Академический Документы

Профессиональный Документы

Культура Документы

QA: 5S Improvement Techniques: Contributing To The Application of Workplace Organisation Techniques

Загружено:

Rashid Ghani0 оценок0% нашли этот документ полезным (0 голосов)

128 просмотров58 страниц5S Presentation Slide

Оригинальное название

5S

Авторское право

© © All Rights Reserved

Доступные форматы

PPT, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документ5S Presentation Slide

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PPT, PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

128 просмотров58 страницQA: 5S Improvement Techniques: Contributing To The Application of Workplace Organisation Techniques

Загружено:

Rashid Ghani5S Presentation Slide

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PPT, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 58

QA: 5S Improvement Techniques

Contributing to the Application of Workplace

Organisation Techniques

Aim of the Unit

The aim of this QA Unit is to give the learner the

knowledge and understanding required to apply the

principles and techniques of workplace organisation,

as embodied within the concepts of 5C/5S.

2

Workplace organisation structure of the

Unit

Aims and objectives of Unit

Learning outcomes

Introduction to 5C/5S

The 5Cs/5Ss

What are they?

How to implement

Auditing the 5C/5S workplace standard

The outcomes of 5C/5S

Successfully implementing 5C/5S

Health and safety considerations

Links with 8W, visual management and standardised work

3

Objectives of the Unit

to understand the importance or 5C/5S and how this concept can be applied

to define and describe the principles of effective workplace organisation as

embodied within the concept of 5C/5S

to demonstrate the application of 5C/5S techniques

to describe why and how the 5C/5S standard within the workplace should be

audited

to define the importance of 5C/5S and understand how to sustain the 5C/5S

process

to understand the health and safety benefits to be gained

to understand how 5C/5S encourages teamwork

4

Learning outcomes

After completing the Unit, you should:

understand the importance of effective workplace

organisation and be able to describe each of the 5Cs/5Ss

understand the process and implications of applying

5C/5S to the workplace

have carried out a 5C/5S activity, probably as part of a

team, to improve the organisation of a work area

be confident that you could repeat the application of the

principles and techniques of 5C/5S to another area

5

Poor workplace organisation

Does any of this look

familiar?

What issues would

result?

Office:

6

Impact of poor organisation

Typical issues:

untidy, clutter, obstacles to workflow

poor image

time wasted searching for things

plant and equipment not positioned to support efficient working

damaged materials

over production/over ordering

potential health and safety issues

poor housekeeping

difficult to see the status of things stock levels

would create inefficiency or waste

impacts on other processes

7

Possible workplace organisation projects

There are many ways in which the organisation of a

workplace can be improved through the use of a variety of

tools:

works planning and programming

layouts and flow (spaghetti) diagrams

standardising work operations

process mapping

But one tool has been specifically designed to improve this

and is known as 5C/5S.

8

5C/5S

The first building block of lean/continuous

improvement

9

5C/5S definition

A structured method for achieving, maintaining and

improving the standard setup, organisation, layout and

control of a work area, so as to ensure safe and efficient

operations with minimum waste.

10

Introducing 5C/5S

The concept of 5C/5S is generally regarded to have originated

from the Japanese automotive industry, and is considered one

of the fundamental building blocks for an organisation striving

to establish lean practices and a culture of continuous

improvement.

Importance

safety, quality, delivery, cost, client satisfaction

sets standards a reflection of how the product/service or

project will be managed/delivered

mindset

image

11

5C / 5S

The original Japanese 5Ss have been adopted and adapted by

Western industries. The translations and basic meanings are

shown in the table.

12

The purpose of 5C/5S

to improve the organisation and working standards of the

work environment

to create a work environment that supports safe working

practices, right first time quality and efficient, productive

working

to provide the basis for other building blocks

13

Health and safety and the 5C/5S process

Carry out a health and safety risk assessment in the work area.

What are the hazards within the target area?

Ensure that all health and safety requirements are met and

understood by everyone involved in the process improvement

activity.

Identify and provide the necessary personal protective

equipment.

Does the team require any further health and safety training?

14

5C/5S

Carrying out a 5C/5S

15

You cant see the wood for

the trees

Remove those items from the workplace that are not

essential to enable the work activity to be carried out.

