Академический Документы

Профессиональный Документы

Культура Документы

Chapter 3 Present NEW

Загружено:

Yana YiИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Chapter 3 Present NEW

Загружено:

Yana YiАвторское право:

Доступные форматы

PRESENTER:

MARINA YUSOFF 2010672752

NUR SYAFIQAH KAMARUDIN 2010847576

CAROLINE APAU 2010488388

AZWADI ALI 2009424756

NURUL AFIQAH MOHD ZAKI 2010802956

PROCESS BACKGROUND/SELECTION

INTRODUCTION

Diabetes is one of the chronic diseases

occurs when the glucose level in blood is

increases due to breakdown of

carbohydrates

Insulin can help to convert excessive

glucose into glycogen to be stored in liver

Human insulin can be produced by

four different methods

Extraction from human pancreas

Chemical synthesis via individual amino

acids.

Conversion of pork insulin of

semisynthesis.

Fermentation of genetically engineered

microorganisms.

fermentation of genetically engineered

microorganisms or can be simply called as

recombinant DNA technology is chosen in

this project

This is because this technique is safe,

high recovery, high purity and almost

same with human insulin

Genetic Modification Organism

GENERAL PROCESS

Consists of fourth teen important steps

35 equipments and reactors involve in this

batch process

Duration for each batch is 6 days

Production for each batch is 1.81 kg

Production per year is 100 kg

Downstream process to improve the

quality of desired product

Fermentatio

n process

Cell

isolation

Cell

Disruptio

n

Centrifugatio

n

Solubilize

Inclusion

Bodies

(IB)

CNBr-

Cleavage

Sulfitolysis Refolding

HIC

column

Enzymati

c

Conversi

on

Reverse

Phase

Chromato

graphy

Second

stage

purification

Polishing

Freeze

Dry

MARKET ANALYSIS

N

Insulin Worldwide Market

Top 10 Countries Number of People with Diabetes

Insulin Worldwide Market

Trends in the Current Depressed

Market

The Price of Insulin

Profit Margin

Break Even Analysis

Break Even Calculation

Variable Cost

Cost Item Formula value

Raw Material RM 286 millions

Waste Treatment RM 27 thousands

Utilities RM 382 thousands

Operating Labour RM 993 thousands

Maintenance and repairs 0.06FCI RM 13 millions

Operating Supplies 0.009FCI RM 1.94 millions

Total

RM 302 millions

Break Even Calculation

Fixed Cost

Cost Item Formula Value

Fixed capital investment FCI RM 215 millions

Local taxes and insurance 0.032FCI RM 6.88 millions

Plant overhead costs 0.708 + 0.036FCI RM 8.45 millions

Total

RM 230 millions

Break Even Calculation

Total Revenue

Total Revenue = Production of insulin x Price of

insulin

Production of insulin = 99.55 kg/year

Price of insulin = RM 11.4 millions

/year

Total Revenue = RM 1.13 billions

Break Even Calculation

Break Even Point (BEP)

BEP = (Fixed cost/ Contribution margin) x Production

Contribution Margin = Revenues Variable Cost

Contribution Margin = RM 834 millions

Fixed Cost = RM 230 millions

Production = 99.55 kg/year

BEP = 27.50 kg/year need to be

produced

Cumulative Cash Flow

Operating Cost for the First Year

Total Cost = Variable Cost + Fixed Cost

Variable Cost = RM 302 millions

Fixed Cost = RM 230 millions

Total Cost = RM 532 millions

Cumulative Cash Flow

Cumulative Cash Flow Analysis

Year Total cost Cumulative cash flow

1 - 532,678,960 - 532,678,960

2 - 372,514,550 - 905,193,510

3

1,136,861,000

231,667,490

4

1,136,861,000

1,368,528,490

5

1,136,861,000

2,505,389,940

6

1,136,861,000 3,642,250,490

7

1,136,861,000 4,779,111,490

8

1,136,861,000 5,915,972,490

9

1,136,861,000 7,052,833,490

10

1,136,861,000 8,189,694,490

11

1,136,861,000 9,326,555,490

12

1,136,861,000 1.05 x 10

10

Cumulative Cash Flow

Cumulative Cash Flow Diagram

-0.2

0

0.2

0.4

0.6

0.8

1

0 2 4 6 8 10 12

C

u

m

u

l

a

t

i

v

e

C

a

s

h

F

l

o

w

(

1

0

1

0

)

(

R

M

)

Year

Payback Period

Conclusion

Market Analysis on Insulin Production

Fixed Capital Investment is RM 215 millions and this cost is

independent of production rate.

