Академический Документы

Профессиональный Документы

Культура Документы

Statistical Process Control (SPC)

Загружено:

Abhishek Prakash Srivastava0 оценок0% нашли этот документ полезным (0 голосов)

53 просмотров28 страницThis document discusses Statistical Process Control (SPC). It defines SPC and outlines its objectives, including increasing knowledge of processes, reducing variation, and improving performance. Key concepts discussed include processes, variation, distributions, stability, common vs special causes, process control, and process capability. The document provides detailed explanations of these concepts and their importance in quality control.

Исходное описание:

Авторское право

© © All Rights Reserved

Доступные форматы

PPT, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документThis document discusses Statistical Process Control (SPC). It defines SPC and outlines its objectives, including increasing knowledge of processes, reducing variation, and improving performance. Key concepts discussed include processes, variation, distributions, stability, common vs special causes, process control, and process capability. The document provides detailed explanations of these concepts and their importance in quality control.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PPT, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

53 просмотров28 страницStatistical Process Control (SPC)

Загружено:

Abhishek Prakash SrivastavaThis document discusses Statistical Process Control (SPC). It defines SPC and outlines its objectives, including increasing knowledge of processes, reducing variation, and improving performance. Key concepts discussed include processes, variation, distributions, stability, common vs special causes, process control, and process capability. The document provides detailed explanations of these concepts and their importance in quality control.

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PPT, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 28

Statistical Process Control (SPC)

QUALITY CIRCLE FORUM OF INDIA

VADODARA CHAPTER

612, Bluechip Business Centre, Near Vadodara Stock Exchange,

Sayajigunj, Vadodara 390 005

Telefax:0265-2361184, Phone: 0265-6596140

E-mail : qcfi2000@yahoo.com

PRESENTED BY

QCFI/SPC-Eng/SCP/1 of 28/12-12-2006

Statistical Process Control (SPC)

1. OBJECTIVES OF SCP

1.1 General Objectives :

One or more of the following objectives

To increase knowledge about the process

To Steer a process to behave in the desired

way

To reduce variation in final product

To improve performance of a process

QCFI/SPC-Eng/SCP/2 of 28/12-12-2006

Statistical Process Control (SPC)

1.2 Specific objectives:

Considerations :

The market being served

Nature of the product

Process technology

Customer needs

Effective implementation of SPC reduces cost

and increase profile How?

QCFI/SPC-Eng/SCP/3 of 28/12-12-2006

Statistical Process Control (SPC)

1.2 Specific objectives: (Contd...)

By managing the process more economically aiming

at greater consistency and improvement.

By reducing variation around a target value in either

a final product or process output parameter.

By transferring variation in an in-process product

parameter to a controllable or manipulated process

variable.

By providing signals and evidence of how a process is

behaving and how it is likely to behave.

QCFI/SPC-Eng/SCP/4 of 28/12-12-2006

Statistical Process Control (SPC)

1.2 Specific objectives: (Contd...)

By assessing and quantifying what quality and

consistency level the process is currently capable of

producing.

By identifying when and where to look for special

causes and / or make preventive process adjustments

and when not to.

By pointing to potential root causes or failure modes

and their sources.

By identifying sources of poor yield and variability

and detecting special causes for the same.

QCFI/SPC-Eng/SCP/5 of 28/12-12-2006

Statistical Process Control (SPC)

1.2 Specific objectives: (Contd...)

By increasing speed of detection and reduce trouble

shooting costs.

By controlling and / or reducing common cause

variation through process design changes and other

system changes to procedures.

By increasing knowledge of how the system of causes

affects the process, to help make improvements to the

process.

SPC IS A STRATEGY FOR DEFECT PREVENTION

QCFI/SPC-Eng/SCP/6 of 28/12-12-2006

Statistical Process Control (SPC)

2. CONCEPTS :

In implementing SPC we need to understand following

concepts / terms

Process

Variation

Distribution

Stability

Common causes & special causes

Process control

Process capability

QCFI/SPC-Eng/SCP/7 of 28/12-12-2006

Statistical Process Control (SPC)

2.1 Process :

Transformation

Activities

People

Equipment

Materials

Methods

Documents /

Specifications

Products /

Services

A process is a set of interrelated or interacting activities

which transform inputs into outputs.

