Академический Документы

Профессиональный Документы

Культура Документы

Group 4

Загружено:

Ankur47Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Group 4

Загружено:

Ankur47Авторское право:

Доступные форматы

PRESENTATION BY:

GROUP-4

11119049 to 11119053

CONTENTS

Definition

History

Working

Characteristics

Types

Advantages

Disadvantages

Application

Strain Gage

Electrical component

Bonded to material

Strains as material strains

Resistance changes as gage strains

R=120 W (nominal)

DEFINITION

A strain gauge is an example of passive transducer that

converts a mechanical displacement into a change of

resistance.

A strain gauge is a thin, wafer-like device that can be

attached to a variety of materials to measure applied strain.

HISTORY

A brief history of the Strain Gauge:

1856 : Lord Kelvin first reported on a relationship between

strain and the resistance of wire conductors.

Early 1930s : Charles Kearns made the first notable use of

bonded resistance strain gauges to measure vibratory

strains in high performance propeller blades.

1937/8 : Arthur Ruge discovered that small diameter wires

made of electrical resistance alloys could be bonded to a

structure to measure surface strain.

1952 : At this time, printed circuits were emerging, and

Saunders-Roe developed the idea of making a strain gauge

by etching the pattern for the gauge from a thin foil.

STRUCTURE

The majority of strain gauges are foil types, available in a

wide choice of shapes and sizes to suit a variety of

applications. They consist of a pattern of resistive foil

which is mounted on a backing material.

They operate on the principle that as the foil is subjected to

stress, the resistance of the foil changes in a defined way.

WORKING

The strain gauge is connected into a Wheatstone Bridge

circuit. The change in resistance is proportional to applied

strain and is measured with Wheatstone bridge.

WORKING

The sensitivity of a strain gauge is described in terms of a

characteristic called the gauge factor, defined as unit

change in resistance per unit change in length, or

Gauge factor is related to Poisson's ratio by,

K=1+2

TYPES

Based on principle of working :

Mechanical

Electrical

Piezoelectric

Based on mounting :

Bonded strain gauge

Unbonded strain gauge

TYPES

Based on construction :

Foil strain gauge

Semiconductor strain gauge

Photoelectric Strain gauge

MECHANICAL STRAIN GAUGE

It is made up of two separate plastic layers. The bottom

layer has a ruled scale on it and the top layer has a red

arrow or pointer. One layer is glued to one side of the crack

and one layer to the other. As the crack opens, the layers

slide very slowly past one another and the pointer moves

over the scale. The red crosshairs move on the scale as the

crack widens.

ELECTRICAL STRAIN GAUGE

When an electrical wire is

stretched within the limits

of its elasticity such that it

does not break or

permanently deform, it will

become narrower and

longer, changes that

increase its electrical

resistance end-to-end.

Strain can be inferred by

measuring change in

resistance.

PIEZOELECTRIC STRAIN GAUGE

Piezoelectric generate electric voltage when strain is

applied over it. Strain can be calculated from voltage.

Piezoelectric strain gauges are the most sensitive

and reliable devices.

BONDED STRAIN GAUGE

A bonded strain-gage element, consisting of a metallic

wire, etched foil, vacuum-deposited film, or

semiconductor bar, is cemented to the strained surface.

UNBONDED STRAIN GAUGE

The unbonded strain gage consists of a wire stretched

between two points in an insulating medium such as air.

One end of the wire is fixed and the other end is attached

to a movable element.

FOIL STRAIN GAUGE

The foil strain gage has metal foil photo-etched in a grid

pattern on the electric insulator of the thin resin and gage

leads attached,

SEMICONDUCTOR STRAIN GAUGE

For measurements of small strain, semiconductor strain

gauges, so called piezoresistors, are often preferred over foil

gauges. Semiconductor strain gauges depend on the

piezoresistive effects of silicon or germanium and measure

the change in resistance with stress as opposed to strain.

PHOTOELECTRIC STRAIN GAUGE

The photoelectric gauge uses a light beam, two fine

gratings, and a photocell detector to generate an electrical

current that is proportional to strain. The gage length of

these devices can be as short as 1/16 inch, but they are

costly and delicate.

STRAIN GAUGE

STRAIN GAUGE SELECTION CRITERIA:

Gauge Length

Number of Gauges in Gauge Pattern

Arrangement of Gauges in Gauge Pattern

Grid Resistance

temperature sensitivity

Carrier Material

Gauge Width

Availability

low cost

ADVANTAGES & DISADVANTAGES

Advantages

There is no moving part.

