Академический Документы

Профессиональный Документы

Культура Документы

Wastewater Treatment: Physical and Chemical Process: Basic Concepts

Загружено:

VIRGILIO MANANGAN0 оценок0% нашли этот документ полезным (0 голосов)

78 просмотров49 страницMore than one treatment is needed to achieve the desired change in quality. In some cases treatment processes do not destroy the impurity but simply concentrate them in the form of sludge or effluent stream. Wastewater treatment is divided into three main processes. Physical processes comprising screening or straining, sedimentation, flocculation and filtration. Chemical treatment using adsorption, coagulation, ion exchange, precipitation. Biological treatment processes with dispersed growth system (activated s

Исходное описание:

Оригинальное название

Wastewater Treatment

Авторское право

© © All Rights Reserved

Доступные форматы

PPT, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документMore than one treatment is needed to achieve the desired change in quality. In some cases treatment processes do not destroy the impurity but simply concentrate them in the form of sludge or effluent stream. Wastewater treatment is divided into three main processes. Physical processes comprising screening or straining, sedimentation, flocculation and filtration. Chemical treatment using adsorption, coagulation, ion exchange, precipitation. Biological treatment processes with dispersed growth system (activated s

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PPT, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

78 просмотров49 страницWastewater Treatment: Physical and Chemical Process: Basic Concepts

Загружено:

VIRGILIO MANANGANMore than one treatment is needed to achieve the desired change in quality. In some cases treatment processes do not destroy the impurity but simply concentrate them in the form of sludge or effluent stream. Wastewater treatment is divided into three main processes. Physical processes comprising screening or straining, sedimentation, flocculation and filtration. Chemical treatment using adsorption, coagulation, ion exchange, precipitation. Biological treatment processes with dispersed growth system (activated s

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PPT, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 49

WASTEWATER TREATMENT:

PHYSICAL AND CHEMICAL

PROCESS

BASIC CONCEPTS:

In order to dispose off the waste water, it should

meet some standards set by local authorities. With

these standards wastewater should be treated.

More than one treatment is needed to achieve the

desired change in quality. Thus, it is a chain

processes operating in sequence.

In some cases treatment processes do not

destroy the impurity but simply concentrate

them in the form of sludge or effluent

stream.

Selection of proper method based on the

characteristics of wastewater is the key to

solving treatment problems.

Nature of Impurities

Rainwater, surface water, groundwater, seawater

can be considered as the different forms of some

basic material, varying in form and amount of

impurities. These impurities decide the level of

treatment provide for its use and disposal.

Municipal water has many types of impurities like floating

and large suspended solids(paper, rags, plastics, grit),

dissolved solids( organic and inorganic);Dissolved gases(

hydrogen sulfide, methane etc.) and

microorganisms(pathogen,bacteria and viruses)

Wastewater on the other hand can have much higher levels

of impurities as discussed because of the human organic

waste added to water along with detergents, pesticides, and

microorganism.

But wastewater can be called as water of different form if

the concentration of impurities is reduced, it can have

applications similar to water.

Different treatment processes

Wastewater treatment is divided into three main

processes.

1. Physical processes comprising screening or

straining, sedimentation, flocculation and

filtration.

2. Chemical treatment using adsorption,

coagulation, ion exchange, precipitation.

3. Biological treatment processes with dispersed

growth system( activated sludge, stabilization

ponds); fixed film reactors( biological filters

such as tricking filter)

Wastewater treatment processes normally

uses physical processes initially and later

chemical processes like precipitation. But if

it not sufficiently treated by the two

processes, the three can be used.

