Академический Документы

Профессиональный Документы

Культура Документы

Toyota Tundra 20% Front Seat FMVSS 207/210 - April-07-05: Analysis Results Summary

Загружено:

api-19817003Исходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Toyota Tundra 20% Front Seat FMVSS 207/210 - April-07-05: Analysis Results Summary

Загружено:

api-19817003Авторское право:

Доступные форматы

ANALYSIS RESULTS SUMMARY:

Toyota Tundra 20% Front Seat

FMVSS 207/210 – April-07-05

Work Order: 233.41860.001.G

FEA Design Level #: 14

Load Case Iteration #: 33,34

Template Revision: 1 Analyst (Employer): Ashish (Altair)

Revision Date: 01/01/05

April/07/05 1 W.O. # 233.41860.001.G

Seat: Toyota Tundra 20% Front Seat FEA Design Level #: 14

Load Case: FMVSS 207/210 Load Case Iteration #: 33,34

I. Conclusions and Recommendations

Design 14 Iteration 33

• The Toyota tundra 20% front seat buckles under the 207/210 load case. At 65 msec bracket

supports right side buckles.

Design 14 Iteration 34

• The Toyota tundra 20% front seat buckles under the 207/210 load case. At 75 msec bracket

supports right side buckles.

April-07-2005 2 W.O. # 233.41860.001.G

Seat: Toyota Tundra 20% Front Seat FEA Design Level #: 14

Load Case: FMVSS 207/210 Load Case Iteration #: 33,34

II. Design Level and Model Description

Design Level 14 and Iteration 33

From the design 14 Iter 32 model: following changes has been done

1) CG loading change as per new EC distribution bar.

2) Lap block change to narrow mga lap block.

L-shaped steel channel 40x40xt4.

April-07-2005 3 W.O. # 233.41860.001.G

Seat: Toyota Tundra 20% Front Seat FEA Design Level #: 14

Load Case: FMVSS 207/210 Load Case Iteration #: 33,34

II. Design Level and Model Description

Design Level 14 and Iteration 34

From the design 14 Iter33 model: following changes has been done

1) The shoulder and lap belt load reduce to 100% of FMVSS standard (from 120%). (13500N)

2) The CG load reduce to 100% of FMVSS standard (from 120%).(3551 N)

April-07-2005 4 W.O. # 233.41860.001.G

Seat: Toyota Tundra 20% Front Seat FEA Design Level #: 14

Load Case: FMVSS 207/210 Load Case Iteration #: 33,34

Design 14:

Welds between outer and inner RH cushion bracket

added as per design11 iteration 19.

April-07-2005 5 W.O. # 233.41860.001.G

Seat: Toyota Tundra 20% Front Seat FEA Design Level #: 14

Load Case: FMVSS 207/210 Load Case Iteration #: 33,34

Design 14 Iteration 33

Material and Thickness information for Major Components

April-07-2005 6 W.O. # 233.41860.001.G

Seat: Toyota Tundra 20% Front Seat FEA Design Level #: 14

Load Case: FMVSS 207/210 Load Case Iteration #: 33,34

III. Detailed Analysis Results

Design 14 Iteration 33

Deformed Shape of Seat @ RH cushion Deformation plot with un-deformed geometry@

bracket buckling starts at 65msec and 125 msec and applied reaches 100% of the full

applied load reaches 91.5% of full load load.

April-07-2005 7 W.O. # 233.41860.001.G

Seat: Toyota Tundra 20% Front Seat FEA Design Level #: 14

Load Case: FMVSS 207/210 Load Case Iteration #: 33,34

III. Detailed Analysis Results

Design 14 Iteration 34

Deformed Shape of Seat @ RH cushion Deformation plot with un-deformed geometry@

bracket buckling starts at 75msec and 160 msec and applied reaches 100% of the full

applied load reaches 98.9% of full load load.

