

2

18.65 mmHg = 18.65 (133.5) = 2489.8 N/m

s

p =

12.79

100 100 68.58%

18.56

v

s

p

p

| = = =

iii. Specific humidity

iv. Latent heat of vaporization of water at dry

bulb and dew-point temperatures of air

(12.79)

0.622 0.622

(736 12.79)

0.011 kg w.v./kg d.a.

v

a

p

p

e

e

= =

=

21

15

( ) 2452 kJ/kg

( ) 2466.2 kJ/kg

fg C

fg C

h

h

=

=

Specific enthalpy of water vapor from Fig. 14.5

by the three methods

Note: The three values are extremely close to

each other.

(4.1868)(21) 2452 2450 kJ/kg w.v.

(4.1868)(15) 2466.2 1.88(21 15)

2540.3 kJ/kg w.v.

2501 1.88(21) 2540.5 kJ/kg w.v.

C

A

A

B

h

h

h

h

= + =

= + +

=

= + =

v. Enthalpy of air using the value of specific

enthalpy of water vapor from the empirical relation

vi. Specific volume of air is equal to the volume of 1

kg of dry air or 0.011 kg of water vapor. Based on

the dry air part

.

1.005(21) 0.011(2540.5)

21.1 27.9 49.0 kJ/kg d.a.

a v

h h h

h

h

e = +

= +

= + =

3

287.3(273 21)

0.875 m /kg d.a.

(723.21)(133.5)

a

a

a

R T

p

v v

+

= = = =

The dry bulb thermometer is directly exposed

to the air and measures the actual

temperature of air.

The bulb of the wet bulb thermometer is

covered by a wick thoroughly wetted by

water.

The temperature which is measured by the

wick-covered bulb of such a thermometer

indicates the temperature of liquid-water in

the wick and is called the wet bulb

temperature.

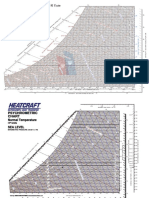

All data essential for the complete

thermodynamic and psychrometric analysis of

air-conditioning processes can be summarized in

a psychrometric chart.

The chart which is most commonly used is the

-t chart, i.e., a chart which has specific

humidity or water vapor pressure along the

ordinate and the dry bulb temperature along the

abscissa.

The chart is normally constructed for a standard

atmospheric pressure of 760 mm Hg or 1.0132

bar, corresponding to the pressure at the mean

sea level.

PSYCHROMETRIC CHART Skeleton

Dry-bulb temperature = The temperature of

air as registered by an ordinary thermometer.

Wet-bulb temperature = The temperature

registered by a thermometer whose bulb is

covered by a wetted wick and exposed to a

current of rapidly moving air.

Dewpoint temperature = The temperature at

which condensation of moisture begins when

the air is cooled.

Relative Humidity = Ratio of the actual water

vapor pressure of the air to the saturated

water vapor pressure of the air at the same

temperature.

Specific Humidity or Moisture Content = The

weight of water vapor in grains or pounds of

moisture per pound of dry air.

Enthalpy = A thermal property indicating the

quantity of heat in the air above an arbitrary

datum, in Btu per pound of dry air. The

datum for dry air is 0F, and for the moisture

content, 32F water.

Specific Volume = The cubic feet of the

mixture per pound of dry air.

Sensible Heat Factor = The ratio of sensible

to total heat.

Pounds of Dry Air = The basis for all

psychrometric calculations. Remains constant

during all psychrometric processes.

Note: The dry-bulb, wet-bulb, and dewpoint

temperatures and the relative humidity are so

related that, if two properties are known, all other

properties shown may then be determined. When

air is saturated, dry-bulb, wet-bulb, and dewpoint

temperatures are all equal.