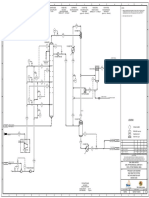

Raw sewage

P P

Sea Outfall

screening

Sedimentation

Raw sewage

P P B

P

Surface

water

Aerobic

oxidation

sedimentation

sedimentation

Screening

Raw

sewage

P P B C

P P

C

Sensitive

surface water

sedimentation

screening

Aerobic

oxidation

Phosphorus

removal

sedimentation

filtration

Disinfection

Note: P- Physical Process

C- Chemical Process

B- Biological Process

Wastewater treatment

process chain

Most of processes in wastewater treatment plant

as it is most cost effective compared to batch

process. However, batch process are preferred in

some cases where the quantity of waste is small

and the waste generation is not continuous.

Physical treatment processes

The main aim of physical treatment process

in a water treatment system is to protect the

main treatment systems from possible

damage or clogging. Various processes are

used to remove large floating and

suspended material.

Screening

The first operation in the physical treatment process. Micro

strainer with specially woven stainless steel meshes size

between 20 to 40 micrometer are usually used in water

treatment plants.

The nature and quantity of screening collected depend

upon the social, dietary, as well sewerage system of the

city. It also depends on the screening bar spacing, which

affect the loss of velocity head. This headloss indicates the

performance of a screen. On an average its quantity ranges

from .01 to .03 cu.m./1000 population per day.

Screening is unpleasant in nature with a strong

odor, particularly in high temperatures. Their

density is usually 1800-1900 kg/cu.m. with a solid

content of 15-30%

Sample problem:

A bar screen is installed in a wastewater treatment

plant receiving a daily peak flow of crude sewage

of 50,000 cu.m. Estimate headloss through the

screen and also the gross area of the screen.

Solution

Maximum flow, Q= 50,000 cu.m.=.5788 cu.m/s

Desired velocity through the screen, V,at ultimate flow= 0 .8m/s

Net area of screen opening required, A= .5788/.8 = 0.72 m/s

Since Q= V/A

Using rectangular bars in the screen having 1 cm width, 1 m height and

placed 5 cm clear spacing,

Number of bars required = .7235 * 100/5 = 14.46

Say 15 bars of 1 cm each

Total area required for screen = 0.7235 + (15 * 10^-2) = 0.87 square meter

Assuming that the inclination of the screen to the horizontal is at 60

degrees

The gross area of screen would be

= 0.87 * (square root of 3/ 2) = 1 square meter

Velocity through the clear screen, v = 0.8m/s

Velocity above the screen , u = 0.8 * 5/6 m/s = 0.67 m/s

Using the equation of continuity

Headloss through the screen is usually given as

= 0.0729 (v^2- u^2)

= 0.0729 (0.8^2 0.67^2)

= 0.014 m

If the screen openings are half plugged with screenings, leaves and

debris, the velocity through the screen is doubled.

v = 0.8 * 2 m/s

= 1.6 m/s

Maximum headloss = .0729 ( 1.6^2 0.67 ^2)

= 0.15m

At this maximum headloss the screen is to be cleaned.

In situ maceration of floating and large suspended solids can be

achieved by a comminutor or macerator in which the material is

trapped between teeth mounted on a slotted rotating drum and a

fixed comb.

Comminution and maceration

Grit removal

In most sewerage plant, considerable amount of sand and grit are

transported to the wastewater treatment plant. These materials arise

from roads and other paved areas. These two should be removed

earlier in order to prevent damage on the pumps and other mechanical

equipments.

Sedimentation

Is the separation of solids based on difference between densities of

solids and wastewater due to gravity.

Stokes law

Vs = (gd^2/18V) (Ss 1)

Where Vs = discrete particle terminal velocity; g is acceleration due to

gravity; d= diameter of the particle ; V = kinematic viscosity of water

Ss = specific gravity of the particle

Practical consideration in settlement of the discrete suspension

involves concept of ideal settling basin in which it is assumed that the

following conditions exists.

Quiescent settlement in the settling zone

Uniform flow through the settling zone

Uniform solids concentrations entering the settling zone.

Solids entering the sludge zone are not resuspended.