April-07-2005 8 W.O. # 233.41860.001.G

Seat: Toyota Tundra 20% Front Seat FEA Design Level #: 14

Load Case: FMVSS 207/210 Load Case Iteration #: 33,34

Maximum Bolt forces at floor mounting locations

RH cushion rear Design 14 Iteration 33

A = 36694.4 SR = 10681.6

LH cushion rear

A = 54733.5 SR = 13040

RH cushion front

A = 46672.3 SR = 8210.88

LH cushion front

A = 60610 SR = 5421.48

A = axial force, SR = shear resultant

April-07-2005 9 W.O. # 233.41860.001.G

Seat: Toyota Tundra 20% Front Seat FEA Design Level #: 14

Load Case: FMVSS 207/210 Load Case Iteration #: 33,34

Maximum Bolt forces at floor mounting locations

RH cushion rear Design 14 Iteration 34

A = 35868 SR = 10585

LH cushion rear

A = 51573 SR = 11272

RH cushion front

A = 47774.6 SR = 8000

LH cushion front

A =59986 SR = 5547

A = axial force, SR = shear resultant

April-07-2005 10 W.O. # 233.41860.001.G

Seat: Toyota Tundra 20% Front Seat FEA Design Level #: 14

Load Case: FMVSS 207/210 Load Case Iteration #: 33,34

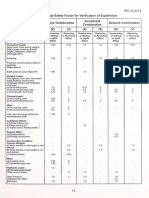

IV. Test Set-up and Acceptance Criteria

Design 14 Iteration 33,34

Generic JCI shoulder

block

Belt exit point

Generic JCI shoulder clevis

Retractor

mounting point.

Generic JCI lap block

CG bars

Note: The “narrow mga lap block” is used for the center lap block

April-07-2005 11 W.O. # 233.41860.001.G

Seat: Toyota Tundra 20% Front Seat FEA Design Level #: 14

Load Case: FMVSS 207/210 Load Case Iteration #: 33,34

Design 14 Iteration 33

16200 N

4261 N

• Seatback in design position.

• Load levels shown are at FMVSS+ 20% (16200N). In the analysis, the applied

loads are held FMVSS + 20% load level.

• The shoulder and lap belt loading =13500x1.2=16200 N

• The CG loading =(20xgxmass)x1.2=(20x9.81x18.1 kg)x1.2=4261 N

Acceptance Criteria:

• Seat must hold FMVSS + 20% loads without any part fracture.

April-07-2005 12 W.O. # 233.41860.001.G

Seat: Toyota Tundra 20% Front Seat FEA Design Level #: 14

Load Case: FMVSS 207/210 Load Case Iteration #: 33,34

Design 14 Iteration 34

13500 N

3551 N

• Seatback in design position.

• Load levels shown are at FMVSS (13500N). In the analysis, the applied loads are

held FMVSS.

• The shoulder and lap belt loading =13500 =13500 N

• The CG loading = 20xgxmass= 20x9.81x18.1 kg = 3551 N

Acceptance Criteria:

• Seat must hold FMVSS loads without any part fracture.

April-07-2005 13 W.O. # 233.41860.001.G

Seat: Toyota Tundra 20% Front Seat FEA Design Level #: 14

Load Case: FMVSS 207/210 Load Case Iteration #: 33,34

Design 14 Iteration 33,34

April-07-2005 14 W.O. # 233.41860.001.G

Seat: Toyota Tundra 20% Front Seat FEA Design Level #: 14

Load Case: FMVSS 207/210 Load Case Iteration #: 33,34

Design 14 Iteration 33,34

April-07-2005 15 W.O. # 233.41860.001.G

Seat: Toyota Tundra 20% Front Seat FEA Design Level #: 14

Load Case: FMVSS 207/210 Load Case Iteration #: 33,34

V. Analysis Methods Summary

The following standardized JCI methods were used for this analysis iteration(s):

Revision

JCI Analysis Method Comments/Exceptions

Level

207/210 General Analysis

1

Procedure (1/1/05)

(207210_Analysis_Procedure.pdf)

207/210 Body Block Positioning

Procedure 1

(1/1/05)

(Belt_Lengths_and_Body_Block_Positioning

_Procedure.pdf)

Dyna General Procedure 1

(Dyna_General.pdf) (1/1/05)

Forming Mapping Procedure 1

(Mapping_Forming_Results.pdf) (1/1/05)

Material Property Curves

0

(10/1/04)

Detailed Bolt Modeling Macro 2

(01/21/05)

April-07-2005 16 W.O. # 233.41860.001.G

Вам также может понравиться

- Hino 300 SeriesДокумент36 страницHino 300 SeriesDe Javu33% (3)