CARRIER PSYCHROMETRIC CHART

PSYCHROMETRIC CHART Skeleton

Edited

Cooling coil

Mixing Box

1

2

2

Blowe

r

In RA

m

1

2

DB

1

DB

2

WB2

WB1

h

2

h

1

RC = m(h1 h2)

FIGURE 1

RETURN AIR

SUPPLY AIR

Cooling coil

Mixing Box

1

2

3

1

2

DB

1

DB

2

WB2

WB1

h

2

h

1

DB

3

WB3

h

3

3

w1

w2

w3

FIGURE 2

Equations that can be derived based on the

Psychrometric Chart (Figure 2):

Example 15.1 (p. 475)

30 m

3

/min of a stream of moist air at 15C DBT

and 13C WBT is mixed with 12 m

3

/min of a second

stream at 25C DBT and 18C WBT. Barometric

Pressure is one standard atmosphere. Determine

the dry bulb and wet bulb temperatures of the

resulting mixture.

Required: WB3 and DB3

SOLUTION

Cooling coil

Mixing Box

15C DB

13C WB

30 m

3

/min

25C DB

18C WB

12 m

3

/min

1

2

25

C

15

C

13C

18C

V1=

0.86

V2=

0.825

Then,

Example 15.2 (p.476)

A stream of moist air at 2C DBT and 80% RH

mixes with another stream of moist air at 30C

DBT and 10C DPT in the ratio by mass of one

part of the first to tow parts of the second.

Calculate the temperature and specific

humidity of the air after mixing.

BYPASS FACTOR

SOLUTION

Cooling coil

Mixing Box

15C DB

13C WB

30 m

3

/min

25C DB

18C WB

12 m

3

/min

1

2

25

C

15

C

13C

18C

Definition

The following figure shows the process that the

moist air undergoes while flowing over a surface

.

The air enters at 1 and leaves at 2 when the

surface is maintained at S.

The state of the contacted air is that of saturated

air at the temperature of the surface. There is

thus the equivalent of perfect contact of a

definite portion of the air particles with the

surface.

The uncontacted air remains at the entering

state.

The end state of the air is the same as that

produced by the complex entering of the

contacted and uncontacted particles.

hs

h2

h1

S

w3

1

t1 t2 ts

2 w2

w1

t

w

Thus one can define a bypass factor of the

apparatus representing the fraction of

uncontacted air in terms of 1,2,and S as:

Conversely, one can define a contact factor

(1-X) representing a fraction of the contacted

air.

Simple Air conditioning system

and state and mass rate of

supply air

RETURN AIR AT t1, w1

SUPPLY AIR AT ts, ws

Room at

t1, w1

AHU

Cooling coil

Mixing Box

Formulas:

Sensible Heat Balance:

Latent Heat Balance:

Base on Enthalpy:

Find the resulting dry bulb temperature of the

mixture given the following conditions:

OUTDOOR AIR RETURN AIR

m= 2 kg/s m= 3kg/s

35

O

CDB 24

O

CDB

25

O

CWB 50% RH

SOLUTION

2kg/s

35

O

CDB

25

O

CWB

Figure

m= 3kg/s

50% RH

24

O

CDB

WBm

Wm

35oC 28.4o

C

24oC

25oC

OA

50%

RM

MIX

Equation:

By: Bautista, Norman George V.

Results from any one single source of heat.

Summation of the heat which evolves from

different sources.

Heat that leaks from the outside space.

Heat that enters the space by radiation.

Heat that enters the space through doors and

windows.

Heat given of by a warm product.

Heat given by people.

Heat given by equipments.

In cases where the refrigerated load was

calculated on a 24 hour basis the load may be

determined directly in KW.

Equation:

Where Q = required equipment capacity, KW

RT= running time, hrs.

qt = total cooling load, KW

A measure of the heat flow rate by

conduction through walls of the refrigerated

space from outside to the inside.

Also called as the wall leakage load

Equation:

Where: Q = rate of heat transferred, W.

A = outside surface area of wall, m

2

U = overall coefficient of heat transmission

(W/ m

2

K), Table 10-2

TD = temperature difference across the wall

) )( )( ( TD U A Q=

Determine the heat flow rate in watts through

a wall 3m by 6m. If the U factor for the wall is

0.37 W/ m

2

K and the temperature on one

side of the wall is 4 C while the temperature

on the other side is 35 C.