Horizontal and radial

flow units

Surface overflow rate 1- 1.5 m/h

Retention time 2 hr

Outlet weir loading < 12.5 cu.m / mh

Width : length

Rectangular units 1:4 to 1: 8

Vertical Flow units

Surface overflow rate 1- 1.8 m/h

Retention time 2-3 hr

Outlet weir loading < 12.5 cu.m /mh

Final settlement after

biological treatment

surface overflow rate 1.5 m/h

Retention time 2 hr

Outlet weir loading < 10 cu.m / mh

Typical design criteria for

sedimentation tanks.

Types of sedimentation tank

parameter Rectangular circular

Max. length 90m -

Max. width 30m -

depth 2- 2..5 2- 3.5 m

Range of

length/width ratio

1.5- 7.5

Range of length/

depth ratio

5 25

Bottom slope 1% 7.5 10% ( from periphery to center)

Max. diameter 30m

inlet multiple pipes on the central inlet pipe with concentric

width side with inlet baffle of diameter 15% of

baffle boards of depth 0.5 m and tank diameter and extending

0.8 m in front of the pipe 1m below surface

inlets and surface

for scum passover

Outlet Overflow weir with V-notches to peripheral weir provided with

Provide uniform flow at low heads. V- notch. Scum baffle

Scum baffles provide ahead of extending 0.3 m below

weir for wastewater installations water surface provided ahead

of effluent weir for

wastewater installation

Peak velocity Depends upon feed

Scraper arms velocity 0.2 m.min

Design features of wastewater sedimentation tank

Types of sedimentation tank

Typical sedimentation tanks: (a) rectangular horizontal flow tank; (b) circular, radial-flow tank; (c) hopper-bottomed, upward flow

tank

(a) Inlet zone at the central well, which has a round baffle plate, the

flow is established in a uniform radial direction so that short-circuiting

does not take place.

(b) Settling zone where settling is assumed to occur as the water

flows towards the outlet.

(c) Outlet zone in which the flow converges up and over the

decanting weirs.

(d) Sludge zone where settled material collects and is pumped out.

Important parts of a sedimentation tanks

Flocculation

This process is used when the small suspended solids having low specific

gravity and low settling velocity cannot be separated by sedimentation

easily. In wastewater treatment,this usually occurs particularly with

particles of less than 50 micrometer in size.

Advanced physical processes

These are used in order to get better

treatment efficiency. Some of the better

known operations used in advanced

treatment are ammonia stripping,

distillation, foam, fractionation,freezing.

Ammonia stripping

Is also known as air stripping of ammonia.

It is a modification of the aeration process

used for the removal of gases dissolved in

water.

Illustration of ammonia stripping

In the first phase, sodium hydroxide (NaOH) is added to the wastewater stream

just before being pumped into the stripping column. This raises the water pH

to the point where ammonium ions (NH 4 + ) are converted to ammonia gas.

Ammonia removal is enhanced by pumping the wastewater stream into the top

of the column which is packed with high surface area packing material. Air is

pumped into the bottom of the column. The ammonia carried by the air stream

is then transferred to liquid in the scrub column.

At the core of AmmEL-HC is a patented electrochemical reactor that converts

the ammonia dissolved in the scrubbing liquid to gaseous Nitrogen without

producing nitrates or greenhouse gases . Chemically inert and occupying an 80

per cent proportion of our atmosphere, gaseous nitrogen is the ideal end

product for safe dispersal into the environment.

Testing of the AmmEL-HC system has demonstrated its capabilities. As

shown below, a percentage removal ranging from 93% to 99% was achieved

throughout the test.

Other advantages of AmmEL-HC include:

Improves performance of existing biological treatment plants by

preventing ammonia toxicity in the activated sludge process

Less expensive than conventional processes, including biological

treatment

Does not convert ammonia to nitrate and does not produce greenhouse

gases

Small footprint - can reduce overall cost of land for new biological

treatment plants

Can operate intermittently without start-up delays

Fully automated - low maintenance

Remotely monitored

distillation

Is a unit operation in which the components of a liquid solution are

separated vaporization and condensation.