QCFI/SPC-Eng/SCP/8 of 28/12-12-2006

Statistical Process Control (SPC)

2.1 Process : (Contd...)

Process performance has to be monitored, to help

timely corrective actions to control the process.

Information about process performance can be had

from process characteristics e.g. Temperature, Cycle

time, Feed rate etc.

Target values for process characteristics are to be set

and monitoring is to be done to see whether actual

process confirms to these targets, to what extent.

Timely action is then taken if needed.

QCFI/SPC-Eng/SCP/9 of 28/12-12-2006

Statistical Process Control (SPC)

2.1 Process : (Contd...)

Action on the process Vs Action on the output

Action on the process is generally most economical

for defect prevention strategy. This helps in stability

and control of variation of process output within

acceptable limits.

Action on the output is generally least economical

when used to defect and to correct out of

specification product.

QCFI/SPC-Eng/SCP/10 of 28/12-12-2006

Statistical Process Control (SPC)

2.2 Variation :

Basic to process control is the concept of

variation.

Not two products or characteristics are exactly

alike because process contains many sources

of variability.

The difference among products may be large

or immeasurably small, but they always exist.

QCFI/SPC-Eng/SCP/11 of 28/12-12-2006

Statistical Process Control (SPC)

2.2 Variation: (Contd...)

Example: A machined shaft diameter; potential

sources of variation.

Machine : Clearances, Bearing wear

Tool : Strength, Rate of wear

Material : Diameter, Hardness

Operator : Part feed, Speed accuracy of centering

Maintenance : Lubrication, Replacement of worn out

: parts

Environment : Temperature consistency of power supply.

QCFI/SPC-Eng/SCP/12 of 28/12-12-2006

Statistical Process Control (SPC)

2.2 Variation : (Contd...)

Variation over time :

Some sources of variation in the process cause short

term piece to piece difference.

Other sources of variation tend to cause changes in

the output only over a long period of time either

gradually or stepwise or irregularly.

Hence time period and conditions over which

measurement are taken will affect total variation.

QCFI/SPC-Eng/SCP/13 of 28/12-12-2006

Statistical Process Control (SPC)

2.2 Variation : (Contd...)

View of Variation:

From requirements point of view, products

within specification limits are acceptable and

those beyond specification limits are not

acceptable.

To manage any process and reduce variation it

must be traced to sources. The causes of

variation are distinguished as COMMON

causes and SPECIAL causes.

QCFI/SPC-Eng/SCP/14 of 28/12-12-2006

Statistical Process Control (SPC)

2.3 Distribution :

While individual measured values may all be different, as a

group they tend to exhibit a pattern. This is called

DISTRIBUTION.

It can be desired by:

Location (Process level or centering)

Spread or dispersion (Range of values from smallest to

largest.)

Shape (Pattern of variation, whether symmetrical or

skewed etc.)

Any changes either in location or spread or dispersion or

shape indicates changes of process performance. No change

in these implies stability and therefore repeatability of the

process.

QCFI/SPC-Eng/SCP/15 of 28/12-12-2006

Statistical Process Control (SPC)

2.3 Distribution : (Contd...)

Changes In Distribution Location

A: Original Process B: Process Level Shifted

A B

Shift in Process Level

QCFI/SPC-Eng/SCP/16 of 28/12-12-2006

Statistical Process Control (SPC)

A

B

Change in Process Spread / Range

2.3 Distribution : (Contd...)

Changes In Distribution Spread

A: Original Process B: Increase in spread with

same location

QCFI/SPC-Eng/SCP/17 of 28/12-12-2006

Statistical Process Control (SPC)

A

B

Change in Shape Pattern of Variation

2.3 Distribution : (Contd...)

Changes In Distribution Shape

A: Original Symmetrical Pattern

B: Pattern is skewed

QCFI/SPC-Eng/SCP/18 of 28/12-12-2006

Statistical Process Control (SPC)

When distribution remains unchanged over a period of

time, then process is said to be stable and Repeatable

(When only common causes are present in the process).

2.4 Stability :

Time

Target

QCFI/SPC-Eng/SCP/19 of 28/12-12-2006

Statistical Process Control (SPC)

2.5 Common Causes :

They are minute and many and individually may not be

measurable.

