Академический Документы

Профессиональный Документы

Культура Документы

GT Mtc. Practices

Загружено:

Abhishek Prakash SrivastavaАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

GT Mtc. Practices

Загружено:

Abhishek Prakash SrivastavaАвторское право:

Доступные форматы

GE FRAME 6B,9E & 9FA

GAS TURBINES

Principle of working:- Works on Braton

Cycle with two nos. Adiabatic

processes of compression & expansion

in compressor and turbine respectively

and two constant pressure processes

i.e. Heat addition in combustion

chambers and exhaust in atmosphere.

BRATON

CYCLE

The Actual Thermodynamic

cycle

For all practical reasons the

actual thermal efficiency

will depend on

Pressure ratio

Turbine inlet Temp

Compressor inlet temp

Efficiency of Compressor and

Turbine

Principle of Operation:- Rotor is initially

brought to speed by starting means.

Atmospheric air is drawn into the compressor

and raised to static pressure more than the

atmospheric. This high pressure air is

allowed to pass through continuous flow

Combustion Chambers where fuel is ignited

with high voltage igniters. The product of

combustion is expanded in the turbine which

cause it to spin and thus applying a torque to

the driven accessories i.e. Generator

WORKING PRINCIPLE

Time

1

2

3

4

0

0-1 Cranking

1-2 Purging

2-3 Speed down to firing speed

3- Firing

3-4 Warm up

4-5 Acceleration

5-6 Full Speed no load

5

6

Torque converter angle

Fuel

Speed

THE MAIN & MOST IMPORTANT

CONCERNS OF THE GT UTILITIES

ARE

LOW MAINTENANCE COST

HIGH AVAILABILITY

TO KEEP LOW COST OF OPERATION

& HIGH AVAILABILITY OF M/Cs, A

WELL PLANNED MTC. PROGRAMME

IS REQUIRED

TYPE OF FUEL USED

FIRING TEMPERATURE

OVERSPEED OPERATION OF M/C

DESIGN FEATURES

DUTY CYCLE

PARTS AVAILABILITY

ON SITE MTC. CAPABILITY

DIAGNOSTIC & EXPERT SYSTEM OF

ANALYSIS

MFRS RECOMMENDED MTC. PROGRAM

MTC. PLANNING IS AFFECTED BY

NATURE OF OPERATION PHILOSOPHY I.E.

PEAKING OR BASE LOAD OPERATIONS,

STANDBY OPERATION & NO. OF STARTS

& SHUTDOWNS.

GAS TURBINE WEARS IN DIFFERENT

WAYS FOR DIFFERENT SERVICE

REQUIREMENTS AND DUTY CYCLES.

THERMAL MECHANICAL FATIGUE IS THE

LIMITER FOR CYCLIC OPERATION AND

CREEP, OXIDATION, HOT CORROSION ARE

THE LIMITER FOR CONTINUOUS DUTY

APPLICATIONS

EFFECTS

TMF

HCF

RUB/ WEAR

FOD

EFFECTS

CREEP

RUPTURE

HCF

CORROSION

OXIDATION

EROSION

RUB/WEAR

FOD

OPERATING DUTY DEFINITION

Fired

Duty Service Factor Hrs/Starts

Stand-by <1 % 1 to 4

Peaking 1% to 17% 3 to 10

Cycling 17% to 50 % 10 to 50

Continuous >90 % >>50

FIRING TEMP. IS THE LIMITING FACTOR

FOR LOAD ON THE TURBINE. HIGHER THE

FIRING TEMP. SHORTER WILL BE THE

MTBI. HIGH FIRING TEMP. MAY BE DUE

TO-

PEAK LOAD OPERATION OF M/C

WET CONTROL CURVE OPERATION OF M/C

WITH STEAM/WATER INJECTION OR WITH

INLET FOGGING

PART LOAD OPERATION OF M/C IN

COMBINED CYCLE

WITH USE OF HEAVY FUELS IN GTs, THE

MTC. INTERVALS ARE REDUCED AS DUE

TO BURNING OF HEAVY FUELS RADIANT

THERMAL ENERGY IS RELEASED

RESULTING INTO REDUCTION OF HGP

SPARES LIFE. ALSO PRESENCE OF

CORROSIVE ELEMENTS IN THE HEAVY

FUELS HOT CORROSION IN HGP SPARES

IS INCREASED.

CONTD.

FUEL USED IN GAS TURBINE IS THE KEY

FACTOR IN DECIDING THE MTC.