The Total Production Cost is RM 532 millions. It is summation

of Variable Cost and Fixed Cost.

The total insulin sale per year is RM 11.4 millions.

Total Revenue = RM 1.14 billions.

Net annual Profit = RM 700 millions

Total Production = 99.55 kg/year

BEP = 27.50 kg/year Productions

Up the BEP, it has been estimated that the plant would gain

some profit and therefore this project can be considered as

profitable as the production rate also is in conjunction with the

supply and demand in Malaysia.

The payback period is estimated about 3 years

SITE SELECTION

Chapter 3 : Site Selection

Comparison between Senai, Pulau Indah and Gebeng between several

criteria

A rating evaluation has been made

After all comparison, we decide to choose Gebeng Industrial Estate Phase

3

Gebeng Pulau Indah Senai

Total Rating 38 37 35

Location Description

a small town and main industrial area in Pahang state in Malaysia

near Kuantan Port

Kuantan is being identified as a Special Economic Zone (SEZ)

located inside East Coast Economic Region (ECER)

located only 5 kilometers from the Kuantan Port in Kuantan City

25km away from the Kuantan town and 250km from the Kuala

Lumpur

Land availability and prices

selling prices RM 15 per sq

can be bought with minimum 3 acres (130680 ft2) up to

maximum 250 acres (10890000 ft2)

So minimum price is RM 1,960,200 for 3 acres

Raw Material Availability

Supply within the Malaysia and imported from the

oversea

Company that responsible for been supplier within

Malaysia is Merck Sdn Bhd, Sigma-Aldrich (M) Sdn.

Bhd, and Fisher CW Medical (M)

Raw materials will be transported from these company

via road

The other raw material imported from oversea is

transported to nearest airport and port.

Transportation Network

Gebeng by-pass between Gebeng Industrial Estate and

Kuantan Port

The by-pass will directly link with the East Coast

Expressway to connect Kuala Lumpur with Kuantan

Kuantan Port is located only 5 kilometers from the

Gebeng Industrial Estate

Sultan Ahmad Shah Airport, Kuantan is approximately

35km from Gebeng Industrial Estate and connected via

Jalan Pintasan Kuantan

Not compacted with other activities, so smooth trafficking

of the import and exporting process

Availability of Utilities

main electricity supplier in Gebeng Industrial Estate is

Tenaga Nasional Berhad (TNB)

Phase I and II is supported by its 132/11kV main intake,

for Phase III, two sources of electricity supply are

available which are and 12/275kV main intake

water supply is Semambu Water Treatment Plant

capacity 2MG/D

main telecommunication supplier is Telekom Malaysia

for instance Integrated Systems Digital Network (ISDN),

digital line, MAYPAC, Internet and video conferencing

Availability of Labour

main labours sources is Kuantan population is

approximately 607,778 persons.

Also involves Kemaman area

Pahang provides access to skilled manpower as which

can be acquired numerous institutions of further studies

Universities Others Facilities

University Teknology MARA

University Malaysia Pahang

International Islamic

University Malaysia

Kolej Islam Pahang,

Politeknik Sultan Haji Ahmad

Shah

Kolej Komuniti Kuantan Kolej

ShahPutra Kuantan

Kolej Poly-Tech MARA

Institut Kemajuan Ikhtisas

Pahang (IKIP) College

Government Incentives

Development of Gebeng Phase III which will be

attraction for the investor to Pahang

The Eastern Industrial Corridor, which is the government

backed economic region developed into an ultra-modern

industrial region

Accelerated capital allowance provides a special

allowance, where the capital expenditure is written off

within 3 years

water supply to 64 MG/D

Building of new pipes and water tanks in Gebeng

Industrial Estate

MATERIAL BALANCE

General Mass Balance

Equation

1 batch approximately 6 days

100 kg/ yr X 1 yr/ 330 days X 6days/batch

= 1.818 kg/batch

330 days/ 1 yr X 6 days/ batch = 55

batches per year

Production rate = 100 kg/year

The calculation is based on the production rate of 100 kg/year of

insulin.