Given: U = 0.37 W/ m

2

-K

T

1

= 4 C

T

2

= 35 C

Solution :

Total Wall Area = 3m x 6m = 18 m

2

TD = T

2

- T

1

= 35-4 = 31 K

Q = AUTD = 18 m

2

(0.37 W/ m

2

-K)(31 K)

Q = 206 W or 0.206 kW

Is the property of a material describing its

ability to conduct heat. W/(Km)

Can be found on Table 10-1.

Equation:

Where: C = thermal conductance

k = thermal conductivity

x = thickness

x k C / =

Determine the thermal conductance for a 125

mm thickness of polyurathane.

Solution:

From table 10-1, k = 0.125 W/m-K

C = 0.025 / 0.125

C = 0. 2 W/m

2

K

Thermal resistance is a measure of a

material's ability to resist heat transfer. The

more a material is able to block heat transfer

through its surface, the greater

its thermal resistance.

Equation:

k x k c U R / / 1 / 1 / 1 = = = =

When a wall is constructed of several layers of

different materials,

Where: = convection coefficient of

inside wall.

= convection coefficient of outside wall.

1/fi

Assuming a wind velocity of 3.35 m/s,

calculate the value of U for a wall constructed

of 200 mm sand aggregate building blocks

insulated with 75 mm of polyurethane and

finished on the inside with 13 mm of cement

plaster.

Solution:

From table 10 1:

200 mm sand aggregate block, C = 5.11

Polyurethane, k = 0.025

Cement plaster, k = 0.72

fi = 9.37

fo = 22.7

1/U = 3.37

U = 0.297 W/ m

2

- K

37 . 9 / 1 72 . 0 / 013 . 0 025 . 0 / 075 . 0 11 . 5 / 1 7 . 22 / 1 / 1 + + + + = U

A walk-in cooler 5m x 7m x 3m high is located in

the southeast corner of a store building in an

area where the outdoor design DB temperatures

in summer and winter are 35 C and -6 C. The

south and east walls of the cooler are adjacent to

and a part of the south and east walls of the

store building. The store has a 4 m ceiling so

that there is a 1 m clearance between the top of

the cooler and the ceiling of the store.

The store is air conditioned and the

temperature inside the store is

maintained at approximately 26 C. The

inside design temperature for the cooler

is 2 C. The north and west (inside) walls,

floor and ceiling are insulated with 75

mm of closed-cell (smooth surface)

polystyrene, and the south and east walls

are insulated with 100 mm of closed-cell

polystyrene. Determine the wall gain load

in kilowatts.

7 m

5

m

Outdoor Design

Temp, 35 C

150 mm clay

tile

150 mm

polystyrene

Cooler 2 C

3m ceiling

Partitions

insulated with

75 mm

polystyrene

Inside Temperature 26

C

Ceiling 4m

K (polystyrene) = 0.029 W/m-K

U (north and west) = 0.346 W/m

2

- K

U (south and east) = 0.267 W/m

2

K

N, W, ceiling = (71)(0.346)(26-2) = 589.6 W

S = (15)(0.267)(37-2) = 140.2 W

E = (21)(0.267)(38-2) = 201.9 W

Floor = (35)(0.346)(25-2) = 215 W

Total wall gain load = 1147 W or 1.147 kW

A warm outside air enters the space to replace

the more dense cold air which is lost from the

refrigerated space through the open door.

Equation:

Where: Q = air change load, kW

m = mass of air entering, kg

ho = enthalpy of outside air

hi = enthalpy of inside air

) ( hi ho m Q =

The rate of air infiltration into a refrigerated

space is 8 L/s. If the inside of the cooler is

maintained at 2 C and the outside dry bulb

temperature and humidity are 30 C and 50%

respectively, determine the air change load in

kilowatts.