PLANNING. THE SEVERITY FACTOR FOR

VARIOUS FUELS ARE AS FOLLOW -

GAS - 1

DISTILLATE - 1.5

CRUDE - 2 TO 3

RESIDUAL - 3 TO 4

GAS TURBINE OPERATION ON GAS

FUEL FOR CONTINUOUS DUTY CYCLE

WITH NO STEAM/ WATER INJECTION IS

CALLED BASE LINE OPERATION .

IN BASE LINE OPERATION MTC.

INTERVAL BETWEEN TWO INSPECTIONS

IS THE MAXIMUM AS THE MTC. FACTOR

IS UNITY.

MTC. FCATOR FOR OVER SPEED

OPERATION OF MACHINE-

%

SPD

100 101 102 103 104 105

MF 1 1.2 1.4 1.6 1.8 2

ALL THE CASINGS STARTING FROM INLET

PLENUM TO EXHAUST CASING ARE SPLIT

AT HORIZONTAL CENTRE LINE TO

ACCESS INTERNALS FOR INSPECTION

/REPLACEMENT. BRGS., IGV, COMP.

STATOR BLADES, NOZZLES, SHROUDS

ETC, CAN BE REPLACED WITHOUT

ACTUALLY LIFTING THE TURBINE ROTOR

AS PER GE FOLLOWING PREVENTIVE MTC.

INSPECTIONS ARE CARRIED OUT ON GTs

BOROSCOPIC INSPECTION

COMBUSTION INSPECTION (CI)

HOT GAS PATH INSPECTION (HGPI)

MAJOR INSPECTION (MI)

DURING CI, FUEL NOZZLES AND

COMBUSTION CHAMBERS OF GAS

TURBINE ARE DISASSEMBLED FOR

INSPECTION AND BOROSCOPIC

INSPECTION IS CARRIED OUT FOR

COMPRESSOR AND TURBINE

PORTION

CONTD....

DURING CI FOLLOWING SPARES ARE

INSPECTED/ REPLACED

FUEL NOZZLES

COMBUSTION LINERS

TRANSITION PIECES

X. FIRE TUBES

RETAINERS

END SEAL BLOCKS

BULL HORN

END SEALS

RECOMMENDED INTERVAL FOR CI IS

AS GIVEN BELOW-

TYPE OF

INSP

RECOMMENDED HRS/STARTS

6B 9E 9FA

CI

DLN

12000/450 12000/450 8000/450

NON

DLN

12000/1200

8000/900 -

CALCULATION FOR MTC. INTERVAL FOR CI BASED ON

HRS CRITERION -

MTC. INTERVALS (HRS)= RECOMMENDED HRS

MTC. FACTOR

MTC. FACTOR = ANNUAL FACTORED HRS

ANNUAL ACTUAL HRS

ANNUAL FACTORED HRS = G+ 1.5D + 3H + 6P

ANNUAL ACTUAL HRS = G + D + H + P

G = ANNUAL HRS OF OPR. ON GAS FUEL

D = ANNUAL HRS OF OPR. ON DISTILLATE FUEL

H = ANNUAL HRS OF OPR. ON HEAVY FUEL

P = ANNUAL HRS OF OPR. ON PEAL LOAD

DURING HGPI, FUEL NOZZLES,

COMBUSTION CHAMBERS AND

TURBINE PORTION OF GAS

TURBINE ARE DISASSEMBLED FOR

INSPECTION AND BOROSCOPIC

INSPECTION IS CARRIED OUT FOR

COMPRESSOR PORTION

CONTD....

DURING HGPI FOLLOWING SPARES ARE

INSPECTED/ REPLACED

ALL THE SPARES OF CI +

BUCKETS STG .I, II & III

SHROUD STG .I, II & III

NOZZLE STG .I, II & III

VIGV & EXHAUST FRAME

BOROSCOPE INSPECTION OF COMPRESSOR

HOT GAS PATH INSPECTION

RECOMMENDED INTERVAL FOR HGPI

IS AS GIVEN BELOW-

TYPE OF INSP RECOMMENDED HRS/STARTS

6B 9E 9FA

HGPI

24000/1200 24000/900 24000/900

CALCULATION FOR MTC. INTERVAL FOR HGPI BAESD

ON HRS CRITERION -

MTC. INTERVALS (HRS)= 24000

MTC. FACTOR

MTC. FACTOR = ANNUAL FACTORED HRS

ANNUAL ACTUAL HRS

ANNUAL FACTORED HRS = G+ 1.5D + 3H + 6P

ANNUAL ACTUAL HRS = G + D + H + P

G = ANNUAL HRS OF OPR. ON GAS FUEL

D = ANNUAL HRS OF OPR. ON DISTILLATE FUEL

H = ANNUAL HRS OF OPR. ON HEAVY FUEL

P = ANNUAL HRS OF OPR. ON PEAL LOAD

HOT GAS PATH INSPECTION

DURING MAJOR INSPECTION,

FLANGE TO FLANGE OF GT IS

DISASSEMBLED/INSPECTED. IT

INCLUDES F/N, CC, TURBINE,

COMPRESSOR & BEARINGS. OTHER

AUXILIARIES AND SUPPORT SYTEM

I.E. INLET PLENUM, EXHAUST

PLENUM, OIL PUMPS, AGB ETC ARE

INSPECTED.