The resulting pattern under the influence of common

causes is called State of Stastical Control or just

In Control.

The advantages of maintaining a state of statistical

control are:

Variation is restricted.

Process is repeatable.

Quality of future production can be predicted.

QCFI/SPC-Eng/SCP/20 of 28/12-12-2006

Statistical Process Control (SPC)

2.5 Special Causes :

When they occur, they make the overall process

distribution change. Unless they are arrested they will

continue to affect the process output in unpredictable

ways.

Changes in process pattern due to special causes can be

either detrimental or beneficial. When detrimental they

need to be identified and eliminated. When beneficial

they need to be continued by making them a permanent

part of the process.

QCFI/SPC-Eng/SCP/21 of 28/12-12-2006

Statistical Process Control (SPC)

2.6 Process Control :

This is the state where only common causes are present.

The proof of this is when the pattern of variation

conforms to the statistical normal distribution.

It involves continuous monitoring of the process for

special causes and eliminating them.

Evidence of special causes is provided by the changes in

process distribution.

QCFI/SPC-Eng/SCP/22 of 28/12-12-2006

Statistical Process Control (SPC)

2.7 Process Capability :

The ability of a process to produce within the variation

permitted by tolerance is called process capability.

The process control and process capability are

different.

Process control is basic and is required for stability

of a process.

Process capability is containment of common cause

variation substantially within the range provided by

the tolerance.

QCFI/SPC-Eng/SCP/23 of 28/12-12-2006

Statistical Process Control (SPC)

2.7 Process Capability : (Contd...)

LSL USL

Process is in Control (Stable) and Capable

QCFI/SPC-Eng/SCP/24 of 28/12-12-2006

Statistical Process Control (SPC)

2.7 Process Capability : (Contd...)

LSL USL

Process is in Control but not

satisfactory (Capable)

QCFI/SPC-Eng/SCP/25 of 28/12-12-2006

Statistical Process Control (SPC)

2.7 Process Capability : (Contd...)

LSL USL

Process is capable but not in control because

process level is not properly centered.

QCFI/SPC-Eng/SCP/26 of 28/12-12-2006

Statistical Process Control (SPC)

2.7 Process Capability : (Contd...)

LSL USL

Process not in control and not capable

QCFI/SPC-Eng/SCP/27 of 28/12-12-2006

Statistical Process Control (SPC)

Process

Capability

Process

In Control

Process

Out of Control

Capable Acceptable Not acceptable

Not capable Not acceptable Not acceptable

QCFI/SPC-Eng/SCP/28 of 28/12-12-2006

Вам также может понравиться

- MHS 06. Statistical Process Control-KWOДокумент55 страницMHS 06. Statistical Process Control-KWOKevin SinagaОценок пока нет

- Statistical Quality ControlДокумент56 страницStatistical Quality ControlcmukherjeeОценок пока нет

- Statistical Process ControlДокумент37 страницStatistical Process ControlGyanesh_DBОценок пока нет

- MeasurementSystemsAnalysis PDFДокумент37 страницMeasurementSystemsAnalysis PDFJorge MartinezОценок пока нет

- A Reduced-Scale Brake Dynamometer For Friction Characterization PDFДокумент7 страницA Reduced-Scale Brake Dynamometer For Friction Characterization PDFashwaniОценок пока нет

- Chapter 3 - Control Chart For VariablesДокумент66 страницChapter 3 - Control Chart For VariablesSultan Almassar100% (1)

- How To Conduct A Measurement Systems AnalysisДокумент5 страницHow To Conduct A Measurement Systems AnalysisNavnath TamhaneОценок пока нет

- QMS Awareness ProgramДокумент9 страницQMS Awareness ProgramshravandownloadОценок пока нет

- Q M S (QMS) : Uality Anagement YstemДокумент37 страницQ M S (QMS) : Uality Anagement YstemDaud AliОценок пока нет

- Bias and Accuracy Definition PDFДокумент7 страницBias and Accuracy Definition PDFVallik TadОценок пока нет

- PPT4-Statistical Process Control and Capability AnalysisДокумент120 страницPPT4-Statistical Process Control and Capability AnalysisDini MaharОценок пока нет