Foam fractionation

Is the separation of colloidal and suspended

material by floatation and dissolved organic

matter by adsorption.

freezing

Wastewater is sprayed into a chamber

operating under a vacuum. A portion of

wastewater gets evaporated and cooling

effect produces contaminant free ice

crystals in the remaining liquid.

Gas phase separation

Is a promising method for removal of

ammonia as gas. This method is based on

the development of selective permeable gas-

phase membranes.

Reverse osmosis

Is the process in which water is separated

from dissolved salts in the solution by

filtering through semi permeable membrane

at a pressure than the osmotic pressure

caused by the dissolved salts in wastewater.

Sorption

Conventional alum treatment for removal of

phosphate increases the concentration of

sulphate ions in the solution. To avoid this,

sorption is developed. Sorption is a process

of removing various forms of phosphate

without increasing the concentration of

sulphates.

Chemical treatment processes

Chemical precipitation- is the method of

addition of chemicals to the wastewater,

converting undesired soluble substances

into an insoluble precipitate which can be

removed easily and rapidly.

The undesired constituents generally found in wastewater are:

Suspended colloidal and supra colloidal solids and their associated

organic matter. They should be removed in order to avoid damage to

performance and reduction in efficiency.

Phosphorus

Toxic heavy metals and organics discharged from industrial plants and

premises into the municipal wastewater treatment plant.

coagulation

Is an important operation in removing colloidal solids. In

wastewater treatment, chemical such as lime, ferric salts

and commercial alum are used as coagulants. This process

removes suspended solids ( 60-80% ), BOD ( 50-70% )

phosphorus ( over 90%) and heavy metal ( over 80%)

Chemical clarification of wastewater can be combined with

the activated carbon adsorption process to provide

complete physical chemical wastewater treatment. the

use of chemical clarification has restricted application in

developing countries because of its constant requirement of

consumable chemical and consequent higher running costs.

Jar Test it is used to calculate the dosage

of the coagulant.

Advanced chemical processes

Ion exchange- although both natural and

synthetic ion exchange resins are available,

synthetic resins are used more widely

because of their durability. Some natural

zeolites (resins) are also used for the

removal of ammonia from wastewater.

Electrochemical treatment

Wastewater is mixed with seawater and is

passed into a single cell containing carbon

electrodes.

Electro dialysis

Ionic components of a solutions are separated

through the use of semi permeable ion-selective

membranes. If the electrical potential is applied

between the two electrodes, which in turn causes a

migration of cations toward the negative electrode

and migration of anions towards the positive

electrode. Due to the alternate spacing of cation

and anion permeable membranes, cells of

concentrated and dilute salts are formed.

. Principle of simple electrodialysis process. Diagram shows the membrane

configuration with alternating cation-selective (1)and anion-selective (2)

membranes between two electrodes ((3) and (4)), one at each end of the stack.

Oxidation and reduction

Oxidation - Chemical oxidation is used to remove

ammonia, to reduce the concentration of residual

organics and to reduce bacterial and viral contents of

wastewater. At present on of the few process for the

removal of ammonical nitrogen , found operationally

dependable , is chlorination. Ammonia can be removed

chemically by adding chlorine or hypochlorite to form

monochloramine and dichloramine as intermediate

products and nitrogen gas and hydrochloric acid as end

products. Problem associate with this method is the

presence of various organic and inorganic compounds

that will exert chlorine demand. Chemical oxidation of

organic material in wastewater.

Reduction

Nitrates present in wastewater can be reduced

electrolytically or by using strong reducing agents(

e.g. ferrous oxide). The reaction must usually

catalyzed while using reducing agents. The two

step processes using different reducing agents and

catalysts are limited by the availability of

chemicals at low cost, and the fact that the treated

effluent and waste sludge may contain toxic

compounds derived from the chemicals used for

catalyzing various reactions.