CONTD....

DURING MAJOR INSPECTION FOLLOWING

VITAL SPARES ARE INSPECTED/

REPLACED

ALL THE SPARES OF HGPI +

VIGV, INLET PLENUM & EXHAUST PLENUM

COMPRESSOR

TURBINE BEARINGS

AGB, MOP, AOP, EOP, ATOM. AIR COMP.

STARTING MEANS, STARTING CLUTCH

ATOM. AIR COOLER & L.O. COOLER

RECOMMENDED INTERVAL FOR MI IS

AS GIVEN BELOW-

TYPE OF

INSP

RECOMMENDED HRS/STARTS

6B 9E 9FA

MAJOR

INSP.

48,000/2,400 48,000/2,400

48,000/2,400

CALCULATION FOR MTC. INTERVAL FOR MAJOR

IISPECTION BAESD ON HRS CRITERION -

MTC. INTERVALS (HRS)= 48,000

MTC. FACTOR

MTC. FACTOR = ANNUAL FACTORED HRS

ANNUAL ACTUAL HRS

ANNUAL FACTORED HRS = G+ 1.5D + 3H + 6P

ANNUAL ACTUAL HRS = G + D + H + P

G = ANNUAL HRS OF OPR. ON GAS FUEL

D = ANNUAL HRS OF OPR. ON DISTILLATE FUEL

H = ANNUAL HRS OF OPR. ON HEAVY FUEL

P = ANNUAL HRS OF OPR. ON PEAL LOAD

LOAD Vs EXHAUST TEMPERATURE

VIBRATION LEVEL

FUEL FLOW AND ITS PRESSURE

EXHAUST TEMPERATURE & SPREAD VARIATION

START UP TIME

COASTING DOWN TIME

WHEEL SPACE TEMPERATURE

CPD & CTD

INLET AIR DIFF. PRESSURE ACROSS FILTERS

EXHAUST PRESSURE DROP

PERFORMANCE INDICATORS

INLET AIR DIFF. PRESSURE

EXHAUST GASES DIFF. PRESSURE

AMBIENT AIR TEMPERATURE

GENERATING FREQUENCE

STEAM / WATER INJECTION

INLET AIR FOGGING

TYPE OF FUEL USED

EFFECT OF DIFF. FACTORS ON

GT PERFORMANCE/ OUTPUT

INLET AIR & EXH. DIFF. PRESSURE

(FRAME 9E)

VALUE F/CONSMP OUTPUT

INLET PR

DROP

100 mm of

H2O

+ 0.4 -1.4

EXH. PR

DROP

100 mm of

H2O

+ 0.4 - 0.4

EFFECT OF INLET AIR TEMP. ON

GT PERFORMANCE/ OUTPUT

MODEL PG 9001E

INLET

TEMP

(F)

EXH.

TEMP

(F)

HEAT

RATE

(%)

OUTPUT

(%)

HEAT

CONSMP.

(%)

AIR

FLOW

(%)

20 929 97 116 112 108.5

40 939 98.5 108 106 104

60 952 100 100 100 100

80 964 102.5 94 94 95.5

100 978 105 84 88 91.5

120 993 108 77 83 87.5

MODEL PG9001E

EFFECT OF FREQUENCY ON

GT PERFORMANCE/ OUTPUT

FREQUENCY

(Hz)

OUTPUT

(%)

50.0 100

49.5 100

49.0 99

48.5 98

48.0 97

47.5 96

47.0 95

LIFE EXPECTANCY OF GT ROTOR

HRS. BASED GT ROTOR LIFE CALCULATION

ROTOR MAINTENANCE INTERVALS = 144000 HRS.