- Toyota Tundra 20% Front Seat FMVSS 207/210 - April-06-05: Analysis Results SummaryДокумент36 страницToyota Tundra 20% Front Seat FMVSS 207/210 - April-06-05: Analysis Results Summaryapi-19817003Оценок пока нет

- Hino 3241 Series700 8x4Документ6 страницHino 3241 Series700 8x4C.H. WEE100% (1)

- Wind Calculation For CanopyДокумент11 страницWind Calculation For Canopyamitkukna100% (3)

- Toyota Tundra 20% Front Seat FMVSS 207/210 - April-07-05: Analysis Results SummaryДокумент28 страницToyota Tundra 20% Front Seat FMVSS 207/210 - April-07-05: Analysis Results Summaryapi-19817003Оценок пока нет

- Analysis Results Summary:: Toyota Tundra 20% Front Seat FMVSS 207/210 - May-26-05Документ18 страницAnalysis Results Summary:: Toyota Tundra 20% Front Seat FMVSS 207/210 - May-26-05api-19817003Оценок пока нет

- Analysis Results Summary:: Toyota Tundra 20% Front Seat FMVSS 207/210 - May-02-05Документ18 страницAnalysis Results Summary:: Toyota Tundra 20% Front Seat FMVSS 207/210 - May-02-05api-19817003Оценок пока нет

- John Deere 5310N Tractor (North America) All Inclusive Service Repair Technical Manual (Tm1717)Документ18 страницJohn Deere 5310N Tractor (North America) All Inclusive Service Repair Technical Manual (Tm1717)laopaodunОценок пока нет

- AD / AT 720T38 TH Tractor 6x4: WEIGHTS (KG.) G.V.W. G.C.W. Front Axle Rear AxleДокумент2 страницыAD / AT 720T38 TH Tractor 6x4: WEIGHTS (KG.) G.V.W. G.C.W. Front Axle Rear AxleHani SweetieОценок пока нет

- Kia Sorento XM TSB042 PDFДокумент2 страницыKia Sorento XM TSB042 PDFAlfateh KingОценок пока нет

- MP720E47HT: Technical DescriptionsДокумент18 страницMP720E47HT: Technical DescriptionsBroCactusОценок пока нет

- TOYOTA GENUINE PARTS CLEARANCE - CatalogueДокумент63 страницыTOYOTA GENUINE PARTS CLEARANCE - CatalogueKeJeОценок пока нет

- Exterior & Interior: SectionДокумент22 страницыExterior & Interior: SectionNilson BarbosaОценок пока нет

- AD AT 410T44 H - Dump TruckДокумент2 страницыAD AT 410T44 H - Dump TruckhendrynОценок пока нет

- Rnym08 1320B 30Документ2 страницыRnym08 1320B 30Andrés VRОценок пока нет

- Ev ZSДокумент2 страницыEv ZSPankaj GuptaОценок пока нет

- MP440E47HT: Technical DescriptionsДокумент20 страницMP440E47HT: Technical DescriptionsBroCactusОценок пока нет

- Case E John Deere: Model CTU 3300 - Applied On Sugarcane HarvestersДокумент8 страницCase E John Deere: Model CTU 3300 - Applied On Sugarcane HarvestersFernando AguilarОценок пока нет

- Iveco AD AT 380T38 WHДокумент2 страницыIveco AD AT 380T38 WHEndang WahyudiОценок пока нет

- Ad at 380T44 WH PDFДокумент2 страницыAd at 380T44 WH PDFHani SweetieОценок пока нет

- Iv4134 Iveco Trakker Ad720t42th 6x4 Tractor Head Specification EnglishДокумент2 страницыIv4134 Iveco Trakker Ad720t42th 6x4 Tractor Head Specification EnglishJavier Ordoñez BarrigaОценок пока нет

- MP720E42HT: Technical DescriptionsДокумент18 страницMP720E42HT: Technical DescriptionsBroCactusОценок пока нет

- Rnym02 1330ya 120Документ2 страницыRnym02 1330ya 120Javier CharrezОценок пока нет

