Академический Документы

Профессиональный Документы

Культура Документы

T.Shivakumar: Kottam Institute of Pharmacy Jntu, A.P

Загружено:

Free Escort ServiceОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

T.Shivakumar: Kottam Institute of Pharmacy Jntu, A.P

Загружено:

Free Escort ServiceАвторское право:

Доступные форматы

T.

SHIVAKUMAR

Kottam institute of pharmacy

J NTU, A.P

INTRODUCTION

Coated tablets are defined as tablets

covered with one or more layers of mixture

of various substances such as

Natural Or Synthetic Resins

Gums

Inactive And Insoluble Filler,

Sugar

Plasticizer

Polyhydric Alcohol

Waxes

Authorized Colouring Material

And Some Times Flavoring Material.

I. Therapy

Avoid irritation of oesophagus and

stomach

Avoid bad taste

Avoid inactivation of drug in the

stomach

Improve drug effectiveness

Prolong dosing interval

Improve dosing interval

Improve patient compliance

II. Technology

Reduce influence of moisture

Avoid dust formation

Reduce influence of atmosphere

Improve drug stability

Prolong shelve life

III. Marketing

Avoid bad taste

Improve product identity

Improve appearance and acceptability

Tablet coating is the application of

coating composition to moving bed of

tablets with concurrent use of heated

air to facilitate evaporation of

solvent.

Basic principle of tablet coating

Sugar coating

Film coating

Enteric coating

Controlled release coating

Specialized coating

Compressed coating

Electrostatic coating

Dip coating

Vacuum film coating

EQUIPMENTS FOR TABLET COATING

Three general types of equipments are available

1.Standard coating pan

e.g., Pellegrino pan system

Immersion sword system

Immersion tube system

2.Perforated pan system

e.g.,Accela cota system

Hicoater system

Glattcoater system

Driacoated system

3.Fluidized bed coater

POLISHING

Standard Coating Pan

Immersion-

tube system

Glatt

Immersion

sword

system

Pellegrini

pan system

STANDARD COATING PAN

PERFORATED PANS

Accela cota

system

Hi-coater

system

PERFORATED PANS (continue)

Dria coater pan

Glatt coater

FLUID BED COATING SYSTEMS

1. Film coating

2. Sugar coating

3. Press coating

Main coating processes

6. Printing

5. Polishing

4. Colouring

3. Smoothing

2. Sub coating

1. Seal tablet core

Traditionally sugar coatings formed the bulk of coated tablets but today film

coatings are the more modern technology in tablet coating.

Description of tablets: Smooth, rounded and polished to a high gloss.

Process: Multistage Process involving 6 separate operations.

Example of sugar coated tablets

Sugar coating

MULTISTAGE PROCESS

1. Sealing tablet core- application of a water impermeable

polymer such as Shellac, cellulose acetate phthalate and

polyvinyl acetate phthalate, which protects the core from

moisture, increasing its shelf life.

2. Sub coating -by adding bulking agents such as calcium

carbonate or talc in combination with sucrose solution.

3. Smoothing process -remove rough layers formed in step

2 with the application of sucrose syrup.

4. Colouring - for aesthetic purposes often titanium based

pigments are included.

5. Polishing - effectively polished to give characteristic shine,

commonly using beeswax, carnauba wax.

6. Printing -indelible ink for characterisation.

1- Sealing (Waterproofing)

This involved the application of one or more coats of a

waterproofing substance in the form of alcoholic spray, such

as pharmaceutical Shellac (traditionally) or synthetic

polymers, such as CAP.

( Unless a modified-release feature needs to be introduced,

the amount of the sealing coat applied should be carefully

calculated so that there is no negative effect on the drug

release characteristics in case of immediate release product.)

(WHY Sealing?)

a- Sugar-coatings are aqueous formulations which allow

water to penetrate directly into the tablet core and thus

potentially affecting product stability and possibly causing

premature tablet disintegration.

b- Application of many coats of partially or completely

water-insoluble polymers in this step, enables sugar-coated

product to exhibit modified-release pattern (extendedrelease

or delayed "enteric"- release characteristics).

