Академический Документы

Профессиональный Документы

Культура Документы

Fatigue Life Is A Statistical Quantity

Загружено:

viv0102Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Fatigue Life Is A Statistical Quantity

Загружено:

viv0102Авторское право:

Доступные форматы

Fatigue Life is a Statistical

Quantity

Introduction to the Weibull

distribution

Consider 2 competing Spring Designs, called A and B.

10 Samples of each spring are tested in fatigue

The number of cycles to failure are recorded.

Spring A:

726000

615000

508000

808000

755000

849000

384000

667000

515000

483000

529000

730000

651000

446000

343000

960000

730000

730000

973000

258000

Spring B

Objective

You need a design where 90% of the springs last (at least) to 400 000 cycles.

First Primitive Test:

Average Lifetime

Design A Design B

726000

615000

508000

808000

755000

849000

384000

667000

515000

483000

631000

529000

730000

651000

446000

343000

960000

730000

730000

973000

258000

635000

Average

Design B looks better..

Next test, a bit more sophisticated:

We plot fraction of springs failed vs number of cycles. We use this to get estimates

of reliability of Design A and Design B as a function of cyles

Example: If first failure in design A is at 200 000 cycles, reliability above 200 000

cycles is reduced from 100% to 90%

0

10

20

30

40

50

60

70

80

90

100

0 100000 200000 300000 400000 500000 600000 700000 800000 900000

Survival Probability vs Cycles Design A

Survival Probability vs Cycles Design A

We now fit a smooth curve (2

nd

order power) to the data and to find F (400000)

y = -7.3352E-11x

2

- 1.0216E-04x + 1.4026E+02

0

10

20

30

40

50

60

70

80

90

100

0 100000 200000 300000 400000 500000 600000 700000 800000 900000

Chart Title

Survival Probability vs Cycles Design A

Survival Probability vs Cycles Design A

Poly. (Survival Probability vs Cycles Design A)

Y = -6.0918E-11 N

2

-1.1619E-4N +144.3

This fit predicts that

the number of

permissible cycles, for

90% reliability, is

386637, for design A.

For 400000, our goal,

the probability is

88.07% for Design A

We repeat the same for Design B

0

10

20

30

40

50

60

70

80

90

100

0 200000 400000 600000 800000 1000000 1200000

Survival Plot Design B

Survival Plot Design B

y = -5.5949E-12x

2

- 1.1626E-04x + 1.2137E+02

0

10

20

30

40

50

60

70

80

90

100

0 200000 400000 600000 800000 1000000 1200000

Survival Plot Design B

Survival Plot Design B

Poly. (Survival Plot Design B)

This plot predicts

that the reliability of

Design B at 400000

cycles is 74.866 %

The question is :

Is our method to decide the best there is ?

(best meaning standing up in court)

Sadly no

But it is not a bad method to make a crude estimate of what the Weibull

distribution predicts.

The Weibull distribution was found by Weibull strictly by trial and error.

He tried to model the distribution of failure strength of steels and derive

probabilities for a high reliability (such as 99.9 %) from a limited set of test

data.

After settled on this distribution:

X is the variable (here the number of cycles to failure) and and are the

Weibull parameters ( is the shape parameter also known to material

scientists as the Weibull modulus and is the scale or length parameter.

Note that has a physical meaning. If a tensile specimen is twice as long, the

probability for a flaw terminating its fatigue life is twice as high.

Size matters.

There is nothing god given about the Weibull distribution. There are other

reliability distributions - all invented before Weibull.

But it does fit, experimentally, a very wide variety of phenomena.

Weibull wrote a famous paper demonstrating it fit the size distribution of beans,

the height distribution of the population on an island (I forgot which one) and so

on, i.e. Biological phenomena as well as steels, with a total of 10 examples

The paper is a classic - I will put it on the website.

The reason is that depending on how the modulus is picked it fits both infant

mortality and wear out phenomena.

And fatigue failure is a kind of wear out phenomena.

MOST IMPORTANTLY IT HAS BECOME A DE FACTO STANDARD FOR ENGINEERS.

TO PREVAIL IN COURT, YOU BETTER SHOW YOU USED IT PROPERLY !

