Академический Документы

Профессиональный Документы

Культура Документы

Fabrication of Mosfet: Dr. Arti Noor, M. Tech Division, CDAC Noida. Email: Artinoor@cdacnoida - in

Загружено:

Debasis MukherjeeОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Fabrication of Mosfet: Dr. Arti Noor, M. Tech Division, CDAC Noida. Email: Artinoor@cdacnoida - in

Загружено:

Debasis MukherjeeАвторское право:

Доступные форматы

8-8-2006 MOS Circuit Design

Lecture-2@2006

FABRICATION OF MOSFET

Dr. Arti Noor,

M. Tech Division, CDAC Noida.

Email : artinoor@cdacnoida.in

MOS Circuit Design

Lecture-2@2006

Introduction

IC technologies :

NMOS

PMOS

CMOS

SOI

BiCMOS

GaAs

MOS Circuit Design

Lecture-2@2006

Basic Fabrication Steps:

Wafer Processing.

Mask making.

Photolithography.

Oxidation.

Diffusion.

Etching.

Poly-gate formation.

Metallization.

MOS Circuit Design

Lecture-2@2006

Basic Fabrication Steps:

Wafer Processing : single crystal wafer, diameter

70 mm to 200 mm, thickness less than 1mm, front

face polished, scratch free mirror finish.

MOS Circuit Design

Lecture-2@2006

Basic Fabrication Steps:

Mask making :

After complete design the drawing is broken

into subsequent IC processing steps.

These steps are called mask levels.

Electron beam machine known as pattern

generator is used for mask making.

The interface is CIF between layout and mask

machine.

Mask machine transfers design features

directly on photosensitive glass plate using

CIF.

MOS Circuit Design

Lecture-2@2006

Basic Fabrication Steps:

Photolithography : The process used to transfer a

pattern on wafer is called lithography. The

process has 6 steps.

1. Photoresist Coating.

2. Pre baking.

MOS Circuit Design

Lecture-2@2006

Basic Fabrication Steps:

3. Alignment and exposing.

MOS Circuit Design

Lecture-2@2006

Basic Fabrication Steps:

4. Development.

5. Post baking.

MOS Circuit Design

Lecture-2@2006

Basic Fabrication Steps:

6. Etching Removal of photoresist.

MOS Circuit Design

Lecture-2@2006

Basic Fabrication Steps:

Wafer after Removal of photoresist.

MOS Circuit Design

Lecture-2@2006

Basic Fabrication Steps:

Oxidation : The purpose of SiO

2

layer is

1. acts as component in MOS.

2. acts as mask against diffusion.

3. used to isolate the devices

4. provides electrical isolation in multilevel

metallization.

Several techniques : thermal oxidation, wet

oxidation, CVD, Plasma oxidation.

LOCOS Oxidation for isolation.

MOS Circuit Design

Lecture-2@2006

Basic Fabrication Steps:

Diffusion : The purpose is to alter the type of

conductivity by diffusing impurities.

Goal :

1. Control of impurity concentration.

2. Uniformity.

3. Reproducibility.

Two techniques : Furnace diffusion and Ion

Implantation.

MOS Circuit Design

Lecture-2@2006

Basic Fabrication Steps:

Ion Implantation : has the capability of highly

prcised control of number of implanted dopant

atoms. Concentration range from 10

14

to 10

21

atoms/ cm

3

.

Mainly used for:

Source and drain.

Threshold adjustment.

Reduction of punch through effects.

MOS Circuit Design

Lecture-2@2006

Basic Fabrication Steps:

Poly gate : poly silicon is used as a gate. Common

method is CVD.

For poly gate

SiH

4

(g) + heat Si(s) + 2H

2

; T= 600 to 700

o

c in N

2

Presence.

For SiO

2

SiH

4

+ 2O

2

SiO

2

+ 2H

2

O; T= 400 to 500

o

c in N

2

Presence.

For Silicon Nitride

3SiH

4

+ 4NH

3

Si

3

N

4

+ 12H

2

; T= 800 to 900

o

c in N

2

Presence.

This is used as dielectric film. This stops Sodium

contamination.

MOS Circuit Design

Lecture-2@2006

Basic Fabrication Steps:

Metallization :

Is done to provide low resistance

interconnects.

Common method is evaporation and

sputtering.

In high vacuum chamber the metal is deposited

by evaporation with subsequent condensation

on substrate target.