2. Subcoating

- Large quantities of sugar-coatings are usually

applied to the tablet core (typically increasing the

tablet weight by ( 50- 100%)

WHY?

In order to round off the tablet edge. Much of this

material build-up occurs during this stage and is

achieved by adding a bulking agent such as

Calcium carbonate, to the sucrose solution.

- Antiadherents e.g. Talc may be added after

partial drying to prevent sticking of the tablets

together.

3- Smoothing

The subcoating stage results in tablets with rough

surfaces. To facilitate the color application (which

requires smooth surface), subcoated tablets are

smoothed out by a thick sucrose syrup coating.

4- Coloring

Color coatings usually consist of thin sucrose

syrup containing the requisite coloring materials.

(water-soluble dyes or water-insoluble pigments

may be used) This step must be done into a clean

pan deprived of any residues from the previous

operations.

5- Polishing

After the coloring step, the tablet surfaces tend to

be smooth but somewhat dull in appearance. To

achieve glossy finish, final stage involving

application of waxes (beeswax carnuba wax) is

employed.

6- Printing

Different tablets could be identified by

manufacturer' logo, product name, dosage strength

or other appropriate code. For sugar-coated tablets,

such identification could be only achieved by

printing process using special edible inks.

Brufen POM

Available in 200mg and 400mg

strength

Premarin POM

Conjugated oestrogens 625mcg

(maroon) and 1.25mcg (yellow)

Colofac P

Mebeverine hydrochloride

100mg Round, white, sugar

coated

Kalms GSL

45mg Hops powder,90mg

Gentian powdered extract, and

135mg Valerian powdered

extract

EXAMPLE OF SUGAR COATED TABLETS

SUGAR COATED PROCESS

Modern approach to coating tablets, capsules, or pellets by

surrounding them with a thin layer of polymeric material.

Description of tablets: Shape dictated by contour of

original core.

Process: Single stage process, which involves spraying a

coating solution containing the following;

1. Polymer

2. Solvent

3. Plasticizer

4. Colourant

The solution is sprayed onto a rotating tablet bed followed

by drying, which facilitates the removal of the solvent

leaving behind the deposition of thin film of coating

materials around each tablet.

FILM COATING

Advantages

Produce tablets in a single step process in

relatively short period of time. Process enables

functional coatings to be incorporated into the

dosage form.

Disadvantages

There are environmental and safety

implications of using organic solvent as well as

their financial expense.

Types of film coating

A. Immediate release

B. Modified release

1.Polymer

31

2.Plasticizers

Plasticizers are generally added to film coating

formulations to modify the physical properties of the

polymer to make it more usable. One important property

is their ability to decrease film brittleness.

Examples of plasticizers are:

polyols, such as polyethylene glycol 400

organic esters, such as diethyl phthalate

oils/glycerides, such as fractionated coconut oil.

In general, only water-miscible plasticizers can be used for aqueous-based

spray systems.

32

3.Colourants

Any permitted colourants in a film coat formula are invariably

water-insoluble colours (pigments). Pigments have certain

advantages over water-soluble colours: they tend to be more

chemically stable towards light, provide better opacity and

covering power, and optimize the impermeability of a given film

to water vapour.

Examples of colourants are:

iron oxide pigments

titanium dioxide

aluminum Lakes.

33

4.Solvents

Modern techniques now rely on water as a

polymer solvent because of the significant

drawbacks that readily became apparent with

the use of organic solvents.

Nonenteric

materials : e.g.

Hydroxypropyl methylcellulose

(HPMC)

Methylhydroxy ethyl cellulose (MHEC)

Ethylcellulose (EC)

Hydroxypropyl cellulose (HPC)

Polyvinyl pyrrolidone (PVP)

Sodium carboxymethyl cellulose (Sod.

CMC)

Polyethylene glycols (PEG)

Acrylate polymers e.g. Eudragit E

Enteric materials:

e.g.

Cellulose acetate phthalate (CAP)

Acrylate polymers (Eudragit L, S)

Hydroxypropyl methylcellulose

phthalate (HPMCP)

Polyvinyl acetate phthalate (PVAP)

MATERIAL USED FOR FILM COATING

The vast majority of film coated tablets are produced by a process which

involves spraying of the coating material on to a bed of tablets. Accela

Cota is one example of equipment used for film coating.

