Академический Документы

Профессиональный Документы

Культура Документы

Elctrical Protection System

Загружено:

Avnish BhasinАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Elctrical Protection System

Загружено:

Avnish BhasinАвторское право:

Доступные форматы

HARYANA VIDYUT PRASARAN NIGAM LIMITED

PRESENTATION OF

TRAINING PROGRAM ON

ELECTRICAL PROTECTION SYSTEM

HELD AT NPTI, NEYVELI

DURING 21.7.2014 T0 25.07.2014

Presented By:

Er Manoj Kumar

SSE, 220 KV S/Stn, Dhurala.

1.

IS: 2705 (Part-I) -

1981

Specification for current transformers

General requirements

2.

IS: 2705 (Part-II) -

1981

- Measuring current

transformers

3.

IS: 2705 (Part-III) -

1981

- Protective current

transformers

4.

IS: 2705 (Part-IV) -

1981

- Protective current

transformers for special purpose

application.

5.

IS: 3156 (Part-I) -

1978

Specification for voltage transformer

- General requirements

6.

IS: 3156 (Part-II) -

1978

- Measuring voltage

transformers

7.

IS: 3156 (Part-III) -

1978

- Protective voltage

transformers

8.

IS: 3156 (Part-

IV) - 1978

- Capacitor voltage

transformers

9.

IEC: 185 -

1987

Current Transformers

10.

IEC: 186 -

1987

Voltage Transformers

11.

IS: 5621 -

1980

Hollow insulators for use in

electrical equipment

12.

IS: 2099 -

1986

Bushings for alternating voltages

above 1000 Volts

13.

IS: 3716 -

1978

Application guide for insulation co-

ordination

INSTRUMENT TRANSFORMERS

Current Transformers(CTs) are used to step down the currents

for the purpose of measurement, protection and control

Secondary ratings 1 or 5A

For ex. 10,000/5A , 100/1A

Voltage Transformer(VTS): are used to step down the voltage

for the purpose of measurement, protection and control

Secondary ratings 110V,115V

For ex. 400KV/110V, 230KV/115V

Types of Current Transformer

According to Construction: The use of one or the other is determined by the

rated current of the apparatus and the rated burden required.

Bar Type: Suitable for large primary current because it can meet with the

burden and accuracy requirements & at the same time can have high thermal

& dynamic short circuit factors.

Wound type: Suitable for low primary current or where the burden &

accuracy requirements are high.

According to Application Point:

Metering: The specific performance of the CT is to be maintained in the range

normally 5% to 120% of the rated current. The CT cores should be such that it

saturates at its ISF for safeguarding the instruments from getting damaged

under faults.

Protection: The Main requirement is that its cores should not get saturated

below its Accuracy Limiting Factor upto which the primary current should

faithfully transformed to the secondary side, maintain the specified accuracy.

Protection CTs for Special Applications

Types of CTs

Hair Pin Design

Eye Bolt Design

Live tank Design

Live Tank CTs

Dead tank CTs

Hairpin design and Eye Bolt design

1. Dome

2. Nitrogen filling valve

3. Primary terminal

4. Collar

5. Porcelain insulator

6. Primary conductor with

insulation

7. Adaptor cylinder

8. Secondary cores

9. Base

10. Oil drain plug

Hair Pin Design

Hair-Pin

design

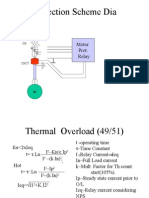

RELAY CIRCUIT

SELECTION OF CURRENT

TRANSFORMER

TYPE

Number of Secondaries

Accuracy class of each secondary:

Selection of Accuracy Class for Measuring CT (Table-I)

Selection of Accuracy Class for Protective CT (Table-II)

Rated burden

Accuracy Limiting factor:

Ratio of the rated accuracy limit primary current to the rated primary

current.

Short Time Current rating

Insulation Values

TABLE-I

Recommendations for Selection of Accuracy of Measuring

CT

Sr No. Application Class of Accuracy

1 For Precision testing or as a Std for testing Labs 0.1

2 For Precision Industrial Metering 0.5

3 For Industrial & commercial metering 0.5 or 1

4 For use with Indicating & Graphic Wattmeters 1 or 3

5 For purpose where the ratio is less important 3 or 5

TABLE-II

Particular Application Accuracy class

1. For instantaneous OC relays & trip coils Class 10 P and ALF 5

2. For OC relays with inverse and Definite min Class 10 P

Time-lag characteristics.

3. For IDMT earth fault relays in which phase Class 10 P or 15 P &

In which phase fault stability & accurate time Rated O/P X ALF=150

grading are not required. Provided relay is not set

below 20 % & burden

does not exceed 4 VA

4. For E/F Schemes Class 5 P &

rated O/P X ALF=150

5. For other forms of protection i.e Biased Diff & Class 5 P or 10 P

Distance Relays

Basic Classification Of CTs

Measurement CTs: (Governed by IS 2705-1992 Part II)

Specified in terms of

Accuracy Class

VA Burden

ISF

Typical Illustration: Class 1.0, VA-15, ISF-3

Standard Error Class: 0.1, 0.2, 0.5, 1.0, 3 & 5.

The errors are specified between 5-120 % of rated current

and 25-100 % of rated burden connected. Higher errors are

permitted at lower currents.