- Audit SkillsДокумент36 страницAudit SkillsSudhagarОценок пока нет

- Sampling Plans: Trainer: Balakrishnan Srinivasan Position: Process and Quality Improvement ExecutiveДокумент31 страницаSampling Plans: Trainer: Balakrishnan Srinivasan Position: Process and Quality Improvement ExecutiveBALAKRISHNANОценок пока нет

- TQM Six SigmaДокумент22 страницыTQM Six SigmaVaibhav Vithoba NaikОценок пока нет

- Quality Management SystemДокумент29 страницQuality Management SystemArunОценок пока нет

- Dead Endclamp Failure AnalysisДокумент26 страницDead Endclamp Failure AnalysisRK KumarОценок пока нет

- Statistical Process ControlДокумент77 страницStatistical Process ControlMahender KumarОценок пока нет

- Lec 5 Variables Control ChartДокумент48 страницLec 5 Variables Control ChartAldwin Angelo Culing MontañezОценок пока нет

- Statistical Quality Control VariableДокумент53 страницыStatistical Quality Control VariableMalaika Qaiser100% (1)

- Calibration TerminologyДокумент15 страницCalibration TerminologyDavid GaryОценок пока нет

- ISO 14000 Quality StandardsДокумент4 страницыISO 14000 Quality Standardsmastercontroldotcom100% (1)

- Lot Acceptance Sampling PlanДокумент17 страницLot Acceptance Sampling PlanRajesh SarkarОценок пока нет

- Process and Measurement System Capability AnalysisДокумент18 страницProcess and Measurement System Capability AnalysisUtkarsh MittalОценок пока нет

- Global Supplier Standards Manual Quality Expectations SectionДокумент18 страницGlobal Supplier Standards Manual Quality Expectations Sectionamhosny64Оценок пока нет

- Understanding Quality Assurance in Construction: Pages 3-10Документ4 страницыUnderstanding Quality Assurance in Construction: Pages 3-10hmd rasikaОценок пока нет

- Basic Principles of GMP: Qualification and ValidationДокумент28 страницBasic Principles of GMP: Qualification and Validationhyde2520015754100% (1)

- List of PPAP DocsДокумент4 страницыList of PPAP DocsSunilОценок пока нет

- Basic Management Principles PDFДокумент88 страницBasic Management Principles PDFDaveP.100% (1)

- Six Sigma Math Primer PDFДокумент16 страницSix Sigma Math Primer PDFajayikayode100% (1)

- NEET Chemistry Syllabus 2024Документ14 страницNEET Chemistry Syllabus 2024jyotisharma20577Оценок пока нет

- CQEДокумент2 страницыCQEfaizanAkhtarОценок пока нет

- Statistic ProcessДокумент39 страницStatistic ProcessxredjokerxОценок пока нет

- Supplier Quality ManagerДокумент7 страницSupplier Quality ManagersaravanakumarpalaniОценок пока нет

- EPRI Supplier Performance Base AuditДокумент84 страницыEPRI Supplier Performance Base AuditixoteeОценок пока нет

- The 7 Basic Quality Tools: Michele CanoДокумент60 страницThe 7 Basic Quality Tools: Michele Canoeko4fxОценок пока нет

- 7 QC ToolsДокумент81 страница7 QC ToolsDonny Agus PrasetyoОценок пока нет

- Internal Auditors Competence Assessment Test-2015: What Is ISO/TS16949:2009?Документ4 страницыInternal Auditors Competence Assessment Test-2015: What Is ISO/TS16949:2009?Rohit SoniОценок пока нет

- Audit Results Summary SQI Rev 0Документ3 страницыAudit Results Summary SQI Rev 0Karen Feyt Mallari100% (1)

- 4 Aa Process CapabilityДокумент30 страниц4 Aa Process CapabilityAniket Jain100% (2)

- Control Charts and Process Control in SAPДокумент18 страницControl Charts and Process Control in SAPDebasish Behera100% (1)

- NOTES Software Quality ManagementДокумент382 страницыNOTES Software Quality Managementgirish_kodagantiОценок пока нет

- Statistical Methods For Quality ControlДокумент2 страницыStatistical Methods For Quality ControlAntonio Lara0% (1)

- Total Quality MangementДокумент129 страницTotal Quality Mangementzenjoy57100% (1)