Accela Cota

Accela Cota

Film coating

Tablet appearance

Retains shape of original core

Small weight increase of 2-

3% due to coating material

logo or break lines possible

Process

Can be automated e.g. Accela

Cota

Easy training operation

Single stage process

Easily adaptable for

controlled release allows for

functional coatings.

Sugar coating

Tablet appearance

Rounded with high degree of

polish

Larger weight increase 30-

50% due to coating material

Logo or break lines are

possible

Process

Difficult to automated e.g.

traditional coating pan

Considerable training

operation required

Multistage process

Not able to be used for

controlled release apart from

enteric coating.

DIFFERENCE BETWEEN

FILM COATNIG & SUGAR COATING

use of compression to form coat around a

pre-formed core

used mainly to separate chemically

incompatible materials

also dual release patterns possible

PRESS COATING

40

To separate chemically incompatible materials, one or more being

placed in the core and the other(s) in the coating layer.

However, there is still an interface contact left between the two

layers.

In cases where even this is important then the process of pre

coating can be taken one stage further.

It is possible to apply two press coatings to a tablet core using

suitable equipment.

This equipment produces press-coated tablets with perfect

separation between active core and coating, as the two can be

separated by an inert middle layer.

press coating is used

Вам также может понравиться

- 02.tablets (-II-)Документ42 страницы02.tablets (-II-)Subha ShankareeОценок пока нет

- AssignmentДокумент12 страницAssignmentAbdul Wahid OrakzaiОценок пока нет

- Lec.1 PowderДокумент41 страницаLec.1 PowderEman Saddar El LeithyОценок пока нет

- Bioassay & BiostandardisationДокумент51 страницаBioassay & BiostandardisationFree Escort Service100% (1)

- Spectra Blend ColorДокумент6 страницSpectra Blend ColorLuz Adriana ManzanoОценок пока нет

- Concrete Mix DesignДокумент7 страницConcrete Mix Designgman444Оценок пока нет

- 3 PDF Original PDFДокумент30 страниц3 PDF Original PDFDevang GondaliyaОценок пока нет

- Tablet CoatingДокумент51 страницаTablet CoatingsuminderОценок пока нет

- Tablet Coating Process: Made byДокумент25 страницTablet Coating Process: Made byYuppie RajОценок пока нет

- 4350 9644 1 PBДокумент65 страниц4350 9644 1 PBWan MuhamammadОценок пока нет

- Tablet Coating With Its DefectsДокумент56 страницTablet Coating With Its Defectsjoshirohan100% (1)

- Tablet Coating - Fundamentals & TechniquesДокумент36 страницTablet Coating - Fundamentals & TechniquesSatyabrata SahuОценок пока нет

- Microencapsulationgss 160227005508 PDFДокумент70 страницMicroencapsulationgss 160227005508 PDFSelva RathinamОценок пока нет

- Tablet Coating PDFДокумент6 страницTablet Coating PDFAsif Hasan Niloy100% (1)

- Pharmaceutical Suspension: Department of Pharmacy GP (Uttawar)Документ56 страницPharmaceutical Suspension: Department of Pharmacy GP (Uttawar)FelixyaОценок пока нет

- Tableting: Compression & Compaction in Tablets FormationДокумент25 страницTableting: Compression & Compaction in Tablets FormationVon Valentine MhuteОценок пока нет

- Problems and Remedies For Tablet CoatingДокумент7 страницProblems and Remedies For Tablet CoatingAnowar HossainОценок пока нет

- MixingДокумент17 страницMixingHaleema SiddiquiОценок пока нет

- Chapter 27 Suspensions and EmulsionsДокумент49 страницChapter 27 Suspensions and EmulsionsKate Montenegro67% (3)

- Stability in PreformulationДокумент48 страницStability in Preformulationmithaann2353Оценок пока нет

- C 14 SuspensionДокумент119 страницC 14 SuspensionVinod ChoudharyОценок пока нет

- Pharmaceutical EmulsionsДокумент55 страницPharmaceutical EmulsionschandramohanОценок пока нет