MOS Circuit Design

Lecture-2@2006

Basic NMOS Fabrication Steps:

Formation of SiO

2

and then photoresist coating

MOS Circuit Design

Lecture-2@2006

Basic NMOS Fabrication Steps:

Photo-mask and then etching of selected area.

MOS Circuit Design

Lecture-2@2006

Basic NMOS Fabrication Steps:

The wafer is then placed into an oxidation furnace

and thin oxide (the gate oxide) is grown to cover the

etched region

MOS Circuit Design

Lecture-2@2006

Basic NMOS Fabrication Steps:

A layer of poly-crystalline silicon is deposited all

over the wafer.

This layer is then patterned and etched to form the

gate of transistor.

MOS Circuit Design

Lecture-2@2006

Basic NMOS Fabrication Steps:

An n-type dopant is introduced into the opened

regions and diffused into the wafers.

MOS Circuit Design

Lecture-2@2006

Basic NMOS Fabrication Steps:

Oxide is deposited using Low Pressure Chemical Vapor

Deposition (LPCVD) and is used for top coat protection.

MOS Circuit Design

Lecture-2@2006

Basic NMOS Fabrication Steps:

A layer of aluminum is deposited all over the wafer

and patterned and etched to form the

interconnecting layers and the connections to

channel Metal Oxide Semiconductor.

MOS Circuit Design

Lecture-2@2006

N-Well CMOS Fabrication Steps

MOS Circuit Design

Lecture-2@2006

N-Well CMOS Fabrication Steps (contd.)

MOS Circuit Design

Lecture-2@2006

N-Well CMOS Fabrication Steps (contd.)

MOS Circuit Design

Lecture-2@2006

MOS Circuit Design

Lecture-2@2006

CMOS Inverter in twin tub process

MOS Circuit Design

Lecture-2@2006

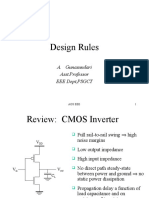

CMOS DESIGN RULES

Fabrication processes are pattern independent.

Design Rules are constraints poses by

processing line in the form of minimum

allowable values for width, separation, extension

and overlap.

The complexity of design rules depends upon

how well a process is characterized.

MOS Circuit Design

Lecture-2@2006

CMOS DESIGN RULES (con.)

A proper set of design rules must take into

account the following considerations:

Characteristic of Photolithography.

Etching capabilities.

Expected misalignment Variance.

Electrical Constraints.

MOS Circuit Design

Lecture-2@2006

Photolithography Constraints:

Minimum geometry to be resolved in the

photoresist.

Impose condition on minimum line width

and separation.

Width and spacing rules must be relaxed

to the upper most non-uniform layer.

MOS Circuit Design

Lecture-2@2006

PHOTOLITHOGRAPHY

MOS Circuit Design

Lecture-2@2006

Etching Constraints:

Additional constraints on line width.

Contact cut dimensions are critical.

Rules are made to etch minimum size.

MOS Circuit Design

Lecture-2@2006

Misalignment Variance:

All subsequent layers are aligned with

previous layer

Proper choice of alignment sequence plays

important role.

Electrical Constraints:

No physical contact in adjacent lines.

Minimum line width must be wide

enough to avoid electromigration.

MOS Circuit Design

Lecture-2@2006

Three approaches for Design Rules

Micron based.

based.

MOS Circuit Design

Lecture-2@2006

CMOS N-Well Design Rules

MOS Circuit Design

Lecture-2@2006

CMOS N-Well Design Rules

MOS Circuit Design

Lecture-2@2006

CMOS N-Well Design Rules

MOS Circuit Design

Lecture-2@2006

CMOS N-Well Design Rules

MOS Circuit Design

Lecture-2@2006

CMOS N-Well Design Rules

MOS Circuit Design

Lecture-2@2006

CMOS N-Well Design Rules

MOS Circuit Design

Lecture-2@2006

CMOS N-Well Design Rules

MOS Circuit Design

Lecture-2@2006

Assignment-1

Draw N-MOSFET which has length 5m and width

10m on Graph Sheet.

Submit your assignment on next class.

