Академический Документы

Профессиональный Документы

Культура Документы

Cooling Tower

Загружено:

Mithun Mohan0 оценок0% нашли этот документ полезным (0 голосов)

192 просмотров8 страницThere are two main classifications of condensers: 1) Direct contact condensers which include spray, barometric, and jet condensers; and 2) Surface condensers which use a shell and tube heat exchanger. There are also two types of cooling towers: 1) Natural draught cooling towers which use large chimneys to introduce air without blowers and work best for large water flows; and 2) Mechanical draught cooling towers which use fans or blowers to move air through the tower and can be located more flexibly than natural draught towers. Mechanical draught cooling towers are more widely used.

Исходное описание:

cooling tower

Авторское право

© © All Rights Reserved

Доступные форматы

PPTX, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документThere are two main classifications of condensers: 1) Direct contact condensers which include spray, barometric, and jet condensers; and 2) Surface condensers which use a shell and tube heat exchanger. There are also two types of cooling towers: 1) Natural draught cooling towers which use large chimneys to introduce air without blowers and work best for large water flows; and 2) Mechanical draught cooling towers which use fans or blowers to move air through the tower and can be located more flexibly than natural draught towers. Mechanical draught cooling towers are more widely used.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PPTX, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

192 просмотров8 страницCooling Tower

Загружено:

Mithun MohanThere are two main classifications of condensers: 1) Direct contact condensers which include spray, barometric, and jet condensers; and 2) Surface condensers which use a shell and tube heat exchanger. There are also two types of cooling towers: 1) Natural draught cooling towers which use large chimneys to introduce air without blowers and work best for large water flows; and 2) Mechanical draught cooling towers which use fans or blowers to move air through the tower and can be located more flexibly than natural draught towers. Mechanical draught cooling towers are more widely used.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PPTX, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 8

CLASSIFICATION OF CONDENSERS

1. DIRECT CONTACT CONDENSERS

a) Spray Condensers

b) Barometric condensers

c) Jet Condensers

2. SURFACE CONDENSERS

a) Shell And Tube Heat Exchanger

SPRAY CONDENSER

Cooling water is sprayed into the steam

Steam directly mixing with cold water and

gets condensed

BAROMETRIC CONDENSER

Cooling water is made to fall in a series of

baffles to expose large surface area for the

steam fed from below to come in direct

contact

The steam condenses and the mixture falls in

a tail pipe to the hot well

SURFACE CONDENSERS

Most commonly used in power plants

Shell and Tube Heat Exchanger

Cooling water flows through the tubes and steam

condenses outside the tubes

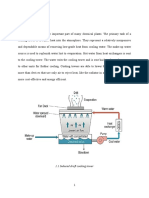

CLASSIFICATION OF COOLING TOWER

1. NATURAL DRAUGHT COOLING TOWER

2. MECHANICAL DRAUGHT COOLING TOWER

These types of towers are used only by utility power stations.

Use very large concrete chimneys to introduce air through the media

Generally used for water flow rates above 45,000 m

3

/hr.

There are no blowers to move air through the tower

Water enters the tower from the top and is cooled as the water falls to

the bottom

Some water evaporates in the process, helping to cool the remaining

water in the tower

Use a fan or blower to move air through the tower

As the water falls through the tower, air is moved across it to aid in

the cooling process

Can be located almost anywhere

The fan is cycled on and off to maintain the desired water temperature

Forced draft Air is pushed through the tower

Induced draft Air is pulled through the tower

mechanical draft cooling towers are much more widely used

Вам также может понравиться

- Chapter SixДокумент25 страницChapter SixADEFRIS BELACHEWОценок пока нет

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesОт EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesОценок пока нет

- Condenser: Function of A CondenserДокумент6 страницCondenser: Function of A CondenserShirr SagerОценок пока нет

- How it Works: Dealing in simple language with steam, electricity, light, heat, sound, hydraulics, optics, etc., and with their applications to apparatus in common useОт EverandHow it Works: Dealing in simple language with steam, electricity, light, heat, sound, hydraulics, optics, etc., and with their applications to apparatus in common useОценок пока нет