It is small and inexpensive.

Disadvantages

It is non-linear.

It needs to be calibrated.

APPLICATIONS

Residual stress

Vibration measurement

Torque measurement

Bending and deflection measurement

Compression and tension measurement

Strain measurement

MANUFACTURERS

INTEGRATED PROCESS SYSTEMS

HANZHONG QUAN YUAN

ELECTRONICS

GOLDBELL

SYSTEMS

VISHAY PRECISION GROUP

MICRO MEASUREMENTS

THANK YOU

Вам также может понравиться

- Electrical Power System Design of High-Rise ResidentialДокумент28 страницElectrical Power System Design of High-Rise Residentialsjaveeds200386% (7)

- Insulation Co-ordination in High-voltage Electric Power SystemsОт EverandInsulation Co-ordination in High-voltage Electric Power SystemsРейтинг: 4.5 из 5 звезд4.5/5 (5)

- Hyundai D6GA General InformationДокумент10 страницHyundai D6GA General InformationBigfair HD78Оценок пока нет

- Straingauge 130703045302 Phpapp02Документ22 страницыStraingauge 130703045302 Phpapp02nithiaashreeОценок пока нет

- Strain GaugesДокумент35 страницStrain GaugesSnigdhaОценок пока нет

- DP CellДокумент18 страницDP CellbrindaОценок пока нет

- p5 En303 Sankalp Purwar 2Документ14 страницp5 En303 Sankalp Purwar 22K20 EN 63 Sankalp PurwarОценок пока нет

- p5 En303 Sankalp PurwarДокумент14 страницp5 En303 Sankalp Purwar2K20 EN 63 Sankalp PurwarОценок пока нет

- ME 402 UNIT 4 IC Force Strain InstrumentsДокумент43 страницыME 402 UNIT 4 IC Force Strain InstrumentsYASH KUMARОценок пока нет

- What Is Strain Gage?: - A Device Whose Electrical Resistance Varies in Proportion To The Amount of Strain in The DeviceДокумент21 страницаWhat Is Strain Gage?: - A Device Whose Electrical Resistance Varies in Proportion To The Amount of Strain in The Devicebishnu kumarОценок пока нет

- Strain Gauge: Keci ShahДокумент15 страницStrain Gauge: Keci ShahAkip PrayotoОценок пока нет

- To Study The Elastic Stress Strain Behavior in Bending Using Electrical Resistance Strain GaugesДокумент8 страницTo Study The Elastic Stress Strain Behavior in Bending Using Electrical Resistance Strain GaugesFaisal SardarОценок пока нет

- Piezoresistive Sensors: Strain GaugesДокумент17 страницPiezoresistive Sensors: Strain GaugesAjinkya DeshmukhОценок пока нет

- Lecture 4Документ32 страницыLecture 4yashagrawal.be18aeroОценок пока нет

- Strainguage ApplicationsДокумент13 страницStrainguage ApplicationsJeyakumar VenugopalОценок пока нет

- Electrical Strain Gauges: A Report OnДокумент31 страницаElectrical Strain Gauges: A Report OnAnonymous GRY6OCJОценок пока нет

- Tirtharaj Pati - Details of Strain Gauge Sensor PDFДокумент13 страницTirtharaj Pati - Details of Strain Gauge Sensor PDFTirtharaj PatiОценок пока нет

- Strain GaugeДокумент3 страницыStrain GaugeNatalio GarzonОценок пока нет

- Tejavathbhavsingh EEN208 Lab5Документ29 страницTejavathbhavsingh EEN208 Lab5suriya rsОценок пока нет

- Industrial Instrumentation: Strain GaugesДокумент58 страницIndustrial Instrumentation: Strain GaugesBhavik PrajapatiОценок пока нет

- EET027 ManualДокумент49 страницEET027 Manual李積奇Оценок пока нет

- Strain MeasurementДокумент31 страницаStrain MeasurementTejal IkharОценок пока нет

- Module 4 PDFДокумент19 страницModule 4 PDFBinoshi SamuvelОценок пока нет

- Strain Gauge Theory of Strain GaugeДокумент22 страницыStrain Gauge Theory of Strain GaugeBenjamin EstrelladoОценок пока нет

- Extenso MeterДокумент8 страницExtenso MeterVijayanandh Raja100% (1)

- Strain Gauges Are Used To Measure The Strain of A MaterialДокумент7 страницStrain Gauges Are Used To Measure The Strain of A MaterialThinesh Rau KrishnamurtyОценок пока нет