MOS Circuit Design

Lecture-2@2006

Next Class Topic

MOS Transistor

Вам также может понравиться

- RCA Transistor Manual 1964Документ387 страницRCA Transistor Manual 1964Alejandro AGDvintageОценок пока нет

- Cross Reference For Diode Bridge Transistor in PDFДокумент23 страницыCross Reference For Diode Bridge Transistor in PDFJoao LuisОценок пока нет

- MOS Fabrication ProcessДокумент22 страницыMOS Fabrication ProcessRishabh RaiОценок пока нет

- Analog VLSI Design: Nguyen Cao QuiДокумент72 страницыAnalog VLSI Design: Nguyen Cao QuiKhuong LamborghiniОценок пока нет

- Vlsi PDFДокумент81 страницаVlsi PDFShruthiОценок пока нет

- Fabrication of MOSFETДокумент48 страницFabrication of MOSFETYogesh TiwariОценок пока нет

- Nmos and Cmos FabricationДокумент33 страницыNmos and Cmos FabricationmannsloveОценок пока нет

- BCD Lite Data SheetДокумент5 страницBCD Lite Data SheetBenjamin DoverОценок пока нет

- Silicon On Insulator TechnologyДокумент32 страницыSilicon On Insulator TechnologyJayanth bemesettyОценок пока нет

- VLSI Micro-Project Report Group A PDFДокумент14 страницVLSI Micro-Project Report Group A PDFganesh SawantОценок пока нет

- Layout Design, Fabrication and Characterization of N-Channel MOSFETДокумент7 страницLayout Design, Fabrication and Characterization of N-Channel MOSFETashiqur rahman rahulОценок пока нет

- IC Technologies:: - Nmos - Cmos - BicmosДокумент24 страницыIC Technologies:: - Nmos - Cmos - BicmosRamsОценок пока нет

- MOS and Bi-CMOS Circuit Design ProcessesДокумент54 страницыMOS and Bi-CMOS Circuit Design ProcessesVenkateswara ReddyОценок пока нет

- Vlsi 1 Chapter 111111111Документ15 страницVlsi 1 Chapter 111111111Dinesh PalavalasaОценок пока нет

- Cmos Digital Integrated Circuits: Fabrication of MosfetsДокумент48 страницCmos Digital Integrated Circuits: Fabrication of Mosfetsapi-127299018Оценок пока нет

- Digital Vlsi Design: Rekha S SДокумент135 страницDigital Vlsi Design: Rekha S SRashmi AОценок пока нет

- Unit 2Документ33 страницыUnit 2Venky VellankiОценок пока нет

- CMOS Layout Design GuideДокумент26 страницCMOS Layout Design Guidemurali veluОценок пока нет

- CH 02 FabricationДокумент55 страницCH 02 FabricationUPADHYAY SHIVANSHОценок пока нет

- The CMOS Fabrication Process & Design RulesДокумент8 страницThe CMOS Fabrication Process & Design RulesBhupender KumawatОценок пока нет

- MODULE 2 - MOS AND BiCMOS CIRCUIT DESIGN PROCESSДокумент33 страницыMODULE 2 - MOS AND BiCMOS CIRCUIT DESIGN PROCESSrahulmohan3777Оценок пока нет

- Fabrication, Layout, and SimulationДокумент26 страницFabrication, Layout, and Simulationshiny johnОценок пока нет

- CMOS Technology for 25 nm Channel LengthДокумент20 страницCMOS Technology for 25 nm Channel LengthtbsuirОценок пока нет

- Design RulesДокумент14 страницDesign RulesmayankfirstОценок пока нет

- Electronic Devices in MTL Annual Report 1999Документ26 страницElectronic Devices in MTL Annual Report 1999tbsuirОценок пока нет

- MOS Fabrication Technology: Abstract This Chapter Is Concerned With The Fabrication of Metal-Oxide-SemiconductorДокумент7 страницMOS Fabrication Technology: Abstract This Chapter Is Concerned With The Fabrication of Metal-Oxide-SemiconductorsammyОценок пока нет

- Micro WindДокумент14 страницMicro Windlak_prabОценок пока нет

- Introduction To MOS TechnologiesДокумент15 страницIntroduction To MOS TechnologieslokeshwarrvrjcОценок пока нет

- Cmos Fabrication TechnologyДокумент36 страницCmos Fabrication TechnologyKhadarОценок пока нет

- Layout Design8Документ34 страницыLayout Design8Sandeep BoyinaОценок пока нет

- Cmos Technology GroupДокумент56 страницCmos Technology GroupAiman NabihahОценок пока нет

- VLSI Circuits and Systems Unit 1: MOS Transistors FundamentalsДокумент86 страницVLSI Circuits and Systems Unit 1: MOS Transistors FundamentalsChinna ChowdaryОценок пока нет