Protection CTs

Protection CTs for Special Applications

Basic Classification Of CTs

Protection CTs: (Governed by IS 2705-1992 Part III)

Specified in terms of

Accuracy Class

VA rating

Accuracy limiting Factor

Typical Illustration: 5P10, 15 VA

Standard Error Class: 5P, 10P, 15P

ALF: 5, 10, 15, 20, 30

VA Rating: 5, 10, 15, 30

Protection class CT

5P10

Factors for Protection

1. Accuracy Limiting Factor/composite error

For e.g if the class designation is 5P20

20 is the Accuracy limiting factor which signifies that when

20 times the rated primary current is applied the composite

error of 5P( +/- 5%) is maintained.

Typical Class designations are

5P10, 5P20, 10P10, 10P20 etc.,

Knee point voltage: That point on the magnetizing

curve where an increase of 10% in the flux density

(voltage) causes an increase of 50% in the

magnetizing force (current).

RATIO ERROR

(KnIs -Ip)

Ratio error = x 100

Ip

Where,

Kn = Rated transformation ratio

Ip = Primary current

Is = Actual secondary current when Ip is

flowing in the Primary.

PHASE DISPLACEMENT:

Phase displacement is the difference between phases of primary

and secondary current vectors. This is normally expressed in

minutes. Phase displacement is said to be positive when the

secondary current vector leads the primary current vector.

Primary current Exciting Current = Secondary Current

when all the values are referred to either primary or

secondary side. Hence the CT will have poor accuracy

if the exciting current is large. To keep the errors low,

the exciting current should be kept as low as possible.

This can be achieved by:

Keeping the burden low

Keeping the flux density low by providing large cross

section of the core.

Keeping the mean length of core as low as possible. This

is done by suitable design techniques for the primary coil

insulation.

PROTECTIVE CURRENT TRANSFORMERS FOR SPECIAL

PURPOSE APPLICATION:

Protective current transformers used in association with

special purpose application such as differential protection

and distance protection schemes are designated as PS

class CTs. For the PS class transformers, current ratio

errors and phase angle errors are not specified, but

instead, the turns ratio error, the minimum knee point

voltage, maximum permissible exciting current and the

maximum secondary winding resistance at 75

o

C are

specified.

There shall not be any turns correction for the PS class

cores and the error in turns ratio shall not exceed +

0.25%.

The following are the various aspects associated with

the fault current through the current transformers:

Large error in ratio and phase angle.

Excessive heating

Development of mechanical forces high enough to

deform the winding and leads.

Generation of transient voltage rises.

Saturation of core may be produced by the excessive symmetrical

fault currents as well as by the lower magnitude of fault currents.

Hence distortion of out put current will occur causing large

errors.

There are three sources of heating in CTs. Viz. magnetic, I

2

R

losses in secondary and primary windings, I

2

R loss in primary

winding under fault conditions will be significant. This cannot be

dissipated so quickly by conduction or convection and hence the

temperature of the winding will rise sharply. If the current

density is so high, it may even cause to melt the winding.

Mechanical forces may deform or displace the

windings. The forces have the greatest value

during the first amplitude. This occurs at a very

short interval after the incidence of short circuit

and thereafter declines rapidly towards its steady

current value. This short duration for the

maximum forces will have an impulsive or hammer

effect.

Reasons of CT Failures

Moisture entry into solid insulation

Wrinkles in aluminium grading

Opening of secondary winding

Opening of tan delta point

High system parameters i.e. voltage & frequency,

switching over voltages, lighting over voltages.

Dielectric failure due to pre-mature ageing

Other dielectric failures due to improper wrapping

of paper, improper flux distribution etc.

Suggested Tests/Checks to Minimize The

Failure of CT

Measurement of Tangent Delta and Capacitance

DGA Monitoring

Furan Analysis

IR Measurement

MAINTENANCE OF CURRENT TRANSFORMER

Typical Arrangement for IR

measurement

TESTING OF CTS

TY

COMMISSIONING TEST

ROUTINE TEST

SPECIAL TEST

CURRENT TRANSFORMER TESTS:

TYPE TESTS:

The following are the type tests for current transformers as per IS:

2705(Part-1)-1992

Type Test of terminal markings Purpose

Short Time Current Test To Measure current density of wdg

wrt rated short ckt time current

Temp Rise Test To know actual temperature rise in

CT under loading condition

Lightening Impulse Test To know lightening impulse voltage

withstand capacity of insulation.

Switching surge test for CTs To know switching impulse voltage above 245

kV class capacity of insulation

HV power frequency wet To verifiy power freq voltage withstand

voltage test withstand capacity of external

insulation.

Determination of error or other To measure actual current ration, actual

characteristics according to accuracy against rated ratio.

requirement of designation & To measure impedance of secondary ckt

accuracy class

ROUTINE TESTS:

The following are the type tests for current transformers as per IS:

2705(Part-1)-1992

Routine Test Purpose

Verification of Terminal marking & To ensure correct marking &

Polarity function of CT

Power freq dry withstand test on To verify power freq withstand

primary wdg capacity bet primary wdg &

earth.

Power freq dry withstand test on To verify power freq withstand

secondary wdg capacity bet secondary wdg &

earth.

Over Voltage inter turn test To ensure inter turn insulation

strength.

Partial Discharge test To ensure insulation strength

Current ratio test To measure actual current ratio

against rated ratio.

Accuracy Class To know actual accuracy against

rated.

Burden To measure the impendence of the

secondary circuit.

SPECIAL TESTS

The following special tests may be carried out by mutual

agreement between the purchaser and the manufacturer.

High voltage power frequency wet withstand voltage test on

outdoor current transformer.

Note: If the porcelain casing has already been tested for the above

separately, then the full assembly need not be tested once again.