- CHAPTER 7 - COOLING TOWER Edit MOSH 211220Документ25 страницCHAPTER 7 - COOLING TOWER Edit MOSH 211220subash1111111Оценок пока нет

- Chapter 10 - Cooling TowerДокумент24 страницыChapter 10 - Cooling TowerAsyraf Sabri100% (1)

- Ppe Activity 6Документ3 страницыPpe Activity 6Marycris Bautista RosarioОценок пока нет

- Unit Notes PDFДокумент29 страницUnit Notes PDFPrashant UbarhandeОценок пока нет

- Chapter 15 Condensate SystemДокумент11 страницChapter 15 Condensate SystemsambhuОценок пока нет

- Chapter 5 Steam CondenserДокумент40 страницChapter 5 Steam CondenserHabtamu Tkubet EbuyОценок пока нет

- Cooling TowersДокумент40 страницCooling Towers1000 Subscribers Without a Video100% (2)

- Cooling TowersДокумент35 страницCooling Towersedbaka100% (1)

- Steam Condenser: Me 420 - Me Laboratory 2Документ74 страницыSteam Condenser: Me 420 - Me Laboratory 2daanОценок пока нет

- Presentation On Condensers and EvaporatorsДокумент32 страницыPresentation On Condensers and Evaporatorsvipul sharma100% (1)

- Building Utilities MechanicalДокумент46 страницBuilding Utilities Mechanicalkate tingzonОценок пока нет

- Steam CondensersДокумент59 страницSteam CondensersBLACK GAMINGОценок пока нет

- Cooling Tower SeminarДокумент67 страницCooling Tower SeminarRupesh Desai100% (1)

- HvacДокумент38 страницHvacJenny RamirezОценок пока нет

- Cooling Tower REPORTДокумент25 страницCooling Tower REPORTSaroj KumarОценок пока нет

- Condensor and Cooling TowerДокумент25 страницCondensor and Cooling TowerYASH ACHARYAОценок пока нет

- Cooling Towers: Presented by Dr. Khalid Mahmood Chemical Engineering Deptt. UET Lahore, FSD CampusДокумент79 страницCooling Towers: Presented by Dr. Khalid Mahmood Chemical Engineering Deptt. UET Lahore, FSD CampusIqra MubeenОценок пока нет

- CondenserДокумент6 страницCondenserSimranjeet SinghОценок пока нет

- Condensing Cooling System-27042020Документ21 страницаCondensing Cooling System-27042020Ashmit TaliyanОценок пока нет

- Activity Week 5Документ5 страницActivity Week 5Anonymous UXZdef7JОценок пока нет

- CondenserДокумент17 страницCondenserSuleimAanBinFaizОценок пока нет

- Condenser CondenserДокумент36 страницCondenser Condenserobisonandlaw100% (1)

- Steam Condenser and Cooling TowerДокумент25 страницSteam Condenser and Cooling TowerDeep KhandhediaОценок пока нет

- Condensers: Report By-Ashna Anamika Mugdha PratishthaДокумент17 страницCondensers: Report By-Ashna Anamika Mugdha PratishtharashmiОценок пока нет

- CONDENSERДокумент24 страницыCONDENSERAmlan ShomeОценок пока нет

- Cooling TowerДокумент47 страницCooling TowerVenkitaraj K P100% (1)

- Study of Condenser Performance Evaluation and Measures To Improve ItДокумент26 страницStudy of Condenser Performance Evaluation and Measures To Improve ItPrudhvi RajОценок пока нет

- 6 Cooling TowerДокумент8 страниц6 Cooling TowerMico Sylvester100% (3)

- Steam Generating Unit: Presented By: Garrido, Francis Collens Mangkit, Vencent Resabal, Marion VincentДокумент75 страницSteam Generating Unit: Presented By: Garrido, Francis Collens Mangkit, Vencent Resabal, Marion Vincentmarvin64Оценок пока нет