Вам также может понравиться

- Mini Refinery Feasibility OverviewДокумент9 страницMini Refinery Feasibility OverviewPouria SabbaghОценок пока нет

- Basic Industrial Wastewater Treatment WorkshopДокумент94 страницыBasic Industrial Wastewater Treatment Workshophenry_tan5328Оценок пока нет

- Wastewater Treatment OverviewДокумент55 страницWastewater Treatment OverviewShorOuq Mohammed Malkawi100% (1)

- LEC 5 Use of Microorganisms in Effluent TreatmentДокумент5 страницLEC 5 Use of Microorganisms in Effluent TreatmentDysmas100% (1)

- Biological Wastewater TreatmentДокумент164 страницыBiological Wastewater TreatmentBenazir Shugufta100% (1)

- Wastewater Treatment: Introduction To BiotechnologyДокумент54 страницыWastewater Treatment: Introduction To Biotechnologyjantskie100% (1)

- Wastewater TreatmentДокумент106 страницWastewater TreatmentFajaryan Wijananto100% (3)

- F CVEN9857 - Biological Nutrient Removal MMДокумент80 страницF CVEN9857 - Biological Nutrient Removal MMWeixuan ZhangОценок пока нет

- Chapter 6 Waste Water TreatmentДокумент93 страницыChapter 6 Waste Water Treatmentshiksha gauliОценок пока нет

- Lecture Iii Cve 503 Biological Treatment of Wastewater1Документ41 страницаLecture Iii Cve 503 Biological Treatment of Wastewater1James Korbla Dodzi Hills100% (1)

- Mixing Mixing: ENVE 301 Environmental Engineering Unit OperationsДокумент47 страницMixing Mixing: ENVE 301 Environmental Engineering Unit OperationsTaha ZiaОценок пока нет

- Lesson 15 - Trickling FiltersДокумент10 страницLesson 15 - Trickling FiltersShane RodriguezОценок пока нет

- What Is Tertiary Treatment PlantДокумент8 страницWhat Is Tertiary Treatment Plantlaloo01Оценок пока нет

- High-Rate Wastewater Treatment by A Shaft-TypeДокумент6 страницHigh-Rate Wastewater Treatment by A Shaft-TypeFabio NascimentoОценок пока нет

- Overview of The Biological TreatmentДокумент4 страницыOverview of The Biological TreatmentJanani SeniappanОценок пока нет

- Unit III Waste Water Treatment and DisposalДокумент26 страницUnit III Waste Water Treatment and DisposalSivaRaman100% (1)

- 9.6.2023 - Shorthand Notes On Sewage Sludge Treatment and DisposalДокумент17 страниц9.6.2023 - Shorthand Notes On Sewage Sludge Treatment and DisposalLucas AgumbaОценок пока нет

- Industrial Wastewater TreatmentДокумент70 страницIndustrial Wastewater TreatmentAudrius100% (3)

- Environmental Engineering (EN) - 20.03.18 PDFДокумент240 страницEnvironmental Engineering (EN) - 20.03.18 PDFRaj VermaОценок пока нет

- Coagulation PDFДокумент72 страницыCoagulation PDFAhmed WagihОценок пока нет

- Active Sludge PDFДокумент8 страницActive Sludge PDFDark_KiroОценок пока нет

- CE-311 Biological Treatment I - Activated Sludge ProcessДокумент40 страницCE-311 Biological Treatment I - Activated Sludge ProcessShubham BansalОценок пока нет

- ENVI Trickling FiltersДокумент23 страницыENVI Trickling FiltersbaBy daBy AnNetTeОценок пока нет

- Wastewater Characterization1Документ39 страницWastewater Characterization1ksbbs100% (1)

- I. Introduction To Air Pollution and Control: Primary PollutantsДокумент26 страницI. Introduction To Air Pollution and Control: Primary PollutantsMoves JaggerОценок пока нет

- Chapter 5Документ23 страницыChapter 5Tefera Temesgen100% (1)