Commissioning tests

Partial discharge test

Tangent delta measurement

Maintenance schedule for Current Transformer

Work to be

carried out

Period Action required if inspection shows

unsatisfactory condition

Check paint work Yearly Repaint after cleaning the surfaces

to be painted

Check oil level &

observe the colour

of the coil

Quarterly Maintain required level

Check the

I.R.Values of the

windings of the

CTs and compare

with the values at

the time of

commissioning

Half

yearly

If low, obtain advice from

manufacturer

Check tightness of

mounting nuts &

bolts and jumpers

Half

yearly

Tighten loose nuts & bolts

Clean & check

insulator

Half

yearly

If cracks observed on

insulator,obtain advice from

manufacturer

Oil dielectric

strength &

moisture content

Yearly Take oil sample from drain valve

and test for dielectric strength and

moisture content. If the dielectric

strength is lower, moisture content

is high as compared to the values as

per relevant standards the oil

should be filtered

Limit values for CT

Sl TEST DATA PERMISSIBLE LIMITS REMARKS

1 Insulation Resistance Value

a) Primary Sec. Cores/Earth 1000 M (Min.) By 5/10.0 kV Megger

b) Sec. Cores Cores/Earth 50 M(Min.) By 0.5 Kv Megger

c) Control Cables 50 M(Min.) By 0.5 Kv Megger

2 a) Tan Delta Value 0.007(Max.)

b) Rate of rise in tan delta 0.001 per year(Max.)

3 Terminal Connector contact

resistance

10 per connector

4 CT ratio errors

a) Protection cores 3 % IS 2705

b) Secondary cores 1% IS 2705

AIS Substation

(Circuit breakers)

CT

(Bus bar)

(Line switches)

CVT

(Line Bay)

RMK Existing range

3 CT design

Hair-Pin ITT - IT 245 to 420 kV

Eye-Bolt IT 245 kV

Top-Core KT 72 to 145 kV

Design CT Type Voltage Range

Eye Bolt Design

IT 72.5-245

1. Dome

2. Collar

3. Top casting

4. Insulator

5. Active part

6. Bottom casting

7. Tank

8. Support frame

9. Secondary cores

10. Pressure relief valve

11. Primary terminal

IT range

Primary conductor (1,2 or 4 turns)

Eye Bolt Design

Active part manufacturing

Primary steel pipe

Paper insulation

Secondary cores

IT range

Eye Bolt Design

Active part manufacturing

IT range

Oven

Eye Bolt Design

Vacuum treatment

Target :

Remove all the water

trapped in the paper (and in

other materials) during

insulation process

Duration :

Up to 3 weeks

High vacuum (0.01 mm Hg)

High Temperature (105 C)

Active

part

IT range

Upper Tank

Nitrogen filling

Eye Bolt Design

Assembly

Bottom Tank

Secondary terminal box

Oil filling

Active part

Porcelain insulator

IT range

Eye Bolt Design

Assembly

Summary of Technical data :

Rated voltage : 123 to 245 kV

Technolgy : Eye-Bolt

Expansion device : Nitrogen

Primary reconnection : 1-2

Rated primary current : 1200 Amp (1440 max)

Short circuit current : 40 kA 1

Total weight (kg)

kV 72.5 145 245

kg 700 750 1200

IT range

Existing range

Hair-Pin design

Tuyau

ITT 245

IT 400

ITT range

Existing range

Hair-Pin design

ITT range

Summary of Technical data :

Rated voltage : 245 to 420 kV

Technolgy : Hair-Pin

Expansion device : Nitrogen

Primary reconnection : 1-2

Rated primary current : 3000 Amp (3000 max)

Short circuit current : - 40 kA 1 (245 kV)

- 60 kA 1 (420 kV)

Total weight (kg)

kV 245 420

kg 1400 2300

Existing range

Top Core design

KT 36

..

KT 245

1. Dome

2. Oil level indicator

3. Primary terminals

5. Upper tank

6. Upper flange

7. Insulator

8. Active part

9. Base

10.Multibushing

11.Pressure relief valve

KT range

Existing range

Top Core design

KT range

Summary of Technical data :

Rated voltage : 72.5 to 245 kV

Technolgy : Top-core

Expansion device : Nitrogen

Primary reconnection : 1-2

Rated primary current : 2000 Amp (2400 max)

Short circuit current : - 40 kA 1 (145 kV)

- 50 kA 1 (245 kV)

Total weight (kg)

kV 72.5 145 245

kg 250 500 850

Factors for Protection

Parameters

1. ALF ( accuracy limiting factor)

2. Composite error

OVER CURRENT AND EARTH FAULT PROTECTION

Factors for Protection

1. Accuracy Limiting Factor

What is Accuracy Limiting factor ?

It is the factor of over current above the rated current which

determines the capability of CT to maintain the error at such

a condition.

2. Composite error

It is the error of the CT when this over current is applied.

Composite error :

Under steady-state conditions, the r.m.s. value of the difference

between:

a) the instantaneous values of the primary current, and

b) the instantaneous values of the actual secondary current

multiplied by the rated transformation ratio

CEI 600 44-1

T

0

2

p s n

p

c

dt . i I K

T

1

I

100

Current Transformers Protection accuracy

classes

K

n

is the rated transformation ratio;

I

p

is the r.m.s. value of the primary current;

i

p

is the instantaneous value or the primary current;

i

s

is the instantaneous value of the secondary current;

T is the duration of one cycle.

Current Transformers

Saturation curve

10 20 30 40

Induction

B [T]

Primary current

Ip/In

Protection CT

18500 gauss

Metering CT

8000 gauss

Factors for Protection

1. Knee Point Voltage(Vk):

Knee point voltage is point beyond which an

application of 10% of voltage increases the exciting

current by 50%.