The target production rate per batch is 1.818 kg/batch.

Operating days for the plant is 330 days per year, 24 hours daily.

The system is a steady-state operation.

The system behaves as an ideal condition.

No leakage in the pipes or vessels inside the plant.

All the catalysts used during the process do not contribute to the

mass inside the system.

The total input of substances to compressor, pump, valve, mixer or

heat exchanger is equal to the total output.

All calculations are done in kg/batch

TSB + O

2

+ N

2

+ NH

3

+ H

2

O + kanamycin biomass

(E.coli) + O

2

+ N

2

+ NH

3

+ H

2

O+CO

2

+ kanamycin + ATPs

Overall mass balance: total in = total output

The percentage of air consists of 21% of oxygen, 79% of

nitrogen

870 kg/batch of Ammonium gas is purge into this system

Basis of 43 504 kg/batch air is purge into the fermenter

system

1.4% of oxygen from respiration of bacteria cell is

release as carbon dioxide

Conversion process for TSB is 95%

0.5 kg biomass can be generate for every 1 kg of TSB

consumed

kanamycin does not take part in the reaction so that total

input = total output

74 % of water will be increase after undergo

fermentation process due to biological process that

occurred.

Percentage error of calculation:

Manual calculation = 1.800kg/batch

Simulation = 1.810 kg/batch

Target production = 1.814kg/batch

(1.810-1.800) /1.810 X 100% = 0.55 %

(1.814-1.800)/1.814X 100% = 0.77 %

ENERGY BALANCE

Important in worldwide manufacturing plant to reduce the

cost and energy consumption.

To analyze and optimize the uses of energy in designing

a plant.

The system is assume as an open system

Q-Ws= H+Ek+Ep

The equation reduced to

= =

=H

f

+

= H

f

+ [

]

Ws, Ek and Ep =0

1. Assumptions:

Open system (Q=H) and steady state process

- No moving parts considered in the system

- All equipments are static

Heat from pressure change is neglected

All streams and reactions occur in liquid phase

- Occurs in homogeneous mixture. Thus, solid and gas is not taken into

account.

Heat of mixing, Hm is neglected

2. Basis:

Tref = 25C = 298.15K

P

ref

= 1atm

Mass flowrate is in kg/hour

Heat capacity,Cp get from SUPERPRO library

Using heat of formation method due to the facts that heat of reaction method for certain standard conditions is

unknown.

ENVIRONMENTAL AND SAFETY CONSIDERATION

Role of chemical engineer

Lack of consideration

Negative impact

-Human

-Animal

-Aquatic life

Follow the Malaysia Act & Regulation

-OSHA

-Environment Quality Act

(Air pollution, Scheduled Waste)

-Biosafety Act

Hazard

HIRARC

HAZARDOUS WASTE

Classification

Treatment

Biological Treatment

1.Inject with Chlorine

2.Sterilize the waste

3.Send to the Jabatan Alam Sekitar

Chemical Treatment

Recycle

Send to the Jabatan Alam Sekitar

Management

Recycle

Waste area

Labeling the waste

Put the sign of hazardous area

Disposal to the sanitary landfill

Вам также может понравиться

- Subordination, Non - Disturbance and Attornment AgreementДокумент7 страницSubordination, Non - Disturbance and Attornment AgreementDavid CromwellОценок пока нет

- Industrial Training ReportДокумент43 страницыIndustrial Training ReportAnirudh Khare50% (2)

- Plant Design-Biscuit ManufacturingДокумент48 страницPlant Design-Biscuit ManufacturingBenjamin Aregbesola100% (3)

- Process CostingДокумент83 страницыProcess CostingMohammad MoosaОценок пока нет

- AEMAS National Council Seminar 21mar2011Документ33 страницыAEMAS National Council Seminar 21mar2011Hishamudin IbrahimОценок пока нет

- Chirimuuta, Mazviita - Outside Color - Perceptual Science and The Puzzle of Color in Philosophy-The MIT Press (2017)Документ263 страницыChirimuuta, Mazviita - Outside Color - Perceptual Science and The Puzzle of Color in Philosophy-The MIT Press (2017)Karishma borgohainОценок пока нет

- Biomass Energy Generation by PTMДокумент24 страницыBiomass Energy Generation by PTMLh KooОценок пока нет