- KIET Group of Institutions, GhaziabadДокумент8 страницKIET Group of Institutions, GhaziabadSandeep ChhabraОценок пока нет

- NTPC Training ReportДокумент83 страницыNTPC Training Reportpankajpnd1100% (1)

- Chapter 6 Steam CondenserДокумент52 страницыChapter 6 Steam CondenserMisge ChekoleОценок пока нет

- CondensorДокумент20 страницCondensorLaka 98Оценок пока нет

- Chapter One: CondenserДокумент10 страницChapter One: Condenserشاكر العاقل100% (1)

- Cooling TowerДокумент9 страницCooling TowerMd. Osman AliОценок пока нет

- Refrigeration System Components: - Vishakh GaneshДокумент34 страницыRefrigeration System Components: - Vishakh GaneshS R Akhil KrishnanОценок пока нет

- Aljon Altiche Efrel John Manlapaz Romyrick Gliponeo Emanoel Brimon Kimberly DuganДокумент30 страницAljon Altiche Efrel John Manlapaz Romyrick Gliponeo Emanoel Brimon Kimberly DuganMalik MussaОценок пока нет

- Cooling Water System Optimization: Figure 1. Cross Section of Counter and Cross Flow TowersДокумент4 страницыCooling Water System Optimization: Figure 1. Cross Section of Counter and Cross Flow TowersLeo PunongbayanОценок пока нет

- Chapter 7 - Steam CondensorДокумент43 страницыChapter 7 - Steam CondensorrrhoshackОценок пока нет

- Boiler Water & Steam CycleДокумент50 страницBoiler Water & Steam CycleRaviKushwahaОценок пока нет

- BLD61304 (Week 2 - Mechanical and Air-Conditioning Systems)Документ33 страницыBLD61304 (Week 2 - Mechanical and Air-Conditioning Systems)khoo chao siangОценок пока нет

- Chapter 7 Steam CondenserДокумент44 страницыChapter 7 Steam Condenserabe9090901Оценок пока нет

- HvacДокумент32 страницыHvacRonald Oliveria BaldiviaОценок пока нет

- Evaporative Condenser FinalДокумент3 страницыEvaporative Condenser Finalvinod kumarОценок пока нет

- Steam CondenserДокумент26 страницSteam CondenserPushkar Pandit100% (1)

- Ppe Steam CondenserДокумент27 страницPpe Steam CondenserNilesh SinghОценок пока нет

- Refrigeration: Refrigeration Is The Process of Removing Heat From A Substance Under ControlledДокумент15 страницRefrigeration: Refrigeration Is The Process of Removing Heat From A Substance Under ControlledWala LangОценок пока нет

- Cooling Towers: Cold Water BasinДокумент13 страницCooling Towers: Cold Water BasinmichsantosОценок пока нет

- CondenserДокумент8 страницCondenserManish MauryaОценок пока нет

- Steam Condensers: Unit 4Документ12 страницSteam Condensers: Unit 4sameer jainОценок пока нет

- 3-Air ConditioningДокумент7 страниц3-Air ConditioningMADHU MITHAОценок пока нет

- Steam Condenser - Lecture SlideДокумент43 страницыSteam Condenser - Lecture SlideKing KОценок пока нет

- Air Conditioning Plant (BSME 5B)Документ128 страницAir Conditioning Plant (BSME 5B)Marvin ArnaizОценок пока нет

- 6 Cooling Tower PDFДокумент8 страниц6 Cooling Tower PDFJohn AlvarezОценок пока нет

- 104 - EarthingДокумент70 страниц104 - Earthingradulescuandrei100Оценок пока нет

- Design Sizing and Implementation of A PV System FoДокумент6 страницDesign Sizing and Implementation of A PV System FoBruno SouzaОценок пока нет

- Adisu DC DCДокумент20 страницAdisu DC DCAdisuОценок пока нет

- Poyri Hydro - PSSДокумент38 страницPoyri Hydro - PSSJosé Pires de SouzaОценок пока нет

- Power Quality ToolsДокумент15 страницPower Quality Toolsrize1159Оценок пока нет