The typical equations for Vk ( based on relay used)

Vk > 24 I

n

(R

c t

+2R

L

)- for Transformer Differential

Where I

n

: Relay rated current

R

L

= Total lead Resistance

R

c t

= CT secondary resistance

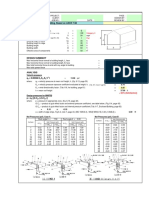

Typical Burden Calculation 400kV Current

Transformer Metering core

The max burdens of all the meters/load = 5 VA (approx) considering

analog meters and max lead length for 400kV switchyard = 1000 meters

The control cable size is 2.5 sq.mm. Always 2 runs of cable are used.

Resistance of 2.5sq.mm cable is 8.5 ohms per kilometre for 2 runs of

cable it is 4.25 Ohms

Therefore the burden of the lead length is = 2* isec

2

* r * 1kM

= 2 *1*1* 4.25

= 8.5 VA

The optimum total burden = 5 + 8.5 = 13.5VA

Therefore realistic burden required is 15 or 20 VA

MAXIMUM BURDEN BE IMPOSED ON THE CURRENT

TRANSFORMER PROTECTION CORE ( 5 P/10 P CLASS ) - FOR

220KV & 132KV SUBSTATIONS

Burden of numerical relay recommended = 2.5 VA

( inclusive of lead length ). The maximum lead length for 220/132kv

switchyard = 500 meters

The control cable size is 2.5 sq.mm. Always 2 runs of cable are used.

Resistance of 2.5sq.mm cable is 8.5 ohms per kilometre for 2 runs of cable

it is 4.25 Ohms

Therefore the burden of the lead length is = 2* isec

2

* r * 500/1000

= 2 *1*1* 4.25*0.5

= 4.25 VA

The optimum total burden = 2.5 +4.25 = 7 VA

Therefore realistic burden required for class 5p cores is 15 VA

NOTE: FOR 400KV CT's ONLY CLASS PS CORES ARE USED. HENCE THIS CALCULATION IS OMITTED FOR 400KV

CTs.

POTENTIAL TRANSFORMER

PTs are used to reduce the system voltage to level low enough to

suit the rating of protective relays & measuring instruments.

Types of Construction:

Electromagnetic type

Conveniently used up to 132 KV.

Capacitor Type

Economical above 132 KV

Residual Voltage T/F

ELECTROMAGNETIC TYPE VT

Works on the same principle as the Power T/F.

Load to be flow is quite limited depending upon purposes.

As voltage decreases, the accuracy of electromagnetic type PTs

decreases but is acceptable down to 1 % of nominal voltage.

At higher voltages, electromagnetic type PTs becomes very expensive

& hence it is common practice to use a Capacitor Voltage Divider.

Capacitor Type Voltage Transformer

The size of electromagnetic voltage transformers for the higher

voltages is largely proportional to the rated voltage; the cost tends to

increase at a disproportionate rate. The capacitor voltage

transformer (CVT) is often more economic.

High voltage capacitors are enclosed in a porcelain housing.

The transient performance of a Capacitor type PT is inferior as

compare to electromagnetic type.

Special Auxilliary Circuit elements are:

Compensating Inductance coil: in series with the primary of the

intermediate T/F compensates the voltage increase on CV divider.

Damping impedance: Avoids ferro-resonance in secondary ckt.

Resistor & Spark Gap: Provides necessary protection against

overvoltages.

CVT Construction Details

CVT Secondary Voltage

CVT Secondary Voltage v = k * V * C1/ C1+C2)

V Primary Voltage

k Secondary Transformation ratio

Note:

Puncturing of C1 Secondary Voltage will

increase

Puncturing of C2 Secondary Voltage will

decrease

Secondary Voltage measurement

Periodic measurement to be carried out. In case

of doubt, simultaneous measurement to be

carried out with another feeder/ Bus CVT.

For 400kV CVTs puncturing of one Capacitor

element in C1 side is likely to increase Secondary

Voltage by about 0.35 0.45% (0.22 0.28V)

Failure of one Capacitor element in C2 side is

likely to decrease Secondary Voltage by 5 6%

(3.2 3.8V)

Secondary Voltage measurement

Norms

Sr.

No.

Drift in Sec.