1. Clear-out/sort

16

1. Clear-out/sort

Clear-out/sort non-essential items (eg tools, equipment,

inventory, paper, rubbish, furniture).

By being present, such non-essential items:

create clutter

can create unsafe working conditions

take up space

can hinder efficient operations

often will be moved from one place to the next

can hide other problems within the work place

17

Designate an area to which all items will be cleared to.

Direct the team on health and safety considerations and how

the activity will be run.

Log all items as they are cleared from the work area.

Red-tag any items that are in a poor condition.

1. Clear-out/sort how do we do it?

18

1. Clear-out/sort how do we do it?

As items are cleared/sorted, and prior to putting back into

the work environment, clean and check:

Make sure the work area and necessary items in as-new

condition

health and safety

efficient operation

makes problems visible

Set the standard condition

Red-tag any items that are in a poor state of repair, etc

Check the condition of all items being put back.

19

1. Clear-out/sort

5C/5S applied to an

office work area

5C/5S applied to a

construction site stores

In one such clear-out

activity in a small office

area, 12 bin sacks were

filled with unnecessary

items!

20

2. Configure/straighten

The orderly organisation of those items that are necessary to

complete the work activity, in a way that ensures safe and

efficient operations, which can be repeated with minimal waste.

A place for everything and everything in its place

21

2. Configure/straighten how do we do it?

1. Identify where to locate each necessary item:

Establish where best to place or store an item, to support

efficient work activity.

Think about how often the item is used.

Consider safe working and minimise bending, reaching,

twisting, etc.

Consider the whole work area and the location of items to

fit with the typical work pattern aim to support efficient

workflow.

22

One step rule:

Ideally nothing stored more than a step away.

Improve efficiency by eliminating time lost looking for items.

30 second rule:

Organise workplace to allow any tool, information or material to

be located and retrieved within 30 seconds. This includes

computer files!

45 degree rule:

Immediate work area layout to minimise twisting.

Strike zone rule:

Store things above the knees and below the chest.

The higher the pounds, the closer to the knuckles:

Locate heavy items to eliminate bending, stooping or unnecessary

arm movements during lifting.

Criteria to help effective configuring

23

2. Configure/straighten how do we do it?

2. Use visual methods to clearly show where each item should

be located:

labels showing name, ID number, etc

shadow boards

floor tape, painted lines and footprints

colour coding

24

2. Configure/straighten how do we do it?

3. Establish ways, preferably visual methods, to manage the

replenishment of regularly used items including materials

and consumables:

determine the lead times for replenishment

set and clearly shown maximum storage quantities and the

point at which an item needs to be re-ordered (ie the

minimum level or re-order point)

min-max labelling

two-bin replenishment system when the first bin is

emptied this is the signal to refill it

25

2. Configure/straighten

A configured/straightened site:

racked-out

stored items have a designated location

locations are labelled:

description

part/order number

min and max storage quantities

area is clean and tidy

lighting helps to improve the storage

environment and standard

What impression does this give?

Would you waste time searching for the

item you want?

Sets the standard for workplace

layout and organisation

26

Configure before and after

items stored with no defined location

What is the stock status?

items have clearly

defined locations

labels used to

indicate what should

be at each location and

the storage quantities

Configuring an office stationery cupboard

27

3. Clean and check/shine

Clean and check (or shine), is used to ensure that items are clean

and ready to be used. Regular, ideally daily, clean and check

activities are carried out to maintain the 5C standards for

cleanliness and workplace organisation.

Keep things clean and in good working order

Clean on the surface! Check uncover the

problems

28

3. Clean and check/shine

Undertake regular clean and check activities.

Ensure that items are clean and ready to be used as new:

identify any abnormal conditions (red-tag)

items missing, damaged or broken

Check for safe operating conditions.

Maintain the 5C/5S standards for cleanliness and workplace

organisation.

Keep things clean and in good working order

29

3. Clean and check/shine

Regular clean and check activity, carried out by the people who

operate within the workplace, will create ownership and make

people aware of any issues.

Aim to make the cleaning activity part of every days work.

On-site, work areas should be tidied and any rubbish disposed

of.