Solution:

By interpolation in Table 10-6A, the enthalpy

change factor is 0.0598 kJ/L

Air change load = (8L/s)(0.0598 kJ/L)

Air change load = 0.478 kW

When a product enters a storage space at a

temperature above the temperature of the

space, the product will give off heat to the

space until it cools to the space temperature.

Equation:

Where: Q = quantity of heat, kJ/kg

m = mass of the product, kg

Cp = specific heat Above freezing Temp.

TD = temperature change in the product

temperature, K

) (TD mCp Q =

This equation is used to know the product

load at a specific time.

Thirty-five hundred kilograms of fresh beef

enter a chilling cooler at 39C and are chilled

to 7C each day. Compute the product load in

kilojoules.

Solution:

Q= mCp(TD)

= (3500)(3.14)(39-7)

Q = 351,680 kJ

Determine the product load in kilowatts

assuming that the beef described in the

previous example is chilled in 20h.

Solution:

Q = 4.88 kW

Fruits and vegetables are still alive after

harvesting and continue to undergo changes

while in storage.

Respiration is a process during which oxygen

from the air combines with the carbohydrates

in the plant tissue and results in the release

of carbon dioxide and heat.

Equation:

Where:

m = mass of product, kg

r

h

= respiration rate, W/kg

A storage cooler 6m x 4m x 3.4m high is

insulated with 100 mm of glass fiberboard.

Overall wall thickness is approximately 200

mm. The outside temperature is 30C and

usage is average. Twelve hundred and fifty

kilograms of wet mixed vegetables are

cooled, 25C to the storage temperature of

5C each day. Compute the required

equipment capacity based on a 16-h/day.

Outside surface area

= 2(6x4)+2(6x3.4)+2(4x3.4)

= 116 m

2

Inside Volume = 5.6 x 3.6 x 3 m = 60.5 m

3

Glass fiberboard, k = 0.036 W/m K

100 mm thick insulation, k = 0.035 W/m-k

U = 0.31 W/m

2

-K

By interpolation, (table 10-7)

Infiltration Rate = 8.13 L/s

Assume a 50 % RH, enthalpy change factor =

0.0536 kJ/L

Cp of wet mixed veg = 3.77 kJ/kg-L

r

h

= 0.097 W/kg

Wall gain load = (116)(0.31)(30-5) = 899

W or 0.899 kW

Air change load = (8.13)(0.0536) =

0.43kW

Product cooling load =

Respiration load = (1250)(0.097) = 121.5

W or 0.121 kW

Sum of heat loads = 1.729 kW

Safety factor (10%) = 0.173 kW

Total cooling load = 1.902 kW

Required equipment capacity =

Вам также может понравиться

- Tutorial 1& 2 - SolДокумент10 страницTutorial 1& 2 - SolAli ZaghloulОценок пока нет

- 2.0 Band Brake Example ProblemsДокумент10 страниц2.0 Band Brake Example Problemsmanalo.jonmeloОценок пока нет

- PDF Compre Special Project Ppe Ampipe DLДокумент92 страницыPDF Compre Special Project Ppe Ampipe DLClint Baring ArranchadoОценок пока нет

- Chapter 1Документ8 страницChapter 1Von A. Damirez0% (1)

- Plate No RaДокумент5 страницPlate No RaEdelleОценок пока нет

- Air ConditioningДокумент20 страницAir ConditioningJohanne Franz Calacday100% (1)

- Nit Mtech Course 1.1Документ61 страницаNit Mtech Course 1.1AbhishekVermaОценок пока нет

- Refrigeration-Systems Part 1Документ11 страницRefrigeration-Systems Part 1Sean GuanzonОценок пока нет

- GearДокумент14 страницGearAnimesh ManiОценок пока нет

- Refrigeration and Airconditioning by S K Mondal T&Q .0001Документ133 страницыRefrigeration and Airconditioning by S K Mondal T&Q .0001ANILОценок пока нет

- Sample Problems SPRINGSДокумент15 страницSample Problems SPRINGSKara KruzОценок пока нет