Voltage

Condition of CVT Measurement

Frequency

1 Upto 0.5 Volts Healthy Six monthly

2 0.5 to 0.8 Volts Needs monitoring Three monthly

3 +0.8 to +1.2 Volts Needs close

monitoring

4 +1.2 to +2.0 Volts Needs close

monitoring

15 days

5 Above +2.0 volts Alarming/ critical Needs replacement

6 -0.8 to -4.0 volts Needs close

monitoring

15 days

7 Less than -4.0 volts Alarming Needs replacement

METERING VTs

Goverened by IS 3156 PartII-1992

Class % Ratio Error Phase Angle error Reference Conditions

0.1 0.1 5 Voltage 80-120 %

Burden 25-100 %

P F 0.8 Lag

Frequency - Rated

0.2 0.2

10

0.5 0.5

20

1.0 1.0

40

3.0 3.0

Not Specified

PROTECTION VTs

Goverened by IS 3156 Part III-1992

Class % Ratio Error Phase Angle error Reference Conditions

3P 3 % 120 BURDEN 25-100%

PF 0.8 LAG

FREQUENCY- RATED

6P 6 % 240

RESIDUAL VTs

Class % Ratio Error Phase Angle error Reference Conditions

5 PR 5 % 200 BURDEN 25-100%

PF 0.8 LAG

FREQUENCY- RATED

10 PR 10 % ------

Capacitance and Tan delta

measurement of stacks

Change in Capacitance value above 6%,

CVT need to be replaced

Tan delta values more than 0.003 from pre-

commissioning value needs replacement

RMK - CVT

Capacitor stack

Inductive VT

CCV 72.5 to 765 kV

Capacitor elements

Capacitor column

Insulating oil

Insulator flange

Secondary terminal box

Inductance

MV Transformer

Oil expansion device

Damping circuit

RMK - CVT

P

Capacitor Voltage Transformer

Diagram

P

GROUND

GS HF

HV Terminal

C1

C2

N

4

a

4

n

11

12

14

1

a

1

n

11

12

14

2

a

2

n

11

12

14

3

a

3

n

11

12

14

MCB

S S S S

GS MV

D

L

HF DC

C

RMK CVT - Manufacturing process

Capacitor packs are made of

- Aluminium foils

- Oil-impregnated paper and film

RMK CVT - Manufacturing process

Capacitor packs are

stacked together and

mounted in a porcelain

insulator

CVT - STACK

Capacitor Voltage Transformer

Ferroresonance

L

1

L

2

Z

N

2

N

1

I

th

C

2

C

1

SG

C

C

Secondary Short Circuit

L

R

2

R

1

D

Ferroresonance

Damping device

on inductive PT

L'

1

L'

2

R

L

SG

L

Ferroresonance

Damping device

on inductance

"Transformer type"

compensating

inductance

CHOICE OF CONNECTIONS OF 3

PHASE PTs

V-Connection: Two single-phasing T/Fs are connected in V both on

Primary & Secondary sides. As there is no neutral on primary

winding, the zero sequence voltage cannot be obtained.

This connection is generally used for three phase 3 wire meters

Star-Star Connection: Most common connections used in metering &

relaying schemes. Typical limb voltage rating 11KV/3/110V/3.

Star Broken Delta Connections: Residual Connections.

The connection is used when zero sequence voltage is required for

earth fault relaying scheme.

Capacitor Voltage Transformers

Routine tests (IEC 60044-5)

Routine tests

The following tests apply to each individual transformer:

a) Verification of terminal markings

b) Power-frequency withstand tests on primary windings

c) Partial discharge measurement

d) Power-frequency withstand tests on secondary windings

e) Power-frequency withstand tests between sections

f) Determination of errors.

G) Ferroresonance test

h) Sealing test

Capacitor Voltage Transformers

Type tests (IEC 60044-5)

a) Temperature-rise test

b) Short-circuit withstand capability test

c) Lightning impulse test

d) Switching impulse test

e) Wet test for outdoor type transformers

f) Determination of errors.

Limit values of CVT

Sl TEST DATA PERMISSIBLE

LIMITS

REMARKS

1 Insulation Resistance Value

a) Primary Sec. Cores/Earth 1000 M (Min.) By 5/10.0 kV

Megger

b) Sec. Cores Cores/Earth 50 M(Min.) By 0.5 Kv Megger

c) Control Cables 50 M(Min.) By 0.5 Kv Megger

2 Tan Delta Value 0.007(Max.)

3 Contact Resistance of terminal

connector

10 per

connector

4 CVT Voltage Ratio Errors

a) Protection cores 5 % IEEE/C93.1.1990

b) Metering cores 0.5 % IEC 186

5 Drift in secondary voltage 2.0 volts

replacement

Maintenance schedule for Potential Transformer

Work to be

carried out

Periodicity Action required if inspection

shows unsatisfactory condition

Check oil level &

observe the

colour of the coil

Quarterly Maintain required level

To check the

earth results of

the base for the

CVTs

Quarterly Maintain required values

Check tightness

of mounting nuts

& bolts and

jumpers

Half yearly Tighten loose nuts & bolts

Clean the

insulators and

check paint work

Half yearly Disconnect the VT from the

supply, inspect & clean HV

insulators

Oil dielectric

strength &

moisture content

Yearly Take oil sample from drain valve

and test for dielectric strength and

moisture content. If the dielectric

strength is lower, moisture content

is high as compared to the values

as per relevant standards the oil

should be filtered

MAXIMUM BURDEN IMPOSED ON THE CAPACITOR

VOLTAGE TRANSFORMER METERING WINDING IN A

400KV SUBSTATION

The max burdens of all the meters/load = 28 VA (approx) when analog

meters are considered and max lead length for 400kv switchyard =

1000 meters

The control cable size is 2.5 sq.mm. Always 2 runs of cable are used.

Resistance of 2.5sq.mm cable is 8.5 ohms per kilometre for 2 runs of

cable it is 4.25 Ohms

Therefore the burden of the lead length is = 2* isec

2

* r * 1km

= 2 * (28/63.5

)2*

4.25*1

= 1.70 VA

The optimum total burden = 28 +1.7 = 29.7 VA

Therefore realistic burden required is 50 VA

Вам также может понравиться

- VA TECH Transmission and Distribution Overcurrent and Earth Fault RelaysДокумент7 страницVA TECH Transmission and Distribution Overcurrent and Earth Fault RelaysBasudev Patra100% (1)

- Scholarly Breaker Failure ProtectionДокумент30 страницScholarly Breaker Failure Protectionkra_amОценок пока нет

- Nanometer Scale Multilayer Coatings Achieve Extreme HardnessДокумент12 страницNanometer Scale Multilayer Coatings Achieve Extreme HardnessBojan PodgornikОценок пока нет

- Tech Con 2011 Kruger New Experience With Diagn Meas On PTДокумент15 страницTech Con 2011 Kruger New Experience With Diagn Meas On PTMichael KrügerОценок пока нет

- Busbar ProtectionДокумент16 страницBusbar ProtectionDEADMANОценок пока нет

- Arrester Protection DistanceДокумент8 страницArrester Protection DistanceyaoОценок пока нет