If done every day, it becomes normal practice.

Clean-up by trades as they finish a job must be enforced, so

that any wasted time experienced by follow-on trades will be

minimised.

Keep things clean and in good working order

30

3. Clean and check/shine

should include the area as well as the tools, equipment and

plant to be used

When checking tools, equipment and plant ask:

Is it in good repair?

Is it fit for purpose?

Does the condition pose a risk to either health and safety or

quality?

If an issue is found, TAG IT!

Keep things clean and in good working order

31

Putting our hands onto and cleaning this motor,

we found:

3. Clean and check/shine

32

3. Clean and check/shine

It is important that where any items have been identified with

issues, the resolution of these is effectively managed.

A commonly applied 5C/5S practice is the use of red-tagging.

Managing any identified issues

33

Tagging procedure

34

3. Clean and check/shine red-tagging

Red tags are used to provide a visual indicator of an abnormal

condition.

Brief details of the issue and possible countermeasure are logged.

Each red tag is given a unique number to enable recording and

tracking of issues.

The red tag is tied to the item that has the issue.

35

Red tag issues

Log all red tag occurrences on a red tag action log sheet.

Prioritise each red tag issue according to the severity of the

issue and/or urgency required for resolution:

A simple system is to categorise an issue as either low,

medium or high.

Use an agreed severity rating scale.

Effective resolution and management

36

3. Clean and check/shine red tag log sheet

A red tag log sheet is used to track the progress of resolving red-tag

issues.

Severity

(H, M, L)

Progress Cause Action Owner

Target

Date

Location Tag No. Issue / Problem

Date

Logged

5C / 5S Red Tag Log Sheet

Location: Activity Owner:

4. Conformity

The process of setting the 5C/5S standards and making them easy

to maintain by using simple systems and processes.

It can prove difficult to maintain the 5C/5S standard that has been

set during the first three 5Cs/5Ss.

The use of forms, diagrams, checklists and clearly defined roles

and responsibilities will help ensure that everyone in the work

area can maintain the 5C/5S standard.

It is important that this information is effectively communicated

to people within the work area and to those people who interact

with the work area.

38

4. Conformity

The process of setting the 5C/5S standards and making them easy

to maintain by using simple systems and processes.

This can be achieved by following some simple guidelines:

pre-work set-up checklist (do you have all the tools, materials and

equipment ready?)

display how work tasks should be done

display the 5C standard of the workplace

define how the 5C standard is to be maintained (eg clean and

check rota)

use visual methods to show the location of necessary items

A 5C/5S board ensures

everyones involved.

4. Conformity

40

Visually defining the workplace layout

Photographs to

illustrate:

Clearout

Configure

Clean to check

Supply of Red Tags

A site layout plan

showing the location of

facilities and is marked-

up to indicate the

Traffic Plan.

Work Type: Site: Ref No. Originator

Last Revised

Form P:19

Standard Job Detail

Ref. No. Standard Workplace Layout

Chart

Timber Frame Erection

LIVING ROOM LIVING ROOM

KITCHEN DINER KITCHEN DINER HALL HALL

NOT DRAWN

TO SCALE

WC WC

FRONT OF PLOT PAD Flow of Timber Frame Products:

- Build from back to front to aid access

1

3

5

6

4 2

8

9

10

12

13

7

14

11 DPC

15

PLOT 1 PLOT 2

Work Type Where Used Previously Ref No.

Last Revised

Standard Job Detail

Ref. No.

Originator

Standard Workplace Layout

Chart

Form P:19

M B M M B

Mixer

Work Type Where Used Previously Ref No.

Last Revised

Standard Job Detail

Ref. No.

Originator

Standard Workplace Layout

Chart

Form P:19

M B M M B

Mixer

A detailed workplace layout

chart indicating the location of

materials and

build sequence for timber

frame erection.

A standardised work layout

chart showing where material

items (bricks and mortar)

should be located to aim

efficient working.

4. Conformity

41

5. Custom and practice/self-discipline

Ensuring consistent adoption and use of 5C/5S by all personnel who

are either involved directly with the workplace or who interact with

the workplace.

Train all personnel in 5C/5S its not just good housekeeping!