- Freeze DryingДокумент14 страницFreeze DryingSanjana BhattacharyyaОценок пока нет

- Biphasic Dosage FormsДокумент5 страницBiphasic Dosage Formslitha100% (1)

- Preformulation MaterialДокумент10 страницPreformulation MaterialRajesh NayakОценок пока нет

- SuspensionsДокумент130 страницSuspensionsHaroon Rahim0% (1)

- 634798775670659161Документ41 страница634798775670659161Suvin PsОценок пока нет

- Lecture 2 - Disperse SystemsДокумент94 страницыLecture 2 - Disperse Systemsapi-370729792% (12)

- CapsuleskncopДокумент181 страницаCapsuleskncopboozokaranОценок пока нет

- Pharmaceutical SuspensionsДокумент52 страницыPharmaceutical SuspensionsUsman Akhtar100% (1)

- SUSPENSIONДокумент11 страницSUSPENSIONAnoosha FarooquiОценок пока нет

- Preformulation StudiesДокумент10 страницPreformulation StudiesHanuma KanthetiОценок пока нет

- Disperse SystemsДокумент4 страницыDisperse SystemsAbby CruzОценок пока нет

- Assignment: (Pharmaceutical Aerosols)Документ10 страницAssignment: (Pharmaceutical Aerosols)Muhammad KafeelОценок пока нет

- NanosuspensionДокумент48 страницNanosuspensionved.g007Оценок пока нет

- Disperse Systems: Reporters: #25 LEE, Sharmaine C. #26 LOTERTE, Edwin A. #27 LUMBAO, Jicah A. #28 MONSALUD, Miguel MДокумент141 страницаDisperse Systems: Reporters: #25 LEE, Sharmaine C. #26 LOTERTE, Edwin A. #27 LUMBAO, Jicah A. #28 MONSALUD, Miguel MSharmaine Margaret LeeОценок пока нет

- Oral FormulationsДокумент10 страницOral FormulationsSiddhartha MuppallaОценок пока нет

- Evalutation Parameter of TabletsДокумент27 страницEvalutation Parameter of TabletsAnkush DwivediОценок пока нет

- Manufacturing of Tablets PART-IIIДокумент12 страницManufacturing of Tablets PART-IIIbalamuruganОценок пока нет

- Tablet FormulationДокумент34 страницыTablet FormulationWicharn KetjindaОценок пока нет

- Powders and GranulesДокумент18 страницPowders and GranulesAlaa Salymeh100% (1)

- Tablet GranulationДокумент17 страницTablet GranulationAnup Bajracharya100% (3)

- Copy of Oral Solid Dosage FormsДокумент86 страницCopy of Oral Solid Dosage Formsrosebelle1906Оценок пока нет

- SUB: Physical Chemistry Topic: Solubilization, Micellar Catalysis, Micro Emulsions, Reverse Micelles, Characterization of Micro EmulsionsДокумент30 страницSUB: Physical Chemistry Topic: Solubilization, Micellar Catalysis, Micro Emulsions, Reverse Micelles, Characterization of Micro EmulsionsVijay PradhanОценок пока нет

- Emulsion and ApplicationДокумент26 страницEmulsion and ApplicationSamay Sharma100% (1)

- EmulsionДокумент13 страницEmulsionPriyanka KushwahaОценок пока нет

- Wet GranulationДокумент3 страницыWet GranulationuddhavОценок пока нет

- Class 1 Size Reduction ZZДокумент43 страницыClass 1 Size Reduction ZZZen EbeОценок пока нет

- CapsulesДокумент44 страницыCapsulesPrinceОценок пока нет

- Seminar On Application of Polymers in Dosage FormsДокумент16 страницSeminar On Application of Polymers in Dosage FormskeyurОценок пока нет

- PreformulationДокумент100 страницPreformulationVikas Jhawat0% (1)

- Tablet FinalДокумент104 страницыTablet FinalAngela PagalilauanОценок пока нет

- Tablet ManufacturingДокумент88 страницTablet ManufacturingStikes SambasОценок пока нет

- Additives in Parenteral FormulationДокумент54 страницыAdditives in Parenteral FormulationMuhammad Hilmi50% (6)