From Wiki

The Weibull distribution is used

In survival analysis[6]

In reliability engineering and failure analysis

In industrial engineering to represent manufacturing and delivery times

In extreme value theory

In weather forecasting (To describe wind speed distributions, as the natural distribution

often matches the Weibull shape[7] Fitted cumulative Weibull distribution to maximum

one-day rainfalls)

In communications systems engineering (In radar systems to model the dispersion of

the received signals level produced by some types of clutters. To model fading channels in

wireless communications, as the Weibull fading model seems to exhibit good fit to

experimental fading channel measurements)

In General insurance to model the size of Reinsurance claims, and the cumulative

development of Asbestosis losses

In forecasting technological change (also known as the Sharif-Islam model)[citation

needed]

In hydrology the Weibull

distribution is applied to

extreme events such as

annual maximum one-

day rainfalls and river

discharges.

In describing the size of

particles generated by

grinding, milling and

crushing operations, the

2-Parameter Weibull

distribution is used, and

in these applications it is

sometimes known as the

Rosin-Rammler

distribution. (In this

context it predicts fewer

fine particles than the

Log-normal distribution

and it is generally most

accurate for narrow

particle size

distributions).[

Stolen From Wiki

So we need to learn to do the proper Weibull analysis

This involves three steps

Massaging the data point .

(we simply took the first spring to fail as the 10% probability for

reliability not a good idea )

Plotting the massaged data point in a double ln plot to get the Weibull

parameters

Learning on how to put confidence limits on the results.

Massaging the data point

The data are plotted in increasing sequence (ranking low to high)

The equivalent of our failure percentage becomes approximately

This will do for most engineering problems. One can do this

better by looking up the F distribution.

There is a nifty website; teach yourself statistics which might

come in handy when you are in industry

(Modern industry runs on statistics)

Once you have done the ranking, it is just plotting :

And, from the double ln plot to extract the values for K and

So here is the plot :

y = 0.2287x + 13.446

y = 0.3846x + 13.486

12.2

12.4

12.6

12.8

13

13.2

13.4

13.6

13.8

14

-3.5 -3 -2.5 -2 -1.5 -1 -0.5 0 0.5 1 1.5 2

Lnln(1/1-Rank) vs ln N Spring A

Lnln(1/1-r) vs Ln N Spring B

400 000 Cycle Line

Linear (Lnln(1/1-Rank) vs ln N Spring A)

Linear (Lnln(1/1-r) vs Ln N Spring B)

Linear (400 000 Cycle Line)

The Weibull plot

of Design A and B

Spring A Spring B

beta = 4.39 2.604167

alpha= 686938 714973

Reliabiliy 0.911098 0.802222

From which you get the following results:

This does not look all that earth shattering different from our

primitive estimate which yielded

0.8807 0. 74866

Which shows you that it is a good idea to make a primitive estimate

first before setting out to do a state of the art Weibull with an F

distribution)

Now, we should put confidence limits on our answer

But as this is not a statistics course, I will leave it at this.

But before you use a statistics package to analyze your data it is a good idea to

make the primitive plot we started out and decide what other curves might

reasonably be drawn to the data.

This will give you a rough idea as to the confidence limits you can put on the

data.

Moving on to the three parameter Weibull Distribution

The three parameter Weibull distribution

The three parameter Weibull distribution uses an additional parameter

to shift the distribution sideways along the horizontal axis (number of

cycles to failure, time to failure .)

Physical meaning in brittle fracture is generally density of flaws per

unit length.

Fiber Optics

For example, if a Corning glass fiber has one defect per 10, and you

test 10 specimens, each one inch long, then 9 will have high strength

and only one low strength. The average fracture strength will be

high.

On the other hand, if you test 10 meter long (~ 40 inches) long

section, the chances are that you 98% of the time will have a

specimen with a flaw. The average fracture strength will be low.

Electronics:

The classic example is the break down strength of DRAM capacitors

(DRAM cells). The break down depends on both the intrinsic breakdown

strength of the oxide and the defects (known as weak spots in the

oxide*)

If you have two oxides A and B, where flawless A has a break down voltage

of 8 MV/cm and flawless B 7 MV/cm, then A is the better oxide.

On the other hand, if A has 1 defect per 20 square m ( square micron) and

B has one defect per 1 cm

2

and the presence of a defect lowers the break

down voltage by 20% AND you measure the break down strength on test

capacitors made 10x10 micron, (because the research lab does not have

state of the art immersion steppers), than your conclusion will be opposite !

Cause you 10x10 test capacitors made in A will have, on average, 5

defects, and therefore now return a breakdown voltage of about 6.4 MV/cm.

Whereas the test capacitors made with the B oxide, will on average, have

near zero defects, you will measure an average breakdown of 7 MV/cm

THE RESEARCH LAB WILL RECOMMEND TO USE OXIDE A

Electronics continued:

But the production capacitors are 0.5 x 0.5 micron.. An area 40 times

smaller than your research lab test specimens !!!