- M2 106 TaДокумент26 страницM2 106 TaFERNANDO FERRUSCAОценок пока нет

- Configuration: Order DataДокумент7 страницConfiguration: Order Dataclaudiu.gheorghe5710Оценок пока нет

- Recommended Parts: Repair DetailsДокумент7 страницRecommended Parts: Repair DetailsAh TeeОценок пока нет

- 205-03 Front Drive Axle and Differential - Removal and Installation - Axle Cover BushingДокумент3 страницы205-03 Front Drive Axle and Differential - Removal and Installation - Axle Cover BushingCARLOS LIMADAОценок пока нет

- Failure Analysis Report - DT 2339 Suspension LH Rev1Документ8 страницFailure Analysis Report - DT 2339 Suspension LH Rev1Eng PLM ACPОценок пока нет

- Braking System Design For All Terrian Vehicle (Atv)Документ8 страницBraking System Design For All Terrian Vehicle (Atv)Karanbir SinghОценок пока нет

- Rnym08 1320B 15Документ2 страницыRnym08 1320B 15Andrés VRОценок пока нет

- Front Wheel AlignmentДокумент4 страницыFront Wheel AlignmentSalud y Cuidado AutomotrizОценок пока нет

- 2010 Ford FusionДокумент176 страниц2010 Ford FusionAishah Ayoshah100% (3)

- 2010 Ford Pickup SVT RaptorДокумент115 страниц2010 Ford Pickup SVT RaptorMiguel Quema100% (1)

- Technical Description: (Euro 3)Документ19 страницTechnical Description: (Euro 3)Rie ReiОценок пока нет

- 99719-88110-01 General InformationДокумент7 страниц99719-88110-01 General InformationSantiago WagnerОценок пока нет

- MP440E43TX/P: Technical DescriptionsДокумент16 страницMP440E43TX/P: Technical DescriptionsBubbleОценок пока нет

- ForkliftДокумент8 страницForkliftmyunusanisОценок пока нет

- MP440E42TY/TN: Technical DescriptionДокумент27 страницMP440E42TY/TN: Technical DescriptionBroCactusОценок пока нет

- 8FBN15 8FBN18: Main Vehicle SpecificationsДокумент28 страниц8FBN15 8FBN18: Main Vehicle SpecificationsJon Duarte100% (1)

- Part 1 Alternators and Starters - 2011 - 2012Документ1 297 страницPart 1 Alternators and Starters - 2011 - 2012Иван ШадринОценок пока нет

- MP440E42T: Technical DescriptionsДокумент20 страницMP440E42T: Technical DescriptionsBroCactusОценок пока нет

- Main Vehicle SpecificationsДокумент3 страницыMain Vehicle SpecificationsCan DraОценок пока нет

- MP400E42WT: Technical DescriptionsДокумент15 страницMP400E42WT: Technical DescriptionsBroCactusОценок пока нет

- Created On July 29, 2022 at 5:28:15 PM UTCДокумент4 страницыCreated On July 29, 2022 at 5:28:15 PM UTCDouglas OliveiraОценок пока нет

- FM306 PDFДокумент6 страницFM306 PDFAnonymous gTerattFpQОценок пока нет

- MP340E34H: Technical DescriptionsДокумент19 страницMP340E34H: Technical DescriptionsBroCactus100% (1)

- MP260E31HB: Technical DescriptionsДокумент15 страницMP260E31HB: Technical DescriptionsBroCactusОценок пока нет

- Fallo Pastillas BMWДокумент3 страницыFallo Pastillas BMWRubén RedvintageОценок пока нет

- Spec Sheet MT31Документ19 страницSpec Sheet MT31Fabricio NavarreteОценок пока нет

- PDFДокумент214 страницPDFLeobardo Genaro Roque NájeraОценок пока нет

- 021 ManДокумент2 страницы021 ManFilipposОценок пока нет

- 715fs AaaДокумент2 страницы715fs AaaMirka LukicОценок пока нет

- Automotive BearingДокумент29 страницAutomotive BearingAhmed AbdelghanyОценок пока нет

- 3518 TCD2012L06 3518P TCD2012L06 W enДокумент2 страницы3518 TCD2012L06 3518P TCD2012L06 W enMDK MAKİNEОценок пока нет

- MP180E24W: Technical DescriptionsДокумент14 страницMP180E24W: Technical DescriptionsBroCactusОценок пока нет