MF

MF = H + 2P + 2 TG

H + P

H = BASED LOAD HRS

P = PEAK LOAD HRS

TG = HRS ON TURNING GEAR

LIFE OF HGP SPARES

MODEL 9E

REPAIR REPLACEMENT

F/NOZZLES CI 2 (CI)/3 (CI)

COMBUSTION LINERS CI 3 (CI)/5 (CI)

TRANSITION PIECES CI 4 (CI)/6 (CI)

X- FIRE TUBES CI 2 (CI)/3 (CI)

BUCKETS STG. I, II & III HGPI 2(HGPI)/3(HGPI)

NOZZLES STG. I, II & III HGPI 3(HGPI)/3(HGPI)

SHROUDS STG. I, II & III HGPI 3(HGPI)/3(HGPI)

Probability of not being forced out of

service when unit is needed

RELIABILITY = (1- FOH /PH)X100

FOH Forced Outage Hrs.

PH Period Hrs.

Probability of being available,

independent of whether the unit is

needed.

AVAILABILITY = (1- UH /PH)X100

UH Unavailable Hrs.

PH Period Hrs.

Probability of a combined cycle power

plant not being totally forced out of

service when unit is required includes

the effect of Gas & Steam cycle MW

output contribution to plant output.

= [1-{GTFOH +B( HRSGFOH +STFOH)}X100]

GTPH BPH STPH

contd.

EQUIVALENT RELIABILITY

GTFOH = GT Forced Outage Hrs.

GTPH = GT Period Hrs.

HRSGFOH = HRSG Forced Outage Hrs.

BPH = HRSG Period Hrs.

STFOH = Steam Turbine Forced Outage Hrs.

STPH = Steam Turbine Period Hrs.

B = Steam Cycle MW output contribution

EQUIVALENT AVAILABILITY

Probability of a combined cycle power

plant available for power generation

independent of whether the unit is

needed -includes the effect of Gas &

Steam cycle MW output contribution to

plant output.

= [1-{GTUH +B( HRSGUH +STUH)}X100]

GTPH BPH STPH

contd.

EQUIVALENT AVAILABILITY

GTUH = GT Unavailable Hrs.

GTPH = GT Period Hrs.

HRSGUH = HRSG Unavailable Hrs.

BPH = HRSG Period Hrs.

STUH = Steam Turbine Unavailable Hrs.

STPH = Steam Turbine Period Hrs.

B = Steam Cycle MW output contribution

MTBF Measure of probability of

completing the current run. Failure

events are restricted to forced outages

while in service.

MTBF= SH/FO

SH Service Hrs.

FO Nos. of Forced Outages

Service Factor Measure of

operational use usually expressed on

an annual basis.

Service Factor = SH/PH X 100

SH Service Hrs.

PH Period Hrs.

OPERATING LEVERAGE

OPERATING LEVERAGE = FIXED COST

VARIABLE COST

OPERATING LEVERAGE IS GETTING

REDUCED AS THE PLANT GOES OLDER

DUE TO REDUCTION OF FIXED COST BY

WAY OF DEPRECIATION AND INCREASE

IN HEAT RATE DUE TO AGING

CONTRIBUTION FACTOR

C. FACTOR= TARIFF/KWH

VARIABLE COST/KWH

GIVE DC TO SLDC IN SUCH A WAY THAT

THE CONTRIBUTION FACTOR SHOULD

ALWAYS REMAIN POSITIVE TO AVOID

LOSSES. THIS CAN BE DONE BY LOADING

THE MACHINES OPTIMALLY AND

AVOIDING THE PARTIAL LOADING OF

MACHINES FOR LONGER DURATION.

HEAT RATE W.R.T.

LOADING

OUT PUT

(%)

HR

(1

0

C)

HR

(15

0

C)

HR

(32

0

C)

HR

(49

0

C)

120 97 99 101 103

100 99 100 102 103

80 105 106 106 107

60 115 115 115 115

40 133 133 133 133

Performance characteristics for

Frame 6 Gas Turbine at base load

Inlet temp

(C)

Ex.

Temp(C)

HR (%) HC (%) Output (%) Flow (%)

49 567 108 83 77 87

38 561 105 88 84 91

27 556 102 94 92 95

15 549 100 100 100 100

4.5 543 98 105 107 104

-6.6 537 97 112 115 109

Model ISO Rating (kw) ISO Efficiency (%)

(1) MS1002 5070 24.5

(2) MS3142(J) 10450 25.6

(3) PG5371(PA) 26300 28.5

(4) PG6581(B) 42100 32.0

(5) PG6111(FA) 75900 35.0

(6) PG9171(E) 123400 33.8

(7) PG9231(EC) 169200 34.9

(8) PG9351(FA) 255600 36.5

(9) PG9551(H) 380,000 -

Note: ISO output is : 15 deg C, 60% RH, Zero MSL, Gas fuel

and standard Inlet/Exh. Pr. drops

GE FRAME OTHER GT MODELS

OEM Conventional Advance (F/FA class)