- Red Flags SurveyДокумент6 страницRed Flags Surveyhmp90Оценок пока нет

- Statistical Process ControlДокумент79 страницStatistical Process ControlKrunal PandyaОценок пока нет

- Statistical Process Control: Douglas M. Stewart, Ph.D. The Anderson Schools of Management The University of New MexicoДокумент68 страницStatistical Process Control: Douglas M. Stewart, Ph.D. The Anderson Schools of Management The University of New Mexicoenzo atsituabОценок пока нет

- CRM in Quality Assurance of Testing LaboratoriesДокумент39 страницCRM in Quality Assurance of Testing LaboratoriesLeonardo Vence OrdoñezОценок пока нет

- Shainin Techniques PDFДокумент4 страницыShainin Techniques PDFrm_muruganОценок пока нет

- What Is A GageДокумент12 страницWhat Is A GageMohini MaratheОценок пока нет

- Capability Analysis and MSA IntroductionДокумент27 страницCapability Analysis and MSA IntroductionJosé María MorenoОценок пока нет

- 21.measurement System Analysis (MSA) Course OutlineДокумент3 страницы21.measurement System Analysis (MSA) Course OutlineeddiekuangОценок пока нет

- Supplier Change Request (SCR) : InstructionsДокумент2 страницыSupplier Change Request (SCR) : Instructionsbackup hmnthОценок пока нет

- Qauality Control Level 1Документ20 страницQauality Control Level 1habtemariam molla100% (1)

- Ansi Asq Z1 4-2003Документ96 страницAnsi Asq Z1 4-2003Lizbeth Rodriguez100% (1)

- Statistical Process ControlДокумент24 страницыStatistical Process ControlAnoopa Narayan100% (1)

- Generator Excitaion & AVRДокумент70 страницGenerator Excitaion & AVRashumanu427100% (2)

- Presentation RIPДокумент26 страницPresentation RIPAbhishek Prakash SrivastavaОценок пока нет

- 3boiler Steam Water Chemistry in Power PlantsДокумент22 страницы3boiler Steam Water Chemistry in Power PlantsAbhishek Prakash SrivastavaОценок пока нет

- 2dm Plant OprДокумент25 страниц2dm Plant OprAbhishek Prakash SrivastavaОценок пока нет

- Water Chemistry IN Thermal Power Plants (An Overview) : O.P.RangwaniДокумент24 страницыWater Chemistry IN Thermal Power Plants (An Overview) : O.P.RangwaniAbhishek Prakash Srivastava100% (1)

- Governing KWU CBT VidyasДокумент35 страницGoverning KWU CBT VidyasAbhishek Prakash SrivastavaОценок пока нет

- Aop Jop Eop InterlocksДокумент27 страницAop Jop Eop InterlocksAbhishek Prakash SrivastavaОценок пока нет

- Energy Audit in IndustriesДокумент14 страницEnergy Audit in IndustriesAbhishek Prakash SrivastavaОценок пока нет

- CCGTДокумент74 страницыCCGTAbhishek Prakash SrivastavaОценок пока нет

- Petrol Pump Hazard Identification & Operation Control ProcedureДокумент6 страницPetrol Pump Hazard Identification & Operation Control ProcedureAbhishek Prakash SrivastavaОценок пока нет

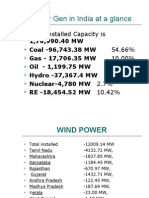

- Power GenДокумент59 страницPower GenAbhishek Prakash SrivastavaОценок пока нет

- GT Mtc. PracticesДокумент59 страницGT Mtc. PracticesAbhishek Prakash SrivastavaОценок пока нет

- ATRSДокумент47 страницATRSAbhishek Prakash Srivastava100% (1)

- Basic Electrical CBIP 30-05-12Документ81 страницаBasic Electrical CBIP 30-05-12Abhishek Prakash Srivastava100% (1)

- HarmonicsДокумент2 страницыHarmonicsAbhishek Prakash SrivastavaОценок пока нет

- Rewoquat We 45 TDS 12 02 01Документ3 страницыRewoquat We 45 TDS 12 02 01chintanictОценок пока нет

- Op Amp AssignmentДокумент10 страницOp Amp AssignmentJuan-Wian CoetzerОценок пока нет