On average, they will not contain a defect, if made either in A or B.

Hence the production people will report that capacitors made with the A

oxide have a higher breakdown voltage, around 8 MV/cm and those

with B will have a breakdown field, on average, of 7 MV/cvm

THE PRODUCTION PEOPLE WILL RECOMMEND OXIDE A

Conflict resolution:

In general, you have no idea about the length scale of the defect

population. Perhaps the difference between the research lab and the

production line is that the production line uses Plasma Processing that

uses higher electric fields than the research lab to etch the

metallization. A long metal line, acting as an antenna, can partly blow

out a gate oxide i.e. damage it, by stressing it too much.

So, a priory it is not clear what is going on

Approach A for the research lab

You plot the Weibull distribution of the breakdown voltage of your

10x10 with a two parameter Weibull. If the distribution is curved,

chances are you have a length scale parameter .

Approach B for the research lab

You make test capacitors of different size. From 1x1 cm down to

2x2 which is the best your equipment can do with enough

geometric precision to know the area within +/- 10%.

You then investigate the dependence of the 2 parameter Weibull

on the capacitor size.

If it does depend, you have a length scale problem and you can

extract the length scale on which the defect occurs.

The three parameter Weibull, accumulated failure function

)) exp(( 1 ) (

t

t F

Failure probability density function

There are various methods of determining . The most simple one is to

plot the data first as a two parameter Weibull (i.e ) . If that one is

curved, then one adds/subtracts values of until the line is reasonably

straight.

Of course, one can also do this with linear regression. To see how,

visit

http://www.weibull.com/LifeDataWeb/estimation_of_the_weibull_param

eter.htm

Weibull.com is a wonderfully informative website which will teach you

everything you ever wanted to know about the Weibull distribution. Here

is (stolen from the Website) an example on how to adjust gamma

The curved original

data a very familiar

to glass fiber guys.

And to capacitor

testing guys math

is math.

And to solar cell

guys, that test

conversion

efficiency vs cell

size

And so on. Math

is math

As a good experimenter (good experimenters are those who a paranoid) you

now investigate design A and B for hidden curvature.

Is there a hidden length effect ???

y = 0.0092x

2

+ 0.2435x + 13.441

y = -0.0193x

2

+ 0.3536x + 13.496

12.2

12.4

12.6

12.8

13

13.2

13.4

13.6

13.8

14

-4 -3 -2 -1 0 1 2

To do so, you make a usual two

parameter Weibull plot, but instead

of fitting a straight line, you fit a

power series.

See left. The quadratic term gives

you the curvature.

The curvature is very small, and of

opposite sign for A and B. So it

seems a wash, given the scatter of

the data.

And so we can conclude (without

Doing a Sigma Analysis) that there

is no length scale or threshold effect

in the spring test data.

QED

Вам также может понравиться

- Support Training Sliding PlatesДокумент10 страницSupport Training Sliding Platesviv0102Оценок пока нет

- LaunchДокумент295 страницLaunchviv0102Оценок пока нет

- Scope, Application & Limitations of API 610: Presented by J.Syed IbrahimДокумент21 страницаScope, Application & Limitations of API 610: Presented by J.Syed Ibrahimviv0102Оценок пока нет

- Distillation Column PipingДокумент57 страницDistillation Column PipingKaran Singh92% (13)

- Acoustically Induced Vibration in Piping - TutorialДокумент13 страницAcoustically Induced Vibration in Piping - TutorialJose PradoОценок пока нет

- Pruclinicare GP Panel List - VJuly 2013Документ20 страницPruclinicare GP Panel List - VJuly 2013viv0102Оценок пока нет

- Wharton Consulting Case BookДокумент68 страницWharton Consulting Case BookAaron ひろき Zhang100% (4)

- Nonconvergence in Caesar in Caesar IIДокумент11 страницNonconvergence in Caesar in Caesar IIviv0102Оценок пока нет

- Frequency Test 9630621Документ5 страницFrequency Test 9630621viv0102Оценок пока нет

- Actuator Blast CalcДокумент10 страницActuator Blast Calcviv0102Оценок пока нет

- Chapter 3 - Stress Intensity FactorДокумент47 страницChapter 3 - Stress Intensity Factorviv0102Оценок пока нет

- Chapter 2 - General Fracture MechanicsДокумент45 страницChapter 2 - General Fracture Mechanicsviv010275% (4)