Model GT ISO

Output

(MW)

Net CC

Efficiency

(%)

Model GT ISO

Output

(MW)

Net CC

Efficiency

(%)

GE 9E 126.10 52.7 9FA 255.6 57.1

Siemens V94.2 159.40 52.2 V94.3

A

265.9 57.3

MHI* 701DA 144.09 51.6 701F 270.3 57.0

Alstom 13E2 165.10 52.9 GT 26 263.0 56.3

FLANGE TO FLANGE VIEW OF

F CLASS GAS TURBINE

QUESTIONS ?

K. S. YADAV

Manager (M-I)

Pragati Power Station

Cell - 9717694741

email ksyadavipgcl@yahoo.co.in

Вам также может понравиться

- GearboxДокумент16 страницGearboxMehul zareОценок пока нет

- Gas Turbine Range OverviewДокумент2 страницыGas Turbine Range Overviewyourikats6161Оценок пока нет

- GT Gas Fuel and Air FlowДокумент38 страницGT Gas Fuel and Air FlowhinaОценок пока нет

- Variable Inlet Guide Vane System: GE Power SystemsДокумент4 страницыVariable Inlet Guide Vane System: GE Power Systemsanggita gigih wahyu iriawan100% (1)

- 1 151125221535 Lva1 App6892Документ40 страниц1 151125221535 Lva1 App6892Darmawan PutrantoОценок пока нет

- GE Capabilities For Ansaldo FleetДокумент17 страницGE Capabilities For Ansaldo Fleetmirphan76Оценок пока нет

- DLN1+ Combustion Upgrade Solution: Fact SheetДокумент1 страницаDLN1+ Combustion Upgrade Solution: Fact SheetAhmad Riaz KhanОценок пока нет

- Dry Low NoxДокумент10 страницDry Low NoxIvan Poma Montes100% (1)

- BHEL Gas Turbines - Correction CurvesДокумент27 страницBHEL Gas Turbines - Correction CurvesRajagopala Sarma Sundar100% (1)

- Ansaldo Energia AE94.2 Upgrading ProjectДокумент20 страницAnsaldo Energia AE94.2 Upgrading Projectvincent8295547100% (1)

- Combustion EnvelopДокумент19 страницCombustion Envelopferas_elnggar100% (1)

- Smple Cycle Thermodynamics OverviewДокумент31 страницаSmple Cycle Thermodynamics OverviewONURОценок пока нет

- Hydraulic Clearance Optimization TrainingДокумент9 страницHydraulic Clearance Optimization Trainingasodiyamech100% (1)

- Pivot Arm Turning GearДокумент24 страницыPivot Arm Turning Gearoom_tgw100% (1)

- MS5002E NewДокумент8 страницMS5002E Newecs71100% (2)

- Equipment Definition: Component LiteratureДокумент5 страницEquipment Definition: Component LiteratureAbbas AkbarОценок пока нет

- Gas Turbine - Traning Report Bhel - 14 PageДокумент14 страницGas Turbine - Traning Report Bhel - 14 PageVivek PatelОценок пока нет

- 04 - Dry Low NOxДокумент15 страниц04 - Dry Low NOxdenmas90Оценок пока нет

- Wabash Gas TurbinesДокумент16 страницWabash Gas TurbinesMadhan Kumar100% (1)

- Gas Turbine 3Документ45 страницGas Turbine 3KorichiKarim100% (1)

- GE Power Systems 7F Users Conference PresentationsДокумент27 страницGE Power Systems 7F Users Conference Presentationsatfrost4638Оценок пока нет

- Gt13e2 Gas Turbine PDFДокумент20 страницGt13e2 Gas Turbine PDFsppram0% (1)

- GT 9E StartupДокумент41 страницаGT 9E StartupNaveed IrshadОценок пока нет

- DLN Controls Code Development 9fa+ EnhancedДокумент28 страницDLN Controls Code Development 9fa+ Enhancednabil160874Оценок пока нет

- Gas TurbineДокумент14 страницGas Turbinevasanth11kv100% (2)

- GE Gas Turbine Compressor Washing GuideДокумент18 страницGE Gas Turbine Compressor Washing GuideEmadAlhosien AlhosienОценок пока нет

- Natural Gas Fuel Specifications for GE Gas TurbinesДокумент29 страницNatural Gas Fuel Specifications for GE Gas Turbinesphoenix609Оценок пока нет