Give ownership of the 5C/5S standard.

Consistently enforce the 5C/5S standard and culture.

Conduct independent 5C/5S audits.

Seek to improve the 5C/5S standard.

Consistent application, training and everyday routine

Good companies develop beginning with the 5Cs /5Ss, bad companies fall

apart beginning with the 5Cs/5Ss.

Hiroyuki Hirano

42

5C summary steps

1. Clear-out

remove everything not bolted to the ground

get rid of all rubbish and unnecessary tools/materials/docs etc

keep, quarantine, chuck areas

2. Configure

decide what do we need?, establish optimum buffer

find everything its home

consider logistics, frequency of use, worker motion waste, sequence of tasks

use visual aids, eg to show location, replenishment of materials,

quarantine area

3. Clean and check/shine

make sure all tools and machinery are in good condition

4. Conformity

create SOPs, eg cleaning schedule, maintenance procedures, location chart

5. Custom and practice

the company way

43

5C/5S

Auditing the 5C/5S standard

44

5C/5S levels of excellence

45

5C/5S audit sheet

46

Division: Auditor: Date:

Name

A

r

e

t

h

e

e

s

s

e

n

t

i

a

l

i

t

e

m

s

i

n

t

h

e

c

o

r

r

e

c

t

p

l

a

c

e

?

A

r

e

t

h

e

r

e

a

n

y

n

o

n

-

e

s

s

e

n

t

i

a

l

i

t

e

m

s

i

n

t

h

e

w

o

r

k

a

r

e

a

?

I

s

t

h

e

w

o

r

k

a

r

e

a

c

l

e

a

n

&

t

i

d

y

?

I

s

t

h

e

d

o

c

u

m

e

n

t

f

i

l

i

n

g

s

y

s

t

e

m

b

e

i

n

g

c

o

r

r

e

c

t

l

y

u

s

e

d

?

A

r

e

t

h

e

r

e

a

n

y

h

e

a

l

t

h

&

s

a

f

t

e

y

i

s

s

u

e

s

(

e

.

g

.

T

r

i

p

H

a

z

a

r

d

s

)

?

A

r

e

a

l

l

d

e

f

e

c

t

i

v

e

i

t

e

m

s

/

a

b

n

o

r

m

a

l

c

o

n

d

i

t

i

o

n

s

r

e

d

-

t

a

g

g

e

d

?

Yes No Garry Cotterrell

1 Is the area clean and tidy? Richard Green

2 Are the floors and aisles clear of non-essential items?

3 Are all cables/wires etc safely stored and connected?

4 Are all storage areas clean and tidy?

5 Are all storage areas free of non-essential items?

6 Are storage areas clearly labelled and is everything in it's place?

7 Are all notice boards tidy?

8 Is all of the required information displayed and is it up-to-date?

9 Are all notice boards free of non-essential items?

10 Is the central filing system in order? (hard and electronic)

11 Is the central filing system clearly marked up?

12 Is the central filing system complete?

13 Is the drawing rack tidy and in order?

14 Are all disks, documents, folders etc clearly labelled/identified?

15 Are reference items such as brochures organised & accessible?

Ref No. Issue/Opportunity Who Target Date Done?

Ref No. Observation

Check

IMPROVEMENT ACTION PLAN

Office 5C Audit Check Sheet

Improvement Action

Desk Office Working Environement

5C/5S

The outcomes of 5C/5S

47

The outcomes of 5C/5S

improved working environment

safer since safety depends on care and workplace

organisation

improved organisation and image

helps create ownership of the working environment and

encourages teamwork

48

The outcomes of 5C/5S

A standard is set :

Only items that are required or essential to support the

work are held in the area.

Essential items are organised and located in a set

position to support effective and efficient work, with

the view of minimising wasteful motion.

Tools, plant and equipment are maintained to support

safe operations and ensure good working conditions.

The outcomes of 5C/5S

The 5S standard:

enables any abnormal conditions to be easily spotted

provides the basis for continuous process improvement

gives confidence to your clients/customers since it reflects

the standards of operation to which your business follows

50

What do we get from 5C/5S?