- DEC50143 CHAPTER 2 - PART C - EditДокумент49 страницDEC50143 CHAPTER 2 - PART C - Edity meОценок пока нет

- Faculty of Engineering Lab Sheet Processing and Fabrication Technology EEN3106Документ15 страницFaculty of Engineering Lab Sheet Processing and Fabrication Technology EEN3106KarimovaRaikhanovnaОценок пока нет

- VLSI DesignДокумент181 страницаVLSI Designprabhug22Оценок пока нет

- CMOS Fabrication Technologies and Process Design RulesДокумент14 страницCMOS Fabrication Technologies and Process Design RulesPrashant SinghОценок пока нет

- Notes NewДокумент14 страницNotes NewPriya SirsatОценок пока нет

- Cmos Fabrication Technology and Design RulesДокумент19 страницCmos Fabrication Technology and Design RulesvenkatmusalaОценок пока нет

- VLSI Circuit Design Process-Unit-IIДокумент51 страницаVLSI Circuit Design Process-Unit-IICatherineОценок пока нет

- C-1 CMOS Processing FlowДокумент76 страницC-1 CMOS Processing FlowKu Ble YanОценок пока нет

- 3.2.2 Surface Micromachining: Dry/wet Isotropic EtchingДокумент7 страниц3.2.2 Surface Micromachining: Dry/wet Isotropic EtchingRana Muhammad UmerОценок пока нет

- Stick Diagram BasicsДокумент26 страницStick Diagram Basicssanju012100% (1)

- 2014 MR - Metal-Layer Capacitors in The 65 NM CMOS Process and The Application For Low-Leakage Power-Rail ESD Clamp CircuitДокумент7 страниц2014 MR - Metal-Layer Capacitors in The 65 NM CMOS Process and The Application For Low-Leakage Power-Rail ESD Clamp CircuitspaulsОценок пока нет

- Design RulesДокумент14 страницDesign RulessivapothiОценок пока нет

- Vlsi SyllabusДокумент2 страницыVlsi SyllabusAkhil NameirakpamОценок пока нет

- Maharashtra State Board of Technical Education Mumbai. (M.S.)Документ9 страницMaharashtra State Board of Technical Education Mumbai. (M.S.)ythОценок пока нет

- 3ec05 LabmanualДокумент86 страниц3ec05 LabmanualnaikmeshwaОценок пока нет

- MOS and CMOS Process OverviewДокумент36 страницMOS and CMOS Process OverviewashishОценок пока нет

- Fundamentals of MOS Chip FabricationДокумент19 страницFundamentals of MOS Chip FabricationSakshi TalwadeОценок пока нет

- Chapter 2 Cmos Fabrication Technology and Design RulesДокумент56 страницChapter 2 Cmos Fabrication Technology and Design Rulesvanarajesh620% (1)

- Fermilab Initiatives in 3D Integrated Circuits and SOI Design For HEPДокумент38 страницFermilab Initiatives in 3D Integrated Circuits and SOI Design For HEPhasanfarazhdfОценок пока нет

- Course Coordinator Module CoordinatorДокумент166 страницCourse Coordinator Module CoordinatorBituОценок пока нет

- Special Report Soi Wafer Technology For Cmos Ics: Robert Simonton President, Simonton AssociatesДокумент11 страницSpecial Report Soi Wafer Technology For Cmos Ics: Robert Simonton President, Simonton AssociatesMoaaz AhmedОценок пока нет

- CMOS Fabrication and Layout RulesДокумент65 страницCMOS Fabrication and Layout Rulessasindhur r100% (2)

- Design Rules: A. Gunasundari Asst - Professor Eee Dept, PSGCTДокумент35 страницDesign Rules: A. Gunasundari Asst - Professor Eee Dept, PSGCTS.DharanipathyОценок пока нет

- Unit 2Документ24 страницыUnit 2SMVОценок пока нет

- Microelectronic Engineering: Alexander Vladimirov GrigorovДокумент9 страницMicroelectronic Engineering: Alexander Vladimirov Grigorov135713571357Оценок пока нет

- Layout-Process Anitha VlsiДокумент27 страницLayout-Process Anitha VlsiTarunChОценок пока нет

- Vlsi Upto 3unitДокумент105 страницVlsi Upto 3unitAsha PagidipalliОценок пока нет

- Cmos Metal GateДокумент56 страницCmos Metal GateSubin AlexОценок пока нет

- Unit 5 - VLSI Design - WWW - Rgpvnotes.inДокумент12 страницUnit 5 - VLSI Design - WWW - Rgpvnotes.intanishachaturvedi2025Оценок пока нет