- Reinforcement CheckДокумент2 страницыReinforcement Checkviv0102Оценок пока нет

- Chapter 1 - Introduction PDFДокумент70 страницChapter 1 - Introduction PDFviv0102Оценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- An-And-1-106 Basic CAN Bit TimingДокумент9 страницAn-And-1-106 Basic CAN Bit TimingNavneet Singh Pathania100% (1)

- Bomba de Vácuo Sotorbilt 4mrДокумент12 страницBomba de Vácuo Sotorbilt 4mrWormInchОценок пока нет

- MC1413 D Integrated Circuit 7xdarlington Driver SO16 On SEMIДокумент8 страницMC1413 D Integrated Circuit 7xdarlington Driver SO16 On SEMIblueword66Оценок пока нет

- Deaton FE Slab DesignДокумент57 страницDeaton FE Slab DesignMohamed AliОценок пока нет

- ARO Pump ManualДокумент8 страницARO Pump Manualrazaq athabОценок пока нет

- FM200Документ23 страницыFM200Ahmed SherifОценок пока нет

- Dse5510 Installation InstДокумент2 страницыDse5510 Installation Instricardo_dionisi2700Оценок пока нет

- Revised Malaysian Code of Practice For Structural Use of TimberДокумент6 страницRevised Malaysian Code of Practice For Structural Use of Timbermcwong_98Оценок пока нет

- Welding ProceduresДокумент11 страницWelding ProceduresnamasralОценок пока нет

- Chapter - I: Hydro DriveДокумент19 страницChapter - I: Hydro Drivekuldeep ududholiraОценок пока нет

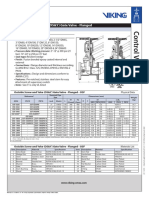

- Outside Screw and Yoke (OS&Y) Gate Valve - Flanged: Technical FeaturesДокумент2 страницыOutside Screw and Yoke (OS&Y) Gate Valve - Flanged: Technical FeaturesMark Louie GuintoОценок пока нет

- LCD TV W DVD PDFДокумент5 страницLCD TV W DVD PDFINJESBGОценок пока нет

- Business Dynamics in The 21st CenturyДокумент270 страницBusiness Dynamics in The 21st CenturyskilmagОценок пока нет

- 592-A2GA DesbloqueadoДокумент27 страниц592-A2GA DesbloqueadoVicktor GranadosОценок пока нет

- Metalco Valve TianjinДокумент20 страницMetalco Valve TianjinsathishОценок пока нет

- Production ManagementДокумент81 страницаProduction ManagementrrathoreОценок пока нет

- ctc-189 Answerbook PDFДокумент136 страницctc-189 Answerbook PDFmenosoft100% (1)

- Haldimann - Structural Use of Glass BookДокумент221 страницаHaldimann - Structural Use of Glass BookKenny Tournoy100% (6)

- DFH00191 - RAUTHERM SPEED HKV P - TI - EN - LayoutДокумент4 страницыDFH00191 - RAUTHERM SPEED HKV P - TI - EN - LayoutRENSO BirouClujОценок пока нет

- Single Col - Tank-2013Документ35 страницSingle Col - Tank-2013Hgagselim SelimОценок пока нет

- Smart Obj. Kiss and SwotДокумент5 страницSmart Obj. Kiss and SwotjtopuОценок пока нет

- Unit 5 GeosyntheticsДокумент315 страницUnit 5 Geosyntheticskowshik1737551Оценок пока нет

- Lectures - Mass TransferДокумент36 страницLectures - Mass TransferaaaОценок пока нет

- Shaft Design Problem 10 - 12Документ9 страницShaft Design Problem 10 - 12BernalynMalinaoОценок пока нет

- Kathrein 739506Документ2 страницыKathrein 739506Carlos CostaОценок пока нет

- BX-74 / BX-78: Sliding Gate Operator BX SeriesДокумент24 страницыBX-74 / BX-78: Sliding Gate Operator BX SeriesStefce PetrovОценок пока нет

- Result Summary: Beam To Girder Shear Tab Shear Connection Code AISC 360-10 LRFDДокумент14 страницResult Summary: Beam To Girder Shear Tab Shear Connection Code AISC 360-10 LRFDLexОценок пока нет

- Oilon 4A Monox en StandardДокумент16 страницOilon 4A Monox en StandardWilbert Consuelo CotrinaОценок пока нет

- US Hex Bolt SizesДокумент2 страницыUS Hex Bolt SizesYana Jarang OlОценок пока нет

- 048Документ6 страниц048kokykarkarОценок пока нет