51

5C/5S

Successfully implementing 5C/5S

52

Successfully implementing 5C/5S

Make sure everyone is involved.

5C /5S is the responsibility of all.

All levels of management should be involved in decision making.

Communicate 5C/5S effectively.

Don't leave people to ask:

Why are we using these red tags?

Is 5C/5S really necessary to improve?

Go all the way.

Use the correct formats and procedures.

53

Successfully implementing 5C/5S

Managers should carry out the 5C/5S audit:

spotting positive and negative conditions

identifying specific improvements

Final responsibility lies with senior management:

The board/senior management needs to take responsibility for and

show interest in 5C/5S for it to be taken seriously.

Managers must take a strong leadership role in promoting 5C/5S.

Never do half a job:

Develop procedures to maintain the discipline.

54

Check sheets and SOPs

Check sheets and other

documentation can be

used to maintain the

standard of the revised

workplace.

SOPs can also be used

to ensure that the

cleaning and checking

regimes are in place.

55

5C/5S activities

Possible team make-up and roles

An activity leader to plan, co-ordinate and organise the team

and to ensure safe working practices are used.

Process stakeholders who do the work to gather, clean, sort

and organise all items in their workplace.

An auctioneer who will lead the sorting process in the work

area.

A scribe to record the disposition of items during the sorting

process. Also to record any red-tag items on a red-tag log

sheet.

56

5C/5S activity

Example agenda for one-day 5C/5S activity

08:00 Activity kick-off and final co-ordination for the 5C/5S leader(s)

09:00 Training and activity planning for 5C/5S team

09:45 Break

10:00 Team returns to the area and conducts survey

10:15 Start sorting process (red-tag exercise carried out in-parallel)

10:45 Complete sorting process and prepare for auction

11:15 Auction (if appropriate)

12:00 Lunch

12:30 Clean and check necessary items (red-tag as necessary)

13:30 Agree locations for necessary items and configure as appropriate

14:30 Create visual controls to support the new 5C/5S standard

15:30 Re-survey area and capture the new 5C/5S standard

16:00 Draft 5C/5S documentation and associated audit check sheet

and roles and responsibilities to maintain the standard

16:30 End of activity review with all relevant personnel

57

Summary

What are the benefits of workplace organisation?

What are the five stages of a 5S/5C activity?

What problems might a Business Improvement Team

encounter when trying to implement 5S/5C?

How would you maintain the standard of good workplace

organisation?

58

Вам также может понравиться

- EPC ContractsДокумент36 страницEPC Contractskesharinaresh50% (2)

- Conducting Human Resource Audits SHRMДокумент7 страницConducting Human Resource Audits SHRMMirzaMuhammadAbubakarОценок пока нет

- Oa Performance Eval Form Structured 8-1-2017Документ4 страницыOa Performance Eval Form Structured 8-1-2017Jobelle Cariño ResuelloОценок пока нет

- Seven Steps of Recruitment Framework: SetupДокумент2 страницыSeven Steps of Recruitment Framework: SetupPRABHAKARAN TОценок пока нет

- Manufacturing Team Leader Generic JDДокумент4 страницыManufacturing Team Leader Generic JDTaufiq KimasОценок пока нет

- Checklist Implementing A Performance Appraisal SystemДокумент4 страницыChecklist Implementing A Performance Appraisal SystemrhishidОценок пока нет

- API RP 16E Control Systems For Drilling Well Control EquipmentДокумент31 страницаAPI RP 16E Control Systems For Drilling Well Control EquipmentRashid GhaniОценок пока нет

- Automatic GearboxДокумент8 страницAutomatic Gearboxmasterash02Оценок пока нет

- HRM - 03 - Recruitment & Selection PDFДокумент38 страницHRM - 03 - Recruitment & Selection PDFmikaОценок пока нет

- Competency Based HRM and Performance Management: Rupeshkumar DwivediДокумент36 страницCompetency Based HRM and Performance Management: Rupeshkumar DwivediPragati Upadhyay100% (1)

- API RP 7C-11F Installation, Maintenance and Operation of Internal Combustion Engines.Документ3 страницыAPI RP 7C-11F Installation, Maintenance and Operation of Internal Combustion Engines.Rashid Ghani100% (1)