- Technical Spec GE Frame 9E'S - Rev1Документ144 страницыTechnical Spec GE Frame 9E'S - Rev1Alaa Zora - OnlineОценок пока нет

- Gt13e2 Gas Turbine 2012 UpgradeДокумент2 страницыGt13e2 Gas Turbine 2012 UpgradeJJ100% (1)

- Gas Turbine Generator: A Summer Intern Project Report inДокумент43 страницыGas Turbine Generator: A Summer Intern Project Report inSantosh KondepudiОценок пока нет

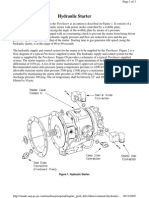

- Figure 1. Hydraulic StarterДокумент3 страницыFigure 1. Hydraulic StarterDenis JimenezОценок пока нет

- 07 Gas Turbine Valves - 0Документ14 страниц07 Gas Turbine Valves - 0VILAS VIJAYANОценок пока нет

- GE Gas Turbines Were Basically Divided Into 3 DifferentДокумент3 страницыGE Gas Turbines Were Basically Divided Into 3 Differentsaikrish36Оценок пока нет

- Mechanical Interview Questions & Answers (Gas Turbine)Документ14 страницMechanical Interview Questions & Answers (Gas Turbine)ChiduОценок пока нет

- EEI 7FA Supplement r1 2octДокумент42 страницыEEI 7FA Supplement r1 2octkshalawi0% (1)

- Gas Turbine Inle and CompressorДокумент23 страницыGas Turbine Inle and Compressorprasad5034100% (1)

- GE 7FA Flex Seal Upgrade SolutionДокумент2 страницыGE 7FA Flex Seal Upgrade SolutionPeter_Phee_341100% (1)

- File No.5 - GT Operating ManualДокумент27 страницFile No.5 - GT Operating ManualMani Kandan0% (1)

- Gas Turbine Questions and AnswersДокумент10 страницGas Turbine Questions and AnswersJêmš Navik100% (1)

- Siemens Gas Turbine Product Range Comparison 0-130 MW: For Siemens Internal Use OnlyДокумент2 страницыSiemens Gas Turbine Product Range Comparison 0-130 MW: For Siemens Internal Use Onlythunder0% (1)

- Comp Amp Turbine COURS 9001EДокумент27 страницComp Amp Turbine COURS 9001Enabil160874100% (1)

- GFA - GT Exhaust Spread ProblemДокумент5 страницGFA - GT Exhaust Spread Problemأمير معروف100% (1)

- LM6000-InD-239 - Improved LPT Coupling NutДокумент9 страницLM6000-InD-239 - Improved LPT Coupling NutIqbal UsmaniОценок пока нет

- Generator Control and Protection System PDFДокумент159 страницGenerator Control and Protection System PDFAdetunji Taiwo100% (1)

- Gas Turbine Combustion SystemДокумент14 страницGas Turbine Combustion Systemrohit uОценок пока нет

- 6 Field ExperienceДокумент9 страниц6 Field ExperiencescribdkhatnОценок пока нет

- Technical Specifications, Fuel Nozzle GR 127 PDFДокумент8 страницTechnical Specifications, Fuel Nozzle GR 127 PDFMadhan KumarОценок пока нет

- Alstom Gas-Turbines-Technical-Performance PDFДокумент2 страницыAlstom Gas-Turbines-Technical-Performance PDFPoull SteeadyОценок пока нет

- Advanced Compressor Less Purge ControlsДокумент32 страницыAdvanced Compressor Less Purge ControlsMaha BlueОценок пока нет

- GE Gas Turbine Extendor Combustion SystemДокумент2 страницыGE Gas Turbine Extendor Combustion SystemRaden Mas100% (1)

- DLN 2.0+ Fuel NozzleДокумент1 страницаDLN 2.0+ Fuel NozzleWedneslao LopezОценок пока нет

- Improving the 7FA Gas Turbine Training LessonДокумент10 страницImproving the 7FA Gas Turbine Training LessonfaisalnadimОценок пока нет

- 06 UCH GT 9001E - Inlet Filter & Duct SystemsДокумент113 страниц06 UCH GT 9001E - Inlet Filter & Duct SystemsHassan Mahmood100% (1)

- GE 9FA Water Wash PROCEDURE FinalДокумент43 страницыGE 9FA Water Wash PROCEDURE FinalAbdelaziz EldeebОценок пока нет

- Lm6000 PF Plus Fact SheetДокумент2 страницыLm6000 PF Plus Fact SheetNivaldo GarciaОценок пока нет