- CHAPTER 10 Cooling Load January 2012Документ50 страницCHAPTER 10 Cooling Load January 2012Franky FlamОценок пока нет

- Section 16Документ97 страницSection 16Carolina FerrerОценок пока нет

- Rac Problems Set 1Документ6 страницRac Problems Set 1Mohammad Umair100% (1)

- Bsme 3-B: Me 114 - Heat Transfer Bachelor of Science in Mechanical EngineeringДокумент3 страницыBsme 3-B: Me 114 - Heat Transfer Bachelor of Science in Mechanical EngineeringJethro Briza GaneloОценок пока нет

- Ppe - Inhouse 2Документ27 страницPpe - Inhouse 2Samuel ArzadonОценок пока нет

- Variable Stresses With Stress ConcentrationsДокумент16 страницVariable Stresses With Stress ConcentrationsBryan GounzoОценок пока нет

- ME Con-1 Mock-1Документ15 страницME Con-1 Mock-1vidya chakitwarОценок пока нет

- Methods of Firing Steam BoilerДокумент22 страницыMethods of Firing Steam BoilerAnonymous mRBbdopMKf100% (2)

- Basic Machine Design Situational Problem by Alcorcon 1 PDFДокумент170 страницBasic Machine Design Situational Problem by Alcorcon 1 PDF3 stacksОценок пока нет

- Compressors: Isothermal - This Model Assumes That TheДокумент12 страницCompressors: Isothermal - This Model Assumes That TheRenneil De PabloОценок пока нет

- Nu Day 3Документ2 страницыNu Day 3Jan Tiangco100% (1)

- AIR CONDITIONING AND VENTILATION SYSTEM Prelim ExamДокумент1 страницаAIR CONDITIONING AND VENTILATION SYSTEM Prelim ExamJames Patrick TorresОценок пока нет

- 19 21Документ6 страниц19 21Aub Enriquez100% (1)

- Maibarara Power PlantДокумент7 страницMaibarara Power PlantPhillip GaiteОценок пока нет

- Pipe 02: by TRC - Tiger's Review CenterДокумент119 страницPipe 02: by TRC - Tiger's Review Centerkristan7Оценок пока нет

- Performance TestДокумент18 страницPerformance TestKumaran PalaniОценок пока нет

- Methods of Handling Air SupplyДокумент10 страницMethods of Handling Air SupplySka dooshОценок пока нет

- BrakesДокумент2 страницыBrakesAngielou SialanaОценок пока нет

- Heat Transfer: Precious Arlene Villaroza-MelendrezДокумент46 страницHeat Transfer: Precious Arlene Villaroza-MelendrezMark Jake Rodriguez0% (1)

- Foundry TerminologyДокумент5 страницFoundry Terminologyahmish kabbaxeОценок пока нет

- Sentence A Is CorrectДокумент14 страницSentence A Is CorrectLister NambatacОценок пока нет

- Basic Design and Concepts To Industrial Plant SystemsДокумент39 страницBasic Design and Concepts To Industrial Plant SystemsCj SiguenzaОценок пока нет

- Problems On Testing and Performance of IceДокумент5 страницProblems On Testing and Performance of Iceasjdkfjskaldjf;klasdfОценок пока нет

- Pipe Preboard 1Документ10 страницPipe Preboard 1Chyno Kang100% (1)

- Otto Cycle ProblemsДокумент4 страницыOtto Cycle ProblemsBipulBrahmaОценок пока нет

- Diesel Power Plant ProblemsДокумент2 страницыDiesel Power Plant ProblemsMaribethCanesoMappeОценок пока нет

- Assignment No. 1 in PpeДокумент3 страницыAssignment No. 1 in PpeJenny Mae PomedaОценок пока нет

- HGFHFGHFGДокумент24 страницыHGFHFGHFGAljhon BautistaОценок пока нет

- ME198D Design ElemetsДокумент2 страницыME198D Design ElemetsChloe OlazoОценок пока нет