- Performance Review Template (Self, Manager, Peers)Документ10 страницPerformance Review Template (Self, Manager, Peers)Marko IllustrisimoОценок пока нет

- API RP 8B - Procedures For Inspections, Maintenance, Repair, and Remanufacture of Hoisting EquipmentДокумент8 страницAPI RP 8B - Procedures For Inspections, Maintenance, Repair, and Remanufacture of Hoisting EquipmentRashid Ghani80% (5)

- Hibon DisplacmentBlower Iom D898Документ55 страницHibon DisplacmentBlower Iom D898Ricardo RGОценок пока нет

- Developing Performance Improvement PlanДокумент3 страницыDeveloping Performance Improvement PlanFidel EstebanОценок пока нет

- A001-MNC Siemens ChillerДокумент24 страницыA001-MNC Siemens ChillerLuis Yama0% (1)

- PWC Feedback Program FY13 FAQs PDFДокумент13 страницPWC Feedback Program FY13 FAQs PDFsupriyacnaikОценок пока нет

- Code of Conduct - Swapnil SahooДокумент10 страницCode of Conduct - Swapnil SahooSwapnil SahooОценок пока нет

- Survey Questionnaire: Kindly Mark Tick ( ) Against The Appropriate Statement. DemographicsДокумент2 страницыSurvey Questionnaire: Kindly Mark Tick ( ) Against The Appropriate Statement. Demographicsjuni bОценок пока нет

- EC7-1 Ch. 8 Anchors Amendment 2012 NOM PDFДокумент36 страницEC7-1 Ch. 8 Anchors Amendment 2012 NOM PDFAnОценок пока нет

- What Is The 5S MethodologyДокумент8 страницWhat Is The 5S MethodologydwaОценок пока нет

- Knowledge Management TutorialДокумент2 страницыKnowledge Management TutorialMk YapОценок пока нет

- Generic ISO 14001 EMS TemplatesДокумент57 страницGeneric ISO 14001 EMS TemplatesRashid GhaniОценок пока нет

- Capital Projects Cost EstimationДокумент87 страницCapital Projects Cost EstimationRapee PuaksungnoenОценок пока нет

- Top Maintenance KPIs For The Optimal CMMS DashboardДокумент12 страницTop Maintenance KPIs For The Optimal CMMS DashboardLaam MeemОценок пока нет

- The Components of Clinic Management System AreДокумент5 страницThe Components of Clinic Management System AreCedric PurgatorioОценок пока нет

- Jira Tutorial PDFДокумент20 страницJira Tutorial PDFregiane100% (5)

- Financial AppraisalДокумент13 страницFinancial Appraisalajityadav1987100% (1)

- Application Total Productive Maintenance (TPM) To Increase The Effectiveness of Engines With OEE As A Tool To Measure in The Industrial Packaging CansДокумент18 страницApplication Total Productive Maintenance (TPM) To Increase The Effectiveness of Engines With OEE As A Tool To Measure in The Industrial Packaging CansAnonymous izrFWiQОценок пока нет

- Pay Structures: Proprietary Content. ©great Learning. All Rights Reserved. Unauthorized Use or Distribution ProhibitedДокумент23 страницыPay Structures: Proprietary Content. ©great Learning. All Rights Reserved. Unauthorized Use or Distribution ProhibitedaahanaОценок пока нет

- Steps To Set Up A Project Check List of SIDBIДокумент14 страницSteps To Set Up A Project Check List of SIDBIAlankrita SawlaniОценок пока нет

- OD Practicioner Job DescriptionДокумент3 страницыOD Practicioner Job DescriptionGerald AbergosОценок пока нет

- Huit Cha Manual v2Документ32 страницыHuit Cha Manual v2samprasОценок пока нет

- Scaling Capacities: Supports For Growing Impact: Topic: Expanding Social ImpactДокумент20 страницScaling Capacities: Supports For Growing Impact: Topic: Expanding Social ImpactMahendra A-Gil KusumaОценок пока нет

- Barkat Recruitment From India Pakistan NepalДокумент5 страницBarkat Recruitment From India Pakistan NepalFiroz RahmanОценок пока нет