- Design and Results of Differential Relay Settings For Power Transformers 80MVA, 40MVA and 100MVAДокумент3 страницыDesign and Results of Differential Relay Settings For Power Transformers 80MVA, 40MVA and 100MVAMatthew Wong100% (1)

- Power Distribution TransformerДокумент25 страницPower Distribution Transformerajs009Оценок пока нет

- MHO Distance Protection SettingДокумент17 страницMHO Distance Protection SettingAdhyartha KerafОценок пока нет

- Ethiopia EEPCOTransmission Substations Mobile Transformer SpecsДокумент9 страницEthiopia EEPCOTransmission Substations Mobile Transformer SpecsNavneeth100% (1)

- KC Agarwal HitsДокумент18 страницKC Agarwal HitskittyОценок пока нет

- Transformer Protection Calculations PDFДокумент44 страницыTransformer Protection Calculations PDFngocanhvyОценок пока нет

- DataSheet (Line Differential 7SD87-P1B177029) PDFДокумент7 страницDataSheet (Line Differential 7SD87-P1B177029) PDFmasudОценок пока нет

- 5 Transformer ProtectionДокумент37 страниц5 Transformer ProtectionSatya VasuОценок пока нет

- Basics of Built-In Motor Protection For BeginnersДокумент8 страницBasics of Built-In Motor Protection For BeginnersrodinooОценок пока нет

- High Voltage Testing Techniques and EquipmentДокумент16 страницHigh Voltage Testing Techniques and Equipmenthadrien100% (1)

- Behavior of Current Transformers (CTS) Under Severe Saturation ConditionДокумент5 страницBehavior of Current Transformers (CTS) Under Severe Saturation ConditionAdianto Ari PurwanaОценок пока нет

- Summation of Alternating CurrentsДокумент3 страницыSummation of Alternating Currentsalexns84Оценок пока нет

- UE Vs E CablesДокумент2 страницыUE Vs E CablesKrishnan KrishОценок пока нет

- Cable Sheath Surge Voltage LimiterДокумент2 страницыCable Sheath Surge Voltage LimiterDes LawlessОценок пока нет

- Tap ChangerДокумент10 страницTap ChangerusefiОценок пока нет

- Presentation o Surge Protection DevicesДокумент50 страницPresentation o Surge Protection DevicesramprakashpatelОценок пока нет

- Distribution Transformer Maintenance and ProtectionДокумент77 страницDistribution Transformer Maintenance and ProtectionAbin PaulОценок пока нет

- Capacitance Voltage Transforme1Документ4 страницыCapacitance Voltage Transforme1ayushОценок пока нет

- Manual 1HSE96002-12Документ48 страницManual 1HSE96002-12seltonjapaoОценок пока нет

- CT Theory and TestingДокумент42 страницыCT Theory and TestingHisham Magdi El Deeb100% (1)

- Partial Discharge Analysis in High-Frequency Transformer Based On High-Frequency Current TransducerДокумент13 страницPartial Discharge Analysis in High-Frequency Transformer Based On High-Frequency Current TransducerKaiba SetoОценок пока нет

- Method Finding Protection Angle For LPSДокумент1 страницаMethod Finding Protection Angle For LPSMatthew WongОценок пока нет

- Cost-Efficient Solution for Power DistributionДокумент8 страницCost-Efficient Solution for Power DistributionaayushОценок пока нет

- Phase Shifting TransformersДокумент7 страницPhase Shifting Transformerse06001Оценок пока нет

- Dielectric Response Measurements in Frequency, Temperature and Time DomainsДокумент29 страницDielectric Response Measurements in Frequency, Temperature and Time DomainsRitesh Jaiswal100% (1)

- P44x en T F65 GlobalДокумент690 страницP44x en T F65 Globalirfu100% (1)

- Transformer BushingДокумент11 страницTransformer BushingNunna BaskarОценок пока нет

- The Role of Communication Systems For Smart Transmission: Irwin Barneto, Abb India LTD., Cigre Nov. 2013Документ23 страницыThe Role of Communication Systems For Smart Transmission: Irwin Barneto, Abb India LTD., Cigre Nov. 2013Bhuiyan Muhammad Mustansir MustafaОценок пока нет

- Henikwon Busduct Systems: Power Delivery Systems To Match Every NeedДокумент31 страницаHenikwon Busduct Systems: Power Delivery Systems To Match Every NeedElectrical Radical100% (1)

- APN-076 - Inrush Restraint For 7UT6 PDFДокумент11 страницAPN-076 - Inrush Restraint For 7UT6 PDFWaskito AjiОценок пока нет

- 0626-REF CT CALCS New Not ReviewedДокумент2 страницы0626-REF CT CALCS New Not ReviewedtceterexОценок пока нет

- Transformer Diagnostic Testing Response: FrequencyДокумент10 страницTransformer Diagnostic Testing Response: Frequencyosvi009Оценок пока нет

- Using Core-Balance Current Transformer For Earth Fault Protection - EEPДокумент2 страницыUsing Core-Balance Current Transformer For Earth Fault Protection - EEPcatalinccОценок пока нет

- Unit-2 Gt-2c Client Finalised Final ReportДокумент50 страницUnit-2 Gt-2c Client Finalised Final ReportSaran KumarОценок пока нет

- Restricted Earth-Fault Protection in REF 542plus: Application and Setting GuideДокумент20 страницRestricted Earth-Fault Protection in REF 542plus: Application and Setting GuideSandeep PanigrahiОценок пока нет

- Bushings PDFДокумент6 страницBushings PDFeider yovannis payares davilaОценок пока нет