- CCGTДокумент74 страницыCCGTAbhishek Prakash SrivastavaОценок пока нет

- Boiler & Turbine Efficiency: Rohit Verma Dy - Director NPTI, FaridabadДокумент77 страницBoiler & Turbine Efficiency: Rohit Verma Dy - Director NPTI, FaridabadLakshya Soni100% (3)

- Gas Turbine Operation, Maintenance & InspectionДокумент57 страницGas Turbine Operation, Maintenance & Inspectionromadhinho100% (3)

- Combustion Chamber GTДокумент18 страницCombustion Chamber GTPRAVEENОценок пока нет

- EA - Turbine CycleДокумент27 страницEA - Turbine CycleMadhav Pande100% (3)

- 3boiler Steam Water Chemistry in Power PlantsДокумент22 страницы3boiler Steam Water Chemistry in Power PlantsAbhishek Prakash SrivastavaОценок пока нет

- ProtectiveДокумент1 страницаProtectiveAbhishek Prakash SrivastavaОценок пока нет

- Generator Excitaion & AVRДокумент70 страницGenerator Excitaion & AVRashumanu427100% (2)

- AOP JOP EOP turbine interlock functionsДокумент27 страницAOP JOP EOP turbine interlock functionsAbhishek Prakash SrivastavaОценок пока нет

- Water Chemistry IN Thermal Power Plants (An Overview) : O.P.RangwaniДокумент24 страницыWater Chemistry IN Thermal Power Plants (An Overview) : O.P.RangwaniAbhishek Prakash Srivastava100% (1)

- Presentation RIPДокумент26 страницPresentation RIPAbhishek Prakash SrivastavaОценок пока нет

- 2dm Plant OprДокумент25 страниц2dm Plant OprAbhishek Prakash SrivastavaОценок пока нет

- Turbine Lub Oil SysДокумент32 страницыTurbine Lub Oil SysAbhishek Prakash SrivastavaОценок пока нет

- Complete Oil AnalysisДокумент33 страницыComplete Oil AnalysisAbhishek Prakash SrivastavaОценок пока нет

- SWGRДокумент26 страницSWGRAbhishek Prakash SrivastavaОценок пока нет

- Transmission LineДокумент34 страницыTransmission LineAbhishek Prakash Srivastava100% (1)

- FACT DevicesДокумент28 страницFACT DevicesAbhishek Prakash SrivastavaОценок пока нет

- HVDC ManojДокумент81 страницаHVDC ManojAbhishek Prakash SrivastavaОценок пока нет

- KVVidyanandan document 12-21-2011Документ35 страницKVVidyanandan document 12-21-2011Abhishek Prakash SrivastavaОценок пока нет

- CCGTДокумент74 страницыCCGTAbhishek Prakash SrivastavaОценок пока нет

- Statistical Process Control (SPC)Документ28 страницStatistical Process Control (SPC)Abhishek Prakash SrivastavaОценок пока нет

- 2 Boiler HydroДокумент16 страниц2 Boiler HydroAbhishek Prakash SrivastavaОценок пока нет

- Article 3: What Is Reactive Power?Документ8 страницArticle 3: What Is Reactive Power?MAT JIBRUDОценок пока нет

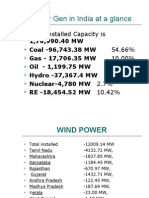

- Power GenДокумент59 страницPower GenAbhishek Prakash SrivastavaОценок пока нет

- NTPC DLN Systems VamsiДокумент13 страницNTPC DLN Systems VamsiAbhishek Prakash SrivastavaОценок пока нет

- HarmonicsДокумент2 страницыHarmonicsAbhishek Prakash SrivastavaОценок пока нет

- Energy Audit in IndustriesДокумент14 страницEnergy Audit in IndustriesAbhishek Prakash SrivastavaОценок пока нет

- ATRS Optimizes Turbine StartupДокумент47 страницATRS Optimizes Turbine StartupAbhishek Prakash Srivastava100% (1)

- Petrol Pump Hazards Risk Assessment ControlДокумент6 страницPetrol Pump Hazards Risk Assessment ControlAbhishek Prakash SrivastavaОценок пока нет

- Basic Electrical CBIP 30-05-12Документ81 страницаBasic Electrical CBIP 30-05-12Abhishek Prakash Srivastava100% (1)

- C20R Optimized Start Technique For C20 and C20RДокумент4 страницыC20R Optimized Start Technique For C20 and C20REstevamОценок пока нет

