Академический Документы

Профессиональный Документы

Культура Документы

Forging

Загружено:

Aeshwrya PandaАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Forging

Загружено:

Aeshwrya PandaАвторское право:

Доступные форматы

Smithing & Forging

Smithing

It is a process of performing various operations on relatively small

work pieces, heated in an open fire (hearth) by means of hand

hammers or small power hammers in a smithy shop.

Forging

Is a process of producing those parts, which must be heated in a

closed furnace, by means of heavy hammers or forging machines or

presses.

2) Fuller

4) Flatter

5) Swage

6) Flat tongs

7) Ring Tongs

8) Gad Tongs

Forging Tools

Beak

9) Swage block

3) Punch

Set Hammer

a) Ball peen

b) Cross peen

c) Straight peen

Sledge Hammer

Hammers

Chisels

Hot Chisel

Set hammer

Anvil: Provides a support for blacksmiths workpiece

when hammering.

-Beak is used for bending the workpieces

Fuller: Necking down a piece of work

Swage: To obtain reduced and finished to round, square or

hexagonal form

- Made with half grooves of dimensions to suit the

work being reduced

Punch: Used for making holes in metal part when it is in

forging heat.

Flatter: To give smoothness and accuracy to components which

have been already shaped by fullers and swages.

Tongs: To hold the workpiece

1) Flat Tong : For holding work of rectangular section

2) Ring Tong : For holding work of circular section

3) Gad Tong : For general pick-up, either straight or tapered

Swage block:

Used for squaring, sizing, bending operations

Chisels: For cutting metals & for nicking prior to breaking

- They may be hot or cold depending on the metal to be cut

is hot or cold.

Hand hammers: They may be classified as a) Ball peen hammer

b) Straight peen hammer c) Cross peen hammer

d) Sledge hammer

Set hammer: Used for finishing corners in shouldered work,

where flatter is inconvenient.

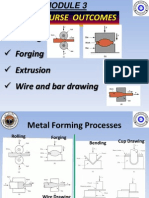

Forging processes

1) Smith Die forging

a) Hand Forging

b) Power Forging

They are classified as:

2) Impression Die forging

a) Drop Forging

b) Press Forging

c) Machine Forging

Power forging

Work

Ram

Anvil

Upper Die

Lower Die

Fig. Steam Hammer

-Also called as an air and

steam hammer

-Operated by either steam or

compressed air

-Principle of operation is

illustrated in the sketch

-Require additional facilities

for supplying high pressure steam

or compressed air.

work

Lower Die

Upper Die

Roll

Board

Drop Forging (Stamping/ Die forging)

Fig. Board Hammer

-Also called as Gravity Hammer

Working:

-Ram is fixed to the lower end of

the board

-Board is placed between 2 rolls

-Ram will be lifted, when both rolls

are pressed against the board

-Working stroke is produced when

the rolls are released.

-Process continues till operator

holds down the treadle

Smith forging operations

Most commonly used forging operations are:

1. Upsetting

2. Bending

3. Punching

4. Drawing down

5. Setting down

6. Punching

7. Welding

8. Cutting

9. Fullering

Smith forging operations

Upset forging operations

Curvilinear

Angular

Bending operations

Upsetting:

Process of increasing the thickness of a bar by

reducing its length by end pressure.

Bending:

Process of producing curvilinear or angular

bends on a bar.

Done on the edge of the anvil face or beak or

swage block

Step 1

Step 2

Step 3

Punching operation

Process of producing of holes by a hot

punch by placing the job over the pritchel

hole of the anvil.

Drawing down or Swaging

Process of increasing the length of a bar at the expense of its width

or thickness or both.

Setting Down

It is a localized drawing down or swaging operation.

Process of spreading the metal along the length of the

job.

Fullering

Cutting

Process of removing a forging from the stock.