- Microencapsulation FinalДокумент17 страницMicroencapsulation FinalHuma Hameed DogarОценок пока нет

- SolutionsДокумент7 страницSolutionsMARIE ERICKA ARONAОценок пока нет

- (Vinesia, 2010: Importance of CapsuleДокумент8 страниц(Vinesia, 2010: Importance of CapsuleFarzana ShantaОценок пока нет

- Tablet CoatingДокумент45 страницTablet CoatingIzamHamMandenoОценок пока нет

- Tablet CoatingДокумент50 страницTablet CoatingNaufal HanifОценок пока нет

- CoatingДокумент50 страницCoatingdwahyusafriОценок пока нет

- CoatingДокумент39 страницCoatingMunna SmileОценок пока нет

- Lecture (5) Tablet Coating (Spring 2023)Документ35 страницLecture (5) Tablet Coating (Spring 2023)ah1589681Оценок пока нет

- Inflammation in Schizophrenia and DepressionДокумент9 страницInflammation in Schizophrenia and DepressionFree Escort ServiceОценок пока нет

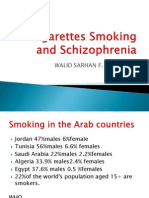

- Walid Sarhan F. R. C. PsychДокумент46 страницWalid Sarhan F. R. C. PsychFree Escort ServiceОценок пока нет

- Role of Nutraceuticals in Health Promotion: Swati Chaturvedi, P. K. Sharma, Vipin Kumar Garg, Mayank BansalДокумент7 страницRole of Nutraceuticals in Health Promotion: Swati Chaturvedi, P. K. Sharma, Vipin Kumar Garg, Mayank BansalFree Escort ServiceОценок пока нет

- Mechanism For The Ability of 5Документ2 страницыMechanism For The Ability of 5Free Escort ServiceОценок пока нет

- Nutraceuticals: Let Food Be Your MedicineДокумент32 страницыNutraceuticals: Let Food Be Your MedicineFree Escort ServiceОценок пока нет

- Reliability and ValidityДокумент15 страницReliability and Validityapi-260339450Оценок пока нет

- Reliablity Validity of Research Tools 1Документ19 страницReliablity Validity of Research Tools 1Free Escort Service100% (1)

- Quality by Design On PharmacovigilanceДокумент1 страницаQuality by Design On PharmacovigilanceFree Escort ServiceОценок пока нет

- Nutraceutical Role in Health CareДокумент1 страницаNutraceutical Role in Health CareFree Escort ServiceОценок пока нет

- Quality Is Built in by Design, Not Tested inДокумент1 страницаQuality Is Built in by Design, Not Tested inFree Escort ServiceОценок пока нет

- Tablets:: Tablets May Be Defined As SolidДокумент13 страницTablets:: Tablets May Be Defined As SolidFree Escort ServiceОценок пока нет

- ResumeДокумент3 страницыResumeFree Escort ServiceОценок пока нет

- ABSTRACT (QBD: A Holistic Concept of Building Quality in Pharmaceuticals)Документ1 страницаABSTRACT (QBD: A Holistic Concept of Building Quality in Pharmaceuticals)Free Escort ServiceОценок пока нет

- 2415 14725 4 PBДокумент13 страниц2415 14725 4 PBFree Escort ServiceОценок пока нет

- Optimizing Quality by Design in Bulk Powder & Solid Dosage: Smt. Bhoyar College of Pharmacy, KamteeДокумент3 страницыOptimizing Quality by Design in Bulk Powder & Solid Dosage: Smt. Bhoyar College of Pharmacy, KamteeFree Escort ServiceОценок пока нет

- Tablet Coating: Why Coat Tablets?Документ12 страницTablet Coating: Why Coat Tablets?Free Escort ServiceОценок пока нет

- 102i Eng Screen 02Документ14 страниц102i Eng Screen 02Free Escort ServiceОценок пока нет

- BIOASSAYДокумент16 страницBIOASSAYFree Escort ServiceОценок пока нет

- (RSC PAPERBACKS) G. Scott - Polymers and The Environment-Royal Society of Chemistry (2003)Документ148 страниц(RSC PAPERBACKS) G. Scott - Polymers and The Environment-Royal Society of Chemistry (2003)nimraОценок пока нет