- Programme Management and Project EvaluationДокумент46 страницProgramme Management and Project Evaluationadarsh rajОценок пока нет

- SGD Setting Up of New FactoryДокумент6 страницSGD Setting Up of New FactoryDipesh WadhwaniОценок пока нет

- Sort Set-In-Order Shine Standardize Sustain: What Is 5-S?Документ44 страницыSort Set-In-Order Shine Standardize Sustain: What Is 5-S?Angel David ChavezОценок пока нет

- Applying Management Strategy Concepts (SFI) On Tata Steel Company (Tata Group)Документ77 страницApplying Management Strategy Concepts (SFI) On Tata Steel Company (Tata Group)lovels_agrawal6313100% (2)

- Helicopter Dynamic Stability-1Документ7 страницHelicopter Dynamic Stability-1KaradiasОценок пока нет

- User Manual Wire Rope SlingДокумент4 страницыUser Manual Wire Rope SlingRashid GhaniОценок пока нет

- Technical Requirements of Telecom TenderДокумент7 страницTechnical Requirements of Telecom TendertoarnabchОценок пока нет

- Job Description HRBPДокумент4 страницыJob Description HRBPEdson VenturaОценок пока нет

- Management Process: A. PlanningДокумент23 страницыManagement Process: A. PlanningKarren FernandezОценок пока нет

- Constructability GuidelinesДокумент34 страницыConstructability GuidelinesDavid SueldoОценок пока нет

- What Are The Differences Between ISO 9001 - 2008 and ISO 9001 - 2015Документ4 страницыWhat Are The Differences Between ISO 9001 - 2008 and ISO 9001 - 2015Sarathiraja SekarОценок пока нет

- Cathay Pacific-Case Study - Section C Group 8Документ10 страницCathay Pacific-Case Study - Section C Group 8gttrans111100% (1)

- FNW Locum Contract TemplateДокумент5 страницFNW Locum Contract Templateapi-279667195Оценок пока нет

- The 5SДокумент4 страницыThe 5SDanice Anne FeriaОценок пока нет

- Mastering The Management System: Group 9Документ14 страницMastering The Management System: Group 9vickyguptavgОценок пока нет

- Juran'S Trilogy-Planning, Control, ImprovementДокумент18 страницJuran'S Trilogy-Planning, Control, ImprovementJoannah RiveraОценок пока нет

- Module IV StaffingДокумент3 страницыModule IV Staffingyang_19250% (1)

- 5 S Notesfor Good HousekeepingДокумент9 страниц5 S Notesfor Good HousekeepingTes TravzОценок пока нет

- Pom 1 Part 2Документ13 страницPom 1 Part 2Sachin SahooОценок пока нет

- 5s Audit ChartДокумент26 страниц5s Audit Charttechnical rndОценок пока нет

- What This Is: INTRODUCTION: Planning Worksheet For A Review MeetingДокумент4 страницыWhat This Is: INTRODUCTION: Planning Worksheet For A Review MeetingRizki ApriliawatiОценок пока нет

- SHR PlanningДокумент21 страницаSHR PlanningJim MathilakathuОценок пока нет

- Work Placement AgreementДокумент7 страницWork Placement AgreementcrckfxОценок пока нет

- Policies & Procedures For Assessment, Surveillance and Re-Assessment of HcoДокумент16 страницPolicies & Procedures For Assessment, Surveillance and Re-Assessment of HcoSubiVictorОценок пока нет

- Coca Cola India RatioДокумент15 страницCoca Cola India RatioKaran VermaОценок пока нет

- Compa-Ratio Calculation: Employee's Annualized Pay Rate Midpoint For Employee's Pay GradeДокумент2 страницыCompa-Ratio Calculation: Employee's Annualized Pay Rate Midpoint For Employee's Pay GradeModerator HRCIОценок пока нет

- Job Description Assembly ManagerДокумент2 страницыJob Description Assembly ManagerSarah ChaudharyОценок пока нет

- Session 111 Clean Desk Policy SampleДокумент1 страницаSession 111 Clean Desk Policy SamplesaadОценок пока нет