- Buena Vista Site Report 210712-210716Документ8 страницBuena Vista Site Report 210712-210716SHRUTIGONUОценок пока нет

- Data Sheet: Tempower 2 Acb: Types: AR208S, AR212S, AR216S, AR220SДокумент7 страницData Sheet: Tempower 2 Acb: Types: AR208S, AR212S, AR216S, AR220SNesil AbieraОценок пока нет

- Univibe ENGДокумент5 страницUnivibe ENGba3jarОценок пока нет

- Me Sci 10 q2 0901 SGДокумент24 страницыMe Sci 10 q2 0901 SGIcia VillegasОценок пока нет

- CET Power - AGIL+SBP Datasheet v1.0Документ2 страницыCET Power - AGIL+SBP Datasheet v1.0Renzo VelardeОценок пока нет

- Inverter Mitsubishi FR-F500 Intruction ManualДокумент217 страницInverter Mitsubishi FR-F500 Intruction Manualsunhuynh100% (1)

- ADAMS Elevator OtisДокумент84 страницыADAMS Elevator Otisamine zighaОценок пока нет

- Boiler RoomДокумент1 страницаBoiler RoomtylerstearnsОценок пока нет

- Catalog AC DRIVESДокумент36 страницCatalog AC DRIVESMr.K chОценок пока нет

- Frame 1014L Winding 6: ShuntДокумент3 страницыFrame 1014L Winding 6: ShuntscribdledeeОценок пока нет

- DCMT - Set 4 GR14 SuppleДокумент2 страницыDCMT - Set 4 GR14 SuppleP Praveen KumarОценок пока нет

- Power Quality Improv With StatcomДокумент6 страницPower Quality Improv With StatcomAnshik BansalОценок пока нет

- What Is Difference Between UPS & InverterДокумент4 страницыWhat Is Difference Between UPS & InverterprakashОценок пока нет

- 30-Jan-2020 2 and 4 Quadrant Choppers Chopper Control DrivesДокумент26 страниц30-Jan-2020 2 and 4 Quadrant Choppers Chopper Control DrivesATULYA ALOK 17BEE0065Оценок пока нет

- EMTP, Transient Stability and Power Flow Models and Controls of VSC Based FACTS Controllers - E. Uzunovic - 2001Документ231 страницаEMTP, Transient Stability and Power Flow Models and Controls of VSC Based FACTS Controllers - E. Uzunovic - 2001M8ow6f100% (1)

- Electrical Engineering Lab V Course Code: Epo 660Документ21 страницаElectrical Engineering Lab V Course Code: Epo 660Faiz BakarОценок пока нет

- 7TKK000108 High-Tech Fuse Catalogue US DGTДокумент76 страниц7TKK000108 High-Tech Fuse Catalogue US DGTjrvvfОценок пока нет

- Daily HLP Report 01 Dec 2022Документ1 страницаDaily HLP Report 01 Dec 2022Vicky YadavОценок пока нет

- Marine Electric Power Generation: Jim Bertsch Marine Program ManagerДокумент27 страницMarine Electric Power Generation: Jim Bertsch Marine Program ManagerFarhan Arif SantosoОценок пока нет

- 1SBE121111R0620 Esb20 20n 06Документ4 страницы1SBE121111R0620 Esb20 20n 06muneeb abdulОценок пока нет

- FCM-75kW-Standalone (ETP-Chennai Location) (ID 793838)Документ12 страницFCM-75kW-Standalone (ETP-Chennai Location) (ID 793838)Gopikrishnan ThangarajОценок пока нет

- Induction Motor ControlДокумент22 страницыInduction Motor ControlSenpai TashiОценок пока нет

- Test Trasformer66Документ3 страницыTest Trasformer66Hassan AbdoОценок пока нет

- Performance of A Double-Star Synchronous Generator With Bridge Rectified OutputДокумент7 страницPerformance of A Double-Star Synchronous Generator With Bridge Rectified OutputManikandan DurairajОценок пока нет

- Y Three Phase MotorДокумент6 страницY Three Phase MotorVladimir233100% (2)