- 7FBE10 7FBE13: Main Vehicle SpecificationsДокумент17 страниц7FBE10 7FBE13: Main Vehicle SpecificationsjohnОценок пока нет

- High Speed Off-Road Vehicles: Suspensions, Tracks, Wheels and DynamicsОт EverandHigh Speed Off-Road Vehicles: Suspensions, Tracks, Wheels and DynamicsОценок пока нет

- Tractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorОт EverandTractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorОценок пока нет

- 233 41800 001 G 207210 Setup Rev 0Документ2 страницы233 41800 001 G 207210 Setup Rev 0api-19817003Оценок пока нет

- HM Training Agenda - Day1: - Automeshing - Surface Less Meshing Techniques - Quality Checking and EditingДокумент40 страницHM Training Agenda - Day1: - Automeshing - Surface Less Meshing Techniques - Quality Checking and Editingapi-19817003Оценок пока нет

- Hmday 2Документ33 страницыHmday 2api-19817003Оценок пока нет

- Printing - Remeshing 2-D Elements - HM-3110Документ6 страницPrinting - Remeshing 2-D Elements - HM-3110api-19817003Оценок пока нет

- Printing - Getting Started With HyperMesh - HM-1000Документ28 страницPrinting - Getting Started With HyperMesh - HM-1000api-19817003Оценок пока нет

- Printing - Tetrameshing A Volume in A Single Step - HM-3230Документ7 страницPrinting - Tetrameshing A Volume in A Single Step - HM-3230api-19817003Оценок пока нет

- Printing - Meshing A Part With Hexahedral Elements - HM-3220Документ30 страницPrinting - Meshing A Part With Hexahedral Elements - HM-3220api-19817003Оценок пока нет

- Printing - Generating 3-D Tetrahedral Elements - HM-3210Документ11 страницPrinting - Generating 3-D Tetrahedral Elements - HM-3210api-19817003Оценок пока нет

- Printing - Creating A Hexahedral Mesh Using The Solid Map Function - HM-3200Документ27 страницPrinting - Creating A Hexahedral Mesh Using The Solid Map Function - HM-3200api-19817003Оценок пока нет

- Printing - Splitting and Combining 2-D Elements - HM-3180Документ10 страницPrinting - Splitting and Combining 2-D Elements - HM-3180api-19817003Оценок пока нет

- Printing - Exploring 2-D Mesh Parameter Options in The Automesh Function - HM-3130Документ6 страницPrinting - Exploring 2-D Mesh Parameter Options in The Automesh Function - HM-3130api-19817003Оценок пока нет

- Printing - Creating and Optimizing A 2-D Mesh Based On User-Defined Quality Criteria - HM-3150Документ4 страницыPrinting - Creating and Optimizing A 2-D Mesh Based On User-Defined Quality Criteria - HM-3150api-19817003Оценок пока нет

- Printing - Creating A 2-D Mesh Using Batch Mesher - HM-3160Документ25 страницPrinting - Creating A 2-D Mesh Using Batch Mesher - HM-3160api-19817003Оценок пока нет

- Printing - Creating 2-D Elements From Surfaces Using The Automesh Function - HM-3100Документ22 страницыPrinting - Creating 2-D Elements From Surfaces Using The Automesh Function - HM-3100api-19817003Оценок пока нет

- Printing - Obtaining and Assigning Beam Cross-Section Properties Using HyperBeam - HM-3020Документ14 страницPrinting - Obtaining and Assigning Beam Cross-Section Properties Using HyperBeam - HM-3020api-19817003Оценок пока нет

- Printing - Controlling The 2-D Mesh Concentration in Curved Areas - HM-3140Документ5 страницPrinting - Controlling The 2-D Mesh Concentration in Curved Areas - HM-3140api-19817003Оценок пока нет

- Printing - Creating 1-D Elements - HM-3000Документ5 страницPrinting - Creating 1-D Elements - HM-3000api-19817003Оценок пока нет

- Week 13 Vertical StressДокумент15 страницWeek 13 Vertical StressJohnri RamirezОценок пока нет

- Pavement Design ReportДокумент11 страницPavement Design ReportIrfanОценок пока нет