- Methyl Acetate Project DesignДокумент36 страницMethyl Acetate Project Designdjona lokimaОценок пока нет

- Manufacturing CostДокумент30 страницManufacturing CostPradika WibowoОценок пока нет

- Plant Design Biscuit ManufacturingДокумент45 страницPlant Design Biscuit ManufacturingRishabh DuttaОценок пока нет

- Project Report Battery Manufacturing PlantДокумент14 страницProject Report Battery Manufacturing PlantVasim Shaikh50% (4)

- Improving Rice Production and Commercialization in Cambodia: Findings from a Farm Investment Climate AssessmentОт EverandImproving Rice Production and Commercialization in Cambodia: Findings from a Farm Investment Climate AssessmentРейтинг: 5 из 5 звезд5/5 (1)

- A.T. Biopower Rice Husk Power Project in PichitДокумент9 страницA.T. Biopower Rice Husk Power Project in PichitDidier SanonОценок пока нет

- Nissin - Monde Philippines Plant AnalysisДокумент44 страницыNissin - Monde Philippines Plant AnalysisDean Paul81% (16)

- Energy Management in Hospital (MGTC)Документ39 страницEnergy Management in Hospital (MGTC)Gillan Lio100% (1)

- Dalmia Cement AriyalurДокумент31 страницаDalmia Cement AriyalurMohammed Shafi AhmedОценок пока нет

- Chemical Engineering Projects Can Be Divided Into Three TypesДокумент25 страницChemical Engineering Projects Can Be Divided Into Three Typestrungson1100% (1)

- ERS MSP Solar Photovoltaics For Your HomeДокумент29 страницERS MSP Solar Photovoltaics For Your HomeTengku Azaha Tengku IsmailОценок пока нет

- 1 - Introduction To ISO 50001Документ27 страниц1 - Introduction To ISO 50001Othmane ElmouatamidОценок пока нет

- Prelims Reviewer Biochem LabДокумент4 страницыPrelims Reviewer Biochem LabRiah Mae MertoОценок пока нет

- Reducing Energy Consumption in Paper Making Using APC and OptimisationДокумент49 страницReducing Energy Consumption in Paper Making Using APC and OptimisationPoojan ThakoreОценок пока нет

- Reflection On The Wedding DanceДокумент48 страницReflection On The Wedding DanceAnnamarie Cagadas DaapongОценок пока нет

- YhДокумент3 страницыYhTan Khai HeanОценок пока нет

- Green Bin Recyclomania: A Project On Sustainable Product DevelopmentДокумент19 страницGreen Bin Recyclomania: A Project On Sustainable Product DevelopmentAravindОценок пока нет

- UntitledДокумент12 страницUntitledBetiОценок пока нет

- Desmond G. - Asia Biogas Group - 2Документ18 страницDesmond G. - Asia Biogas Group - 2Sha PhireОценок пока нет

- Economic Feasibility StudiesДокумент7 страницEconomic Feasibility StudiesAkpan Anthonia AthanasiusОценок пока нет

- Rotary Presentation: February 23th, 2009Документ35 страницRotary Presentation: February 23th, 2009Kalidass Back100% (1)

- Unit 5 NewДокумент65 страницUnit 5 NewVivek BendeОценок пока нет

- MED TEST - Tunisia: The Case StudiesДокумент30 страницMED TEST - Tunisia: The Case StudiestsakiriОценок пока нет

- Em - Itc - Group 6Документ26 страницEm - Itc - Group 6Alok BugdeОценок пока нет

- Total Energy Management: Trichur DairyДокумент12 страницTotal Energy Management: Trichur DairyAswathi AchuОценок пока нет

- Unit Profile: Binani Cement LimitedДокумент7 страницUnit Profile: Binani Cement LimitedPriyank MaheshwariОценок пока нет

- Bangladesh Water Pact OverviewДокумент16 страницBangladesh Water Pact OverviewSazid RahmanОценок пока нет

- Production and Cost Analysis of Beverage IndustryДокумент12 страницProduction and Cost Analysis of Beverage IndustryGautam BindlishОценок пока нет

- Project On Budget & Budgetary ControlДокумент22 страницыProject On Budget & Budgetary ControlMukesh ManwaniОценок пока нет

- Energy Audit in The Dairy IndustryДокумент4 страницыEnergy Audit in The Dairy Industrykeya2020Оценок пока нет