- Settling TanksДокумент33 страницыSettling TanksWei ShienОценок пока нет

- Unit 3Документ155 страницUnit 3rangaОценок пока нет

- STP PDFДокумент16 страницSTP PDFhumaidjafriОценок пока нет

- Water Management1Документ22 страницыWater Management1Angelie Lape100% (1)

- School of Civil Engineering & Architecture: Adama Science and Technology UniversityДокумент112 страницSchool of Civil Engineering & Architecture: Adama Science and Technology UniversityHusen DugoОценок пока нет

- Aeration System in WWTPДокумент10 страницAeration System in WWTPashokОценок пока нет

- Literature Study For Ultra Filtration ProcessДокумент29 страницLiterature Study For Ultra Filtration ProcessSheldonОценок пока нет

- Advanced Wastewater Treatment: Gyeongsang National UniversityДокумент31 страницаAdvanced Wastewater Treatment: Gyeongsang National UniversityEdwin KamalhaОценок пока нет

- 05 SedimentationДокумент70 страниц05 SedimentationAnonymous Cpe6vcОценок пока нет

- CE-311 Biological Treatment I - Trickling FilterДокумент17 страницCE-311 Biological Treatment I - Trickling FilterShubham BansalОценок пока нет

- Activated Sludge Treatment ProcessДокумент7 страницActivated Sludge Treatment ProcessMaizan Sofia100% (1)

- Isea - Wastewater Treatment Plant For Residental Communities and Industrial FacilitiesДокумент19 страницIsea - Wastewater Treatment Plant For Residental Communities and Industrial FacilitiesAG-Metal /Tretman Otpadnih Voda/Wastewater Treatment100% (3)

- Wastewater Treatment Methods Physical Unit Operations Chemical Unit Operations Biological Unit OperationsДокумент34 страницыWastewater Treatment Methods Physical Unit Operations Chemical Unit Operations Biological Unit OperationsNumanОценок пока нет

- LECTURE 11 - Conventional Water Treatment Facility2014Документ51 страницаLECTURE 11 - Conventional Water Treatment Facility2014Kaaviyan thirunyanamОценок пока нет

- Rotating Biological ContactorДокумент6 страницRotating Biological ContactorDebasish NayakОценок пока нет

- Glossary For Water Treatment Systems 2007Документ10 страницGlossary For Water Treatment Systems 2007Ahmad Mamdouh100% (1)

- Nitrification and DenitrificationДокумент4 страницыNitrification and DenitrificationJpricarioОценок пока нет

- CH 9 - Attached Growth ProcessДокумент30 страницCH 9 - Attached Growth Processxuantra92100% (1)

- Activated Sludge - Troubleshooting GuideДокумент5 страницActivated Sludge - Troubleshooting Guidekuthappady0% (1)

- Tertiary TreatmentДокумент45 страницTertiary TreatmentsunitaudayОценок пока нет

- FiltrationДокумент23 страницыFiltrationNeha PatelОценок пока нет

- Course Material Week 10 Biological Process Technology Environmental Engineering Dept. Institut Teknologi BandungДокумент50 страницCourse Material Week 10 Biological Process Technology Environmental Engineering Dept. Institut Teknologi BandungAnnisa MaulinaОценок пока нет

- Coagulation FlocculationДокумент71 страницаCoagulation FlocculationDeepa Singh100% (1)

- 2021 CH 274Документ23 страницы2021 CH 274Ali Raza MeharОценок пока нет

- Primary Treatment of Sewage 3Документ17 страницPrimary Treatment of Sewage 3sasisОценок пока нет

- LamellaДокумент5 страницLamellaKhoa Nguyen DangОценок пока нет

- Types of Screens: Primary TreatmentДокумент20 страницTypes of Screens: Primary TreatmentMadhuri GuptaОценок пока нет

- L13-15 Water+Treatment Coagulation,+Flocculation,+Sedimentation,+FiltrationДокумент13 страницL13-15 Water+Treatment Coagulation,+Flocculation,+Sedimentation,+Filtrationsalil dubey100% (1)