Drop forging

-Uses drop hammers of 2 types

-Hammers can make 50 75 strokes/ min

-Lower maintenance cost & easy to operate

-Tools, Gear blanks, Machine parts

Gravity hammer

Steam hammer

Press forging

Done in presses than with hammers

More accurate than drop forgings

Relatively slow squeezing but better penetration

Screws, nuts & rivets can be made

High operating speed

Machine / Upset forging

Lengthwise pressure will be applied on the component held

between grooved dies to enlarge some sections

Operates at very high rate

Bolts, nuts, washers can be made

Produce 400 600 forgings per hour

Pritchel hole

Back

Вам также может понравиться

- Forging DefectДокумент4 страницыForging DefectRashmi Bhatt NautiyalОценок пока нет

- Surya Black SmithyДокумент11 страницSurya Black Smithy2K20B671 Shivam GargОценок пока нет

- Forging and Its TypesДокумент9 страницForging and Its TypesHarinath GowdОценок пока нет

- ForgingДокумент19 страницForgingSarthakОценок пока нет

- MR Sunil Kumar Ojha: Assistant Professor Mechanical Engineering Department JRE Group of Institutions Greater NoidaДокумент61 страницаMR Sunil Kumar Ojha: Assistant Professor Mechanical Engineering Department JRE Group of Institutions Greater NoidaGurjinderSinghDoshanjhОценок пока нет

- L8 - Bulk Deformation ProcessingДокумент70 страницL8 - Bulk Deformation ProcessingAstha PantОценок пока нет

- Hot Working ProcessДокумент35 страницHot Working ProcessDea NabilaОценок пока нет

- Unit-3, Metal Froming ProcessДокумент83 страницыUnit-3, Metal Froming ProcessMudit MaheshwariОценок пока нет

- Forging - The Process: Metal Forging Is A Metal Forming Process That Involves ApplyingДокумент25 страницForging - The Process: Metal Forging Is A Metal Forming Process That Involves ApplyingAdityasinh DesaiОценок пока нет

- Hot Cold WorkingДокумент40 страницHot Cold Workingpatel ketanОценок пока нет

- Smithy & Forging ShopДокумент24 страницыSmithy & Forging Shopashok junapudiОценок пока нет

- Blacksmithy: Engineering Work Shop Department of Mechanical EngineeringДокумент4 страницыBlacksmithy: Engineering Work Shop Department of Mechanical EngineeringSourabh DhavalaОценок пока нет

- Chapter 14.1 To 14.4,14.6Документ20 страницChapter 14.1 To 14.4,14.6Lhekha RaviendranОценок пока нет

- Unit Iii Bulk Processes Bulk DeformationДокумент77 страницUnit Iii Bulk Processes Bulk DeformationAkash akОценок пока нет

- Forging 2Документ39 страницForging 2ssukhmeet551Оценок пока нет

- Metal FormingДокумент40 страницMetal Formingsreeeram100% (1)

- 2017im148, PTD Assignment 6 & 7Документ8 страниц2017im148, PTD Assignment 6 & 7rehmatali11121314Оценок пока нет

- Black Smithy ShopДокумент3 страницыBlack Smithy ShopAmarjeet Singh (Assistant Professor- Mechanical Engineer)Оценок пока нет

- Smithy: Applications of ForgingДокумент8 страницSmithy: Applications of Forginghuman kindОценок пока нет

- 2017im148, PTD Assignment 6 & 7Документ8 страниц2017im148, PTD Assignment 6 & 7rehmatali11121314Оценок пока нет

- Performing Hand Forging: LO1: Analyze and Plan HandДокумент21 страницаPerforming Hand Forging: LO1: Analyze and Plan HandZimbelachew Emawoy100% (2)

- Mechanical Working of MetalsДокумент76 страницMechanical Working of MetalsPradip GuptaОценок пока нет

- 1) - Introduction:: Metal Forming ProcessesДокумент10 страниц1) - Introduction:: Metal Forming Processesphysics a2Оценок пока нет

- Aircraft Material & Production - MANUALДокумент45 страницAircraft Material & Production - MANUALKV Yashwanth100% (1)

- Blacksmithy or Forging NoteДокумент4 страницыBlacksmithy or Forging NoteSomnath MondalОценок пока нет