- BJT Familiarization and CharacteristicДокумент12 страницBJT Familiarization and CharacteristicCyville AvenirОценок пока нет

- N-Channel Powertrench Mosfet 30V, 58A, 9M: April 2008Документ11 страницN-Channel Powertrench Mosfet 30V, 58A, 9M: April 2008Kevin TateОценок пока нет

- Master in Nanoscience - High Electron Mobility Transistor (HEMT) Structure and Working PrincipleДокумент17 страницMaster in Nanoscience - High Electron Mobility Transistor (HEMT) Structure and Working PrincipleBhaswati ChakrabortyОценок пока нет

- EC105Документ16 страницEC105api-3853441Оценок пока нет

- BSM75GD120DLC: Technische Information / Technical InformationДокумент9 страницBSM75GD120DLC: Technische Information / Technical InformationolegОценок пока нет

- Book SOI 3Документ379 страницBook SOI 3Rodrigo FerreiraОценок пока нет

- LM494 Pulse Width Modulated Control Circuit CircuitДокумент3 страницыLM494 Pulse Width Modulated Control Circuit CircuitRobertОценок пока нет

- 1.2 Describe The Concept of Cache MemoryДокумент18 страниц1.2 Describe The Concept of Cache Memory00.wonderer.00Оценок пока нет

- The Bsim Spice ModelДокумент17 страницThe Bsim Spice Modelapi-19772070Оценок пока нет

- 7-Channel Darlington Transistor Array Technical SpecificationsДокумент7 страниц7-Channel Darlington Transistor Array Technical SpecificationsliderfgvОценок пока нет

- Rare component inventory and pricingДокумент9 страницRare component inventory and pricingMohan Nivas NОценок пока нет

- Cmos Sram K6X1008C2D Family: Document TitleДокумент10 страницCmos Sram K6X1008C2D Family: Document TitleНиколайОценок пока нет

- SCRДокумент4 страницыSCRJoshua Amiel javines100% (1)

- SD Tech TLAS9004E 3Документ8 страницSD Tech TLAS9004E 3Du RoyОценок пока нет

- Pal 2021 IOP Conf. Ser. Mater. Sci. Eng. 1187 012008Документ11 страницPal 2021 IOP Conf. Ser. Mater. Sci. Eng. 1187 012008seshu bradyОценок пока нет

- TriacДокумент13 страницTriacNaveedОценок пока нет

- Bachelor of Engineering in Electrical & Electronics Engineering - Specialization in Power & Control EngineeringДокумент2 страницыBachelor of Engineering in Electrical & Electronics Engineering - Specialization in Power & Control EngineeringWhite WolfОценок пока нет

- Emx1 / Umx1N / Imx1: General Purpose Transistor (Dual Transistors)Документ9 страницEmx1 / Umx1N / Imx1: General Purpose Transistor (Dual Transistors)Juan CarlosОценок пока нет

- 3 Zener DiodeДокумент16 страниц3 Zener DiodeGurudevОценок пока нет

- Ee5311 Module 4 Comb CKTДокумент72 страницыEe5311 Module 4 Comb CKTAnmol SinhaОценок пока нет

- Electronic Circuits - FET Amplifier AnalysisДокумент17 страницElectronic Circuits - FET Amplifier AnalysisMutharasu SОценок пока нет

- EECE 310 Sample BJT ProblemsДокумент8 страницEECE 310 Sample BJT ProblemsALi AlawiehОценок пока нет

- IS P627 DatasheetДокумент2 страницыIS P627 Datasheetucb51525354Оценок пока нет

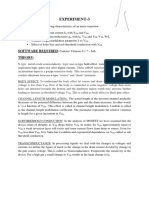

- Experiment-3:: Cadence Virtuoso 6.1.7 - 64bДокумент9 страницExperiment-3:: Cadence Virtuoso 6.1.7 - 64bSrujan MulkaОценок пока нет

- Triac OperationДокумент8 страницTriac OperationArpit PatelОценок пока нет

- Chapter 9: Thyristors Thyristors: (C) Diac (D) Triac (A) (E) SCS (B) SCR 4-Layer DiodeДокумент5 страницChapter 9: Thyristors Thyristors: (C) Diac (D) Triac (A) (E) SCS (B) SCR 4-Layer DiodeAngel CondiОценок пока нет