- Resistive & Capacitive TransducerДокумент52 страницыResistive & Capacitive TransducerAimenRaza89% (19)

- Mi CT 3 AinДокумент1 страницаMi CT 3 AinMd. Anwar HossinОценок пока нет

- TransducersДокумент48 страницTransducersB11 Aswathy SureshОценок пока нет

- Module 6Документ91 страницаModule 6Midhun SukumaranОценок пока нет

- Resentation ON Strain Gauge: by Altab Hossain EIE, 4 Year Roll No-46Документ18 страницResentation ON Strain Gauge: by Altab Hossain EIE, 4 Year Roll No-46aslamhossainОценок пока нет

- Lecture 5Документ14 страницLecture 5havishalhumОценок пока нет

- Experimental Techniques: Unit I - Forces and Strain MeasurementДокумент35 страницExperimental Techniques: Unit I - Forces and Strain MeasurementGokulОценок пока нет

- Strain Gauge: Load CellДокумент33 страницыStrain Gauge: Load CellPrashant ShahОценок пока нет

- Unit - 3 Transducers: Lecture - 3.2 Strain GaugeДокумент12 страницUnit - 3 Transducers: Lecture - 3.2 Strain GaugeRahul kumarОценок пока нет

- Strain GaugeДокумент9 страницStrain GaugeAAKASHОценок пока нет

- TransducersДокумент35 страницTransducersm.srinivasa raoОценок пока нет

- Unit 2classnotesstraingageДокумент13 страницUnit 2classnotesstraingagesvnet vizagОценок пока нет

- Types of Strain GaugesДокумент3 страницыTypes of Strain Gaugesprabhushankar05Оценок пока нет

- NDT Eddy CurrentsДокумент13 страницNDT Eddy Currentsyashwant verma100% (1)

- Strain Measurement MEASUREMENT EXPERIMENT: 1. ObjectДокумент7 страницStrain Measurement MEASUREMENT EXPERIMENT: 1. ObjectKenny KenzoОценок пока нет

- Subject: Power Systems-II: InsulatorsДокумент16 страницSubject: Power Systems-II: InsulatorssaiОценок пока нет

- Interpreting PDFДокумент7 страницInterpreting PDFHồ ThắngОценок пока нет

- Strain GaugeДокумент34 страницыStrain Gaugerobomango0625Оценок пока нет

- Strain Gauge-LectureДокумент48 страницStrain Gauge-Lecturerameshbabu_197963% (8)

- Strain Gauge ReportДокумент34 страницыStrain Gauge ReportJay PatelОценок пока нет

- Stain GaugeДокумент20 страницStain GaugearunachelamОценок пока нет

- Strain GaugeДокумент7 страницStrain GaugeIanosi SorinОценок пока нет

- Chapter 21 ElectronicsДокумент107 страницChapter 21 ElectronicsPathmanathan NadesonОценок пока нет

- MMM Lecture - Unit 3 - Strain MeasurementДокумент40 страницMMM Lecture - Unit 3 - Strain MeasurementAlanka BhanuОценок пока нет

- Physical Operation: Electrical Conductance Electrical Conductor ElasticityДокумент4 страницыPhysical Operation: Electrical Conductance Electrical Conductor Elasticitydwarika2006100% (1)

- STRAIN GageДокумент5 страницSTRAIN Gagemanoish07Оценок пока нет

- Strain GaugesДокумент7 страницStrain GaugesRoss Jay MichelОценок пока нет

- Piezoresistive Sensors - Principles, Materials, Fabrication and ApplicationsДокумент43 страницыPiezoresistive Sensors - Principles, Materials, Fabrication and ApplicationsArun KiranОценок пока нет

- University Institute Engineering Department Academic UnitДокумент28 страницUniversity Institute Engineering Department Academic UnitAkhil SainiОценок пока нет

- L L L L LДокумент14 страницL L L L LBah NahОценок пока нет

- Strain Gauge 1Документ26 страницStrain Gauge 1ULFAT HUSSAINОценок пока нет

- Electronics Workshop Manual 2Документ141 страницаElectronics Workshop Manual 2Manu Yadav100% (1)

- Experimental Stress Analysis Strain Gauges: Mechanical Engineering Amrita VishwavidyapeethamДокумент14 страницExperimental Stress Analysis Strain Gauges: Mechanical Engineering Amrita VishwavidyapeethamMuhammed SulfeekОценок пока нет

- Chapter Two: Sensors and ApplicationДокумент10 страницChapter Two: Sensors and ApplicationAddisu Safo BoseraОценок пока нет