- MP Forging KSR 2015Документ78 страницMP Forging KSR 2015pavan ChintuОценок пока нет

- FORGING Full NotesДокумент44 страницыFORGING Full NotesShaina Hayat KhanОценок пока нет

- Metal Forming Process: Unit IIДокумент89 страницMetal Forming Process: Unit IIgiriaj kokareОценок пока нет

- Extrusión-Rolling and Forming ProcessДокумент50 страницExtrusión-Rolling and Forming Processquiron2010Оценок пока нет

- Forging Die of SpannerДокумент16 страницForging Die of Spannervirendra pawarОценок пока нет

- Engineering Workshop Lab Manual (Smithy Shop)Документ8 страницEngineering Workshop Lab Manual (Smithy Shop)Sumit Chauhan0% (2)

- Week 5Документ53 страницыWeek 5aqsa zahidОценок пока нет

- MP-I - Unit 5 - Sheet Metal WorkingДокумент60 страницMP-I - Unit 5 - Sheet Metal WorkingTirumala Height Phase-IОценок пока нет

- U-2 Mechanical Working of MetalsДокумент76 страницU-2 Mechanical Working of Metalsapi-271354682Оценок пока нет

- Mechanical Working of MetalsДокумент96 страницMechanical Working of Metalsashoku2Оценок пока нет

- Sheet Metal Shearing and Bending: Training ObjectiveДокумент6 страницSheet Metal Shearing and Bending: Training ObjectiveLovely RainОценок пока нет

- Teknologi Manufaktur (TPS-1116A) : Prodi Teknologi Pengolahan Sawit (D-3) Institut Teknologi Sains Bandung (ITSB) 2021Документ62 страницыTeknologi Manufaktur (TPS-1116A) : Prodi Teknologi Pengolahan Sawit (D-3) Institut Teknologi Sains Bandung (ITSB) 2021Aszhari AszhariОценок пока нет

- Manufacturing Practice Lab ManualДокумент59 страницManufacturing Practice Lab ManualLeam Minz100% (1)

- Final Unit 3 Manufacturing Processes PDFДокумент227 страницFinal Unit 3 Manufacturing Processes PDFHardik ChhabraОценок пока нет

- Laboratory Manual: Chandigarh Engineering College, Landran (Mohali)Документ15 страницLaboratory Manual: Chandigarh Engineering College, Landran (Mohali)Jay PandeyОценок пока нет

- Forging - Class NotesДокумент51 страницаForging - Class NotesShovan KarmakarОценок пока нет

- SWEPДокумент11 страницSWEPRizzleОценок пока нет

- ADVANCED TOOLING LAB MANUAL - PDF NEWДокумент16 страницADVANCED TOOLING LAB MANUAL - PDF NEWHOD TD GITОценок пока нет

- Blacksmithy Shop: By: Manoj YadavДокумент49 страницBlacksmithy Shop: By: Manoj YadavvijaykumarОценок пока нет

- Unit IIIДокумент114 страницUnit IIIManoj Kumar SОценок пока нет

- Lecture05-Sheet Metalmorking ProcessДокумент54 страницыLecture05-Sheet Metalmorking ProcessberhaneОценок пока нет

- Forging Design ConsiderationsДокумент81 страницаForging Design ConsiderationssuneethaОценок пока нет

- Forging Is A: Manufacturing ProcessДокумент12 страницForging Is A: Manufacturing ProcessMuhammad ShahirОценок пока нет

- FR ManualДокумент10 страницFR ManualMuhd Shabeeb AОценок пока нет

- Study of Forging Process Equipemnts-Practical-3Документ12 страницStudy of Forging Process Equipemnts-Practical-3prashantОценок пока нет

- My ForgingДокумент20 страницMy ForgingRam Janm SinghОценок пока нет

- Forging, Rolling, Extrusion and Drawing ProcessesДокумент45 страницForging, Rolling, Extrusion and Drawing ProcessesHarshan Arumugam100% (1)

- Injection MoldingДокумент10 страницInjection MoldingKalam Kulai100% (1)