- Viscometer-Group 7Документ25 страницViscometer-Group 7Camille Millondaga100% (1)

- tubothal관련 도면Документ10 страницtubothal관련 도면최승환Оценок пока нет

- Dharhara Pyramid STR ReportДокумент48 страницDharhara Pyramid STR ReportAmok BajracharyaОценок пока нет

- Set 2Документ23 страницыSet 2Sherwin Millares100% (1)

- SPE-184102-MS (2 Technology For Cementation)Документ14 страницSPE-184102-MS (2 Technology For Cementation)Randy SooknananОценок пока нет

- Chapter 4Документ140 страницChapter 4Solomon MehariОценок пока нет

- IRC 62014 TablesДокумент4 страницыIRC 62014 TablesvivekОценок пока нет

- Uog-Iot Construction Technology and Management Bsc. Program - Year IiiДокумент120 страницUog-Iot Construction Technology and Management Bsc. Program - Year Iiigugsa araya100% (1)

- Construction Technology B AssignmentДокумент71 страницаConstruction Technology B AssignmentBihanChathuranga100% (2)

- Adobe PolymerДокумент3 страницыAdobe PolymerSintayehu MeseleОценок пока нет

- Straight Run EccentricДокумент4 страницыStraight Run EccentricLegend AnbuОценок пока нет

- NPSH CalculationДокумент10 страницNPSH CalculationBalamuruganОценок пока нет

- C8516-CLT-QMT-0002 Rev.02-Inspection Checklist For Precast Gully InstallationДокумент1 страницаC8516-CLT-QMT-0002 Rev.02-Inspection Checklist For Precast Gully InstallationJabinОценок пока нет

- Rural Water Supply in Nepal-Stone Masonry CourseДокумент32 страницыRural Water Supply in Nepal-Stone Masonry Coursedemullu reddiОценок пока нет

- 170926bs PILE2017 GTL EfffectofLateralMovementДокумент20 страниц170926bs PILE2017 GTL EfffectofLateralMovementMed El Hadi AbidiОценок пока нет

- GTESD - PICE NATCON 2022 Case Study of Geogrid Raft Foundation in The Philippines AAMadrazo 11122022Документ22 страницыGTESD - PICE NATCON 2022 Case Study of Geogrid Raft Foundation in The Philippines AAMadrazo 11122022Lawrence Kevin FrencillanoОценок пока нет

- Is 6966 1989 (PART 1) Hydraulics Design of Barrages and WeirsДокумент12 страницIs 6966 1989 (PART 1) Hydraulics Design of Barrages and Weirsarvind.singhОценок пока нет

- Dereje Fufa: Integrated Design 2Документ2 страницыDereje Fufa: Integrated Design 2Michael GezahegnОценок пока нет

- Daniele - Casagrande - PHD - Thesis - Timber FrameДокумент200 страницDaniele - Casagrande - PHD - Thesis - Timber FrameBanuta GabrielОценок пока нет

- ASME PTC 25 - PRV TestДокумент28 страницASME PTC 25 - PRV Testchuckhsu124886% (14)

- Arel Concrete-Reinforcement Bond in Different Concrete ClassesДокумент6 страницArel Concrete-Reinforcement Bond in Different Concrete ClassesRazanОценок пока нет

- Data Sheet Sylomer Marine FR 455 ENДокумент2 страницыData Sheet Sylomer Marine FR 455 ENnipper7Оценок пока нет

- On The International Propagation of The Melan Arch System Since 1892Документ9 страницOn The International Propagation of The Melan Arch System Since 1892fanfengliОценок пока нет

- Equipment Wise Qty VerificationДокумент20 страницEquipment Wise Qty VerificationSmart ShivaОценок пока нет

- Experimental Investigation On Compressive Strength of PaverblockДокумент35 страницExperimental Investigation On Compressive Strength of PaverblockPachai ManiОценок пока нет

- Parala Maharaja Engineering College, Berhampur: 1. List Out The Advantages of Model AnalysisДокумент10 страницParala Maharaja Engineering College, Berhampur: 1. List Out The Advantages of Model AnalysisRohan KumarОценок пока нет

- TP DesignContainerYardPortBalboaДокумент10 страницTP DesignContainerYardPortBalboaEndar T. PrakosoОценок пока нет