- Act 441 Process CostingДокумент9 страницAct 441 Process CostingShahriar AkashОценок пока нет

- Unit Profile: (A Unit of Valsad District Co-Operative Milk Producer Union LTD Alipur - Gujarat)Документ25 страницUnit Profile: (A Unit of Valsad District Co-Operative Milk Producer Union LTD Alipur - Gujarat)Prasad YadavОценок пока нет

- Presentation On Operation Management HegДокумент13 страницPresentation On Operation Management HeggaganОценок пока нет

- JP Singh-TexTech AddressДокумент11 страницJP Singh-TexTech Addresssbos1Оценок пока нет

- Promotion of The Improved Water Mills in NepalДокумент16 страницPromotion of The Improved Water Mills in NepalWorkshop on Enhancing the Regional Distribution of CDM Projects in Asia and the Pacific, 6-7 Sep 2011, Kathmandu, NepalОценок пока нет

- Cogen 3 Technical Financial Analysis ModelДокумент58 страницCogen 3 Technical Financial Analysis ModelLai Mei EeОценок пока нет

- Sugarcandy AgraДокумент9 страницSugarcandy AgraMeng HeangОценок пока нет

- Purdue Senior Design Project 2012 ChEДокумент15 страницPurdue Senior Design Project 2012 ChEchrisweinkaufОценок пока нет

- WCE2015 pp326-331Документ6 страницWCE2015 pp326-331kirbeyОценок пока нет

- Duration: Submitted By: Yo Yo Goli SinghДокумент35 страницDuration: Submitted By: Yo Yo Goli SinghAayush Ghosh ChoudhuryОценок пока нет

- 1173-Article Text-2795-1-2-20191209Документ17 страниц1173-Article Text-2795-1-2-20191209MelakuОценок пока нет

- Manufacturing Cost: Jono - Suhartono@itenas - Ac.idДокумент29 страницManufacturing Cost: Jono - Suhartono@itenas - Ac.idFrans ArapentaОценок пока нет

- MANAN..Defatted Groundnut Cake Products.Документ66 страницMANAN..Defatted Groundnut Cake Products.arunfrnd4uОценок пока нет

- Production of Ethylene From CoalДокумент13 страницProduction of Ethylene From CoalL.y. ChongОценок пока нет

- Process CostingДокумент16 страницProcess CostingPiyush Gupta100% (2)

- Ghana Cocobod ReportДокумент20 страницGhana Cocobod ReportKookoase KrakyeОценок пока нет

- Cpe 613 Project Simulation: Production of Propylene GlycolДокумент11 страницCpe 613 Project Simulation: Production of Propylene GlycolDafiMaboОценок пока нет

- Mohit Malik, Archit AroraДокумент49 страницMohit Malik, Archit AroraRaju SinghОценок пока нет

- Presentation 1Документ20 страницPresentation 1Parveen Bairagi100% (1)

- Mother Dairy DelhiДокумент10 страницMother Dairy Delhibugoff700Оценок пока нет

- Qaisae Shah's CV-2Документ3 страницыQaisae Shah's CV-2Rafhan HyderОценок пока нет

- Termiiiomii - Delayed Coker Unit (Dcu)Документ15 страницTermiiiomii - Delayed Coker Unit (Dcu)Arnab Guha MallikОценок пока нет

- CSA NOTES - Green Building Index - ResidentialДокумент19 страницCSA NOTES - Green Building Index - ResidentialSim Khoon AunОценок пока нет

- Design of Plant For Producing Methanol From Nigerian Natural GasДокумент22 страницыDesign of Plant For Producing Methanol From Nigerian Natural GasJohnОценок пока нет

- Capstone AbstractsДокумент9 страницCapstone AbstractsFrank MtetwaОценок пока нет

- Weight % Dmta Test Flexural Test: Table of Expected ResultДокумент1 страницаWeight % Dmta Test Flexural Test: Table of Expected ResultYana YiОценок пока нет

- Gant Chart MASTERДокумент2 страницыGant Chart MASTERYana YiОценок пока нет

- Report Viewer 0.4Документ7 страницReport Viewer 0.4Yana YiОценок пока нет

- Application ExerciseДокумент7 страницApplication ExerciseYana YiОценок пока нет