- RR300Документ4 страницыRR300mangeshbramheОценок пока нет

- Addtiopnal Comments: Item Noun Modifier Characteristics Values Additional Information Part No. Manufacturer/SupplierДокумент5 страницAddtiopnal Comments: Item Noun Modifier Characteristics Values Additional Information Part No. Manufacturer/SupplierashrafОценок пока нет

- FIS BOOK 3: AERO ENGINE (PISTON) CHAPTERSДокумент71 страницаFIS BOOK 3: AERO ENGINE (PISTON) CHAPTERSabhishek soniОценок пока нет

- Aircraft Propulsion-2Документ222 страницыAircraft Propulsion-2Aghil Buddy100% (2)

- Rotating Equipment OverviewДокумент106 страницRotating Equipment OverviewInamullah Khan0% (1)

- Pre Feasibility Study Mundargi Gas Based Power PlantДокумент71 страницаPre Feasibility Study Mundargi Gas Based Power Plantrrs41100% (1)

- MS5001 PA Complete Maintenance MANUALДокумент989 страницMS5001 PA Complete Maintenance MANUALarabi222295% (57)

- Gas Turbine Inlet Air Cooling TechnologyДокумент12 страницGas Turbine Inlet Air Cooling TechnologyAndry KurniaОценок пока нет

- An Introduction To Computational Fluid Dynamics - VersteegДокумент267 страницAn Introduction To Computational Fluid Dynamics - Versteegkelvinhoh83100% (12)

- Gas Turbine Simulation Model Performance AnalysisДокумент6 страницGas Turbine Simulation Model Performance AnalysisMuhammad Redzuan33% (3)

- Overview of StartupДокумент3 страницыOverview of StartupUr FriendОценок пока нет

- Exploring in AeronauticsДокумент408 страницExploring in AeronauticsBob AndrepontОценок пока нет

- #4 TV2 - TV3 Turboshaft Engine Journal IJRPR6639Документ17 страниц#4 TV2 - TV3 Turboshaft Engine Journal IJRPR6639Lijalem GebrehiwetОценок пока нет

- Woodward - Catalogo de Productos PDFДокумент40 страницWoodward - Catalogo de Productos PDFgabrielОценок пока нет

- Frame 5/2E Gas Turbine (33.8 MW, 50/60 HZ) : Heavy-Duty Power With Aero EfficiencyДокумент7 страницFrame 5/2E Gas Turbine (33.8 MW, 50/60 HZ) : Heavy-Duty Power With Aero EfficiencyhasnaОценок пока нет

- Ae2304 LPДокумент3 страницыAe2304 LPUmayal GaneshОценок пока нет

- 001 Turbo ChargerДокумент26 страниц001 Turbo ChargerfrankОценок пока нет

- Zorya Mashproekt Gas Pipelines 2016 1Документ12 страницZorya Mashproekt Gas Pipelines 2016 1jmpandolfi100% (1)

- Power Plant Design InformationДокумент47 страницPower Plant Design InformationSISWANTO100% (1)

- Marine Propulsion SystemsДокумент5 страницMarine Propulsion SystemsIbrahim SameirОценок пока нет

- Gas Turbine Guide: Introduction, Components, Performance & ApplicationsДокумент34 страницыGas Turbine Guide: Introduction, Components, Performance & ApplicationsDiogo MonteiroОценок пока нет

- Gas T Gas Tur Urbin Bines Es: Perfor Performance T Mance Test Codes Est CodesДокумент83 страницыGas T Gas Tur Urbin Bines Es: Perfor Performance T Mance Test Codes Est CodesAmit Kumar100% (2)

- 1 - 5071382346712744122 Mech NotesДокумент22 страницы1 - 5071382346712744122 Mech NoteskadarОценок пока нет

- Turbomachines: Credits - 3Документ49 страницTurbomachines: Credits - 3nico NicoОценок пока нет

- Evolution of Superalloy Turbine BladesДокумент20 страницEvolution of Superalloy Turbine BladesCaio Fazzioli TavaresОценок пока нет

- PapersДокумент57 страницPapersMOHANBALAJIECEОценок пока нет

- Stec Redgate Wartsila Power PlantДокумент13 страницStec Redgate Wartsila Power PlantJarvi Al habibiОценок пока нет

- Air Standard Assumptions:: EN560: Foundation For Energy TechnologyДокумент5 страницAir Standard Assumptions:: EN560: Foundation For Energy TechnologypoojaОценок пока нет

- Commissioning Manual (Rev 4, 10-6-06) Tp60Документ321 страницаCommissioning Manual (Rev 4, 10-6-06) Tp60Ismar Adrian100% (4)