- TM 55 1520 400 14 PDFДокумент227 страницTM 55 1520 400 14 PDFOskar DirlewangerОценок пока нет

- ASTM D4852-88 (Reapproved 2009) E1Документ3 страницыASTM D4852-88 (Reapproved 2009) E1Sandra LopesОценок пока нет

- A. Questions: Conversation Activities - TravelДокумент11 страницA. Questions: Conversation Activities - TravelkicsirekaОценок пока нет

- TM 55 1520 236 23P 1Документ843 страницыTM 55 1520 236 23P 1Tod A. Wulff100% (1)

- 1 An Introduction Basin AnalysisДокумент29 страниц1 An Introduction Basin AnalysisMuhamadKamilAzharОценок пока нет

- Amenzade Yu.a. - Theory of Elasticity-Mir (1979)Документ284 страницыAmenzade Yu.a. - Theory of Elasticity-Mir (1979)Javier100% (1)

- 09.3090 USTR2433b T Series Cassettes Omega IFU enДокумент51 страница09.3090 USTR2433b T Series Cassettes Omega IFU enAdi SaputraОценок пока нет

- MKRS Training ProfileДокумент10 страницMKRS Training ProfileZafri MKRS100% (1)

- April262019 Airline Economic Analysis 2018-2019vfwebДокумент62 страницыApril262019 Airline Economic Analysis 2018-2019vfwebapi-548139140Оценок пока нет

- S01 Hydraulic and Eletric DiagramДокумент18 страницS01 Hydraulic and Eletric DiagramgadeharogОценок пока нет

- Untitled DocumentДокумент6 страницUntitled DocumentrameezshyamaleeОценок пока нет

- Bruce Lyon - Occult CosmologyДокумент55 страницBruce Lyon - Occult Cosmologyeponymos100% (1)

- 14 Parabola Formula Sheets QuizrrДокумент9 страниц14 Parabola Formula Sheets QuizrrChandanОценок пока нет

- Homework 3rd SteelДокумент4 страницыHomework 3rd SteelPiseth HengОценок пока нет

- CO3053 - Lecture 1 - What Is Embedded SystemДокумент21 страницаCO3053 - Lecture 1 - What Is Embedded SystemKhánh Tôn Thất PhúcОценок пока нет

- Estericlean Agroalimentaria Registro NSFДокумент1 страницаEstericlean Agroalimentaria Registro NSFwilber jovany monzon uriasОценок пока нет

- Squad3.fire NSD GPMДокумент7 страницSquad3.fire NSD GPMMac CorpuzОценок пока нет

- GalvInfoNote 1 4Документ4 страницыGalvInfoNote 1 4rplata63Оценок пока нет

- Interference Measurement SOP v1.2 Sum PDFДокумент26 страницInterference Measurement SOP v1.2 Sum PDFTeofilo FloresОценок пока нет

- Alum Rosin SizingДокумент9 страницAlum Rosin SizingAnkit JainОценок пока нет

- Deep Carbon ObservatoryДокумент90 страницDeep Carbon ObservatorygoblinОценок пока нет

- Galactic Federations, Councils Secret Space Programs (Michael Salla) (Z-Library)Документ289 страницGalactic Federations, Councils Secret Space Programs (Michael Salla) (Z-Library)Junior VeigaОценок пока нет

- Comparative Study of Conventional and Generative Design ProcessДокумент11 страницComparative Study of Conventional and Generative Design ProcessIJRASETPublicationsОценок пока нет

- Defeat Cancer NaturallyДокумент94 страницыDefeat Cancer NaturallyRknuviprasys Low100% (3)

- 4.5.redistrribution - PBR Quiz AnswersДокумент4 страницы4.5.redistrribution - PBR Quiz AnswersffbugbuggerОценок пока нет

- Exam of Refinery PDF 2Документ20 страницExam of Refinery PDF 2ئارام ناصح محمد حسێن0% (1)

- Elementary Statistics A Step by Step Approach 9th Edition Bluman Solutions ManualДокумент23 страницыElementary Statistics A Step by Step Approach 9th Edition Bluman Solutions Manuala305894328100% (3)

- CMC 2023 Senior Category Question BankДокумент5 страницCMC 2023 Senior Category Question BankNikita AgrawalОценок пока нет