- Competency DICTДокумент22 страницыCompetency DICTbook xpert1Оценок пока нет

- Job Evaluation Procedure For SupervisorsДокумент30 страницJob Evaluation Procedure For SupervisorscruscadenОценок пока нет

- Management by Objectives Performance AppraisalДокумент6 страницManagement by Objectives Performance AppraisalMunroe BuckОценок пока нет

- Motion StudyДокумент32 страницыMotion StudySartika CahyasariОценок пока нет

- Skill Matrix DocumentДокумент3 страницыSkill Matrix Documentjagansd3Оценок пока нет

- Full Paper - Quality Improvement Using Model Based & Integrated Process Improvement (MIPI)Документ6 страницFull Paper - Quality Improvement Using Model Based & Integrated Process Improvement (MIPI)Febi ArfiyantoОценок пока нет

- MBOДокумент16 страницMBODr. Rakshit SolankiОценок пока нет

- Key Account Manager@ HULДокумент3 страницыKey Account Manager@ HULDushyant ChaturvediОценок пока нет

- Purpose To Ensure Replacements For Key Job Incumbents in Executive, Management, Technical, andДокумент2 страницыPurpose To Ensure Replacements For Key Job Incumbents in Executive, Management, Technical, andezekielbidesОценок пока нет

- Candidate Personal Data StatementДокумент1 страницаCandidate Personal Data StatementmarkcoatesОценок пока нет

- Operating IN The FieldДокумент9 страницOperating IN The FieldEshan MaheshwariОценок пока нет

- Series 38 Super Durable 20091125 173441Документ8 страницSeries 38 Super Durable 20091125 173441K-fioОценок пока нет

- India Cements LTDДокумент24 страницыIndia Cements LTDqwertyОценок пока нет

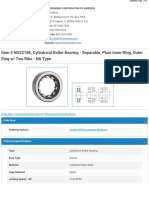

- NU2218E CylindricalRollerBearing Separable PlainInnerRing OuterRingwTwoRibs NUTypeДокумент3 страницыNU2218E CylindricalRollerBearing Separable PlainInnerRing OuterRingwTwoRibs NUTypeEmmanuel Quequesana VílchezОценок пока нет

- CISM BrochureДокумент2 страницыCISM BrochurevihitvasaniОценок пока нет

- Lathe Machine DataДокумент10 страницLathe Machine DataRaju MalhotraОценок пока нет

- Warehouse and StorageДокумент3 страницыWarehouse and StorageAnonymous mO72yqNcОценок пока нет

- Cellnex IA 2017 ENG LRДокумент291 страницаCellnex IA 2017 ENG LRDavid KřížОценок пока нет

- SF Eng BrochureДокумент24 страницыSF Eng BrochuremanixОценок пока нет

- Ilham Kurniawan ResumeДокумент2 страницыIlham Kurniawan ResumeIlku100% (1)

- Wiki PDFДокумент8 страницWiki PDFYogennder NaagarОценок пока нет

- 1402vlzpro Om SPДокумент36 страниц1402vlzpro Om SPproimagen2007Оценок пока нет

- The Whitehead Torpedo Deck TubeДокумент148 страницThe Whitehead Torpedo Deck TubeDongelxОценок пока нет

- Informacion Tecnica Bomba de Vacio DekkerДокумент1 страницаInformacion Tecnica Bomba de Vacio DekkerMiguelon AngelОценок пока нет

- Safety SloganДокумент3 страницыSafety SloganGanesan Pavuniah100% (1)

- Tektronix, Inc.: Global ERP Implementation: Case Write-Up - IIДокумент3 страницыTektronix, Inc.: Global ERP Implementation: Case Write-Up - IIkevalОценок пока нет

- Appendix KДокумент26 страницAppendix KRaj BindasОценок пока нет

- Sap Hana Attribute ViewsДокумент15 страницSap Hana Attribute ViewskhanmdОценок пока нет

- Final ExamДокумент8 страницFinal Examviraivil9417Оценок пока нет

- Your Interactive Guide To The Digital WorldДокумент67 страницYour Interactive Guide To The Digital Worldrana khubaibОценок пока нет

- The Java MagzineДокумент67 страницThe Java Magzinesankalp.ims29310% (1)