- "Water Treatment Process": (Subject Code: 3714802)Документ33 страницы"Water Treatment Process": (Subject Code: 3714802)mritunjay yadavОценок пока нет

- CalculationДокумент28 страницCalculationManish Kumar Ghora100% (1)

- Chapter-14 Final Aerobic-DigestionДокумент18 страницChapter-14 Final Aerobic-DigestionIrvin joseОценок пока нет

- Wastewater Treatment Mechanic: Passbooks Study GuideОт EverandWastewater Treatment Mechanic: Passbooks Study GuideОценок пока нет

- DAO 1992-29 - IRR of RA6969Документ27 страницDAO 1992-29 - IRR of RA6969Pacific Spectrum100% (1)

- Motorstar R155Документ4 страницыMotorstar R155VIRGILIO MANANGANОценок пока нет

- Waste ManagementДокумент34 страницыWaste ManagementOvertson SyiemliehОценок пока нет

- Law and Logic (Fallacies)Документ10 страницLaw and Logic (Fallacies)Arbie Dela TorreОценок пока нет

- Backyard CattleДокумент9 страницBackyard CattleToy GolosinoОценок пока нет

- RA6969Документ8 страницRA6969Gino Luna CondecionОценок пока нет

- GP For The Rama Phosphates LTD.: Case Study of Soy Oil Processing Industry (DOC Production)Документ39 страницGP For The Rama Phosphates LTD.: Case Study of Soy Oil Processing Industry (DOC Production)VIRGILIO MANANGANОценок пока нет

- Requirements For Building Permit in The PhilippinesДокумент1 страницаRequirements For Building Permit in The PhilippinesVIRGILIO MANANGANОценок пока нет

- Do You Want To Go Into BusinessДокумент50 страницDo You Want To Go Into BusinessDomingo NacionОценок пока нет

- 8hr Training For Managing Heads - (Bellevue, Sept19) General InvitationДокумент4 страницы8hr Training For Managing Heads - (Bellevue, Sept19) General InvitationVIRGILIO MANANGANОценок пока нет

- Design of Concrete Foundation Fr6mt Test BenchДокумент1 страницаDesign of Concrete Foundation Fr6mt Test BenchVIRGILIO MANANGANОценок пока нет

- ISO14001 Implementation & Operation, Checking and Management ReviewДокумент45 страницISO14001 Implementation & Operation, Checking and Management ReviewVIRGILIO MANANGANОценок пока нет

- Safety ProgramДокумент23 страницыSafety ProgramVIRGILIO MANANGANОценок пока нет

- Excel Loan CalculatorДокумент1 страницаExcel Loan CalculatorAbhishek ShrivastavОценок пока нет

- ISO Orientation12Документ24 страницыISO Orientation12VIRGILIO MANANGANОценок пока нет

- Building Fire SafetyДокумент78 страницBuilding Fire SafetyVIRGILIO MANANGANОценок пока нет

- SY Vs CAДокумент5 страницSY Vs CAAyries AntonioОценок пока нет

- ISO Orientation20Документ18 страницISO Orientation20VIRGILIO MANANGANОценок пока нет

- Project Experiences - Gunawan MuktiwibowoДокумент29 страницProject Experiences - Gunawan MuktiwibowoGunawan Raharjo100% (1)

- Harrison Catalog OnlineДокумент20 страницHarrison Catalog OnlineHAROLDОценок пока нет

- Chemical Cleaning ProcessДокумент7 страницChemical Cleaning ProcessmechanikyОценок пока нет

- Conversion of Sulfinol To BASF' S Amdea: SM ® SM SMДокумент12 страницConversion of Sulfinol To BASF' S Amdea: SM ® SM SMvaratharajan g rОценок пока нет

- Compressed Air FiltersДокумент8 страницCompressed Air FiltersJuan Carlos Vazquez RosasОценок пока нет