- MIB Settings of 20 MVA Power TransformerДокумент3 страницыMIB Settings of 20 MVA Power TransformerRavi Shankar VОценок пока нет

- Distance Relay Principle: Suppose Relay Is Designed To Operate WhenДокумент40 страницDistance Relay Principle: Suppose Relay Is Designed To Operate WhenAnonymous 9VcxlFErfОценок пока нет

- Essential guide to voltage transformers (VTs) and capacitive voltage transformers (CVTsДокумент4 страницыEssential guide to voltage transformers (VTs) and capacitive voltage transformers (CVTsrupali patilОценок пока нет

- DTS 2687 - 132kV GIS Method Statement For HV Test & Partial Discharge Measurement - Rev.CДокумент38 страницDTS 2687 - 132kV GIS Method Statement For HV Test & Partial Discharge Measurement - Rev.Cমোঃ মহসিনОценок пока нет

- Diff Protection PDFДокумент14 страницDiff Protection PDFarunОценок пока нет

- Instrument Transformer Requirements for Protection RelayingДокумент32 страницыInstrument Transformer Requirements for Protection Relayingዛላው መና100% (1)

- Alfanar Co.: Respon Sibilities Legend CSDДокумент5 страницAlfanar Co.: Respon Sibilities Legend CSDjayabalОценок пока нет

- 07 SEP674 RET670 Overexcitation Protection PDFДокумент17 страниц07 SEP674 RET670 Overexcitation Protection PDFarunmozhiОценок пока нет

- CT Calculation MFAC14Документ10 страницCT Calculation MFAC14Jay WinОценок пока нет

- Easun Reyrolle: Figure 11. Star Connected Bank, Two Limbs Per PhaseДокумент20 страницEasun Reyrolle: Figure 11. Star Connected Bank, Two Limbs Per PhaseE.AvinashОценок пока нет

- Bcconduitcatalog PDFДокумент34 страницыBcconduitcatalog PDFDiadam SharmaОценок пока нет

- Protection Scheme Dia: Motor Prot. RelayДокумент9 страницProtection Scheme Dia: Motor Prot. RelayPradipta Kumar MohantyОценок пока нет

- Fault Current: Larsen & Toubro LimitedДокумент1 страницаFault Current: Larsen & Toubro Limitedjm.mankavil6230Оценок пока нет

- EE6702-PSG - Unit-III Apparatus ProtectionДокумент235 страницEE6702-PSG - Unit-III Apparatus ProtectionedhanaaОценок пока нет

- Current TransformersДокумент7 страницCurrent Transformersmn_sundaraamОценок пока нет

- CT&PTДокумент131 страницаCT&PTDipanjan SenguptaОценок пока нет

- Current Transformers, Voltage Transformers and Instrument Transformers - IndiaДокумент10 страницCurrent Transformers, Voltage Transformers and Instrument Transformers - IndiaVijay PitchaiahОценок пока нет

- Combined 16Документ333 страницыCombined 16Avnish BhasinОценок пока нет

- Format of AnswerДокумент36 страницFormat of AnswerAvnish BhasinОценок пока нет

- 08 - Chapter 3Документ21 страница08 - Chapter 3Avnish BhasinОценок пока нет

- Application For Child Care LeaveДокумент1 страницаApplication For Child Care LeaveAvnish BhasinОценок пока нет

- Answer Sheet 24 PGДокумент24 страницыAnswer Sheet 24 PGtanvi5gupta-7Оценок пока нет

- Attri D's Mathematics Academy and Resonant ClassesДокумент50 страницAttri D's Mathematics Academy and Resonant ClassesAvnish BhasinОценок пока нет

- Foaming Capacity of Soap Chemistry Project ReportДокумент2 страницыFoaming Capacity of Soap Chemistry Project ReportAvnish BhasinОценок пока нет

- Format of Answer (Without Page)Документ36 страницFormat of Answer (Without Page)Avnish BhasinОценок пока нет

- Format of AnswerДокумент30 страницFormat of AnswerAvnish BhasinОценок пока нет

- Study oxalate ions in guava at ripening stagesДокумент2 страницыStudy oxalate ions in guava at ripening stagesAvnish BhasinОценок пока нет

- BibliographyДокумент10 страницBibliographyAvnish BhasinОценок пока нет

- Bio Gyan Transport in PlantsДокумент9 страницBio Gyan Transport in PlantsAvnish BhasinОценок пока нет

- Sets, Relations and FunctionsДокумент73 страницыSets, Relations and FunctionsAvnish Bhasin100% (1)

- Sequence and SeriesДокумент55 страницSequence and SeriesAvnish BhasinОценок пока нет

- Binomial TheoremДокумент30 страницBinomial TheoremAvnish BhasinОценок пока нет

- Circul and Conic SectionДокумент25 страницCircul and Conic SectionAvnish BhasinОценок пока нет

- Relations and FunctionsДокумент55 страницRelations and FunctionsAvnish BhasinОценок пока нет

- In Each of The Exercises 1 To 9Документ1 страницаIn Each of The Exercises 1 To 9Avnish BhasinОценок пока нет

- RELATION AND FUNCTION MATRIXДокумент21 страницаRELATION AND FUNCTION MATRIXAvnish BhasinОценок пока нет

- 8.3 Exercise Short Answer (S.A.) : X y X y Py X PX y X yДокумент5 страниц8.3 Exercise Short Answer (S.A.) : X y X y Py X PX y X yAvnish BhasinОценок пока нет

- Relationship Marketing EvolutionДокумент188 страницRelationship Marketing EvolutionAvnish BhasinОценок пока нет