- Forging: Unit - 3Документ50 страницForging: Unit - 3Solomon DuferaОценок пока нет

- C6 - DrillingДокумент7 страницC6 - DrillingHans PinonОценок пока нет

- Aluminum 5052Документ2 страницыAluminum 5052Praveen ThomasОценок пока нет

- Astm A530Документ2 страницыAstm A530Thiruvengadam75% (4)

- Cien 14 00063Документ9 страницCien 14 00063tth28288969Оценок пока нет

- BacauДокумент90 страницBacauDictie CopiiОценок пока нет

- Ra Elevatorr Maintenance ManualДокумент8 страницRa Elevatorr Maintenance ManualBahman MatouriОценок пока нет

- SpaceX Boosts Classified U.SДокумент2 страницыSpaceX Boosts Classified U.SDarrek F CrisslerОценок пока нет

- Catalogo Thyssen PDFДокумент8 страницCatalogo Thyssen PDFbiancogallazzi0% (1)

- Distribution Channel Management AmulДокумент41 страницаDistribution Channel Management AmulGaganpreetmultani9860% (5)

- Order 7360.1D Aircraft Type Designators FINAL PDFДокумент628 страницOrder 7360.1D Aircraft Type Designators FINAL PDFJulio Cesar LibrerosОценок пока нет

- Defects SlagДокумент3 страницыDefects SlagMuhammed SulfeekОценок пока нет

- Theory 1poultry IndustryДокумент15 страницTheory 1poultry IndustryRamesh BeniwalОценок пока нет

- Hydrocarbon Eng Feb 2017Документ24 страницыHydrocarbon Eng Feb 2017jcarbajal2013Оценок пока нет

- Gruvlok Stainless SteelДокумент16 страницGruvlok Stainless Steellink2u_007Оценок пока нет

- Raillok w30 Data Sheet ImperialДокумент2 страницыRaillok w30 Data Sheet Imperial30410929Оценок пока нет

- MRP ExcelДокумент33 страницыMRP ExcelJOSE2finaОценок пока нет

- Piping Design Professional: Kamalakannan AДокумент3 страницыPiping Design Professional: Kamalakannan AKamalakannan AyyaduraiОценок пока нет

- List of Airports in JapanДокумент19 страницList of Airports in JapanAmira Abd RahimОценок пока нет

- Demand Generation & Strategy (MIT Guys)Документ9 страницDemand Generation & Strategy (MIT Guys)Rashmi HulsurkarОценок пока нет

- DSR Electrical 2012Документ78 страницDSR Electrical 2012জেত বন100% (2)

- Forklift Truck SopДокумент1 страницаForklift Truck SopnoormuddassirkhanОценок пока нет

- Seal StorageДокумент1 страницаSeal StorageAhmad DeyabОценок пока нет

- BK Chapter 8Документ33 страницыBK Chapter 8anirОценок пока нет

- Technical Specifications For BuildingsДокумент340 страницTechnical Specifications For BuildingsTanvir Shahrier MahmudОценок пока нет

- APL Logistics FactsheetДокумент2 страницыAPL Logistics FactsheetSarvesh RathiОценок пока нет

- Welding Types and Their Applications - 1Документ18 страницWelding Types and Their Applications - 1tgu1eramos100% (3)

- Guided Study Manual For Deck Cadets and at Operational LevelДокумент284 страницыGuided Study Manual For Deck Cadets and at Operational LevelNikhil Yadav100% (3)

- PD 1096 Implementing Rules (A3)Документ6 страницPD 1096 Implementing Rules (A3)Charles Joseph JacobОценок пока нет

- Aircraft Design Competition v171013Документ10 страницAircraft Design Competition v171013JagadishRajОценок пока нет

- Questions of The Forging and Casting ProcessesДокумент2 страницыQuestions of The Forging and Casting ProcessesMohamed IbrahimОценок пока нет

- 03 HeavyTransport 2day UK 50 Pages - KeyДокумент25 страниц03 HeavyTransport 2day UK 50 Pages - KeyJavier Páez100% (5)