- Unit 2Документ29 страницUnit 2nikhill kundarОценок пока нет

- HV Machines WEBДокумент16 страницHV Machines WEBVassilis DanakasОценок пока нет

- Science5 ST3 Q3Документ4 страницыScience5 ST3 Q3ronaldОценок пока нет

- CMC Mid-I Question BankДокумент10 страницCMC Mid-I Question BankAkash BiswasОценок пока нет

- 1 Electrical RegulationsДокумент37 страниц1 Electrical RegulationsGraezelОценок пока нет

- TC4066BFДокумент11 страницTC4066BFdonghungstbОценок пока нет

- Evolution of Communication Networks: Unit 01.01.01 CS 5220: Computer CommunicationsДокумент14 страницEvolution of Communication Networks: Unit 01.01.01 CS 5220: Computer Communicationssaru priyaОценок пока нет

- 4 Hspice TutorialДокумент134 страницы4 Hspice Tutorialspiderman86Оценок пока нет

- Gujarat Technological UniversityДокумент3 страницыGujarat Technological UniversityTanvi IsraniОценок пока нет

- Harmonic Current Emission of Wind Farms Exceeding The Limiting ValuesДокумент3 страницыHarmonic Current Emission of Wind Farms Exceeding The Limiting ValuesgusutnarОценок пока нет

- Parts Manual: Generator SetДокумент60 страницParts Manual: Generator SetAnderson PioОценок пока нет

- MB Fault - CodesДокумент38 страницMB Fault - CodesssbsandvikОценок пока нет

- Measurement While Drilling (MWD)Документ14 страницMeasurement While Drilling (MWD)Hamza Moussa100% (1)

- Tesys U - A4 - Tesys U - P - enДокумент38 страницTesys U - A4 - Tesys U - P - enlaloedu472Оценок пока нет

- Fire Alarm-Fir (Shield) : 2 Core (Cu/Mica Tape/PVC-FR/CAM+ATC Drain wire/PVC-FRLS)Документ1 страницаFire Alarm-Fir (Shield) : 2 Core (Cu/Mica Tape/PVC-FR/CAM+ATC Drain wire/PVC-FRLS)Cost RootsОценок пока нет

- Power System Analysis EEE-486: Fahd Ali ShifaДокумент19 страницPower System Analysis EEE-486: Fahd Ali ShifaFahd Ali ShifaОценок пока нет

- Cat C32: Diesel Generator SetsДокумент6 страницCat C32: Diesel Generator SetsIlung MarpaungОценок пока нет

- Owners Manual Evidence PlatinumДокумент30 страницOwners Manual Evidence PlatinumAmanda ValladaresОценок пока нет

- STPSC20H12: 1200 V Power Schottky Silicon Carbide DiodeДокумент8 страницSTPSC20H12: 1200 V Power Schottky Silicon Carbide DiodeshivguptaОценок пока нет

- Class 12th Chapterwise Jee Main Session 1 2024 Pyq's ChapterwiseДокумент48 страницClass 12th Chapterwise Jee Main Session 1 2024 Pyq's ChapterwisePratham MittalОценок пока нет

- SLC 30 SeriesДокумент16 страницSLC 30 Serieshipnos_1982Оценок пока нет

- Technical Service For Brush Transformers and OltcsДокумент2 страницыTechnical Service For Brush Transformers and OltcsMOHAMAD ABDELRAHMANОценок пока нет

- Fully Integrated LDO Linear Voltage RegulatorДокумент15 страницFully Integrated LDO Linear Voltage RegulatorAram ShishmanyanОценок пока нет

- Pyqs of Electric Potential and CapacitenceДокумент3 страницыPyqs of Electric Potential and Capacitencetechnicalchirag4Оценок пока нет

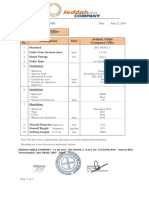

- Jeddah Cable Cu Xlpe-PvcДокумент2 страницыJeddah Cable Cu Xlpe-PvcSoltani AliОценок пока нет

- Ch23 Electric FieldДокумент61 страницаCh23 Electric FieldNavpreet SinghОценок пока нет

- Mentor IIДокумент107 страницMentor IIMOHD AKHALAK AHAMADОценок пока нет

- Cold Fusion Replication ExperimentsДокумент14 страницCold Fusion Replication ExperimentsXR500Final100% (6)

- Book 4Документ197 страницBook 4fgdfgdfОценок пока нет