- Operation Manual For PX ABS 3.4m3 Portable Assembly Biogas SystemДокумент10 страницOperation Manual For PX ABS 3.4m3 Portable Assembly Biogas SystemShahabas ShabuОценок пока нет

- Chemistry Solutions DPP EtoosДокумент8 страницChemistry Solutions DPP EtoosabhishekОценок пока нет

- SPT Cynara Co2 BrochureДокумент2 страницыSPT Cynara Co2 BrochurexaxaxОценок пока нет

- FPFF 1Документ8 страницFPFF 1ShashankNageshОценок пока нет

- The Effects of Hydrogen Fluoride On The Wooden Surface of Historic Buildings During Fire Suppression Using Fluorinated Chemical GasesДокумент12 страницThe Effects of Hydrogen Fluoride On The Wooden Surface of Historic Buildings During Fire Suppression Using Fluorinated Chemical GasesTatiana FabianОценок пока нет

- Notes: Process Flow Diagram Melamine Off-Gas Condensation (Section 25)Документ1 страницаNotes: Process Flow Diagram Melamine Off-Gas Condensation (Section 25)rajindo1Оценок пока нет

- RefrigerantsДокумент149 страницRefrigerantsSatyendraОценок пока нет

- Ashish Shrivastava-Training Consultant ProfileДокумент6 страницAshish Shrivastava-Training Consultant Profileashish shrivastavОценок пока нет

- Simulation of Air Liquefaction Using Aspen PlusДокумент39 страницSimulation of Air Liquefaction Using Aspen PlusAhmed AliОценок пока нет

- Acid DewpointДокумент2 страницыAcid Dewpointachmadh_2010Оценок пока нет

- 110-RB-701 110-VV-703 110-VV-702 110-EE-702 110-EE-703: LegendДокумент1 страница110-RB-701 110-VV-703 110-VV-702 110-EE-702 110-EE-703: LegendDIPANKAR LALAОценок пока нет

- How Much Coal Required To Produce 1 MW Power?: What Is The TPH of A Boiler?Документ5 страницHow Much Coal Required To Produce 1 MW Power?: What Is The TPH of A Boiler?coconut borneoОценок пока нет

- Gas Flaring Basic InformationДокумент4 страницыGas Flaring Basic InformationFriday IjokgwungОценок пока нет

- Pensky MartensДокумент2 страницыPensky Martensharry_chemОценок пока нет

- Flue Gas DesulfurisationДокумент22 страницыFlue Gas DesulfurisationManishankar PandaОценок пока нет

- Questions of CEM PDFДокумент2 страницыQuestions of CEM PDFAnonymous Anzt6fAeM100% (1)

- 氫氣高壓用閥Документ2 страницы氫氣高壓用閥William ChangОценок пока нет

- PE 311 (13 Credits) :: Unit Operation For Petroleum IndustryДокумент52 страницыPE 311 (13 Credits) :: Unit Operation For Petroleum IndustryMbarouk Shaame MbaroukОценок пока нет

- HF Alkylation and NExOCTANE Tech For Gasoline ProductionДокумент42 страницыHF Alkylation and NExOCTANE Tech For Gasoline ProductionUsama Shakil0% (1)

- Modeling and Simulation of Steam CrackersДокумент6 страницModeling and Simulation of Steam CrackersFathan FathullahОценок пока нет

- DHDT BaiscsДокумент2 страницыDHDT BaiscsAvik Bhai100% (1)

- Kinetics of Methanol Synthesis From Carbon Dioxide-Portha2017Документ24 страницыKinetics of Methanol Synthesis From Carbon Dioxide-Portha2017fkgui2014Оценок пока нет

- 021 2008 Abstracts Chemreactor 18 MaltaДокумент558 страниц021 2008 Abstracts Chemreactor 18 MaltaChau MaiОценок пока нет

- Improved Procedure For The Preparation of 1 - (2-Phenethyl) - 4-PiperidoneДокумент5 страницImproved Procedure For The Preparation of 1 - (2-Phenethyl) - 4-PiperidonejesusОценок пока нет