- Continuity and Differentiability FunctionsДокумент18 страницContinuity and Differentiability FunctionsAvnish BhasinОценок пока нет

- High Court of Punjab and Haryana at Chandigarh: January February MarchДокумент1 страницаHigh Court of Punjab and Haryana at Chandigarh: January February MarchsanjeevpunjОценок пока нет

- Continuity and Differentiability FunctionsДокумент18 страницContinuity and Differentiability FunctionsAvnish BhasinОценок пока нет

- MRPL recruitment drive for SC/ST positionsДокумент5 страницMRPL recruitment drive for SC/ST positionsbhaskar5377Оценок пока нет

- Flowers and Plants: Student's NameДокумент25 страницFlowers and Plants: Student's NameAvnish BhasinОценок пока нет

- 3.3 ExerciseДокумент47 страниц3.3 ExerciseAvnish BhasinОценок пока нет

- Fact It Est Sun A MiДокумент2 страницыFact It Est Sun A MikagomekikioОценок пока нет

- C 36554 A 93 e 3 B 66 F 1 Eb 77 C 5447 C 2 BbeДокумент83 страницыC 36554 A 93 e 3 B 66 F 1 Eb 77 C 5447 C 2 BbeAvnish BhasinОценок пока нет

- Decddfad 8 B 5352 C 671 A 13216231 B 50Документ25 страницDecddfad 8 B 5352 C 671 A 13216231 B 50Avnish BhasinОценок пока нет

- Assignment 1 (ELE8306 - 21)Документ5 страницAssignment 1 (ELE8306 - 21)umarsaboОценок пока нет

- Light FundamentalsДокумент75 страницLight FundamentalsErica QuirobОценок пока нет

- Constraint PDFДокумент12 страницConstraint PDFNeelesh BenaraОценок пока нет

- EE207 Problem Set 1Документ2 страницыEE207 Problem Set 1Rishabh AgarwalОценок пока нет

- Analysis and Design of Underpass RCC BridgeДокумент7 страницAnalysis and Design of Underpass RCC Bridgeaaditya chopadeОценок пока нет

- Unit 15 - Reaction Rates and EquilibriumДокумент68 страницUnit 15 - Reaction Rates and EquilibriumGarett Berumen-RoqueОценок пока нет

- National Level E-Conference On Innovative Trends in MechanicalДокумент16 страницNational Level E-Conference On Innovative Trends in MechanicalA BBОценок пока нет

- Foundation Class X PCMBДокумент1 571 страницаFoundation Class X PCMBJack CrookОценок пока нет

- Resume AyanchattopadhyayДокумент2 страницыResume Ayanchattopadhyayapi-163237383Оценок пока нет

- Analysis AssigmentДокумент50 страницAnalysis AssigmentAliyi MuktarОценок пока нет

- Ossd U1Документ26 страницOssd U1huangjunxiang4Оценок пока нет

- Apllied Electric Circuit Objective Question and AnswerДокумент42 страницыApllied Electric Circuit Objective Question and AnswerGanesan KandasamyОценок пока нет

- Compass Swing ProcedureДокумент23 страницыCompass Swing ProcedureMiro Hsd100% (2)

- Wind Analysis For Low-Rise Building, Based On ASCE 7-98Документ2 страницыWind Analysis For Low-Rise Building, Based On ASCE 7-98reynoldОценок пока нет

- Energies: Exergy Analysis and Process Optimization With Variable Environment TemperatureДокумент19 страницEnergies: Exergy Analysis and Process Optimization With Variable Environment TemperatureFranco Camacho CanchariОценок пока нет

- Chapter 9 VibrationДокумент83 страницыChapter 9 Vibration胡宇晟Оценок пока нет

- Models of The AtomДокумент38 страницModels of The AtomKC TorresОценок пока нет

- Dynamic Parameter Identification of The Universal Robots UR5 PDFДокумент7 страницDynamic Parameter Identification of The Universal Robots UR5 PDFAyman DamounОценок пока нет

- MomentumДокумент2 страницыMomentumMuhammad UsmanОценок пока нет

- Colless, Matthew - The New CosmologyДокумент249 страницColless, Matthew - The New CosmologyShade SemjazaОценок пока нет

- The CRS A255 RobotДокумент20 страницThe CRS A255 RobotnguyendattdhОценок пока нет

- Reiki Is A Great Tool For Stress Reduction and Relaxation (!)Документ16 страницReiki Is A Great Tool For Stress Reduction and Relaxation (!)vaniaОценок пока нет

- Numerical Simulation of Ultrasonic Wave Propagation in Flawed DomainДокумент4 страницыNumerical Simulation of Ultrasonic Wave Propagation in Flawed DomainGrit WingsОценок пока нет

- Blocked Rotor TestДокумент11 страницBlocked Rotor TestIjabi100% (1)

- Experiment No 8: Aim: To Determine The Frequency & Wavelength in A Rectangular Waveguide Working inДокумент5 страницExperiment No 8: Aim: To Determine The Frequency & Wavelength in A Rectangular Waveguide Working inSanab KumarОценок пока нет

- Kid-sized humanoid robot design paperДокумент4 страницыKid-sized humanoid robot design paperHimanshu VermaОценок пока нет

- ADMmodule - STEM - GP12N-Id-28Документ24 страницыADMmodule - STEM - GP12N-Id-28Jersa Mae MaravillaОценок пока нет

- Grounding - Industry Experiences - 2013Документ292 страницыGrounding - Industry Experiences - 2013Minhthien NguyenОценок пока нет

- torque 정의Документ40 страницtorque 정의valmaxjeonОценок пока нет