- Assignment 2 MEC451 HampaskacaДокумент2 страницыAssignment 2 MEC451 HampaskacahampaskacaОценок пока нет

- Present Perfect Mind MapДокумент2 страницыPresent Perfect Mind MappaulssОценок пока нет

- APA 6th Edition - Citation Styles APA, MLA, Chicago, Turabian, IEEE - LibGuДокумент2 страницыAPA 6th Edition - Citation Styles APA, MLA, Chicago, Turabian, IEEE - LibGuJan Louis SalazarОценок пока нет

- Kajima's Three PolicyДокумент2 страницыKajima's Three PolicyBe Seang SeОценок пока нет

- Plastics Library 2016 enДокумент32 страницыPlastics Library 2016 enjoantanamal tanamaОценок пока нет

- Catalogue Colorants TextilesДокумент5 страницCatalogue Colorants TextilesAs Des As BenedictionОценок пока нет

- Iraqi Portal of Knowledge and Heritage With Format Edits - 11-21-2023Документ6 страницIraqi Portal of Knowledge and Heritage With Format Edits - 11-21-2023محمد الكربلائيОценок пока нет

- Quantum Data-Fitting: PACS Numbers: 03.67.-A, 03.67.ac, 42.50.DvДокумент6 страницQuantum Data-Fitting: PACS Numbers: 03.67.-A, 03.67.ac, 42.50.Dvohenri100Оценок пока нет

- Led Matrix A-788bsДокумент5 страницLed Matrix A-788bsjef fastОценок пока нет

- TTC 1000Документ2 страницыTTC 1000svismaelОценок пока нет

- Legal Aspects of Construction Ethics PaperДокумент11 страницLegal Aspects of Construction Ethics PaperbikaresОценок пока нет

- CS 2400 - 2500 BrochureДокумент8 страницCS 2400 - 2500 BrochureOo Kenx OoОценок пока нет

- Cutting Conics AsДокумент3 страницыCutting Conics Asbabe09Оценок пока нет

- The History of The Photocopy MachineДокумент2 страницыThe History of The Photocopy MachineAndy WijayaОценок пока нет

- Particle FilterДокумент16 страницParticle Filterlevin696Оценок пока нет

- Microtech Testing & Research Laboratory: Condition of Sample, When Received: SatisfactoryДокумент1 страницаMicrotech Testing & Research Laboratory: Condition of Sample, When Received: SatisfactoryKumar AbhishekОценок пока нет

- CV (Martin A Johnson)Документ7 страницCV (Martin A Johnson)kganesanОценок пока нет

- Concept PaperДокумент4 страницыConcept Paperjanet a. silosОценок пока нет

- Chapter - 1 - Digital - Systems - and - Binary - Numbers EE228 15-16Документ81 страницаChapter - 1 - Digital - Systems - and - Binary - Numbers EE228 15-16mohamed hemdanОценок пока нет

- Small Scale IndustriesДокумент6 страницSmall Scale IndustriesMangesh KadamОценок пока нет

- NPN Silicon: Semiconductor Technical DataДокумент8 страницNPN Silicon: Semiconductor Technical DataMinh Hà QuangОценок пока нет

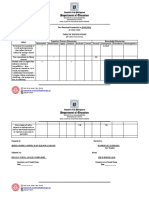

- TOS 1st QuarterДокумент6 страницTOS 1st QuarterQuerisa Ingrid MortelОценок пока нет

- Cultures of The West A History, Volume 1 To 1750 3rd PDFДокумент720 страницCultures of The West A History, Volume 1 To 1750 3rd PDFtonnyОценок пока нет

- The Design and Development of Organic Chemistry Module For College StudentsДокумент6 страницThe Design and Development of Organic Chemistry Module For College StudentsEight AlykОценок пока нет

- 3 - RA-Erecting and Dismantling of Scaffolds (WAH) (Recovered)Документ6 страниц3 - RA-Erecting and Dismantling of Scaffolds (WAH) (Recovered)hsem Al EimaraОценок пока нет

- Box Transport MechanismДокумент36 страницBox Transport MechanismInzi Gardezi81% (16)

- Amended August 8 2016Документ31 страницаAmended August 8 2016lux186Оценок пока нет

- Science 10 FINAL Review 2014Документ49 страницScience 10 FINAL Review 2014Zara Zalaal [Student]Оценок пока нет