- Automatic White Board Cleaner ARTICLE 1 DUERRДокумент6 страницAutomatic White Board Cleaner ARTICLE 1 DUERRborjajovenileОценок пока нет

- 2nd Law EfficiencyДокумент7 страниц2nd Law EfficiencyBilly JhunОценок пока нет

- Module 4: Activity No. 2: SolutionДокумент2 страницыModule 4: Activity No. 2: SolutionLeyzer Malumay100% (1)

- Question Number 1Документ82 страницыQuestion Number 1Ryan Llona FernandezОценок пока нет

- Air Quantities Sample Problems (Latent Heat and Cooling Load)Документ8 страницAir Quantities Sample Problems (Latent Heat and Cooling Load)Yan BerbosidadОценок пока нет

- ICE - Lecture From MapuaДокумент48 страницICE - Lecture From MapuaMarcial Jr. MilitanteОценок пока нет

- Anemometer and Air Velocity MeasurementДокумент2 страницыAnemometer and Air Velocity MeasurementSHERWIN MOSOMOSОценок пока нет

- Batch 3 MCQ (Valve and Rocker Arm)Документ4 страницыBatch 3 MCQ (Valve and Rocker Arm)Hemanth SidharthaОценок пока нет

- Neil Chester C. HernaezДокумент6 страницNeil Chester C. HernaezSka dooshОценок пока нет

- Machine Design, Engineering Materials and Machine Shop Problem Solving Examination No. 4 / Second Semester, A.Y. 2008-2009Документ9 страницMachine Design, Engineering Materials and Machine Shop Problem Solving Examination No. 4 / Second Semester, A.Y. 2008-2009maria katherine pantojaОценок пока нет

- ME543: Me Laws, Contracts, Specifications, and EthicsДокумент13 страницME543: Me Laws, Contracts, Specifications, and EthicsEm JhayОценок пока нет

- Mechanical Engineering Applied-Thermodynamics Refrigeration NotesДокумент24 страницыMechanical Engineering Applied-Thermodynamics Refrigeration Notesminesh.manu6531Оценок пока нет

- Gas Compressor ProblemsДокумент2 страницыGas Compressor Problemskim dianon0% (1)

- M E LAB 3 Experiment 4 Heat Losses From Pipes 3Документ20 страницM E LAB 3 Experiment 4 Heat Losses From Pipes 3Alister Mae ZafraОценок пока нет

- Module 5 Activity No. 4Документ1 страницаModule 5 Activity No. 4dracarysОценок пока нет

- (x4) Problem 5 - 9 Multi Stage CompressionДокумент15 страниц(x4) Problem 5 - 9 Multi Stage CompressionLester Alfred M. OlasimanОценок пока нет

- Section 16 PDFДокумент97 страницSection 16 PDFherrerafaridОценок пока нет

- Gas - Vapor Mixtures & Air - ConditioningДокумент27 страницGas - Vapor Mixtures & Air - ConditioningElena Romero ArandaОценок пока нет

- Lecture # 13: Dr. Muzaffar AliДокумент41 страницаLecture # 13: Dr. Muzaffar Alikamran bhatОценок пока нет

- Ice Manufacturing: A. Can SystemДокумент3 страницыIce Manufacturing: A. Can Systemengrjayasis20Оценок пока нет

- Experiment 11-Hvac For Small HouseДокумент9 страницExperiment 11-Hvac For Small Houseengrjayasis20Оценок пока нет

- Aircon Jive Part 3 of Chapter 15Документ14 страницAircon Jive Part 3 of Chapter 15engrjayasis20Оценок пока нет

- Airconditioning System ApplicationДокумент6 страницAirconditioning System Applicationengrjayasis20Оценок пока нет

- HvacДокумент249 страницHvacengrjayasis20Оценок пока нет

- All Cooling Load RulesДокумент31 страницаAll Cooling Load RulesEngFaisal AlraiОценок пока нет