- Design of High Strength Concrete Using Superplastisizer and Stone DustДокумент19 страницDesign of High Strength Concrete Using Superplastisizer and Stone DustEditor IJTSRDОценок пока нет

- Armix HyyeCrete PC 20 Ver 6Документ2 страницыArmix HyyeCrete PC 20 Ver 6Deepthi RОценок пока нет

- 3.29 Sucrose Derivatives Eastman SAIB-100: General InformationДокумент14 страниц3.29 Sucrose Derivatives Eastman SAIB-100: General InformationIcha ChairunОценок пока нет

- Coating Technology of TabletsДокумент64 страницыCoating Technology of Tabletsdeepthi_puramОценок пока нет

- TPO Coated PP Fabrics and Their ApplicationsДокумент14 страницTPO Coated PP Fabrics and Their ApplicationsrejoramaОценок пока нет

- Polymer Additives: Fillers & ReinforcementsДокумент5 страницPolymer Additives: Fillers & ReinforcementsHina IbrahimОценок пока нет

- Solvent Cast Technology - A Versatile ToolДокумент14 страницSolvent Cast Technology - A Versatile ToolsggdgdОценок пока нет

- Cemwet SP 3000 (Pce 3)Документ2 страницыCemwet SP 3000 (Pce 3)Angry BoyОценок пока нет

- Brochure Admixtures For Concrete enДокумент12 страницBrochure Admixtures For Concrete enrezartОценок пока нет

- Hemali Davande Et Al - Quantum Chemistry-Based Force Field For Simulations of Energetic Dinitro CompoundsДокумент33 страницыHemali Davande Et Al - Quantum Chemistry-Based Force Field For Simulations of Energetic Dinitro CompoundsPomaxxОценок пока нет

- Construction Chemicals: Total Solution ofДокумент4 страницыConstruction Chemicals: Total Solution ofdwijОценок пока нет

- Admixture - 1Документ10 страницAdmixture - 1Baibaswata DasОценок пока нет

- Advanced Concrete TechnologyДокумент3 страницыAdvanced Concrete TechnologyAnonymous fYHyRa2XОценок пока нет

- Modification of PVC Compounds With NBRДокумент4 страницыModification of PVC Compounds With NBRAnonymous twSsELVPОценок пока нет

- TDS - Micro-Air 120Документ3 страницыTDS - Micro-Air 120aahtagoОценок пока нет

- Formulation Guideline Sent Eric enДокумент3 страницыFormulation Guideline Sent Eric enParina FernandesОценок пока нет

- WO 2007/060660 Al: (19) World Intellectual Property OrganizationДокумент36 страницWO 2007/060660 Al: (19) World Intellectual Property OrganizationenthaiОценок пока нет

- Chaochanchaikul Et Al-2021-Journal of Polymers and The EnvironmentДокумент11 страницChaochanchaikul Et Al-2021-Journal of Polymers and The EnvironmentPornlada PongmuksuwanОценок пока нет

- Final Capstone Research Paper Euclid DiazДокумент44 страницыFinal Capstone Research Paper Euclid DiazClark Gultiano RoblesОценок пока нет

- Thermal Degradation of PVC PlastigelДокумент9 страницThermal Degradation of PVC Plastigelkang8886021Оценок пока нет

- Polycure FT TDДокумент2 страницыPolycure FT TDMarius IanaОценок пока нет

- Carboplast G 2002Документ2 страницыCarboplast G 2002Anas NomanОценок пока нет

- Polymer CompositeДокумент65 страницPolymer Compositeamor20006100% (2)

- Construction Materials in Civil EngineeringДокумент350 страницConstruction Materials in Civil EngineeringEnes Karaaslan100% (3)

- Plastic Mark SpecificationsДокумент16 страницPlastic Mark SpecificationszuconjaОценок пока нет

- Soy Based PlasticsДокумент6 страницSoy Based PlasticsAbilash SubbaramanОценок пока нет

- Akshay PDFДокумент26 страницAkshay PDFA1DA17CV014Bharatkumar MuddebihalОценок пока нет