- Hvac Systems and Designs: Psychrometry of Air Conditioning PROCESSES - Processes inДокумент45 страницHvac Systems and Designs: Psychrometry of Air Conditioning PROCESSES - Processes inJames Caballes50% (2)

- Chap # 07 Psychrometry-03Документ18 страницChap # 07 Psychrometry-03Aleena Amin KhuwajaОценок пока нет

- Rac QBДокумент9 страницRac QBAsif jabarОценок пока нет

- Study of Psychometry Properties, Chat and Its UseДокумент7 страницStudy of Psychometry Properties, Chat and Its Usesantosh IndulkarОценок пока нет

- Cartas Psicometricas PDFДокумент4 страницыCartas Psicometricas PDFDebora Lezama UtrillaОценок пока нет

- Che 320 ExamДокумент3 страницыChe 320 ExamAnjolaoluwa Oreoluwa AfolabiОценок пока нет

- Solution To Mid Term ExamДокумент9 страницSolution To Mid Term ExamMariel MirafloresОценок пока нет

- Applied Thermodynamics 2Документ26 страницApplied Thermodynamics 2Ankit SharmaОценок пока нет

- 2 & 16 MarksДокумент23 страницы2 & 16 Markstamilselvan nОценок пока нет

- QB 114335Документ6 страницQB 114335Vijay AnandОценок пока нет

- Climate Analysis WorkshopДокумент0 страницClimate Analysis WorkshopShashi Kant Singh100% (1)

- Chapter 3 Psychrometric ChartДокумент41 страницаChapter 3 Psychrometric ChartvinoОценок пока нет

- Camel5111 User Guide - PDF (9933)Документ164 страницыCamel5111 User Guide - PDF (9933)Samuel AnguloОценок пока нет

- Grafik PsicrometricДокумент3 страницыGrafik PsicrometricDwi CahyoОценок пока нет

- NPTEL Phase II - Mechanical Engineering - Refrigeration and Air ConditioningДокумент6 страницNPTEL Phase II - Mechanical Engineering - Refrigeration and Air ConditioningADITYAОценок пока нет

- Humidification and Cooling Towers FullДокумент114 страницHumidification and Cooling Towers FullHoorish NiaziОценок пока нет

- Experiment 5 Liquid Diffusion CoefficientДокумент55 страницExperiment 5 Liquid Diffusion Coefficienttaj232Оценок пока нет

- Psychometric ChartДокумент9 страницPsychometric Chartqms1234Оценок пока нет

- T.E MechanicalДокумент62 страницыT.E MechanicalhaptooorОценок пока нет

- Using A Psychrometric Chart Is Quite Easy If You Know The Properties of Air2Документ14 страницUsing A Psychrometric Chart Is Quite Easy If You Know The Properties of Air2SeindahNyaОценок пока нет

- Psychrometric ChartДокумент39 страницPsychrometric ChartSalley BukhariОценок пока нет

- Gas Vapor MixturesДокумент47 страницGas Vapor MixturesMo SalihОценок пока нет

- Calculation of The Outlet Air Conditions in The Direct EvaporativeДокумент9 страницCalculation of The Outlet Air Conditions in The Direct EvaporativeĐức LêОценок пока нет

- Dry Air Gas PropertiesДокумент25 страницDry Air Gas Propertiesmshah222Оценок пока нет

- T-S ChartДокумент1 страницаT-S ChartPhanhai KakaОценок пока нет

- MEC1405 - Thermodynamics I (2009Документ3 страницыMEC1405 - Thermodynamics I (2009Maria CutajarОценок пока нет

- Topic 4.1 Psychometry and Air ConditioningДокумент76 страницTopic 4.1 Psychometry and Air ConditioningCARL IJADE PINOОценок пока нет

- Hvac Design PDFДокумент100 страницHvac Design PDFJamie LaoОценок пока нет

- Chapter00 Subsurface Ventilation EngineeringДокумент12 страницChapter00 Subsurface Ventilation EngineeringadityatheaaaОценок пока нет